Hmm, based on published specs, theoretical ideal alignment for these type drivers is a balanced compliance reflex = Vas/1.44 for best box Q above tuning and tuned to Fs for best group delay.

It cuts power handling from your 400 W to 250 W, so a little dB loss up high, but group delay at peak power is nearly 4x less, a good reason to at least lower tuning to actual Fs once built.

GM

It cuts power handling from your 400 W to 250 W, so a little dB loss up high, but group delay at peak power is nearly 4x less, a good reason to at least lower tuning to actual Fs once built.

GM

Ah, thank you GM!

so, Vas = 402L = 14.196 ft3

14.196/1.44 = 9.858 ft3

tuned to 28.3 hz...

Looks pretty similar, but better. Only thing worse is excursion gets out of control a bit higher, so a 20 hz highpass is definitely needed... Cool beans, I'll get these guys ordered tomorrow!

Thanks,

Jesse

so, Vas = 402L = 14.196 ft3

14.196/1.44 = 9.858 ft3

tuned to 28.3 hz...

Looks pretty similar, but better. Only thing worse is excursion gets out of control a bit higher, so a 20 hz highpass is definitely needed... Cool beans, I'll get these guys ordered tomorrow!

Thanks,

Jesse

Ah, thank you GM!

so a 20 hz highpass is definitely needed...

You're welcome! Trust me, with 6 mm Xmax, if one needs it, then the other does too when tuned this low, especially if there's any significant signals < ~25 Hz with 120+ dB peaks potential in stereo.

GM

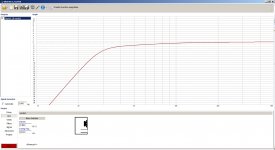

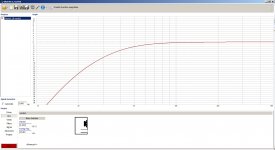

Brings the f3 up to about 45 hz, f10 26 hz, shallower roll off, still looks pretty good to me.how does it look with Vb=6.3 cubic feet and Fb=26.8?

(@ 9.86 ft3 and tuned to 28.3 hz its f3 is 34 hz and f10 is 23 hz)

Agreed! I just meant that it exceeded xmax sooner/@ slightly higher frequency.Trust me, with 6 mm Xmax, if one needs it, then the other does too

I'm just waiting on confirmation of ideal fasteners for the PA460s and then these will be on order. Next will start mocking up the enclosure in Cad... 🙂

Thanks all,

Jesse

Last edited:

fwiw I think the smaller box could be run with ~3-6 dB boost @~27 and perform well. That's usually done with an active underdamped 2nd order highpass filter which rolls off the stuff below the passband - (win win)

that's a really good deal on a good 18 these days.

that's a really good deal on a good 18 these days.

Thanks Freddi, but I don't mind a ~10 ft3 box, its not really all THAT big... 🙂

Don't forget it needs to make a nice "stand" for the full range Fane 12"s too.

I wonder if I could do a high ratio slot port and control the excursion down low without using the additional line level 20 hz high pass filter? Is there a simple way to calculate this or model it? It's been a while since I looked at Reynolds numbers and flow calculations....

...I think Dave @ P10 had mentioned 56:1 slot ratio on his aperiodic Em-ken type cabinets.

WinISD says a 33" tall by 1/2" wide (slot running height-wise) x 2.25 deep would work out the same as the original 21" wide x 2" high x 9" deep slot port. I don't think it's taking the shape into account, just the CSA.

Don't forget it needs to make a nice "stand" for the full range Fane 12"s too.

I wonder if I could do a high ratio slot port and control the excursion down low without using the additional line level 20 hz high pass filter? Is there a simple way to calculate this or model it? It's been a while since I looked at Reynolds numbers and flow calculations....

...I think Dave @ P10 had mentioned 56:1 slot ratio on his aperiodic Em-ken type cabinets.

WinISD says a 33" tall by 1/2" wide (slot running height-wise) x 2.25 deep would work out the same as the original 21" wide x 2" high x 9" deep slot port. I don't think it's taking the shape into account, just the CSA.

Last edited:

Correct, unless AkAbak will do it, then none will AFAIK. Better to use HR or similar where you can add stuffing to the vent to get an idea whether it will work or not. If so, then either stuff the vent or tightly stretch as many layers of a porous cloth or similar as required over it terminus to damp it [original aperiodic vent concept].

