French polish is just shellac dissolved in alcohol. The shellac in the polish seals the wood reasonably well - not to the same degree as varnish or epoxy but not too bad. Of course there's unfinished wood on the inside, but that's almost entirely MDF and ply.

From virtually all views expressed on here, solid wood cabinets have splitting problems with changes in humidity. Although internal, there will still be changes in air vapour content and, therefore, expansion and contraction. I would hate to think such beautiful craftsman(?)ship might be spoiled.Of course there's unfinished wood on the inside, but that's almost entirely MDF and ply.

Interesting. You've got me reading and learning about shrinkage in timber, which I'd never really thought terribly much about.

In traditional boat building its expected that if a boat is allowed to dry out it'll leak like a sieve as all the planks shrink and, in extreme cases, the caulking falls out. The common remedy, at least with dinghys, is to pull the bungs and sink it for a week or two so things swell back up and the ocean stays on the outside (after refloating and bailing).

My dinghy is made from plywood, so suffers from none of this. Each of the planks is securely glued to its neighbour with a healthy clinker overlap and a pile of thickened epoxy. To be certain, it's got a good layer of epoxy on both sides, followed by ridiculously expensive marine enamel.

Of course the speakers are built in complete ignorance of any of this. I simply biscuit jointed planks with PVA and then laminated them to MDF with lots more PVA.

I guess one advantage of this construction is that any cracks that form in the Jarrah are unlikely to be audible, as there is still a layer of MDF to seal the speaker up. Perhaps the MDF will hold everything together strongly enough, like some coarse plywood and prevent cracking?

My benchtops are made from Jarrah planks joined in the same fashion, with biscuits. They have cross pieces underneath (more Jarrah) every perhaps 200mm, and are held together with nails and glue. Thus far I've not noticed anything untoward happening with my bench, but that may be more luck than good design.

One thing that I have noticed with my laminated speaker sides is that the sides that were built up but not glued into speakers bowed. I guess that the MDF is a lot drier than the Jarrah, so once everything was glued up the MDF sucked moisture from the Jarrah, causing perhaps 2mm of bowing over the 280mm width.

I mostly sorted that when gluing the second side onto my first speaker by using a truly enormous collection of clamps to pull the panel flat. Even then the gap between the side and baffle was more than I'd like. The other two sides have been sitting clamped to one another with the Jarrah on the outside and a couple of straight planks crosswise to hold everything true while I cut out the rest of the bits.

I read just now that Jarrah certainly isn't the worst timber for dimensional stability, but it's not the best either. The "unit tangential movement" spec for Jarrah is 0.3 percent per percent change in moisture content (http://www.dtmtimber.com.au/downloads/TQ_TDS/tds_28_Moisture-in-Timber_final.pdf. So for a 5% moisture content change, such as you'd expect from a variation in RH between 30% and 60% (http://www.fwpa.com.au/images/processing/PN01.1305.pdf, I'd expect an unconstrained change in panel width of 4mm in my 280mm wide panel, which is alarmingly large.

Of course the MDF will try to prevent this from happening, as the MDF, from what I've read, doesn't grow or shrink. It'll also be braced by the interior, top and bottom cross-grain or ply pieces

Geraldton is pretty dry, so we've got that working in our favour I guess 🙂 also in my favour the Ariels are tall and skinny, so the variation is going to be less than short fat speakers, and issues are likely to come up on the sides, where they won't be as obvious as on the baffle.

Anyway, it'll be fascinating (and perhaps depressing) to see what happens over the coming year or so as the humidity changes.

In traditional boat building its expected that if a boat is allowed to dry out it'll leak like a sieve as all the planks shrink and, in extreme cases, the caulking falls out. The common remedy, at least with dinghys, is to pull the bungs and sink it for a week or two so things swell back up and the ocean stays on the outside (after refloating and bailing).

My dinghy is made from plywood, so suffers from none of this. Each of the planks is securely glued to its neighbour with a healthy clinker overlap and a pile of thickened epoxy. To be certain, it's got a good layer of epoxy on both sides, followed by ridiculously expensive marine enamel.

Of course the speakers are built in complete ignorance of any of this. I simply biscuit jointed planks with PVA and then laminated them to MDF with lots more PVA.

I guess one advantage of this construction is that any cracks that form in the Jarrah are unlikely to be audible, as there is still a layer of MDF to seal the speaker up. Perhaps the MDF will hold everything together strongly enough, like some coarse plywood and prevent cracking?

My benchtops are made from Jarrah planks joined in the same fashion, with biscuits. They have cross pieces underneath (more Jarrah) every perhaps 200mm, and are held together with nails and glue. Thus far I've not noticed anything untoward happening with my bench, but that may be more luck than good design.

One thing that I have noticed with my laminated speaker sides is that the sides that were built up but not glued into speakers bowed. I guess that the MDF is a lot drier than the Jarrah, so once everything was glued up the MDF sucked moisture from the Jarrah, causing perhaps 2mm of bowing over the 280mm width.

I mostly sorted that when gluing the second side onto my first speaker by using a truly enormous collection of clamps to pull the panel flat. Even then the gap between the side and baffle was more than I'd like. The other two sides have been sitting clamped to one another with the Jarrah on the outside and a couple of straight planks crosswise to hold everything true while I cut out the rest of the bits.

I read just now that Jarrah certainly isn't the worst timber for dimensional stability, but it's not the best either. The "unit tangential movement" spec for Jarrah is 0.3 percent per percent change in moisture content (http://www.dtmtimber.com.au/downloads/TQ_TDS/tds_28_Moisture-in-Timber_final.pdf. So for a 5% moisture content change, such as you'd expect from a variation in RH between 30% and 60% (http://www.fwpa.com.au/images/processing/PN01.1305.pdf, I'd expect an unconstrained change in panel width of 4mm in my 280mm wide panel, which is alarmingly large.

Of course the MDF will try to prevent this from happening, as the MDF, from what I've read, doesn't grow or shrink. It'll also be braced by the interior, top and bottom cross-grain or ply pieces

Geraldton is pretty dry, so we've got that working in our favour I guess 🙂 also in my favour the Ariels are tall and skinny, so the variation is going to be less than short fat speakers, and issues are likely to come up on the sides, where they won't be as obvious as on the baffle.

Anyway, it'll be fascinating (and perhaps depressing) to see what happens over the coming year or so as the humidity changes.

Last edited:

BTW when I refer to bowing in the previous post I really mean cupping. My terminology is completely out of phase (pun intended).

Also I note I've created engineered timber flooring by laminating MDF and solid timber, though the rule of thumb with engineered flooring appears to be more like 4-6mm solid timber on 12-14mm ply, or much closer to veneered ply than what I've done (12mm solid timber, 9mm MDF). I could conceivably thin the Jarrah out such that the MDF is the thickest bit, but I'd run the risk of exposing the biscuits, and one should never show one's biscuits.

Anyway, I figure if it cracks and looks terrible then I'll just build new cabinets with thinner timber (maybe even buy myself a bandsaw so I can saw 19mm thick planks in half) and call it a hell of a learning experience.

Also I note I've created engineered timber flooring by laminating MDF and solid timber, though the rule of thumb with engineered flooring appears to be more like 4-6mm solid timber on 12-14mm ply, or much closer to veneered ply than what I've done (12mm solid timber, 9mm MDF). I could conceivably thin the Jarrah out such that the MDF is the thickest bit, but I'd run the risk of exposing the biscuits, and one should never show one's biscuits.

Anyway, I figure if it cracks and looks terrible then I'll just build new cabinets with thinner timber (maybe even buy myself a bandsaw so I can saw 19mm thick planks in half) and call it a hell of a learning experience.

Last edited:

Completely airtight construction is pretty important; otherwise bass will be thin. Make sure all the joins are fully sealed on the inside. For my pair, I avoided biscuit fasteners and went with rabbeted joins sealed with wood glue for the entire length of the mating area between two wood surfaces. As a result, the joined areas are actually stronger than the surrounding Baltic Birch plywood, and are airtight as well.

Inside boxes, I run a bead of PVA along all joins to ensure a good seal. The inside is also coated with a water based clear coat which reduces the MDF absorbing moisture. In essence, the outside and inside are sealed to the elements which helps to make the enclosure more stable.

I can say from four decades of speaker building that it is virtually impossible to prevent mdf joints from moving. The only partial solution I have found is cladding a mdf carcass with marine plywood. The marine ply has a waterproof laminating glue which helps isolate the mdf from enviromental humidity. What you tend to find is that the mdf swell and shows seams through veneer and will try to move any solid timber cladding. Marine ply is the most useable solution I have found. (9 ply seems about optimal). It stiffens the enclosure and damps very well too. It usually has a preferred hardwood ply face that finishes well. I have even seen mdf seams show through 3 mm thick laminated fibreglass. This might take a few months to a year to show up.Perhaps the MDF will hold everything together strongly enough, like some coarse plywood and prevent cracking?

.....

I guess that the MDF is a lot drier than the Jarrah, so once everything was glued up the MDF sucked moisture from the Jarrah

.....

Of course the MDF will try to prevent this from happening, as the MDF, from what I've read, doesn't grow or shrink.

.....

Geraldton is pretty dry, so we've got that working in our favour I guess 🙂

.....

Anyway, it'll be fascinating (and perhaps depressing) to see what happens over the coming year or so as the humidity changes.

Last edited:

My experience is exactly the same, mdf being butt joined and veneered and I have no tools to do the 45 deg cuts.

Btw, to the OP, cabinets are magnificiently looking.

Btw, to the OP, cabinets are magnificiently looking.

A miniDSP arrived in the mail today, along with a measurement microphone.

This thing is sooooo cool!

A quick 18dB butterworth crossover at 3K, with 2dB extra gain for the tweeter, and it's Good enough for some proper listening...

Sounds pretty good to my cloth ears. My lounge room looks like a bomb hit it.

This thing is sooooo cool!

A quick 18dB butterworth crossover at 3K, with 2dB extra gain for the tweeter, and it's Good enough for some proper listening...

Sounds pretty good to my cloth ears. My lounge room looks like a bomb hit it.

Attachments

Adding some tweeter delay helps immeasurably.

With 10us delay, 3.5KHz 18dB Butterworth filters, +2dB relative gain for the tweeter, and +6dB BSC (250Hz, