I'm glad to see someone posting about the Dual 1229. That's the table I have and am in the process of modding and I was starting to worry that I must be off on a crazy tangent since nobody was even talking about this table!

So far, I have removed all the automatic parts (don't stone me! ... the table was largely trash when I got it, totally non-functional), cleaned and regreased everything, disassembled and re-lubed the motor bearings, damped the chassis using an automotive product called B-Quiet which has worked quite well, cleaned up and tweaked the idler wheel and associated assembly, removed the tonearm (again, it was totally non-functional on arrival) and replaced with a DIY clone of the latest golf-ball well-tempered tonearm (I'm really surprised that not many people are trying this by the way, a very simple build for amazing results), and mounted in a rough plywood plinth for testing which is weighted with lead shot and mineral oil.

It sounds fantastic! I have to say, I have owned a lot of turntable over the years and this one at this point is the equal of the best I owned (a VPI Mk. IV with fully tweaked out ET 2.5 tonearm). I'm running a Shure V15 V-MR cart and the combo is sweet. On the lookout right now for an affordable moving coil to test out (my amp - a Nakamichi TA-4A - had both MC and MM phono stages.

Still, I think the biggest weakness of the system is the platter bearing which is difficult to address. I have considered building a ring magnet levitation-type bearing but it is proving to be a bit beyond my meager abilities and tools (all hand tools here and no background in manufacturing or engineering!).

So far, I have removed all the automatic parts (don't stone me! ... the table was largely trash when I got it, totally non-functional), cleaned and regreased everything, disassembled and re-lubed the motor bearings, damped the chassis using an automotive product called B-Quiet which has worked quite well, cleaned up and tweaked the idler wheel and associated assembly, removed the tonearm (again, it was totally non-functional on arrival) and replaced with a DIY clone of the latest golf-ball well-tempered tonearm (I'm really surprised that not many people are trying this by the way, a very simple build for amazing results), and mounted in a rough plywood plinth for testing which is weighted with lead shot and mineral oil.

It sounds fantastic! I have to say, I have owned a lot of turntable over the years and this one at this point is the equal of the best I owned (a VPI Mk. IV with fully tweaked out ET 2.5 tonearm). I'm running a Shure V15 V-MR cart and the combo is sweet. On the lookout right now for an affordable moving coil to test out (my amp - a Nakamichi TA-4A - had both MC and MM phono stages.

Still, I think the biggest weakness of the system is the platter bearing which is difficult to address. I have considered building a ring magnet levitation-type bearing but it is proving to be a bit beyond my meager abilities and tools (all hand tools here and no background in manufacturing or engineering!).

I'm a bit embarassed at my workmanship with my plinth and tonearm which are still in the prototype stage.... when i get them in their finished state, i'd love to share

Embarrassed? Say it isn't so.

fmelindy: well I too have a had a "prototype" 1216 for sometime. Up until recently, I was listening to it on a chunk of BB ply supported by the world's ugliest possible "sub-plinth". I call it my "beater" or "fugly"...with my home-made tonearm/Grado signature8 cartridge mounted, it gives my Oracle Alex MkII/SME309(mag)/Grado Sig8 a good run for the money. I think I prefer the old Dual to the Oracle in their current iterations.

Regarding affordable MC cartridges: Denon still lists the DL110 as available, and list ids something like $140 or so (a lot less than a DL103). Apparently the DL160 is no longer available.

I gave the parts here to make a WT "Amadeus" knock off, which should be quite easy. I also want to try a DIY Cantus linear tracker. I'm familiar with the ET tonearms, a friend had one on his Oracle.

Strictly speaking this is not restoring, it is "improving" or else "resto-modding".

fmelindy: well I too have a had a "prototype" 1216 for sometime. Up until recently, I was listening to it on a chunk of BB ply supported by the world's ugliest possible "sub-plinth". I call it my "beater" or "fugly"...with my home-made tonearm/Grado signature8 cartridge mounted, it gives my Oracle Alex MkII/SME309(mag)/Grado Sig8 a good run for the money. I think I prefer the old Dual to the Oracle in their current iterations.

Regarding affordable MC cartridges: Denon still lists the DL110 as available, and list ids something like $140 or so (a lot less than a DL103). Apparently the DL160 is no longer available.

I gave the parts here to make a WT "Amadeus" knock off, which should be quite easy. I also want to try a DIY Cantus linear tracker. I'm familiar with the ET tonearms, a friend had one on his Oracle.

Strictly speaking this is not restoring, it is "improving" or else "resto-modding".

Hello

Picture of your tone arm please!

Thank you.

Today I purchased for $3.03 a golf club light weight carbon fibre. Look nice, I will test it as a tone arm that sure.

The store had a titanium type and a carbon and boron mixture to.

Monday probably I buy some more, let see the guy from EPay if he prepared my next package.

Greetings Gabor

Picture of your tone arm please!

Thank you.

Today I purchased for $3.03 a golf club light weight carbon fibre. Look nice, I will test it as a tone arm that sure.

The store had a titanium type and a carbon and boron mixture to.

Monday probably I buy some more, let see the guy from EPay if he prepared my next package.

Greetings Gabor

I somehow get the feeling that I'm not supposed to say this, but I'm working on a terminator clone at the moment and have already built a somewhat rough schroder clone as well. Amazing what one can do in one's own basement with hand tools! I can certainly see what you mean with the Duals.... i was going to get a lenco but i'm not sure i can justify it considering how happy i am with my Dual 1229!

Incidentally i have owned all three of the denons you mentioned in the past and was relatively unimpressed with any of them... not sure why, maybe they didn't mate well with my tonearm at the time.

Incidentally i have owned all three of the denons you mentioned in the past and was relatively unimpressed with any of them... not sure why, maybe they didn't mate well with my tonearm at the time.

Hello

Picture of your tone arm please!

Thank you.

Today I purchased for $3.03 a golf club light weight carbon fibre. Look nice, I will test it as a tone arm that sure.

The store had a titanium type and a carbon and boron mixture to.

Monday probably I buy some more, let see the guy from EPay if he prepared my next package.

Greetings Gabor

Seriously, i don't consider my workmanship to be photo-ready but it was very easy to build and sounds fantastic. Make sure you get the right silicone fluid and use nice floppy tonearm wire to make cable dressing easy. I used graphite for the shaft... was easy and cheap to build- a great combo! I was astounded at how good it sounds...

Hello

Picture please!

Do not think I'm so professional. We can learn from each-other.

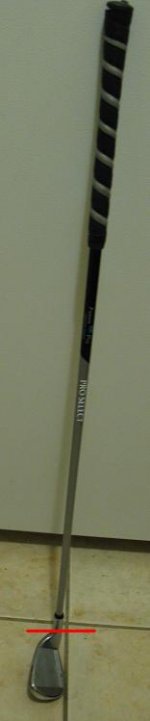

Here is my golf club. Graphite not carbon fibre how I wrote, if there is any difference between the two material.

I will cut it done at the neck to see if hollow all the way. If yes I will buy the titanium and the graphite boron mixture to.

I'm mostly interested on your tone arm suspension. I would love to cut the metal part so on that side use the counter weight but unfortunately that side of the tube will be thinner side.(I marked with red)

I will cut some brass material for counter weight, I will make the hole almost on the top not the center so the weight be as close to the table as possible.

I will buy tonearm silicone fluid.

Do you think solid wire it would be OK? I know a jewelry wire 999.9 pure copper, silver plated and protected with a cote of varnish. Sound very good as signal wire! I would use a cotton tube inside in the arm. The wire will come out on both end the pipe so not be bent.

That wire is 34AWG and again sound great.

If not the best idea, I'll buy some Cardas tonearm wire.

Greetings

Picture please!

Do not think I'm so professional. We can learn from each-other.

Here is my golf club. Graphite not carbon fibre how I wrote, if there is any difference between the two material.

I will cut it done at the neck to see if hollow all the way. If yes I will buy the titanium and the graphite boron mixture to.

I'm mostly interested on your tone arm suspension. I would love to cut the metal part so on that side use the counter weight but unfortunately that side of the tube will be thinner side.(I marked with red)

I will cut some brass material for counter weight, I will make the hole almost on the top not the center so the weight be as close to the table as possible.

