Hi Sync,

I bought other HP instruments cheap for the knobs. Of course, I was able to fix the donors so they weren't dead soldiers. I still did a knob transplant.

I have just come back after a few years away, but this thread really interests me. I use a 339A myself. You appear to be improving the performance which is something I would like to do. Any suggestions to come up to speed on this topic more quickly? Has anyone put together the changes in one document?

When I received my 339A originally, it didn't work. No surprise (from Eeekbay). I did go over the unit and managed to get everything working okay. Being familiar with HP products, I did not have to make any adjustments to perform to spec, so I left everything where it was.

I have another 339A for a spare. What I think I'll do is go over this one carefully while making recommended changes people have come up with here.

I can't tell you all how much I love using the 339A after using osc-generator combinations for years. These are a joy to operate. I have to create some shielded dual binding post plugs to BNC adapters as well. Has anyone here done this?

David, good to see you! I didn't get around to sending you anything, but I still intend to do so once my bench is created and the basement mess subsides. I can't reach most of my stuff right now. I'm just getting on my feet again.

Thank you all, Chris

I bought other HP instruments cheap for the knobs. Of course, I was able to fix the donors so they weren't dead soldiers. I still did a knob transplant.

I have just come back after a few years away, but this thread really interests me. I use a 339A myself. You appear to be improving the performance which is something I would like to do. Any suggestions to come up to speed on this topic more quickly? Has anyone put together the changes in one document?

When I received my 339A originally, it didn't work. No surprise (from Eeekbay). I did go over the unit and managed to get everything working okay. Being familiar with HP products, I did not have to make any adjustments to perform to spec, so I left everything where it was.

I have another 339A for a spare. What I think I'll do is go over this one carefully while making recommended changes people have come up with here.

I can't tell you all how much I love using the 339A after using osc-generator combinations for years. These are a joy to operate. I have to create some shielded dual binding post plugs to BNC adapters as well. Has anyone here done this?

David, good to see you! I didn't get around to sending you anything, but I still intend to do so once my bench is created and the basement mess subsides. I can't reach most of my stuff right now. I'm just getting on my feet again.

Thank you all, Chris

Hi Chris,

Welcome back. Good to hear from you again. I was wondering where

you might have disappeared to, I'm glad to see that it wasn't permanent.

The HP339a info isn't all in once place. This thread has some.

The R&D into were from David (Davada), Dick (RichEEM), with

Richard (RNMarsh) and Demian (1Audio) providing guidance and support.

There were other folks stopping by from time to time to help.

It started over on the long low distortion thread. Somewhere around

the #900.

http://www.diyaudio.com/forums/equipment-tools/205304-low-distortion-audio-range-oscillator-18.html

Then near the beginning of this thread, I asked Richard and David,

what should be done, David gave a quick summary and off I went.

Some mods I tried, I didn't know where abandoned, aren't so good

and undoing them led to my 339a undoing...and I've been trying

to get it back working again...Richard saved my from my waterboarding. 🙂

So it's not all in once place. I've not gotten around to doing it

as I did have a starting point. Now that things are working again

should probably put it in the wiki.

And that is where we are...

As for the binding post to BNC connector, I just bought adapters

from Pomona were reasonably priced for the quality, I got some

and Fry's Electronics, but any ELE DIST house should have them.

Cheers,

Welcome back. Good to hear from you again. I was wondering where

you might have disappeared to, I'm glad to see that it wasn't permanent.

The HP339a info isn't all in once place. This thread has some.

The R&D into were from David (Davada), Dick (RichEEM), with

Richard (RNMarsh) and Demian (1Audio) providing guidance and support.

There were other folks stopping by from time to time to help.

It started over on the long low distortion thread. Somewhere around

the #900.

http://www.diyaudio.com/forums/equipment-tools/205304-low-distortion-audio-range-oscillator-18.html

Then near the beginning of this thread, I asked Richard and David,

what should be done, David gave a quick summary and off I went.

Some mods I tried, I didn't know where abandoned, aren't so good

and undoing them led to my 339a undoing...and I've been trying

to get it back working again...Richard saved my from my waterboarding. 🙂

So it's not all in once place. I've not gotten around to doing it

as I did have a starting point. Now that things are working again

should probably put it in the wiki.

And that is where we are...

As for the binding post to BNC connector, I just bought adapters

from Pomona were reasonably priced for the quality, I got some

and Fry's Electronics, but any ELE DIST house should have them.

Cheers,

Last edited:

Hi Chris,

It been a long time since I heard from you. Was just thinking of you recently.

