Hello Alsyd,

I put it around the top as well. And about the same as you have got under the driver with the same effect. I ended up with it nearly 3/4's down the front and had to make a wire basket to hold it. I do use the original CHP70 4 Ohm 86 dB and don't experience any problems with the new trio Tangerine Dream.

I didn't bother with weights stuffed it thicker down the Vee and less as I came around. If you can test it with one side removable I'd be inclined to try various stuffings, you won't regret it.

Cheers - J

I put it around the top as well. And about the same as you have got under the driver with the same effect. I ended up with it nearly 3/4's down the front and had to make a wire basket to hold it. I do use the original CHP70 4 Ohm 86 dB and don't experience any problems with the new trio Tangerine Dream.

I didn't bother with weights stuffed it thicker down the Vee and less as I came around. If you can test it with one side removable I'd be inclined to try various stuffings, you won't regret it.

Cheers - J

I’m not experienced in this yet - I just finished my own cuts today - however I was watching this guy on YouTube. He’s stuffing with 175g on both sides (which is more than 10x the 30g you noted) and advises that both front and back channels should have equal stuffing. I’m sure your mileage may vary, but perhaps it will make a difference? Frugel Horn Build - Part 3 - Stuffing and final gluing - YouTube

Edit: Just realized he’s assembling the XL. It’s not 10x larger than the mk3, I’m guessing the 300g is too much 🙂, but maybe the idea that a bit more is needed still holds?

Edit: Just realized he’s assembling the XL. It’s not 10x larger than the mk3, I’m guessing the 300g is too much 🙂, but maybe the idea that a bit more is needed still holds?

Last edited:

Thanks guys.

I progressivley added more stuffing in the top of the point, under the driver and behind the driver.

Sound is definitely more balanced but once I put enough in to roll the bass off, the mids started going with it... will continue to experiment - perhaps having the stuffing right behind the driver started to effect the mids... thoughts?

Adding an extra basket to facilitate more stuffing further down the front rather than increasing the density of my current set up will be tomorrow's project.

I progressivley added more stuffing in the top of the point, under the driver and behind the driver.

Sound is definitely more balanced but once I put enough in to roll the bass off, the mids started going with it... will continue to experiment - perhaps having the stuffing right behind the driver started to effect the mids... thoughts?

Adding an extra basket to facilitate more stuffing further down the front rather than increasing the density of my current set up will be tomorrow's project.

yes, you can over damp. there is a sweet spot. driver, amp, room, room placement, taste all play a role in how much damping is needed.

dave

dave

Thanks!

Thanks I’m about to install mine this week too. (Cutting up a cheap, dense, and heavy woven cotton bath mat in lieu of proper felt.) Will report the findings I have.

Thanks I’m about to install mine this week too. (Cutting up a cheap, dense, and heavy woven cotton bath mat in lieu of proper felt.) Will report the findings I have.

Isnt lining purpose to prevent reflection? If I understand correctly, if I put too dense material Ill change internal volume and if to porous it will not stop reflection. Question Im asking, since there is no cotton felt in my country of any kind so i had to combine 5mm industrial wool felt and polyester, can that be too much or can it somehow choke some frequencies?yes, you can over damp. there is a sweet spot. driver, amp, room, room placement, taste all play a role in how much damping is needed.

dave

I also received bunch of melamine sponge 20 mm thick, will that be too much?

And forgot to mention, I have no measuring equipment.

Last edited:

I have no idea how the sponges work, X is the one says they work well.

The main purpose of the damping is to kill the natural ripple (caused by unwanted harmonics) that is undesirable. It is a trade-off as more damping reduces bass quantity. The lining near the driver is secondary, the purpose being to increas eth eability to kill stuff getting to the walls & preventing it from reflecting back thru the cone.

dave

The main purpose of the damping is to kill the natural ripple (caused by unwanted harmonics) that is undesirable. It is a trade-off as more damping reduces bass quantity. The lining near the driver is secondary, the purpose being to increas eth eability to kill stuff getting to the walls & preventing it from reflecting back thru the cone.

dave

So, if lining around the driver kills unwanted reflections and dont change internal volume too much can it be overdone?

You can always take things too far. A bit thicker gives the material a lower LF cutoff, but the absorption character of your damping material also is a consideration. Thicker also means you lose volume for the fibrous/pluffy material. How that works is also dependent of its frequency characteristics and density.

