A quieter supply may possibly be an improvement as well. Testing and experimenting is part of the fun of building.

10,000 per rail or total per channel?

Yes, that's per rail, per channel. A stereo 100W amp would require 40000uF total.

I had my amp running all day in the office at moderate levels. Output devices were all around 100F, nice and cool.

My supplies are drooping a little bit under high power sine waves, not really a surprise with a 300VA transformer. It starts to clip at around 25VRMS output, so 78WRMS output. 1mV noise on the output with inputs shorted, very silent😎.

I'll post some scope shots when I have it hooked to some better test equipment. Next is the important test. It goes home for a test run!😀

My supplies are drooping a little bit under high power sine waves, not really a surprise with a 300VA transformer. It starts to clip at around 25VRMS output, so 78WRMS output. 1mV noise on the output with inputs shorted, very silent😎.

I'll post some scope shots when I have it hooked to some better test equipment. Next is the important test. It goes home for a test run!😀

0.3" is sufficient for tapping into aluminium.I like their products too. It would be nice if the base was a little thicker though. .300" isn't a lot of depth to drill and tap, and drilling through looks terrible.

Mine stayed fairly cool for the week I had it running on my test bench. Hopefully the laser shop has my covers done for the weekend, so I can assemble this and give it a proper test/audition. I'm quite happy with the sound so far. You wouldn't know it's a little 90W amp if you didn't see it.

The recommend thread length for tapping into mild steel is about 1times the thread diameter.

I double that for aluminium, i.e. 2 thread diameters.

for a 3mm diameter screw/bolt one could use 6mm of thread and plug tap into a 7mm deep hole.

Just tap right through for thin back plates.

If I have a blind hole tapped as deep as a plug will go, I use a set screw turned all the way down to bottom and have an extra nut under the head. I use the nut to tighten on to the fixing clamp.

I think that 1mV a.c noise is'nt a good measurement while input is shorted.I had my amp running all day in the office at moderate levels. Output devices were all around 100F, nice and cool.

My supplies are drooping a little bit under high power sine waves, not really a surprise with a 300VA transformer. It starts to clip at around 25VRMS output, so 78WRMS output. 1mV noise on the output with inputs shorted, very silent😎.

I'll post some scope shots when I have it hooked to some better test equipment. Next is the important test. It goes home for a test run!😀

Last edited:

VLatFet Variant

Hallo Albert & Valery

Thank you for picking up the old simple RED Circuit and update to this very

clever new One. 😛 😀

By reading the Thread here i now learned a bit more well passed working condition Transistors.

That gives a thought for me. 😕

I have lounge around nearly finished OS Baby slew and no IPS to work.

Is it possible to put the Baby Slew together with your IPS? 🙄

Could it be also a idea for Terry- the most experimenting man here?

So i can get a Amp on work wich i not must buy much extra parts.

If i have visit your website, Valery, i have not seen the IPS- Board to sell-

is it possible, or is it yours not to share that way?

If not i will build my own next time by using the single Output Boards.

Regards Bangla.

Bangla.

Hallo Albert & Valery

Thank you for picking up the old simple RED Circuit and update to this very

clever new One. 😛 😀

By reading the Thread here i now learned a bit more well passed working condition Transistors.

That gives a thought for me. 😕

I have lounge around nearly finished OS Baby slew and no IPS to work.

Is it possible to put the Baby Slew together with your IPS? 🙄

Could it be also a idea for Terry- the most experimenting man here?

So i can get a Amp on work wich i not must buy much extra parts.

If i have visit your website, Valery, i have not seen the IPS- Board to sell-

is it possible, or is it yours not to share that way?

If not i will build my own next time by using the single Output Boards.

Regards

Bangla.

Bangla.1mVAC of hum and noise is terrible.

<0.1mVac is good.

0.3mVac is acceptable for normal speakers of less than 90dB sensitivity.

30uVac is excellent and should probably be the target for >100dB speakers.

<0.1mVac is good.

0.3mVac is acceptable for normal speakers of less than 90dB sensitivity.

30uVac is excellent and should probably be the target for >100dB speakers.

Hallo Albert & Valery

Thank you for picking up the old simple RED Circuit and update to this very

clever new One. 😛 😀

By reading the Thread here i now learned a bit more well passed working condition Transistors.

That gives a thought for me. 😕

I have lounge around nearly finished OS Baby slew and no IPS to work.

Is it possible to put the Baby Slew together with your IPS? 🙄

Could it be also a idea for Terry- the most experimenting man here?

So i can get a Amp on work wich i not must buy much extra parts.

If i have visit your website, Valery, i have not seen the IPS- Board to sell-

is it possible, or is it yours not to share that way?

If not i will build my own next time by using the single Output Boards.

RegardsBangla.

Hi Bangla,

In fact, I think Terry has already tested this IPS with Baby Slew - it works fine.

Let me check later today - I think I've got a couple of standalone IPS boards left in my stock - I will let you know.

Cheers,

Valery

P.S. It looks like the attached one when populated.

Attachments

0.3" is sufficient for tapping into aluminium.

The recommend thread length for tapping into mild steel is about 1times the thread diameter.

I double that for aluminium, i.e. 2 thread diameters.

for a 3mm diameter screw/bolt one could use 6mm of thread and plug tap into a 7mm deep hole.

Just tap right through for thin back plates.

If I have a blind hole tapped as deep as a plug will go, I use a set screw turned all the way down to bottom and have an extra nut under the head. I use the nut to tighten on to the fixing clamp.

The issue isn't getting a thread in the aluminum. The issue is the length of the threaded stud that is inserted. A standard 6-32 standoff has a .250" male stud on it. They are nickle plated brass with a .075" portion under the head that is unthreaded, so cutting them down leaves a very poor thread engagement. The point on a #36 drill bit is .035". so minimum hole depth for bottoming would be .285". I switched to 3mm standoffs which have a stud length of .200", which leave lots of extra depth to tap with a standard plug tap, so no wasted time messing around with bottoming taps, ect.

I think that 1mV a.c noise is'nt a good measurement while input is shorted.

I was tired and forgot to explain the test equipment. The only meters I have at the office are automotive grade, so they really aren't designed to read at that low a voltage in AC. With all the noise in a vehicle it's unlikely you would ever have that low a voltage even in a piece of wire. My meters reads 5 - 7 mV just from the florescent lights in the room. 1mV is a very good reading here with this equipment. These tests will be repeated with proper equipment. My Klipch's will let me know better than any meter if there's a hum issue.😀

Try 4-40 I use it ion same heatsink and works fine.

Yes 4-40 would be similar length to 3mm. 6-32 standoffs are the easiest and cheapest to source in my area (standard atx motherboards). 3 mm are the next most popular. 4-40 aren't really popular at all, so poor selection and more expensive to use.

Sorry i couldn't know test conditions.🙁I was tired and forgot to explain the test equipment. The only meters I have at the office are automotive grade, so they really aren't designed to read at that low a voltage in AC. With all the noise in a vehicle it's unlikely you would ever have that low a voltage even in a piece of wire. My meters reads 5 - 7 mV just from the florescent lights in the room. 1mV is a very good reading here with this equipment. These tests will be repeated with proper equipment. My Klipch's will let me know better than any meter if there's a hum issue.😀

Yes testing by ears is accurate enough.😉

Last edited:

Sorry i couldn't know test conditions.🙁

Yes testing by ears is accurate enough.😉

Yes I tend to judge amp qualities more on listening test than test specs. These DIY amps are such high quality that they all measure incredibly well, but there are still little nuances and sonic qualities that can't be measured. That being said, I need to start accumulating some better audio grade test equipment. What I have is excellent quality for automotive applications because that's what I do for a living, but that environment is completely different.

Yes 4-40 would be similar length to 3mm. 6-32 standoffs are the easiest and cheapest to source in my area (standard atx motherboards). 3 mm are the next most popular. 4-40 aren't really popular at all, so poor selection and more expensive to use.

I use 3mm standoffs with 4-40 hardware.

Hallo Albert & Valery

Thank you for picking up the old simple RED Circuit and update to this very

clever new One. 😛 😀

By reading the Thread here i now learned a bit more well passed working condition Transistors.

That gives a thought for me. 😕

I have lounge around nearly finished OS Baby slew and no IPS to work.

Is it possible to put the Baby Slew together with your IPS? 🙄

Could it be also a idea for Terry- the most experimenting man here?

So i can get a Amp on work wich i not must buy much extra parts.

If i have visit your website, Valery, i have not seen the IPS- Board to sell-

is it possible, or is it yours not to share that way?

If not i will build my own next time by using the single Output Boards.

RegardsBangla.

Hi Bangla,

I do think member thimios also did some works on pairing Valery's IPS with the Slew output.

Regards!

Hi Bangla,

In fact, I think Terry has already tested this IPS with Baby Slew - it works fine.

Let me check later today - I think I've got a couple of standalone IPS boards left in my stock - I will let you know.

Cheers,

Valery

P.S. It looks like the attached one when populated.

Hi Bangla - I have checked, I have 2 of these boards available.

I will send you a PM.

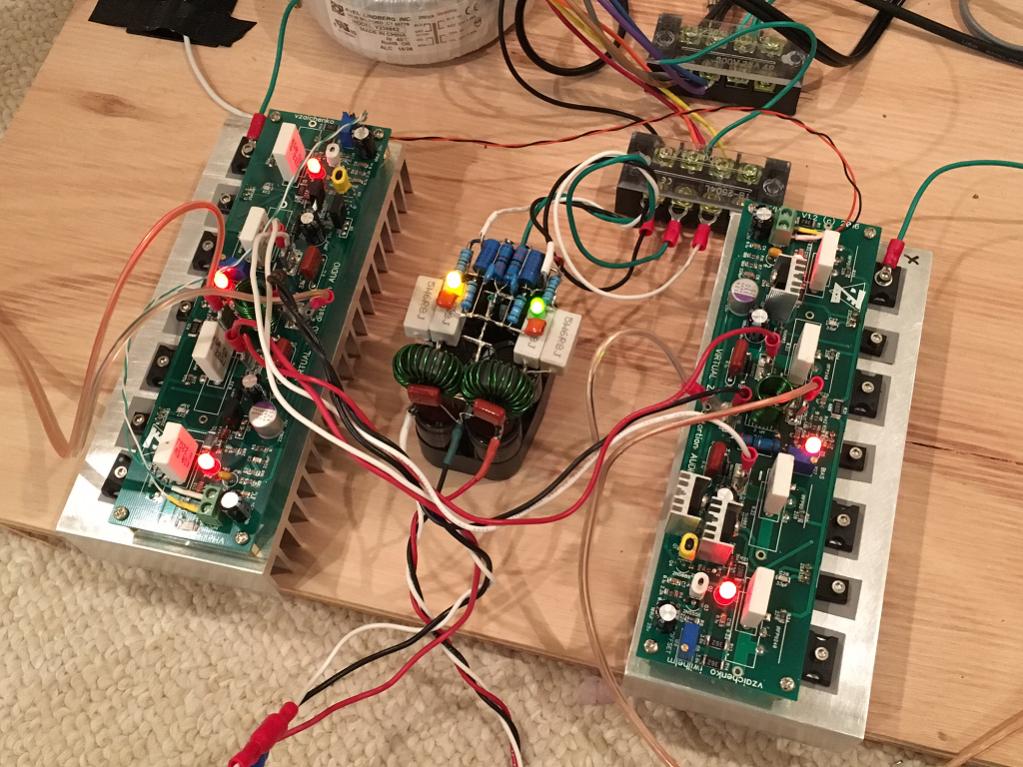

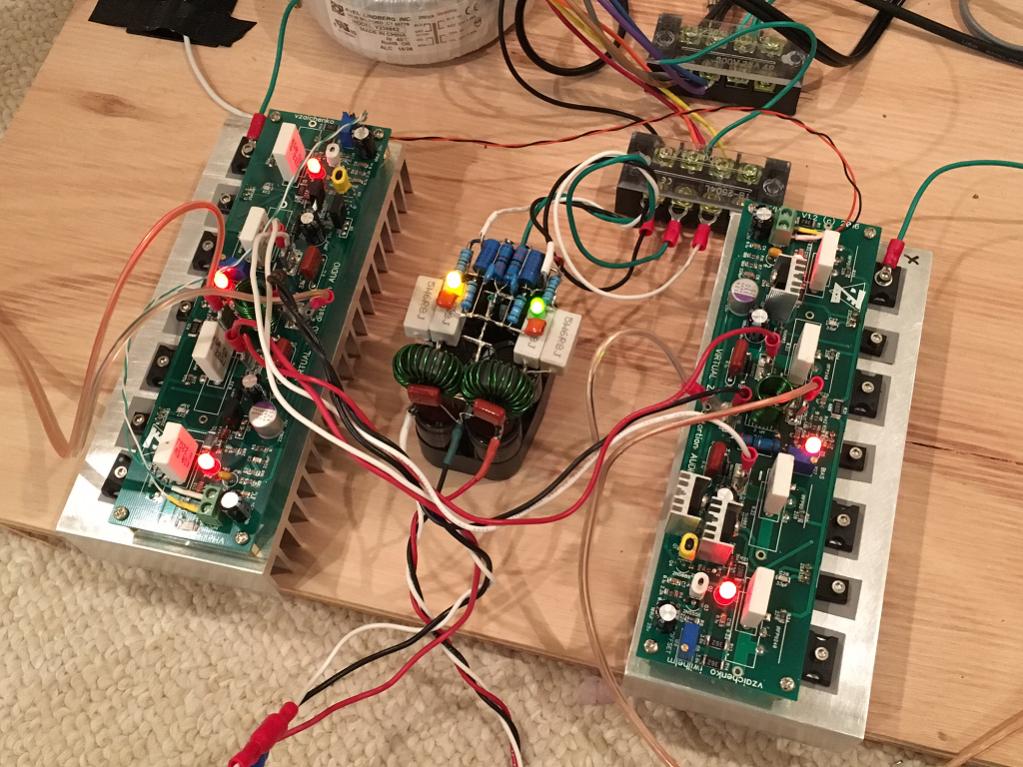

vHEX 1.1 in stereo

I finally finished the second one and now playing in stereo. I had some problems with the second one due to some cold solder joints. My thanks go out to Valery and Jeff for helping me diagnose and debug the amp.

Sounds fantastic - super bass, smooth and clear mids and sparkling highs.

I need to build a second PSU, right now running both off the same one until some more 4700uF 50v caps come in.

I am running 80mA bias and offset is now 0mV and stable. The matched input LTP's really helps.

I finally finished the second one and now playing in stereo. I had some problems with the second one due to some cold solder joints. My thanks go out to Valery and Jeff for helping me diagnose and debug the amp.

Sounds fantastic - super bass, smooth and clear mids and sparkling highs.

I need to build a second PSU, right now running both off the same one until some more 4700uF 50v caps come in.

I am running 80mA bias and offset is now 0mV and stable. The matched input LTP's really helps.

Attachments

Last edited:

- Home

- Amplifiers

- Solid State

- IRFP240/9240 Amplifier (simulated on TINA)