I will buy tonearm silicone fluid.

Do you think solid wire it would be OK? I know a jewelry wire 999.9 pure copper, silver plated and protected with a cote of varnish. Sound very good as signal wire! I would use a cotton tube inside in the arm. The wire will come out on both end the pipe so not be bent.

That wire is 34AWG and again sound great.

If not the best idea, I'll buy some Cardas tonearm wire.

Greetings

Attachments

Last edited:

The Dual the most under rated decks!

Now people started to realise and their price will go up.

These 1229 is a great deck, if you have thick paint usually used at the buttom of cars that help (as a damping material) a lot if you paint the buttom side and under the platter the metal part..

The 704 even in Germany sometimes 300 Euros.

The 5000 not the best how is it and considering the price, because the arm. I read many statement about. Some people ask $700-800 for her because a beautiful deck.

Can we do something with the bearing to make it better. I think later I ad a 5mm thick soft copper math. That weight a lot to..

I have a Elac (brother of the Dual) and sound better than the Yamaha YP801 BL. I just got a Kenwood KD550 real marble plinth, not even com pared with the Elac. I removed the arm.

I have to have some good quality factory arm so I can compare the quality of the arms what I will build

Greetings Gabor

Now people started to realise and their price will go up.

These 1229 is a great deck, if you have thick paint usually used at the buttom of cars that help (as a damping material) a lot if you paint the buttom side and under the platter the metal part..

The 704 even in Germany sometimes 300 Euros.

The 5000 not the best how is it and considering the price, because the arm. I read many statement about. Some people ask $700-800 for her because a beautiful deck.

Can we do something with the bearing to make it better. I think later I ad a 5mm thick soft copper math. That weight a lot to..

I have a Elac (brother of the Dual) and sound better than the Yamaha YP801 BL. I just got a Kenwood KD550 real marble plinth, not even com pared with the Elac. I removed the arm.

I have to have some good quality factory arm so I can compare the quality of the arms what I will build

Greetings Gabor

Hello

Nice arm!!

Well Tempered Simplex Turntable

With my 6mm titanium tube it would be possible to test these..

Greetings

Nice arm!!

Well Tempered Simplex Turntable

With my 6mm titanium tube it would be possible to test these..

Greetings

here's a photo of my "fugly Dual". This is with an earlier arm and without a top plate for the plinth.

And it looks terrible but sounds great.

Hello Nannok

Yes I want to see her! "but sounds great"

That is the most important. Are you using a 12" arm? If yes you can help me to know the best location for the 12" suspension!

Please let me know! Thank you🙂

The golf club arm has to tick wall. At the neck 2mm and about 18" another side 1.5mm.

Do you have any idea how much would be the optimal weight for a 12" arm.

I have to go to the post office to measure the weight.

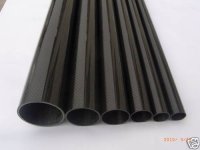

For the 9" I want to use the golf ball set up titanium tube or carbon tube that 7mm thick 1mm wall thickness

I found in China very nice carbon tube 1mm wall thickness.

I'll buy 9mm tick and 7mm thick.

If someone interested on carbon tube or titanium tube with one shipping cost I can order some extra.

The titanium tube 6mm and 04mm wall thickness.

I will order tomorrow or Monday!

I advise try to find a 1219 Dual (same as 1229) no strobe light. Over 3Kg platter, strong motor because 3 speed..

There is one on Kijiji for good price.

Same heavy platter great arm (best Dual arm).

If I didn't have already $180 on my 1229 now I would take the 1219.

Les than $100 Sony cartridge "advertised" dust cover with a little crack

Vintage Dual 1219 Turntable - Markham / York Region Electronics For Sale - Kijiji Markham / York Region Canada.

Greetings and thank you

Gabor

Last edited:

guys, great stuff... (admin, please read!)