Hope things are going well for you.

It been a long time since I heard from you. Was just thinking of you recently.

Hope things are going well for you.

Synch ---- That is great to hear that your torture is over. It was torture for me to read of it.

When in my area come over and hang with me awhile....... be sure to bring the little girl, too.

-Richard

When in my area come over and hang with me awhile....... be sure to bring the little girl, too.

-Richard

Hi Sync,

Many thanks. Still getting back on my feet.

I'll search through the various threads, but it will take a while. I'm sure that there are a number of 339A's out there. The only complaint I have about that era HP equipment is that the knobs disintegrate. Gorilla Glue seems to work really well, better than some epoxy types I used first. Those blue and black skirts on some knobs go to pieces easily, and the darn markings come off very easily! These days I clean the rear with plain water and a Q-tip, very gently dabbing them cleaner. I don't even try for getting them very clean. If we could only get replacements for those knobs. Some of the cranks with handles also fall apart easily. What a shame. Still, Tektronix knobs are at least that bad, and when they break it's total knob failure. I guess we can't complain.

Maybe a wiki is a good idea. People can add all the improvements they know of (real ones, not audiophile parts!).

Good luck with your 339A. What stage are you at with it now?

Binding post to BNC adapters. I have some Pomona adapters. I agree they are decent for the money. What I can't find are the dual binding post plugs with the ground skirt. Maybe they will be a DIY thing.

-Chris

Many thanks. Still getting back on my feet.

I'll search through the various threads, but it will take a while. I'm sure that there are a number of 339A's out there. The only complaint I have about that era HP equipment is that the knobs disintegrate. Gorilla Glue seems to work really well, better than some epoxy types I used first. Those blue and black skirts on some knobs go to pieces easily, and the darn markings come off very easily! These days I clean the rear with plain water and a Q-tip, very gently dabbing them cleaner. I don't even try for getting them very clean. If we could only get replacements for those knobs. Some of the cranks with handles also fall apart easily. What a shame. Still, Tektronix knobs are at least that bad, and when they break it's total knob failure. I guess we can't complain.

Maybe a wiki is a good idea. People can add all the improvements they know of (real ones, not audiophile parts!).

Good luck with your 339A. What stage are you at with it now?

Binding post to BNC adapters. I have some Pomona adapters. I agree they are decent for the money. What I can't find are the dual binding post plugs with the ground skirt. Maybe they will be a DIY thing.

-Chris

Hi David,

Time will tell. But being able to get back here is really great! How is everything going with you? You're still buried in snow, aren't you?

As you can see, I'm interested in squeezing a little more performance from the old 339A THD test set. I think it might be accomplished best by adjusting things not called out in the manual. Those parts that can be trimmed to increase nulls and that sort of thing. The op amps we have today will probably help here and there as well. After that, maybe some power supply improvements and then the possibility of added circuits. You're the master on this and I have only begun to catch up. I have a long road to travel before I'm competent enough to dive in.

I recently sent you a PM didn't I? If not, I intended to.

Best, Chris

Time will tell. But being able to get back here is really great! How is everything going with you? You're still buried in snow, aren't you?

As you can see, I'm interested in squeezing a little more performance from the old 339A THD test set. I think it might be accomplished best by adjusting things not called out in the manual. Those parts that can be trimmed to increase nulls and that sort of thing. The op amps we have today will probably help here and there as well. After that, maybe some power supply improvements and then the possibility of added circuits. You're the master on this and I have only begun to catch up. I have a long road to travel before I'm competent enough to dive in.

I recently sent you a PM didn't I? If not, I intended to.

Best, Chris

Hi David,

Time will tell. But being able to get back here is really great! How is everything going with you? You're still buried in snow, aren't you?

As you can see, I'm interested in squeezing a little more performance from the old 339A THD test set. I think it might be accomplished best by adjusting things not called out in the manual. Those parts that can be trimmed to increase nulls and that sort of thing. The op amps we have today will probably help here and there as well. After that, maybe some power supply improvements and then the possibility of added circuits. You're the master on this and I have only begun to catch up. I have a long road to travel before I'm competent enough to dive in.

I recently sent you a PM didn't I? If not, I intended to.

Best, Chris

Hi Chris. Not I didn't get a PM.

The most gain you can get is with the oscillator mods. Richard can help you with cap advise. Try the LT1468 for the oscillator it self. The osc buffer, I haven't found a best op amp. Maybe the other guys can help with that and some suggestion for the analyzer portion. The filters remain an area of interest for upgrade. It's hard to find 14 legged creatures in DIP14 these days. Maybe a breakout board would help, smt to dip.

Hi David,

I was sure I sent you a message. Must not have, but I did begin writing one. I'm sorry about that.

I'll chase down those hints. Many thanks David. As for the oscillator - yes. It would be nice to reduce problems in that area. Some equipment is pushing the noise floor these days. I was just glancing at an article (AN245 from Analog Devices, Instrumentation Amplifiers Solve Unusual Design Problems) where they talk about pre-nulling the fundamental signal to extend the noise floor to -140 dB. I don't think you could reach that level, but even getting another 10 to 20 dB would be worthwhile. I forgot where the link was for this, but it may be available on the Analog Devices web site.

Here it is from the source : http://www.analog.com/media/en/technical-documentation/application-notes/5866763300941AN245.pdf That bit is near the end of the document.

-Chris

I was sure I sent you a message. Must not have, but I did begin writing one. I'm sorry about that.

I'll chase down those hints. Many thanks David. As for the oscillator - yes. It would be nice to reduce problems in that area. Some equipment is pushing the noise floor these days. I was just glancing at an article (AN245 from Analog Devices, Instrumentation Amplifiers Solve Unusual Design Problems) where they talk about pre-nulling the fundamental signal to extend the noise floor to -140 dB. I don't think you could reach that level, but even getting another 10 to 20 dB would be worthwhile. I forgot where the link was for this, but it may be available on the Analog Devices web site.

Here it is from the source : http://www.analog.com/media/en/technical-documentation/application-notes/5866763300941AN245.pdf That bit is near the end of the document.

-Chris

Synch ---- That is great to hear that your torture is over. It was torture for me to read of it.

When in my area come over and hang with me awhile....... be sure to bring the little girl, too.

-Richard

Will do. Not sure now what is going to happen, schedules got rearranged

might have to postpone or take advantage of another opportunity. It would

definitely be fun to hang.

Cheers,

Any one interested in the HP339A I now have a blog where the updates to the

HP339A are located. Hope this helps those that are thinking of or going to be

doing upgrades. Here is the link,

Link to: HP339A blog

It's not a perfect blog, its headers are off and its kind of ugly, but it appears to

be working at least for now. Many of the links are working but some are

and that will link back to the original discussions when possible.

If you have comments or need clarifications make a comment or

send me a text and I'll try to hunt down answers and make suggested

changes as time permits.

Best of all Happy DIY-ing as that is what the site is all about.

Cheers,

Sync

HP339A are located. Hope this helps those that are thinking of or going to be

doing upgrades. Here is the link,

Link to: HP339A blog

It's not a perfect blog, its headers are off and its kind of ugly, but it appears to

be working at least for now. Many of the links are working but some are

and that will link back to the original discussions when possible.

If you have comments or need clarifications make a comment or

send me a text and I'll try to hunt down answers and make suggested

changes as time permits.

Best of all Happy DIY-ing as that is what the site is all about.

Cheers,

Sync

Thx.... so many people had a hard time going thru the many issues with us to find the DIY mod info.

THx-RNMarsh

THx-RNMarsh

Advice needed for 339a repair

Hi, guys ' n' gals

I've been watching this site for quite a while and stand in awe of the knowledge and passion here. But this is my first post.

I have recently scored a 339a in very good cosmetic nick (all knobs intact!) with quite a late S/N - later than all of the addenda in the manual. But it has a curious fault - works fine when switching S1 in one direction, but goes completely mad when switching it in the other. I traced this to S1 in the analyzer section - the alignment is about 5 degrees off and the wiper doesn't clear the contacts properly, meaning than, when moving the switch in one direction, two fixed contacts remain shorted (on at least three sections). The front section in the oscillator looks OK. Looks to me like the switch has been like this since it was made.

(In general, I agree with other comments on this thread - this is not a physical implementation that hp should be proud of, even if the design itself was SOTA).

I have been through most of the 339a thread, but didn't find much on how to pull this apart. (S1 cannot simply be I soldered in place because a couple of the terminals on each wafer are covered by metalwork).

Is it as ugly as it looks? Or is there a trick somewhere? I want to try to get the rear switch shaft out and machine another with a 5 degree "twist".

Roman

Hi, guys ' n' gals

I've been watching this site for quite a while and stand in awe of the knowledge and passion here. But this is my first post.

I have recently scored a 339a in very good cosmetic nick (all knobs intact!) with quite a late S/N - later than all of the addenda in the manual. But it has a curious fault - works fine when switching S1 in one direction, but goes completely mad when switching it in the other. I traced this to S1 in the analyzer section - the alignment is about 5 degrees off and the wiper doesn't clear the contacts properly, meaning than, when moving the switch in one direction, two fixed contacts remain shorted (on at least three sections). The front section in the oscillator looks OK. Looks to me like the switch has been like this since it was made.

(In general, I agree with other comments on this thread - this is not a physical implementation that hp should be proud of, even if the design itself was SOTA).

I have been through most of the 339a thread, but didn't find much on how to pull this apart. (S1 cannot simply be I soldered in place because a couple of the terminals on each wafer are covered by metalwork).

Is it as ugly as it looks? Or is there a trick somewhere? I want to try to get the rear switch shaft out and machine another with a 5 degree "twist".

Roman

It has been a couple of years since I have been inside my 339A, so I'm going from memory, but as I recall, the switches are connected together by some couplers on the shafts that must be adjusted properly to get the switches to align properly with the detents. The detents are determined by the front section and the actual switch wafers are free to rotate without stops. So you must loosen the coupler in the shaft (two or four small allen screws) and adjust the shaft positions so the switches are aligned properly. I remember it required a bit of trial and error.

Terry

Terry

Terry,

Thanks. You are quite right - I discovered this just yesterday when I pulled the thing apart just enough to get the shafts and couplers associated with S1 out of the unit. While all the individual bits have flats and grub screws which should all align in. Perfect world, there are a number of connections in series which (especially with the plastic shafts involved) allow the tolerances to accumulate to a point where the back switch doesn't switch as intended. Having pulled out the bits, I carefully aligned and tightened them and bingo! I have a working analyzer.

Interesting to know how common the problem is.

As a number of people have noted, the actual implementation of this unit is not one that messrs Hewlett or Packard would have been particularly proud of.

Thanks again.

Roman

Thanks. You are quite right - I discovered this just yesterday when I pulled the thing apart just enough to get the shafts and couplers associated with S1 out of the unit. While all the individual bits have flats and grub screws which should all align in. Perfect world, there are a number of connections in series which (especially with the plastic shafts involved) allow the tolerances to accumulate to a point where the back switch doesn't switch as intended. Having pulled out the bits, I carefully aligned and tightened them and bingo! I have a working analyzer.

Interesting to know how common the problem is.

As a number of people have noted, the actual implementation of this unit is not one that messrs Hewlett or Packard would have been particularly proud of.

Thanks again.

Roman

I finally decided to join the ranks of the HP 339A owners. I picked one up off the big auction site for a really good price. I received it this week and the faceplate and meter are in great shape but as is typically the case, the knobs are torn up.

When testing it had a bunch of quirks in operation. I finally tore it down and carefully cleaned ALL of the rotary switch contacts. I went through about 50 q-tips soaked with alcohol then deoxit. I found it best to remove some of the internal shields to be able to fully access some of the switch wafers. I also took the oscil. output pot apart and blasted it out with deoxit. While I had it apart I replaced the 4 large power supply electrolytics with some 1500uF caps I had in my drawer, but other than that I haven't replaced anything else.

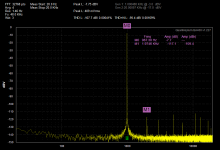

After the major cleanup its now working great. I went through the setup procedure in the service manual but really didn't need to change much of anything. In its current configuration the meter is displaying .0011% THD when measuring a 1V/1KHz signal from the internal oscillator and that rises to about .0012% at 3V of output. I also included a quick scan of the oscillator hooked up directly to my QA400. Not too shabby... I may go ahead and do a few of the tweeks you guys have mapped out. Namely replace the output pot and install the pot to the Oscill control FET to adjust the 2H but I hate to put much more money into it as I got it so cheap. 🙂

When testing it had a bunch of quirks in operation. I finally tore it down and carefully cleaned ALL of the rotary switch contacts. I went through about 50 q-tips soaked with alcohol then deoxit. I found it best to remove some of the internal shields to be able to fully access some of the switch wafers. I also took the oscil. output pot apart and blasted it out with deoxit. While I had it apart I replaced the 4 large power supply electrolytics with some 1500uF caps I had in my drawer, but other than that I haven't replaced anything else.

After the major cleanup its now working great. I went through the setup procedure in the service manual but really didn't need to change much of anything. In its current configuration the meter is displaying .0011% THD when measuring a 1V/1KHz signal from the internal oscillator and that rises to about .0012% at 3V of output. I also included a quick scan of the oscillator hooked up directly to my QA400. Not too shabby... I may go ahead and do a few of the tweeks you guys have mapped out. Namely replace the output pot and install the pot to the Oscill control FET to adjust the 2H but I hate to put much more money into it as I got it so cheap. 🙂

Attachments

Good to hear another succes story. Its been a while ince I joined in, but I stillnwant to revive my HP339 and your post gives new inspiration.

what symptoms did you experience before you cleaned it?

what symptoms did you experience before you cleaned it?