GM

GM

I've noticed with really restricted ports such as the saw blade height horizontal slits used in the Karlson 12 and also with a 3.6CF test box with 15" speaker whose port panel was tuned to ~40Hz via 43 * 0.375" holes (in a 1/2" thick port panel) , that sine wave input of one watt in the vicinity of Fb created a lot of loud overtones in the little K and also the effect was heard with the 15" Peavey speaker. The 15 had the advantage of making a reasonably efficient "fan" - I could feel the breeze from the ports 10 foot away with a 10 watt input. 😀

since the wind was felt at that distance - can that be considered "port rectification" ? (I think that's the geezer term)

how ports like this interact with music = ? if it were a bass viola - then probably not heard - if a modern rap "bass drop" then maybe (?)

a long distance friend played with a distributed slit port on a small K-type loaded with 18" (more a "midbass") and felt the highly resistive * port might had the edge - - with acoustic instruments

it might be good to have a separate & removable port panel if you wish to experiment.

would a 1/2" wide and very tall port audibly wheeze at Fb during strong bass passages ? ( * seems like ports have been considered "resistive" when a dimension is less than the thickness of the cabinet wall ???)

re: 10CF vs 6.3 -which has the edge in the punch region where drums are tuned ? (~50 - 200) my 6.4CF RJ18 was punchier than the 8.2 version - but the 6.4 used a lower Q woofer so I never had a fair comparison.

I've very interested in speakers with "punch" - but these days, they have to be small

since the wind was felt at that distance - can that be considered "port rectification" ? (I think that's the geezer term)

how ports like this interact with music = ? if it were a bass viola - then probably not heard - if a modern rap "bass drop" then maybe (?)

a long distance friend played with a distributed slit port on a small K-type loaded with 18" (more a "midbass") and felt the highly resistive * port might had the edge - - with acoustic instruments

it might be good to have a separate & removable port panel if you wish to experiment.

would a 1/2" wide and very tall port audibly wheeze at Fb during strong bass passages ? ( * seems like ports have been considered "resistive" when a dimension is less than the thickness of the cabinet wall ???)

re: 10CF vs 6.3 -which has the edge in the punch region where drums are tuned ? (~50 - 200) my 6.4CF RJ18 was punchier than the 8.2 version - but the 6.4 used a lower Q woofer so I never had a fair comparison.

I've very interested in speakers with "punch" - but these days, they have to be small

Last edited:

Good questions Freddi. I'm wondering similar things... Like even if having a high ratio slot does tame the woofer excursion down below Fb, does it affect transient response or "punch" up higher, since this seems to be an effect (or maybe caused by) the degree to which the port output couples to the air?

9.86 @ 28.3hz vs. 6.30 @ 26.8 hz, per Freddi:

9.86 @ 28.3hz vs. 6.30 @ 26.8 hz, per Freddi:

Attachments

Last edited:

if the port is really restrictive compared to cone displacement, I think it would act something like a sealed box at LF, port cease to have useful radiation, and the double hump impedance curve more like a single hump or suppressed lower peak. GM can tell us.

for a real small system, I'm thinking a good 12" with qt ~0.31, Q=2 boost @fb and maybe a passive radiator would be nice - kind of like EV's old "Interface" series. Make it 3 way for reduced distortion. I might have enough stuff other than cabinet to do one with a 15" and duct port.

for a real small system, I'm thinking a good 12" with qt ~0.31, Q=2 boost @fb and maybe a passive radiator would be nice - kind of like EV's old "Interface" series. Make it 3 way for reduced distortion. I might have enough stuff other than cabinet to do one with a 15" and duct port.

Last edited:

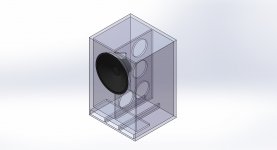

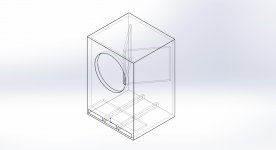

Perhaps something along these lines. 26" wide x 20" deep x 33 high (measured above vent). Vent is then 22.5 wide x 1.75 high (after subtracting for stiffeners), for port resonance of 825 hz and port air velocity of <11.5 m/s.

I'm not sure if it would fit in the room better with a wider or deeper cross section... Either way, trying to keep the top of the box around 35" high so that the full range 12" driver stacked on top is at ear level, ~42" or so.

Edit:

Tried a different approach with the driver support combined with a backwave deflector... More bracing needed in either case, but might this be a good way of reducing backwave effects? The volume inside the triangle shape is left open, so it should still count as interior volume...

I'm not sure if it would fit in the room better with a wider or deeper cross section... Either way, trying to keep the top of the box around 35" high so that the full range 12" driver stacked on top is at ear level, ~42" or so.

Edit:

Tried a different approach with the driver support combined with a backwave deflector... More bracing needed in either case, but might this be a good way of reducing backwave effects? The volume inside the triangle shape is left open, so it should still count as interior volume...

Attachments

Last edited:

I thought about adding holes to them... but then they don't reflect away? Though probably as effective or more so anyway... The brace is open top and bottom, so shouldn't be any strange TL effects there...

I'm assuming all the interior walls should be lined with felt carpet padding or similar.

I'm assuming all the interior walls should be lined with felt carpet padding or similar.

PA460 drivers have arrived, they look pretty nice. Looking to nail down dimensions now for prototype boxes and make a cut list... Need to add bracing and corner cleat pieces yet. Any further suggestions on bracing, and also damping?

Was going to use carpet underlay padding, but I'm reading that it may or may not be effective... Purchased stuff from PE for sound is mondo expensive for some reason. Found this stuff recommended elsewhere instead:

UltraTouch 16 in. x 48 in. Denim Insulation Multi-Purpose Roll (6-Pack)-60306-16482 - The Home Depot

That 6 roll package will be enough to do my two large cabinets.

There's also the Roxul rock wool stuff that's supposed to be very effective, though I'm not sure I want mineral fibers floating around in the air coming out of the port... (though not as bad as fiberglass at least). The denim is still 2" thick, and seems like a good compromise. Will use 3m #77 to stick it to the interior panels of the cabinets, but leave the bottom bare wood for now, to allow full port height.

UltraTouch 16 in. x 48 in. Denim Insulation Multi-Purpose Roll (6-Pack)-60306-16482 - The Home Depot

That 6 roll package will be enough to do my two large cabinets.

There's also the Roxul rock wool stuff that's supposed to be very effective, though I'm not sure I want mineral fibers floating around in the air coming out of the port... (though not as bad as fiberglass at least). The denim is still 2" thick, and seems like a good compromise. Will use 3m #77 to stick it to the interior panels of the cabinets, but leave the bottom bare wood for now, to allow full port height.

These cabinets are definitely bigger in reality than on paper... 9.86 ft^3 doesn't sound like much, but as they had to be shortish to function as stands for the mid/high cabs, they have a fair amount of girth....

Have not added any bracing other than the corner cleats thus far, though I have the sheets roughed out for doing a brace vertically along the centerline. Even this big, 3/4 OSB seems plenty sturdy. Oh, and they weigh a ton! 🙂

I need to take more pictures, will do so while building the 2nd cab...

Have not added any bracing other than the corner cleats thus far, though I have the sheets roughed out for doing a brace vertically along the centerline. Even this big, 3/4 OSB seems plenty sturdy. Oh, and they weigh a ton! 🙂

I need to take more pictures, will do so while building the 2nd cab...

even my 6.4CF internal volume RJ18 seemed chunky. How's that OSB cut? is it reasonably stiff? it can look really pretty with a clear coat. MDF can be ok - I liked the old heavy particleboard which was sold locally under "Novaply"

Hey Freddy, the OSB cuts ok, but its certainly not great to work with, it chips and splinters like hell! I'm not sure I care for the look of it, in the house anyway... stained and cleared in the right environment could look okay or even good. They will likely end up painted black with steel corner covers from PE. This is a minimal WAF build for now, haha.

If they sound as good as I hope, I'd like to redo them in birch ply sometime soon, and stain/clearcoat them so they are pretty.

I need to get a router and route the edges next.. dreading how that's going to go with the OSB.

If they sound as good as I hope, I'd like to redo them in birch ply sometime soon, and stain/clearcoat them so they are pretty.

I need to get a router and route the edges next.. dreading how that's going to go with the OSB.

- Home

- Loudspeakers

- Multi-Way

- Helper Woofer(s) for "punchy" FAST/WWW/SAW/etc. to go w/ Fane 12" full range drivers