Guys, if you read the title, you may ask why get an administrator or moderator to read? So here it is.

to admin/moderators:I think this thread has become more than what the original poster had thought when it started. Perhaps a new thread should be created such as "good cheap turntables for resto-mods". If suitable, I am willing to go through the complete thread and note which posts might be best moved, so as to keep the original intent of this thread intact, and yet provide a thread for the ever expanding "resto-mod" theme that has been going on here.

And now a reply to the thread:.

gaborbela: Yes, the whole point is that it sounds great. The arm presently looks good too! Really similar to your ideas for an arm. I use 70ksi + arrow shafts (Easton). They are relatively cheap, and very easy to get. Ti may be better, but no Ti was easily available here. I like the idea of using "made in the USA" (or Canada ) products as much as possible. Often "True Temper", and "Easton" branded stuff is produced in North America, and for me that is a no-brainer. Carbon fiber hafts are as well, again using arrow shafts. Even the lower quality shafts have a very good spec. The only titanium arm I've had experience was an old Alphason that I wish I still owned.

Info on the arm: The arm itself has a effective length (pivot to stylus tip) of approximately 305 mm. I never bothered trying to make or have made a headshell that has any offset angle. I just use smaller bolts (2mm ) to retain the cartridge. That way alignment can be easily done by loosening the bolts and twisting the cartridge. The headshell is a custom piece done by a friend of a friend. I have since been able to get access to a end mill, so I can make headshells now that are absolutely accurate. The counter-weight is a salvaged piece from a Garrard LAB60. I can now make a similar piece myself, again using the end mill. The great thing is based on this trapazoind design, once a location is found that allows for correct VTF and azimuth, you only have to finger tighten it. Similarly a disk of material could be used, using a similar arrangement, but with an offset hole, thus ensuring that the centre of gravity (c.o.g.) of the counter-weight is lower that the centre of the shaft, and (I haven't done any calculations) approaches the same plane as the stylus. I'll take a couple of photos of the current configuration.

The pivot point is above the centre of the shaft. The female portion of the bearing is installed into a carrier that is glued in place. I use a precision 1 mm tungsten carbide roller as the pivot, installed in a metal carrier (a ball point pen nub). That is then installed into a shaft that can be easily adjusted. The shaft is held in place by a locking collar.

Finding the location for the tonearm is pretty easy. As I used a similar length as a SEAC 12" tonearm, I assume an O/H of 15mm. I then use my Oracle "calibrator" disc (Oracle's protractor), and adjust the location of the base of the tonearm to allow good alignment with the protractor. Once determined, I mark he plinth, so that if it gets nudged from the location, it is easy to put back. As I experiment with various alignments, I have yet to permanently fix the tonearm to the plinth. In a previous post, my audio partner's Dual 1226 is shown with essentially the same thing. He just used some 1" precision rod that he cut and tapped for a set screw to hold the pivot, and used o-rings to hold a tonearm lift.

I'm attaching a few photos of the Lab60 and the tonearm, as well as Mike's implementation of the tonearm. Any are appreciated (as long as they do not affect the sound). All three of the tables (the "fugly Dual", Mike's Dual, and the LAB60) easily bested my Oracle Alex MkII/SME309 MkII/Grado sig8, and Mike's Roksan Xerxes MkI/tweaked RB250/Ortofon MC3 Turbo.

Info on the Thorens headshell: I've also attached a marked up picture of the Thorens headshell. As long as the indicated edge of the headshell is parallel to the centre-line of the arm tube it should be fine. If not more work is required.

Cambe: I bet it sounds good. I think the PLC590 was the closest thing that Pioneer had to an SP10 or SP15. Certainly one of the best DDs that Pioneer ever made (and perhaps anyone), but I think they are quite rare.

Guys, if you read the title, you may ask why get an administrator or moderator to read? So here it is.

to admin/moderators:I think this thread has become more than what the original poster had thought when it started. Perhaps a new thread should be created such as "good cheap turntables for resto-mods". If suitable, I am willing to go through the complete thread and note which posts might be best moved, so as to keep the original intent of this thread intact, and yet provide a thread for the ever expanding "resto-mod" theme that has been going on here.

And now a reply to the thread:.

gaborbela: Yes, the whole point is that it sounds great. The arm presently looks good too! Really similar to your ideas for an arm. I use 70ksi + arrow shafts (Easton). They are relatively cheap, and very easy to get. Ti may be better, but no Ti was easily available here. I like the idea of using "made in the USA" (or Canada ) products as much as possible. Often "True Temper", and "Easton" branded stuff is produced in North America, and for me that is a no-brainer. Carbon fiber hafts are as well, again using arrow shafts. Even the lower quality shafts have a very good spec. The only titanium arm I've had experience was an old Alphason that I wish I still owned.

Info on the arm: The arm itself has a effective length (pivot to stylus tip) of approximately 305 mm. I never bothered trying to make or have made a headshell that has any offset angle. I just use smaller bolts (2mm ) to retain the cartridge. That way alignment can be easily done by loosening the bolts and twisting the cartridge. The headshell is a custom piece done by a friend of a friend. I have since been able to get access to a end mill, so I can make headshells now that are absolutely accurate. The counter-weight is a salvaged piece from a Garrard LAB60. I can now make a similar piece myself, again using the end mill. The great thing is based on this trapazoind design, once a location is found that allows for correct VTF and azimuth, you only have to finger tighten it. Similarly a disk of material could be used, using a similar arrangement, but with an offset hole, thus ensuring that the centre of gravity (c.o.g.) of the counter-weight is lower that the centre of the shaft, and (I haven't done any calculations) approaches the same plane as the stylus. I'll take a couple of photos of the current configuration.

The pivot point is above the centre of the shaft. The female portion of the bearing is installed into a carrier that is glued in place. I use a precision 1 mm tungsten carbide roller as the pivot, installed in a metal carrier (a ball point pen nub). That is then installed into a shaft that can be easily adjusted. The shaft is held in place by a locking collar.

Finding the location for the tonearm is pretty easy. As I used a similar length as a SEAC 12" tonearm, I assume an O/H of 15mm. I then use my Oracle "calibrator" disc (Oracle's protractor), and adjust the location of the base of the tonearm to allow good alignment with the protractor. Once determined, I mark he plinth, so that if it gets nudged from the location, it is easy to put back. As I experiment with various alignments, I have yet to permanently fix the tonearm to the plinth. In a previous post, my audio partner's Dual 1226 is shown with essentially the same thing. He just used some 1" precision rod that he cut and tapped for a set screw to hold the pivot, and used o-rings to hold a tonearm lift.

I'm attaching a few photos of the Lab60 and the tonearm, as well as Mike's implementation of the tonearm. Any are appreciated (as long as they do not affect the sound). All three of the tables (the "fugly Dual", Mike's Dual, and the LAB60) easily bested my Oracle Alex MkII/SME309 MkII/Grado sig8, and Mike's Roksan Xerxes MkI/tweaked RB250/Ortofon MC3 Turbo.

Info on the Thorens headshell: I've also attached a marked up picture of the Thorens headshell. As long as the indicated edge of the headshell is parallel to the centre-line of the arm tube it should be fine. If not more work is required.

Cambe: I bet it sounds good. I think the PLC590 was the closest thing that Pioneer had to an SP10 or SP15. Certainly one of the best DDs that Pioneer ever made (and perhaps anyone), but I think they are quite rare.

Attachments

Hello

Welcome Cambe...

Nannok do you think my graphite tube heavy?

Now 18" long now and weight 42Gr. I know is to long I have to cut done may be 3" or more because I still have to ad a head shell.

I found a great Carbon fibre pipe source 9mm inside diameter 7mm and another 7mm inside 5mm.

That is from China 2PC from each 50Cm long plus shipping cost $34. Picture att.

Very nice pipe, but I still don't know which material better, titanium, carbon fibre, graphite...

I do not want to waste money. If is good tube of course I'll buy it... Some opinion it would be great

Comercial tone arms use carbon fiber and other moterials to..

Greetings Gabor

Welcome Cambe...

Nannok do you think my graphite tube heavy?

Now 18" long now and weight 42Gr. I know is to long I have to cut done may be 3" or more because I still have to ad a head shell.

I found a great Carbon fibre pipe source 9mm inside diameter 7mm and another 7mm inside 5mm.

That is from China 2PC from each 50Cm long plus shipping cost $34. Picture att.

Very nice pipe, but I still don't know which material better, titanium, carbon fibre, graphite...

I do not want to waste money. If is good tube of course I'll buy it... Some opinion it would be great

Comercial tone arms use carbon fiber and other moterials to..

Greetings Gabor

Attachments

Last edited:

Hello

Yes I understand what you mean. The center of the cartridge (actually the needle) must be at the center of the pipe...

May be I get read of that head shell and I'll ad a 2mm piece of titanium for head shell

I just purchased yesterday.

I taught to build some titanium and carbon fibre head shell to.

Thank you

Greetings Gabor

Yes I understand what you mean. The center of the cartridge (actually the needle) must be at the center of the pipe...

May be I get read of that head shell and I'll ad a 2mm piece of titanium for head shell

I just purchased yesterday.

I taught to build some titanium and carbon fibre head shell to.

Thank you

Greetings Gabor

Hello Nanook

I made two picture where you can see the center of the head shell.

Actually the drill bit is the center of the pipe.

The cartridge mounting screws are attached to the finger lift not to the head shell. So if I move in angle the finger lift that moves the cartridge to..

With that I can adjust the cartridge to a position where the needle will be right at the center of the pipe.

Please look at the two screws and com pare the two picture to.

Right now it look like OK to me.

May be I'll make another head shell from the 2mm titanium I just purchased last night..

These Thorens was removed also from straight arm, what I do not like about the Z model.

Greetings Gabor

I made two picture where you can see the center of the head shell.

Actually the drill bit is the center of the pipe.

The cartridge mounting screws are attached to the finger lift not to the head shell. So if I move in angle the finger lift that moves the cartridge to..

With that I can adjust the cartridge to a position where the needle will be right at the center of the pipe.

Please look at the two screws and com pare the two picture to.

Right now it look like OK to me.

May be I'll make another head shell from the 2mm titanium I just purchased last night..

These Thorens was removed also from straight arm, what I do not like about the Z model.

Greetings Gabor

Attachments

Most spares are still available for old Rega turntables. From Rega. I live 30 miles away from a Rega dealer in the UK though.

Add photo

Ok, it's up and running; Mission 774 arm and an old AT OC9 cart. for now.

New springs and suspension internals, new belt and oil, alloy arm board damped with Dynamat, new clamp (the original was missing), Delrin feet and suspension parts, Delphi MkVI MVSS damping system, foamed vinyl mat (home made). Voltage regulator added to the outboard PSU. A magnetic arm lift, so I don't wear out the stylus when I fall asleep (getting old!).

I just got an email from Oracle today saying; yes, I can use a MkVI bearing housing if I machine out the holes in the subchassis and acrylic plinth and adjust the screws in the housing to fit my bearing shaft. So that will be the next on the list, when I can afford it.

I just paid over £200 to have my Decca refurbished, so I may have to wait a while. Besides, some new records would be nice, too.

I bought an Oracle Delphi Mk.1 with missing parts and broken lid for about £300, plus maintenance kit for £170, made the missing parts (I have a lathe), glued the lid, made some upgrade parts, and for around £500 have a deck I have wanted for 25 years.

Without the workshop equipment, I could not have done it; it all depends on your skills set. I need lots of help with electronics, but metal and wood working are what I do.

Ok, it's up and running; Mission 774 arm and an old AT OC9 cart. for now.

New springs and suspension internals, new belt and oil, alloy arm board damped with Dynamat, new clamp (the original was missing), Delrin feet and suspension parts, Delphi MkVI MVSS damping system, foamed vinyl mat (home made). Voltage regulator added to the outboard PSU. A magnetic arm lift, so I don't wear out the stylus when I fall asleep (getting old!).

I just got an email from Oracle today saying; yes, I can use a MkVI bearing housing if I machine out the holes in the subchassis and acrylic plinth and adjust the screws in the housing to fit my bearing shaft. So that will be the next on the list, when I can afford it.

I just paid over £200 to have my Decca refurbished, so I may have to wait a while. Besides, some new records would be nice, too.

Last edited:

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- good turntables for restoring?