Well I'll be honest with you. I was quite lazy when doing measurments. I wasn't really trying to do them anechoically. Now I did. With a blanked around the speaker. As a sort anechoic tunnel to the microphone.

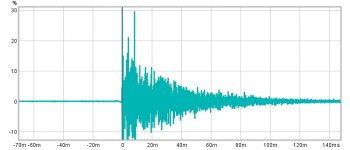

you should do a bit more reading on how to get your measurements... should be gating the the measurement in the impulse window based on when you see the first reflection from the roof/floor/wall. this is an anechoic measurement.

your blanket is likely reflecting some proportion of sound back towards the microphone ruining the measurement!!!

your blanket is likely reflecting some proportion of sound back towards the microphone ruining the measurement!!!

Indeed

Indeed. It is also as much knowing which ones not to fix.Still not perfect after million DSP presets.

^ totally. It is mostly experimenting, keeping notes, assessing what works and what doesn't, returning to the previous best etc. while having a goal somehow (a reference, or an ideal). Mostly learning and building confidence and having fun 🙂 But, I feel I've got a lot forward in terms of sound quality by doing so. I can't imagine one could pull the best out straight away unless very lucky or very experienced, it is a long process at first.

or very experienced

Some experience or knowledge is needed for setting targets, and some luck or testing with drivers. After that proper measurement and design methods are needed to implement balanced sound at once without iteration or listening.

Getting a feel how graphs on simulator screen translates to sound in room needs some experience. Personally I've taken the long route since somehow I feel I need build up confidence to call a crossover done. Confidence on the measurements, simulation, listening, the goal and even to push it a little bit further if possible. This has taken a long time since it is a hobby and sometimes it is just tinkering around while enjoying the music, sometimes a more concentrated effort. I'm sure many would do the process much quicker and call it finished sooner. Having lotsa fun 😀

Not necessarily. I can do the process with detailed measurements, and then room interaction means there is no very good solution unless the acoustic design is modified, or even something simple like room placement. EQ/crossover cannot fix all problems.

Targets are needed and implementation should be okay also in mechanical/acoustical design. Room placements and acoustics are independent from sound balancing with crossover. EQ/crossover just finalizes speaker to be as flawless and universal/flexible combination of mechanical/acoustical and electrical parts as possible. With this policy environment does not interfere speaker design. Speaker designing is not to control everything and everyone around the speakers.

i rarely check with measurements after crossover work in cad, i tweak the crossover and then listens, i tweak more and listens, tweak more and listens, and this work keeps on forever. small small adjustements in each tweak.

i really do not understand those who conciders themself done with a design, in my world there excists no such a stage, ever

i really do not understand those who conciders themself done with a design, in my world there excists no such a stage, ever

Infinite iterating process is okay for diy or if listening and evaluation of sound features is more important than e.g. listening music, but methods could be few decades smarter. Especially with commercial because target is to get best achievable result with selected concept and available time. Not entertain or torment designer or listening group by repeating Diana Krall etc. until end of the world.

i rarely check with measurements after crossover work in cad, i tweak the crossover and then listens, i tweak more and listens, tweak more and listens, and this work keeps on forever. small small adjustements in each tweak.

i really do not understand those who conciders themself done with a design, in my world there excists no such a stage, ever

Sounds like a great subscription business model for lending out crossover parts to rich people with plenty of spare time. Would you like to subscribe to my monthly delivery of the newest in inductors and caps, please? You send the old back with every new.

For the rest of us I think design freeze is a understandable concept both for manufacturing, invoicing and also for the end user wanting predictable results both setup and performance.

Edit: what a great idea. The client subscribed to a set of preferences (SPL, range, room size, tone) and the vendor send parts monthly to meet that demand. With assembly manuals updates online for every new sprint.

Someone would need to use the stock return though, I guess vendor could use it in a poor people subscription option; second hand parts yearly swap simple assembly for the stupid and impatience.

I like it. I wouldn’t invest in it though.

Last edited:

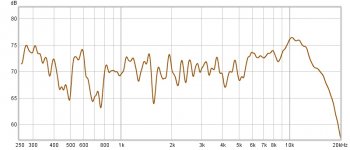

So I tried it with the blanket anyway. This is what the setup looks like. And the measured response so far. I've put a second blanket on the inside which is a more wooly blanket, I thought that would be effective against further minimizing the higher frequency reflections of the blanket.

Aren't there drawbacks to gated measurments? And my room is super small so the time until the first reflection will be very short. I will look in to how to do gated measurments.

Aren't there drawbacks to gated measurments? And my room is super small so the time until the first reflection will be very short. I will look in to how to do gated measurments.

Attachments

Yes gated measurements have a reduced frequency resolution. 5 ms gate means 200 Hz resolution. That is acceptable when checking for obvious tonal errors > 1000 Hz.

I see your microphone is mounted near a box. The box will reflect sound towards the microphone. Try using a full size microphone stand.

I see your microphone is mounted near a box. The box will reflect sound towards the microphone. Try using a full size microphone stand.

Last edited:

So you can't measure lower than 200 Hz? That wouldn't be a problem. I've got the bass figured out.

Actually, you can do gated measurements down around the Schroeder frequency (usually down to lower midrange, upper bass), below that the room modes dominates anyway.

Last edited:

Infinite iterating process is okay for diy or if listening and evaluation of sound features is more important than e.g. listening music, but methods could be few decades smarter. Especially with commercial because target is to get best achievable result with selected concept and available time. Not entertain or torment designer or listening group by repeating Diana Krall etc. until end of the world.

sure, if you do this for clients and have a dead line you must consider your design done regardless if it sounds **** or not, but this is diy and we can do better then that

- Home

- Loudspeakers

- Multi-Way

- In need of warmth