Looks like some kind of mineral wool / rockwool to me, but too dense material would be less effective in absorbing sound, which defeats the point. So try tapping on a sheet laid on the floor and see if the sound turns out to be damped. If it does, then you may use it as the first layer, followed by some glass wool and lining (3"-4" in all).

Personally, I think mineral wool is itchy and annoying to work with, even glass-wool was a pain with the flying and all, but somehow finished it and cleaned the place quickly. 🙂

If possible, get some carpets to reduce floor bounce, in case you don't have any.

Personally, I think mineral wool is itchy and annoying to work with, even glass-wool was a pain with the flying and all, but somehow finished it and cleaned the place quickly. 🙂

If possible, get some carpets to reduce floor bounce, in case you don't have any.

Ok, so im thinking sandwich should look like this.

wood / bigger fabric / glasswool / smaller fabric

15mm / 10mm / 50mm / ~5mm / = ~80mm which is around 3"

I will try to enclose glasswool with smaller fabric as much as possible.

What glue should i use for this ?

Also for alu profile, it say i should damp with 10mm behind array drivers and put glasswool on sides, to create a cavity for speaker array.

Rest of tube they fill with something called sonofill, which is some polyester mashup

In guide they said they closed off top part of tube, and bottom can be closed off aswell but they left it open.

Also, glasswool is not electrically conductive right ?

And for cabinet feet, it say they are 10cm, will it affect it if i raise it a bit ? i was thinking of placing rubber layer under feet to help with vibration and movement.

wood / bigger fabric / glasswool / smaller fabric

15mm / 10mm / 50mm / ~5mm / = ~80mm which is around 3"

I will try to enclose glasswool with smaller fabric as much as possible.

What glue should i use for this ?

Also for alu profile, it say i should damp with 10mm behind array drivers and put glasswool on sides, to create a cavity for speaker array.

Rest of tube they fill with something called sonofill, which is some polyester mashup

What would be good substitute for this ? Glasswool or ticker/thinner fabric ?IT Sonofil Polyester 400x500x30 MM

High-construction polyester fleece for filling loudspeaker housings. Excellent absorption properties.

SONOFIL can be processed without dust or fiber formation.

SONOFIL consists of a mixture of polyester fibers of different strengths, which are bonded to the cross points by a dispersion binder.

In guide they said they closed off top part of tube, and bottom can be closed off aswell but they left it open.

Also, glasswool is not electrically conductive right ?

And for cabinet feet, it say they are 10cm, will it affect it if i raise it a bit ? i was thinking of placing rubber layer under feet to help with vibration and movement.

I think he said its used for isolation for concrete or something.

Right, it's felt for carpet underlayment to both isolate and add a 'plushness' walking on it; unscrupulous types have been known to double up and lay cheap carpet, claiming super expensive 'plush' carpet. 🙁

Also was used for vehicle carpet underlayment, sound deadening in general [including speakers] until reducing weight became a prime imperative, so maybe way too thick unless small patches are strategically spaced.

Try talking, blowing through it.

Also, i am now positive that in guide they didnt dampen bass cabinet. All dampening material is for alu tube.

I still think little dampening in cabinet wont hurt.

I still think little dampening in cabinet wont hurt.

We only want the cabinet for bass frequencies and so we add these damping materials to clean out the multiple unwanted midrange reflections. These materials have little effect on the longer wavelengths (bass) anyway...

For the aluminium you could use glass wool in place of the polyfill and close it off if you want better health. If you believe the open end would make a difference, try that first. You could close it later if otherwise

For the aluminium you could use glass wool in place of the polyfill and close it off if you want better health. If you believe the open end would make a difference, try that first. You could close it later if otherwise

Glass wool and rock wool are both good choices for airborne waves, but not for panel resonances.

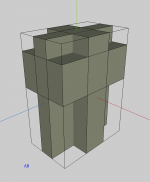

You don't need glue if you arrange them in a certain way. Below is a suggestion for a good concept but you may not need to get so fancy.

Glass is an excellent insulator.

You don't need glue if you arrange them in a certain way. Below is a suggestion for a good concept but you may not need to get so fancy.

Glass is an excellent insulator.

Attachments

Also, i am now positive that in guide they didnt dampen bass cabinet.

Interesting! HR sims a near +5 dB peak at a ~37 Hz Fb!!!

I find it hard to believe they would tolerate this, much less recommend it. Even standard QL7 has a ~ 1 dB 'bump', though the modest compression chamber behind the driver and crude phase plug in front of it will skew these results a bit.

That said, damping as I suggested with 1" OC 703 gets you down to ~QL7 in a large cab, so felt plus other stuff is probably going to over damp it.

Frankly, being a vintage style cab design, I'd be prone to start with some felt around the rear cavity's perimeter and just a pad on the back wall behind the driver to give it a vintage 'lively' type performance.

please share, would love to archive all of this stuff.

This one went the way of the Dodo Bird after Bob died, but thankfully is mostly intact in the Archives: LDSG Introduction

Glass wool and rock wool are both good choices for airborne waves, but not for panel resonances.

