Ok, apprently i suck at math...

db gain for 3.6w is not 5.5, but

20 - 13 = 3.6 - X

20X = 46.8

X = 2.34db

So in total we are looking at 97.3db

db gain for 3.6w is not 5.5, but

20 - 13 = 3.6 - X

20X = 46.8

X = 2.34db

So in total we are looking at 97.3db

97.3dB @1m is the same as 91.3dB @2m, 85.5dB @ 4m, and so on. So what is your listening distance? Also, do remember that your tweeter doesn't look equally efficient at 86dB/1m and this may require you to settle down for ~92dB (net) sensitivity instead of 95, and add some more headroom for equalisation. I think you'll be needing at least 10W per channel, hope you have it.

Last edited:

Living room has a table that will be 1, 2m away from speakers. The hole room layout will change, thats another project of mine, to redecorate the living room.

There is couch that is around 4m away, and a comfy chair that is at the end of the room.

Entire length of living room is ~6m

I do have other amps, but rather use this one i bought, i tested it today with some meh speakers 6om , and it sounds really warm and light, love the sound. Also source was a phone with really whimps RCA cables i had laying around, so when everything is setup correctly it will be decent 🙂

For cables im thinking of buying 4mm copper with silver layout, price is 5e per meter. Also thinking of using that cable aswell when i build crossover.

Regarding crossover, from what i understand, if i want to split LF and HF sections to run on two amps, it can be done. If i want to run it as single unit i will just need to bridge the terminals ? Or there is more to it and entire redesign is needed ?

For time being i will have to make ends meet ends with lower power.

Im still thinking about amp i will build and how will it all look, but im planning on 20-40w amplification class A SE.

There is couch that is around 4m away, and a comfy chair that is at the end of the room.

Entire length of living room is ~6m

I do have other amps, but rather use this one i bought, i tested it today with some meh speakers 6om , and it sounds really warm and light, love the sound. Also source was a phone with really whimps RCA cables i had laying around, so when everything is setup correctly it will be decent 🙂

For cables im thinking of buying 4mm copper with silver layout, price is 5e per meter. Also thinking of using that cable aswell when i build crossover.

Regarding crossover, from what i understand, if i want to split LF and HF sections to run on two amps, it can be done. If i want to run it as single unit i will just need to bridge the terminals ? Or there is more to it and entire redesign is needed ?

For time being i will have to make ends meet ends with lower power.

Im still thinking about amp i will build and how will it all look, but im planning on 20-40w amplification class A SE.

Last edited:

Any "special" cables for speaker/crossover are not required. I use regular 4 sq. mm electrical wiring, easily available in different colours, at great prices. And do you know what pro-audio and cinema people use? Same thing!

However, always get good quality shielded cables for carrying the line-level signals (RCA), in order to avoid EMI/stray signal pickup and the tarnishing / corrosion of contacts.

You do not need for more than one amplifier, since you already have a network to split the lows and highs. With more than one amplifier, people are more likely to use active rather than passive crossover. However, if you really believe in bi-wiring, go ahead and get separate binding posts for the woofer and tweeter.

20-40W is the correct amplifier sizing for your speakers, room, seating distances and the typical SPL requirements of 80-90dB, for both music and movies.

Do show some photos when it's ready.

Cheers.

However, always get good quality shielded cables for carrying the line-level signals (RCA), in order to avoid EMI/stray signal pickup and the tarnishing / corrosion of contacts.

You do not need for more than one amplifier, since you already have a network to split the lows and highs. With more than one amplifier, people are more likely to use active rather than passive crossover. However, if you really believe in bi-wiring, go ahead and get separate binding posts for the woofer and tweeter.

20-40W is the correct amplifier sizing for your speakers, room, seating distances and the typical SPL requirements of 80-90dB, for both music and movies.

Do show some photos when it's ready.

Cheers.

Last edited:

Any "special" cables for speaker/crossover are not required. I use regular 4 sq. mm electrical wiring, easily available in different colours, at great prices. And do you know what pro-audio and cinema people use? Same thing!

However, always get good quality shielded cables for carrying the line-level signals (RCA), in order to avoid EMI/stray signal pickup and the tarnishing / corrosion of contacts.

You do not need for more than one amplifier, since you already have a network to split the lows and highs. With more than one amplifier, people are more likely to use active rather than passive crossover. However, if you really believe in bi-wiring, go ahead and get separate binding posts for the woofer and tweeter.

20-40W is the correct amplifier sizing for your speakers, room, seating distances and the typical SPL requirements of 80-90dB, for both music and movies.