Given this is diy, the range of damping materials we can source is different world over, different drivers, different rooms, different room placement, different tastes it becomes very difficult to closely define much wrt to the best damping for an individual situation.

It is entirely possible that one might get satisfactory resuts with just lining (but more) or just fibrous material.

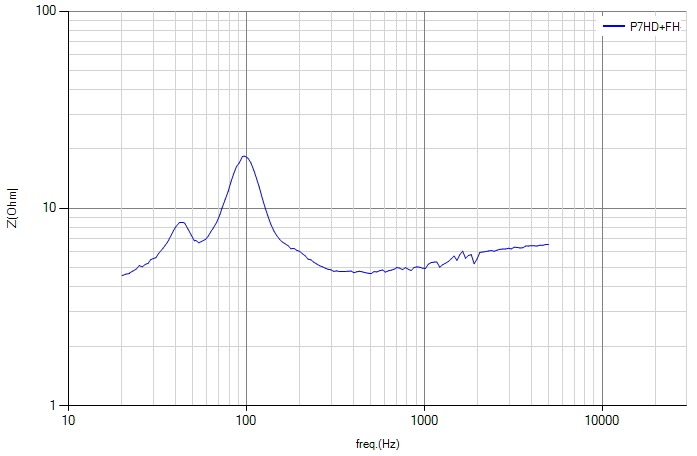

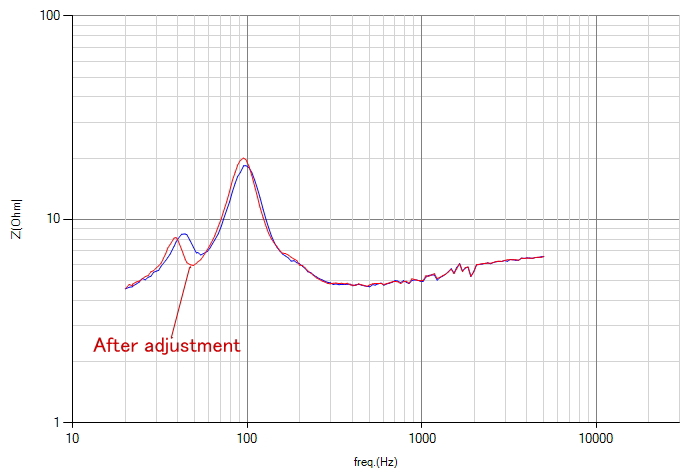

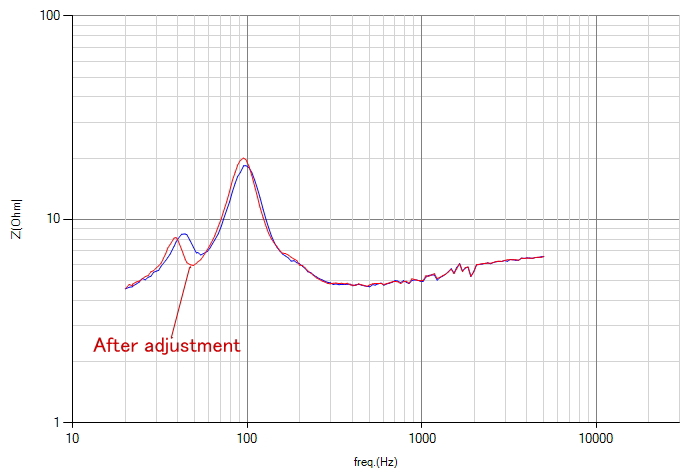

You can measure impedance and use a mic to help but in the end you have to trust your ears.

If one was making many of these, had a consistent material supply a damping optimization could be made but it would need to be made not knowning: rooms, room placement, taste.

dave

Given this is diy, the range of damping materials we can source is different world over, different drivers, different rooms, different room placement, different tastes it becomes very difficult to closely define much wrt to the best damping for an individual situation.

It is entirely possible that one might get satisfactory resuts with just lining (but more) or just fibrous material.

You can measure impedance and use a mic to help but in the end you have to trust your ears.

If one was making many of these, had a consistent material supply a damping optimization could be made but it would need to be made not knowning: rooms, room placement, taste.

dave

nandappe,

The nicely folded “polestar wool” batting should be pulled out and properly teased.

Teasing bat is not easy. You might start with fluff.