You don't need glue if you arrange them in a certain way. Below is a suggestion for a good concept but you may not need to get so fancy.

Glass is an excellent insulator.

I dont think i will need that much dampening 🙂 But interesting design.

I will also use some glue, maybe wood glue or something more elastic to hold glasswool in bass cabinet.

For alu tube, il just jam it in there, maybe glue thicker felt fabric to back side of alu.

Interesting! HR sims a near +5 dB peak at a ~37 Hz Fb!!!

I find it hard to believe they would tolerate this, much less recommend it. Even standard QL7 has a ~ 1 dB 'bump', though the modest compression chamber behind the driver and crude phase plug in front of it will skew these results a bit.

That said, damping as I suggested with 1" OC 703 gets you down to ~QL7 in a large cab, so felt plus other stuff is probably going to over damp it.

Frankly, being a vintage style cab design, I'd be prone to start with some felt around the rear cavity's perimeter and just a pad on the back wall behind the driver to give it a vintage 'lively' type performance.

I dont have OC 703 type avaible, only ones rolled in big bag tubes, and they are 2" thick. Should i splice it in half and use think cloth/felt to enclose it to prevent fibers flying around and outside the box.

When you say rear cavity perimeter, you mean alu tube or wood cab ?

For wood bass cab, this is what im going to do. Put glasswool on back panel and cover it with fabric. thats it.

For alu tube, place a thicker felt behind array drivers, and put glasswool on side and bit over felt to create a cavity in picture.

Rest i will fill with glasswool but loosely packed.

This one went the way of the Dodo Bird after Bob died, but thankfully is mostly intact in the Archives: LDSG Introduction

Thats really useful, lot of various info, thanks.

Oh, my God, what are those, ferrite-core inductors? What saturation current rating? Or are they just air-core ones on plastic former?

Transparent ones are, well, air cores.

Grey ones are ferrite.

Smaller one is pure ferrit FC

Grey ones are ferrite.

Smaller one is pure ferrit FC

And bigger one is LR, aka mushroom inductor.FC 3,9 mH

Ferrite coils with tinned wire ends.

Technical Data:

Height 31 mm Diameter 40 mm Wire diameter 0,9 mm Internal resistance 0,5 Ohm Saturation current 6,1 A

This was by design.LR 3,3 mH

Ferrite coil with tinned wire ends. Very high power handling, low loss due to the low internal resistance.

Technical Data:

Height 36 mm Diameter 56 mm Wire diameter 1,32 mm Internal resistance 0,25 Ohm Saturation current 12,1 A

Last edited:

I dont have OC 703 type avaible, only ones rolled in big bag tubes, and they are 2" thick. Should i splice it in half and use think cloth/felt to enclose it to prevent fibers flying around and outside the box.

When you say rear cavity perimeter, you mean alu tube or wood cab ?

For wood bass cab, this is what im going to do. Put glasswool on back panel and cover it with fabric. thats it.

For alu tube, place a thicker felt behind array drivers, and put glasswool on side and bit over felt to create a cavity in picture.

Rest i will fill with glasswool but loosely packed.

Thats really useful, lot of various info, thanks.

You're welcome!

I assumed as much; it's just for comparing specs. 😉

Compare specs, but historically and in general [haven't messed with this for several decades now!], it takes 6" of roll attic fiberglass insulation to ~match 1" duct board [703], so try the 2" over ~half of the area of one side, top, back as any eigenmodes well below the driver tend to damp the vent a bit.

Ignore, another sleepless late night had me misreading the side view drawing. 🙁

Better to just loosely cover the back of the driver with cheesecloth or similar like the pioneers did as it will change/limit the insulation's broadband effectiveness unless very open weave, which of course defeats the cover's purpose.

Ditto the array, i.e. these kinds of insulation rely on being able to move to scatter, dissipate as heat whereas duct board relies mostly on sheer mass.

Correct, see this page for placement of coilsBut I think the bottom left inductor needs to be turned around, see picture.

View attachment 960985

Better to just loosely cover the back of the driver with cheesecloth or similar like the pioneers did as it will change/limit the insulation's broadband effectiveness unless very open weave, which of course defeats the cover's purpose.

I did actually wanted to find cheesecloth or something similar, but cant find it anywhere. Any substitute comes to mind ?

I rearranged XO

Saturation currents are probably sufficient. But I think the bottom left inductor needs to be turned around, see picture.

What about saturation currents, i dont know much about them, do we need certain amps or we want less ? What is the endgame here ?

Last edited:

Try cotton, gauze like, material called "tetra pelene". Available in every pharmacy, DM, Lilly stores. Buy 1 piece for testing. It's cheap and ubiquitous.

Any substitute comes to mind ?

Assuming Amazon in Britain or other Euro country isn't an option: What to Use If You Don't Have Cheesecloth

"tetra pelene"

Interesting! A search only returned an incredible number of businesses selling Tetra diapers. 🙁

- Home

- Loudspeakers

- Multi-Way

- Help chosing high SPL drivers for 3way classic loudspeaker