Do show some photos when it's ready.

Cheers.

Will do, currently im debating what to do with amp, output trafos arnt grounded aswell as speaker ground, could be bit hazardous 😀 I will have to fix that, and from looks of it rebuild/rewire amp entirely.

For crossover, i was more curios if what i currently have could be used for active crossover, without changing parts ?

Yesterday i started making some layouts, im thinking of using some plastic/wood board, drill the hole for leads and layout components on top of it and do the wiring on bottom side (Use leads as much as possible and little bit of copper cable for places it cant reach. Leave crossover boards near amp for more aesthetic look and easy service/upgrade.

Active crossovers maybe made from opamp circuits at very low power as they operate before the power stages. However, passive ones consist of LP and HP filters matched to the impedances of the woofer and the tweeter respectively.

I think your idea of connecting the woofer and tweeter separately to the amplifier is known as bi-wiring, while the term that pertains to active crossover is bi-amping. Be careful not to mix these up.

I think your idea of connecting the woofer and tweeter separately to the amplifier is known as bi-wiring, while the term that pertains to active crossover is bi-amping. Be careful not to mix these up.

Alright, so components i have for this passive version wont work as active, got it 🙂

This week im buying Alu profile, when i get back home il try to cut that hole somehow 🙂

Also amp volume pot will be replaced aswell.

Slowly but steady we are approaching the end 🙂

This week im buying Alu profile, when i get back home il try to cut that hole somehow 🙂

Also amp volume pot will be replaced aswell.

Slowly but steady we are approaching the end 🙂

Little update.

I bought Alu profiles, 100x40 x 2.5mm, there are some rough edges i will have to sand, and also some scratches and dimples on body that will have to be polished. Still thinking how should i paint them.

I also ordered wood for cabinet, Poplar 15mm plywood. should arrive during next week.

Im still little conflicted on what to do with damping. I was thinking to damp all sides but the front and bottom where the bass reflex is, kinda makes sense since there are no holes or stuff on other sides.

Next week im taking some holidays so i will finish crossover, hopefully my friend with cut and paint cabinet pieces, then just to install damping and glue everything together.

I bought Alu profiles, 100x40 x 2.5mm, there are some rough edges i will have to sand, and also some scratches and dimples on body that will have to be polished. Still thinking how should i paint them.

I also ordered wood for cabinet, Poplar 15mm plywood. should arrive during next week.

Im still little conflicted on what to do with damping. I was thinking to damp all sides but the front and bottom where the bass reflex is, kinda makes sense since there are no holes or stuff on other sides.

Next week im taking some holidays so i will finish crossover, hopefully my friend with cut and paint cabinet pieces, then just to install damping and glue everything together.

Still thinking how should i paint them..

I suggest you first get things functional and see if you like how it sounds. You could later come back to do the artistic part of it, painting and all. You can't paint (brush or spray) on aluminium and stainless steel directly. An acid-based etching primer is required for painting such materials.

Only 15mm? A big box like that has lower structural integrity. I would have gone for 1" board, 3/4" at the very least. It's a ported bass reflex and not a sealed box, so don't worry, it should still work fine, with bracing and all.

I suggest you first get things functional and see if you like how it sounds. You could later come back to do the artistic part of it, painting and all. You can't paint (brush or spray) on aluminium and stainless steel directly. An acid-based etching primer is required for painting such materials.

Only 15mm? A big box like that has lower structural integrity. I would have gone for 1" board, 3/4" at the very least. It's a ported bass reflex and not a sealed box, so don't worry, it should still work fine, with bracing and all.

Thats why i want to prepare alu box before hand, but since only array will be in alu box, maybe i can do it after.

Yes, 15mm its from the manual. I spoke with my guy and no bracing needed. We are going to glue them all in one go. Thats why im thinking of adding bit more thicker damping, like at least 5cm of it on each side. 15mm was bit low for me too, but hey, if design say 15mm, lets go with it 🙂

Here is what it say about cabinet

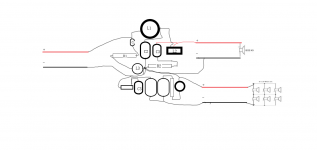

And final assembly

And here is sound measurementcasing Such a large case is really stable too building runs on a logistical challenge out. We wanted this but keep manageable and the bass cabinet not necessarily "dead as a mouse" design and him, just like old fathers Custom, a small amount of life of its own allow. We chose 15 multiplex, taking all walls diagonally with upright stiffened roof batten sections become - that can still be carried and behaves acoustically like us wanted to. The bass reflex opening does not need a pipe in this case, but rather only one that is exactly 15 centimeters in diameter round hole. Combined with the wall thickness does exactly what it does should and is guaranteed to be free of pipe resonance. We placed the opening off-center to the bottom of the case, for that it then needs ten centimeters high Feet under the box. The BGS 40 wants 15 Recessed millimeters deep into the front become. So get the baffle a corresponding continuous opening, behind it is a second plate with a smaller opening glued in which is screwed to the chassis. The Assembling the six full-range speakers initially a bit of a headache, ultimately proved to be a suitable solution an aluminum rectangular tube with a cross section of 100 x 40 with a Wall thickness of three millimeters. The Profile is available as a meter on Ebay and certainly elsewhere as well. The meter-long tube offers the six broad bands enough volume and shade not too much area from the woofer. The six little drivers sit on one thin MDF board that has the necessary Distance from the magnets to the back wall of the profile and besides is much easier to work with than the aluminum tube. You only need one here rectangular cutout, the millings for the broadband are in the MDF board. The aluminum tube is on the top with a matching piece of multiplex and plenty of glue sealed the profile remains open on the underside; the definitely does not hurt at this point, besides, you can easily do that there Lead out the connection cable. The question remains, how to get the profile afterwards gets attached to the box. We chose a very pragmatic one Solution: Velcro. That holds up pretty well provides some degree of decoupling and can be solved again in case of doubt - fits perfectly.

And testMeasurements We are satisfied. It's a speaker with a clean 95 decibel efficiency become. It works in the bass (minus three decibels) to just below 40 Hertz, that is always enough. Ask the treble drop we take the caution already advised to consider that is a measurement in one meter distance. There was a certain one that could not be avoided entirely Angular dependence of the sound pressure in the midrange, the big one Woofer inevitably bundles at some point. The impedance record (here without Linearization) reveals uncritical issues Eight ohm behavior, including the electrical one Phase is good-natured. One of the highlights of the box is its distortion behavior: The Phi has so little distortion that let's go next to the distortion at 85 decibels not the one at 95, but immediately at 105 Show decibels. At 85 decibels it rattles Box over 500 Hertz not measurable what is simply the best we've ever done before Had micro. Even move at 105 decibels we are mostly in the range of 0.2 to 0.3 percent, which is also absolute outstanding. The waterfall diagram reveals the expected, but low pronounced irregularity around a Kilohertz, otherwise everything is fine.

Hearing test Whichever way you turn it and applies: Nothing beats such a large one "Cardboard". The Phi is, you see me that bad pun, a "cattle" in the bass. The BGS 40 plays fast, clean, Dust dry and so deep that you can't get any Wasting thoughts on “more” got to. The bill goes over that too on: the small line array creates the dynamic connection to the Fifteen-inch dials without any problems, in short said: The box really pulls you Take off your shoes if you are not careful. Transparency, resolution - all great Class. Here, the low pays off Low distortion caused by diaphragm strokes fully, the thing plays absolutely spick and span over the entire area. Room? But something of. We're glad via typical "broadband space" with extremely sharply defined sound events, great freely distributed in the room. And tonal? It depends. With a rather not very gentle amplifier it sounds driven - not very gentle. The mid-high part is certainly not a child of Sadness, you have to like that. Single- Ended tube? Of course! Then it also works with the family peace. In short, this is a great speaker become. Certainly not that typically audiophile, but rather one that shows that music after goes ahead, and that without the neglect crucial virtues.

And final assembly

Assembly instructions First you equip both fronts with appropriate Cut out and glue them exactly centered on each other. Subsequently all walls except the floor from the inside with a diagonal stiffener from one Piece of roof batten provided. Those so prepared Plates then become the housing glued. An insulation of the bass housing is not provided. A jigsaw is used to cut a rectangular tube into the aluminum tube Cut the recess, then the MDF baffle with all millings glued. We got here on purpose MDF was chosen because it is less prone to cracking tends to be a multiplex; with the sometimes quite thin Stegen an advantage. Then locks the aluminum tube above with a matching one Wood section. Now the pipe is insulated: Comes on the back wall behind the drivers a piece of Damping 10, the remaining space in addition to the drivers, there is a double Strand of Angel Hair filled. The cavity below the driver will not work with Sonofill tightly stuffed. The latter should only be done after Take care of the installation and wiring of the drivers. It follows the surface treatment according to personal Gusto, in the end the aluminum profile is With Velcro in the middle over the bass chassis attached to the front.

Last edited:

Ok, apprently i suck at math...

Really?! 10*log[3.6] = ~5.56 dB

Really?! 10*log[3.6] = ~5.56 dB

I thought soo, but this one guy said its less, soo... Good thing im still good for it 🙂

Oh boy GM, you are just always full of useful stuff 🙂

I think il keep this one for myself and future reference, if you have more of such sites etc. cookbooks etc... please share, would love to archive all of this stuff.

On other note, quick question, regarding damping, what do you recommend for my situation ? Thickness 5 or 10mm glasswool ? Im thinking of not damping front board and bottom board.

I use to collect them along with numerous HDs full of pics, articles, etc., with consolidation as HDs got bigger, then a computer MB short?/fire ruined the HD + BU HD during a BU. 🙁

There out there though, including some old, but still pertinent, textbooks by Olson, et al, and if a dead link, many can be recovered in the web archives: Internet Archive: Wayback Machine

The pioneers taught me to line one side, back and panel opposite the vent [usually the top] with whatever density worked best, though in my case it normally was 1" acoustic fiberglass insulation [OC 703 nowadays] and only cover the other side panel if required.

Sealed were typically well stuffed using attic insulation with cheesecloth or similar lightly draped over the components: Altec Heathkit legato 2-15 inch horn & driver

Vented was critically damped using an impulse response: Click Test: Click Test | GM210 | Flickr

FWIW, recommend the industrial grade of Velcro, way stronger as I learned the hard way; just a small square at the top and bottom of something has often proven to be overkill until the weight or extension away from the mounting surface is significant.

There out there though, including some old, but still pertinent, textbooks by Olson, et al, and if a dead link, many can be recovered in the web archives: Internet Archive: Wayback Machine

The pioneers taught me to line one side, back and panel opposite the vent [usually the top] with whatever density worked best, though in my case it normally was 1" acoustic fiberglass insulation [OC 703 nowadays] and only cover the other side panel if required.

Sealed were typically well stuffed using attic insulation with cheesecloth or similar lightly draped over the components: Altec Heathkit legato 2-15 inch horn & driver

Vented was critically damped using an impulse response: Click Test: Click Test | GM210 | Flickr

FWIW, recommend the industrial grade of Velcro, way stronger as I learned the hard way; just a small square at the top and bottom of something has often proven to be overkill until the weight or extension away from the mounting surface is significant.

I have used 2" non-acoustic medium-density glasswool used for thermal insulation, available in hardware stores, works OK. You don't necessarily have to damp all the sides, but whatever you choose to do, do it for both speakers alike.

Don't worry about amplifier power, as 101 dB is good enough (I already said this earlier). However, it is always better (and reliable) if a larger amplifier (say 10W) operates at a fraction of its power capability (say 1W) than a smaller one working hard at full power.

Don't worry about amplifier power, as 101 dB is good enough (I already said this earlier). However, it is always better (and reliable) if a larger amplifier (say 10W) operates at a fraction of its power capability (say 1W) than a smaller one working hard at full power.

Ok, so i will damp with 20-30cm glasswool backside, top side and left side that will face the wall. Now question, should those sides be symetrical, or should i flip for other speaker, so damping also faces the other wall ?

Six of one, half a dozen of the other. 😉

edit: Normally true since the driver is centered, but just remembered the vent isn't, so technically it should be on the side furthest from it, though except in rare cases it's not an audible difference.

edit: Normally true since the driver is centered, but just remembered the vent isn't, so technically it should be on the side furthest from it, though except in rare cases it's not an audible difference.

Last edited:

Ok, so wood panels arrived,

I was looking for damping material, there is 50mm glasswool

And guy also showed me this much denser fabric, its more dense and heavier, but thickness is around 10mm. I think he said its used for isolation for concrete or something.

Should i go with denser and stack it for 20mm ?

Maybe get both this and glasswool, and maybe make a sandwich fabric-glasswool-fabric ?

There is also this more lose 0.5mm fabric available aswell and is similar to the first one, its just bit lighter and less dense.

I was looking for damping material, there is 50mm glasswool

And guy also showed me this much denser fabric, its more dense and heavier, but thickness is around 10mm. I think he said its used for isolation for concrete or something.

Should i go with denser and stack it for 20mm ?

Maybe get both this and glasswool, and maybe make a sandwich fabric-glasswool-fabric ?

There is also this more lose 0.5mm fabric available aswell and is similar to the first one, its just bit lighter and less dense.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Help chosing high SPL drivers for 3way classic loudspeaker