Good to hear another succes story. Its been a while ince I joined in, but I stillnwant to revive my HP339 and your post gives new inspiration.

what symptoms did you experience before you cleaned it?

> Occasional lack of meter reading when powering the 339a on and checking the internal oscillator level.

> Occasional loss of voltage reading on the meter (with input set to Osc Level) when connecting a cable between the Osc. output and the Dist. meter input. And by loss I mean total loss, the needle would drop to zero.

> Varying 339a meter readings, usually by 50 - 150mV, when switching between Osc. Level and Input Level. This was with the Dist. meter input in loopback with the osc. so they should always read the same.

< Varying distortion levels when measuring the 339a osc. Sometimes 1V/1KHz might measure .002% then the next time it might be .0025% then .0017%, etc.

I haven't seen any of the issues others have reported of the front and rear switch wafers becoming misaligned. The electrolytic caps I replaced in the power supply had 35th week of 1984 date codes on them so my 339a appears to be a somewhat later production model. I do not know if that's a factor in the switch couplings coming loose or not.

Anyone know when HP discontinued the production of the 339a?

I finally decided to join the ranks of the HP 339A owners. I picked one up off the big auction site for a really good price. I received it this week and the faceplate and meter are in great shape but as is typically the case, the knobs are torn up.

When testing it had a bunch of quirks in operation. I finally tore it down and carefully cleaned ALL of the rotary switch contacts. I went through about 50 q-tips soaked with alcohol then deoxit. I found it best to remove some of the internal shields to be able to fully access some of the switch wafers. I also took the oscil. output pot apart and blasted it out with deoxit. While I had it apart I replaced the 4 large power supply electrolytics with some 1500uF caps I had in my drawer, but other than that I haven't replaced anything else.

After the major cleanup its now working great. I went through the setup procedure in the service manual but really didn't need to change much of anything. In its current configuration the meter is displaying .0011% THD when measuring a 1V/1KHz signal from the internal oscillator and that rises to about .0012% at 3V of output. I also included a quick scan of the oscillator hooked up directly to my QA400. Not too shabby... I may go ahead and do a few of the tweeks you guys have mapped out. Namely replace the output pot and install the pot to the Oscill control FET to adjust the 2H but I hate to put much more money into it as I got it so cheap. 🙂

I totally understand your point of view that you got this piece equipment at a bargain price and you hesitate to put any more work into it.

The way I look at it is why not put some of the savings back into restoring it.

The modes in the forum was for the 339A were more and exploration to see if we could improve the performance. Some of it did but it was very costly and the improvements in performance were slight and don't justify the cost.

The 339A was state of the art at the time and by design. Looking back I would say do the modes to the oscillator and just clean the analyzer and complete any required repairs.

Leaky caps, power supply rebuild and call it day.

There is better equipment available at bargain prices. Might fit your budget right now but maybe one day.

The 339A is a great start. Our friend the late Richard Moore did some amazing things with the 339A. Richard found that if he placed his Twin T notch filter in front of the 339A analyzer he achieved a better than 1 magnitude increase in measurement performance.

Instead of the usual 0.0018% THD+N he was able to get 0.0001% THD+N on a stock 339A.

You can also achieve this using Bob Cordel's distortion magnifier. Both of these methods Twin T and Bob's DM fit a DIY budget.

Using the 339 as a front end for a QA400 is a great way to extend the QA400 and address its limitations. I would look at the 339's internals and figure out where to tie a QA400 to it. The 339 gives the QA400 the wide dynamic range and high CMRR differential input plus taking advantage of the 339's output attenuator addresses that limitation of the QA400. Maybe not ideal or pushing the SOTA but very good for a reasonable and modest investment.

The 339 type knobs are a problem. They were a neat solution when new but difficult to repair/replace. Maybe someone has replicated them or figured out how to get knobs engraved in a way to replace them. I did see a long involved effort to replace the skirts somewhere.

The 339 type knobs are a problem. They were a neat solution when new but difficult to repair/replace. Maybe someone has replicated them or figured out how to get knobs engraved in a way to replace them. I did see a long involved effort to replace the skirts somewhere.

- Home

- Design & Build

- Equipment & Tools

- HP339A distortion analyser