Listen to Gnomus! Even if you DON'T have to use an insulating washer because the active device is isolated on a single heatsink, you still should use the grease! The grease has nothing to do with electrical insulation-it is to help transfer heat.

People seem to confuse the two issues.

People seem to confuse the two issues.

Mica and Kapton

As far as I know Kapton is not better than mica.

The thermal resistance for mica is .75-1.0, Kapton .9-1.5.

Beryllim oxide (.25) is the best but I do not think it is made any more because it is toxic. They all have excellent electrical isolation.

As far as I know Kapton is not better than mica.

The thermal resistance for mica is .75-1.0, Kapton .9-1.5.

Beryllim oxide (.25) is the best but I do not think it is made any more because it is toxic. They all have excellent electrical isolation.

Kapton can give extremely low thermal impedance (this has been discussed to death at least twice before) figures but usually requires both surfaces to be extremely flat, large, or able to cope with high mounting pressures or some combination of these... none of these is suitable for diy stuff as a stock heatsink is not flat enough and nor is the device heatspreader, transistor surface is small and can only take about 15lb/in^2 mounting pressure. Personally I feel mica is the way to go. Sure there are better things available but for availability, suitability and cost they are pretty much impossible to beat.

Mica TO-247 insulators

A number of folks have promoted using mica insulators over kapton ones recently, but I'd like to ask again:

Can anyone suggest a US source for the mica insulators in the TO-247 size? I, for one, am happy to go along with N.P's experience on this one. Not interesting enough an issue (to me) to be breaking new ground.

Thanks!

A number of folks have promoted using mica insulators over kapton ones recently, but I'd like to ask again:

Can anyone suggest a US source for the mica insulators in the TO-247 size? I, for one, am happy to go along with N.P's experience on this one. Not interesting enough an issue (to me) to be breaking new ground.

Thanks!

Whatever you use, use a torque wrench set to the correct torque for the transistors you are going to mount. Not enough and your contact is not good enough, to much and your transistor base gets deformed (even worse). This will probably make more difference than a specific type of grease or insulator.

PS if the thermal resistance of your insulator is that important, something is wrong. Use a larger heatsink or reduce dissipation.

PS if the thermal resistance of your insulator is that important, something is wrong. Use a larger heatsink or reduce dissipation.

soldering TO-3

Hello Folks,

Is there any good advice to solder the two pins of a TO-3 transistor. My problem is such that the heatsink is so thick that the end of the pins are almost flush with the other side of the heat sink therefore I think I have to solder the wires to the pins prior to mounting it to the heat sink. So the wire has to feed through the holes before I can solder the wire to the PCB. It seems the procedure is wrong some how. Also, as I understand it that I should use the thickest wire that I can get away with, so I am using AWG#14 which is twice as thick as the pins, how do you solder the hard pin and hard wire together without end up with drilling the holes too big on the heatsink and secure so that it will not short to the heat sink metal?

Sorry for such a long wind question. I guess you guys would know my concern.

Thanks....

Hello Folks,

Is there any good advice to solder the two pins of a TO-3 transistor. My problem is such that the heatsink is so thick that the end of the pins are almost flush with the other side of the heat sink therefore I think I have to solder the wires to the pins prior to mounting it to the heat sink. So the wire has to feed through the holes before I can solder the wire to the PCB. It seems the procedure is wrong some how. Also, as I understand it that I should use the thickest wire that I can get away with, so I am using AWG#14 which is twice as thick as the pins, how do you solder the hard pin and hard wire together without end up with drilling the holes too big on the heatsink and secure so that it will not short to the heat sink metal?

Sorry for such a long wind question. I guess you guys would know my concern.

Thanks....

I heard of wire wrap method, is it just like the fly fishermen wraping the fly? Do I have to use such a method to wrap the pin and the wire first prior to soldering?

I heard of wire wrap method, is it just like the fly fishermen wraping the fly? Do I have to use such a method to wrap the pin and the wire first prior to soldering?

You dont solder wirewraps:some reading :

http://www.ece.queensu.ca/hpages/sstaff/techserv/Wirewrap.htm

Keld

TO-3 pins hook up wire

The reason why I want to wire wrap the TO-3 pins and the hook up wire first prior to solder them together is to maintain a perfect straight alignment for it to go through the heat sink holes afterwards.

Otherwise with no mechanical contact between the pin and the hook up wire AWG#14 prior to soldering the solder iron tip would be pushing the pin and or the wire all over the place and I would end up with a cold solder join on either the wire or the pin. The solder iron can not heat up both at the same time.

Any other suggestions?

The reason why I want to wire wrap the TO-3 pins and the hook up wire first prior to solder them together is to maintain a perfect straight alignment for it to go through the heat sink holes afterwards.

Otherwise with no mechanical contact between the pin and the hook up wire AWG#14 prior to soldering the solder iron tip would be pushing the pin and or the wire all over the place and I would end up with a cold solder join on either the wire or the pin. The solder iron can not heat up both at the same time.

Any other suggestions?

Chris

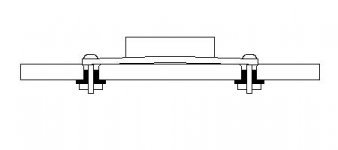

Try to obtain some thin tube with an ID slightly greater than the TO3 pin diameter. Solder a 15 to 20mm (5/8" to 3/4") piece of the tube to each pin. Use longer pieces if your heatsinks are particularly thick. After mounting the TO3, the connecting wires can be soldered into the open ends of the tubes.

Geoff

Try to obtain some thin tube with an ID slightly greater than the TO3 pin diameter. Solder a 15 to 20mm (5/8" to 3/4") piece of the tube to each pin. Use longer pieces if your heatsinks are particularly thick. After mounting the TO3, the connecting wires can be soldered into the open ends of the tubes.

Geoff

tube lead extension

Great idea even if Geoff doesn't like me. You may want to put some heat shrink tubing on the transistor pin and tubing extension to keep the tube from shorting on the hole or sliding down the transistor pin and shorting against the transistor body during soldering the other end of the tube. Also pieces of teflon tubing one just larger than transistor lead and the other just larger than extension tube would work. I would post a picture but..... well you know.

H.H.

Great idea even if Geoff doesn't like me. You may want to put some heat shrink tubing on the transistor pin and tubing extension to keep the tube from shorting on the hole or sliding down the transistor pin and shorting against the transistor body during soldering the other end of the tube. Also pieces of teflon tubing one just larger than transistor lead and the other just larger than extension tube would work. I would post a picture but..... well you know.

H.H.

Ah don't feel bad Harry,

As someone once said about your namesake:

"Many loved him as a refined and clever and interesting man, and were horrified and disappointed when they come upon the wolf in him"

Jake

As someone once said about your namesake:

"Many loved him as a refined and clever and interesting man, and were horrified and disappointed when they come upon the wolf in him"

Jake

For madmen only

Finally someone who read Steppenwolf!!!!!! Thanks you figured out my user name and why I use it. You are entitled to my best shot at at answering any question you may have and without me baring my teeth at you.

Harry Haller the Steppenwolf

Finally someone who read Steppenwolf!!!!!! Thanks you figured out my user name and why I use it. You are entitled to my best shot at at answering any question you may have and without me baring my teeth at you.

Harry Haller the Steppenwolf

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- How do you mount your transistors ?