I expect the amount you have is excessive.

The cotton wool probably works better than the polyester. It could better fill the point. It should be fairly tight right at the point.

But it all comes down to sound.

dave

The nicely folded “polestar wool” batting should be pulled out and properly teased.

Teasing bat is not easy. You might start with fluff.

I expect the amount you have is excessive.

The cotton wool probably works better than the polyester. It could better fill the point. It should be fairly tight right at the point.

But it all comes down to sound.

dave

I’m about to glue up my sides. In my situation, I found the all-cotton bath mat worked well in the driver area. I used 30g of fluff evenly distributed from the convergence point of the back and middle baffle, stopping about two inches shy of the top is all I need. Additional fluff on the way down the front to the terminus wasn’t needed in my room.

7-ADBE2-F0-8-A03-4649-AA12-576-F5-A0-FB8-F7 — ImgBB

7-ADBE2-F0-8-A03-4649-AA12-576-F5-A0-FB8-F7 — ImgBB

Last edited:

It’s all cotton woven on back, so it was applied with the same pva glue. I feel like other synthetic materials like rayon or polyester carpets break down over time and I think the more organic cotton will retain its integrity longer. It’s not too plush or thick, and just right IMO for killing the ripples and deadening the area.

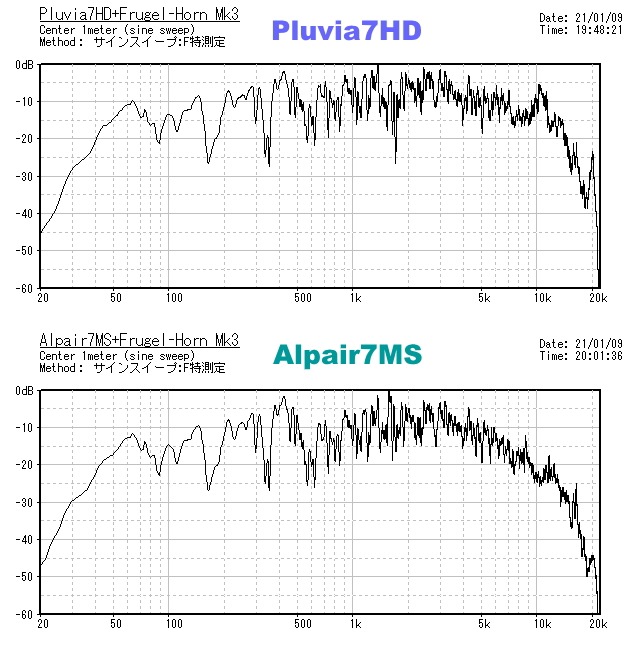

And yes, copper Alpair 7 MS in use. Gluing the cabinets after lunch! I anticipate -a veneer finish.

I have to say that they sound so damn good, that the wait to finish them is going to really irk me! I’m quite impressed with these and will do a full “review” and share my thoughts etc when 100% done. I just know that if i slap the drivers back in before finishing them I’ll be looking at bare plywood for a very long time. 😀

And yes, copper Alpair 7 MS in use. Gluing the cabinets after lunch! I anticipate -a veneer finish.

I have to say that they sound so damn good, that the wait to finish them is going to really irk me! I’m quite impressed with these and will do a full “review” and share my thoughts etc when 100% done. I just know that if i slap the drivers back in before finishing them I’ll be looking at bare plywood for a very long time. 😀

Organic materials like cotton, wool (moths have to be worried about), and other natural fibrous materials generally perfotm better than synthetic materials, but things like fiberglass and modern really kinky poly fillings have their place and ar enot slouches.

dave

dave

Thank you everyone for your advice.

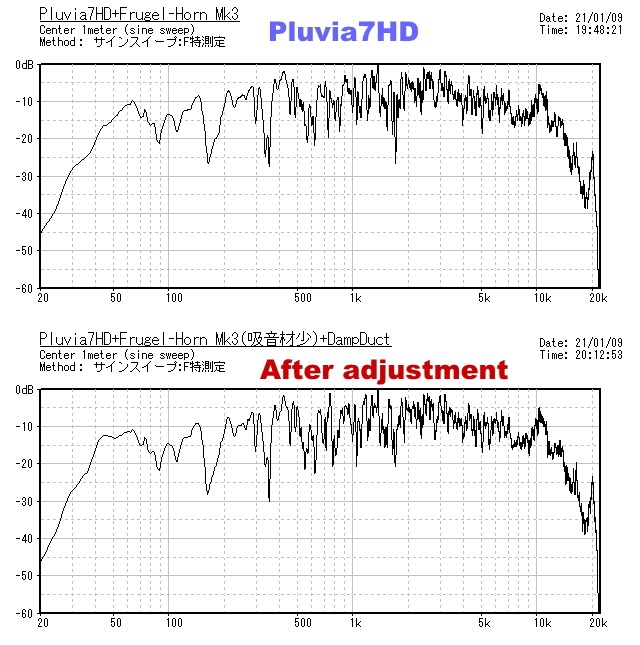

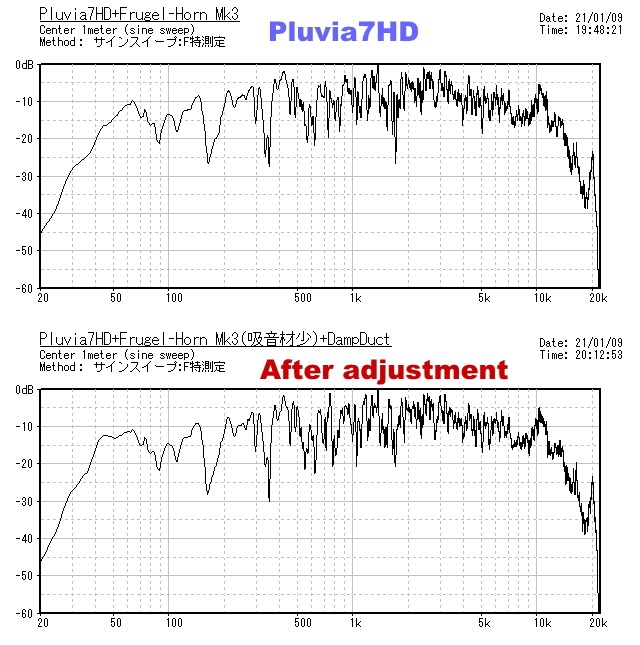

I adjusted it to my taste.

