I have a question about Brians Gainclone. Can you use +26V and - 26v and Grnd from a pwr supply in a pre built amp or do you have to use Brians PWR Supply board and seperate transformers. I am confused sorry.

Serosmaness.

Serosmaness.

Thanks Peter. I thought so . I built the amp and had it working untill I drilled a hole it to the heatsink and bolted the chip down. Fired it up and apparently the chip was shorted to the sink. POOF.

Anyway thanks.

Serosmaness

Anyway thanks.

Serosmaness

Single PCB gainclone

Peter Daniel and Brian,

Thanks for your input on the single board idea. I was mainly concerned with sound quality. I guess it boils down to which is best; board traces or wire. Just curious; can board traces better quality wire under any circumstances?

Peter Daniel and Brian,

Thanks for your input on the single board idea. I was mainly concerned with sound quality. I guess it boils down to which is best; board traces or wire. Just curious; can board traces better quality wire under any circumstances?

CT Transformer Update

OK, last night I completed my cigar box Gainclone amp based on Brian's boards. I used a single 40VCT transformer for the power supply.

It plays very nicely with plenty of power. I don't know the exact details of the transformer. It was one of the PE buyouts ($10) rated by PE as 40VCT, 200VA. Peter Daniel said he thought it was closer to 100VA. In either case it seems to be enough. Power on the rails is now 27VDC with the + and - matching perfectly.

The center tapped transformer is running through both bridges (just like a "real" transformer).

Wiring was done like this-

AC1 from transformer to AC1H on PS board, CT from transformer to AC1N and AC2H on PS board and AC2 from transformer to AC2N on PS board.

Pics of the finished amp posted on the contest thread. I'll be emailing some to Brian for his gallery as well.

OK, last night I completed my cigar box Gainclone amp based on Brian's boards. I used a single 40VCT transformer for the power supply.

It plays very nicely with plenty of power. I don't know the exact details of the transformer. It was one of the PE buyouts ($10) rated by PE as 40VCT, 200VA. Peter Daniel said he thought it was closer to 100VA. In either case it seems to be enough. Power on the rails is now 27VDC with the + and - matching perfectly.

The center tapped transformer is running through both bridges (just like a "real" transformer).

Wiring was done like this-

AC1 from transformer to AC1H on PS board, CT from transformer to AC1N and AC2H on PS board and AC2 from transformer to AC2N on PS board.

Pics of the finished amp posted on the contest thread. I'll be emailing some to Brian for his gallery as well.

Re: Re: -=Sneak Peak=-

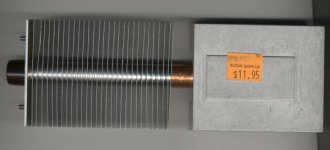

I guess there are two different Active Surplus stores in our area😉

Coulomb said:

Hey, I have seen those Heat transfer pipes at a local supplier for $3 CAD each! 🙂

Antrhony

I guess there are two different Active Surplus stores in our area😉

Attachments

Peter,

What do you use to tap your aluminum chassis with? I bought a tap and drill at Lowes for a 10-24 machine screw & I ended up with a hole bigger than the screw! And yes it was a 10-24 screw. I used my drill press to drill it and tap it so I know it wasn't due to sloppiness. Have any tips or secret sources for good taps??

What do you use to tap your aluminum chassis with? I bought a tap and drill at Lowes for a 10-24 machine screw & I ended up with a hole bigger than the screw! And yes it was a 10-24 screw. I used my drill press to drill it and tap it so I know it wasn't due to sloppiness. Have any tips or secret sources for good taps??

Re: How good is this 47Labs player?

It's the best one yet (out of my 3). I think the very short wires made a difference. But the construction was difficult (the plitron TF was a pain to fit) and I made the mistake of not pre-wiring the boards so I was soldering in a tiny space.

The stepped attenuators are home made and they help too.

It's the best one yet (out of my 3). I think the very short wires made a difference. But the construction was difficult (the plitron TF was a pain to fit) and I made the mistake of not pre-wiring the boards so I was soldering in a tiny space.

The stepped attenuators are home made and they help too.

kestrel200 said:Peter,

What do you use to tap your aluminum chassis with? I bought a tap and drill at Lowes for a 10-24 machine screw & I ended up with a hole bigger than the screw! And yes it was a 10-24 screw. I used my drill press to drill it and tap it so I know it wasn't due to sloppiness. Have any tips or secret sources for good taps??

I get my taps from Home Depot. 10-32 is better for screws. You must have made a mistake somwhere, but you can alsways use next size screw, to make up for a too big hole😉

clean edges

peter whats the best way to smooth out edges on cut aluminum?

or what do you do😉

thanks...

peter whats the best way to smooth out edges on cut aluminum?

or what do you do😉

thanks...

10-24 should be a #25 and a 10-32 should be a #21. The fine thread will provide a "nicer" fit in thinner workpieces. You will often get an "extra" thread in the workpiece ~ it will have a better feel.

I wonder what our Euro foreign intrigue bro's think about all this #21 ~ #25, "F drill" 13/64's stuff. They must think we are absolutely, positively CRAZY.

I wonder what our Euro foreign intrigue bro's think about all this #21 ~ #25, "F drill" 13/64's stuff. They must think we are absolutely, positively CRAZY.

Re: clean edges

I usually use a belt sander, but you can use a block of wood with some sandpaper on it. Anything around 100 - 200 will do. You might try filing initially, but it might not be necessary.

karma said:peter whats the best way to smooth out edges on cut aluminum?

or what do you do😉

thanks...

I usually use a belt sander, but you can use a block of wood with some sandpaper on it. Anything around 100 - 200 will do. You might try filing initially, but it might not be necessary.

Wet or dry paper with WD-40 or soapy water peels aluminum right off. Makes a nice brushed finish (without the brush).

For Deburring edges of cuts I use a special blade made for the job that sort of looks like a question mark.

Anthony

Anthony

chipco3434 said:like this...

they're very handy and cheap.

Yeah that't it, they work great, on most any shape.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Chip Amps

- Gainclone building thread based on BrianGT's boards