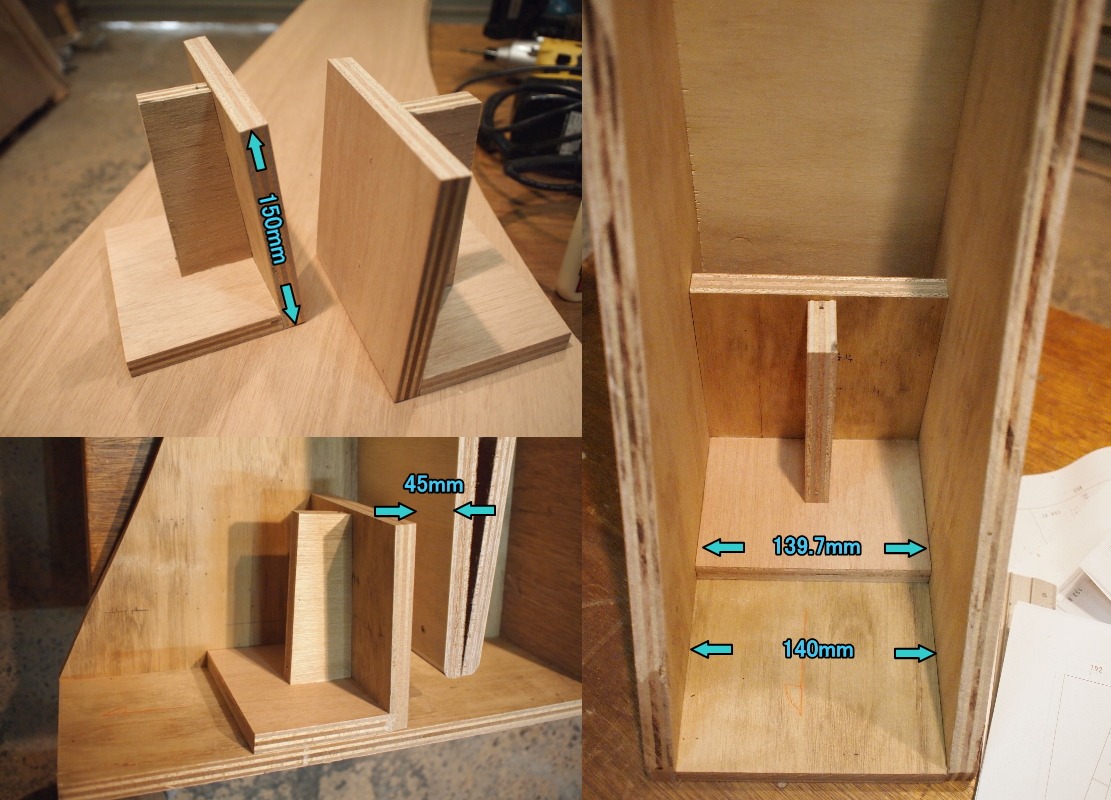

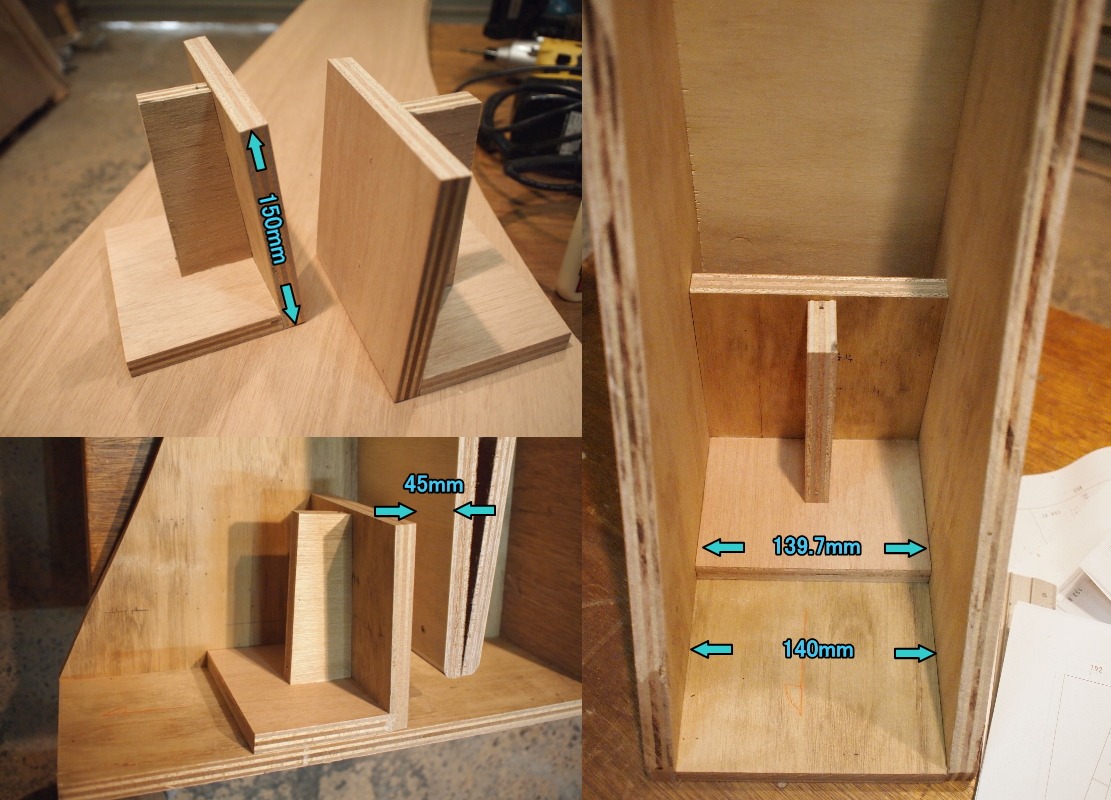

Polyester wool Pulled out and added Damp-duct.

Maybe, over 10kHz response is mic-trouble.

I adjusted it to my taste.

Polyester wool Pulled out and added Damp-duct.

Maybe, over 10kHz response is mic-trouble.

This is really interesting! Can someone please explain the thinking behind a ‘Damp duct’? And no stuffing is used at all? This looks like an easy experiment and I can see that some areas of measurement are tidied up too. The slight extension at 40Hz and reduced drop just under 2k with no other obvious adjustments is intriguing.

- Home

- Loudspeakers

- Full Range

- Frugel-Horn Mk3 Builds & Build Questions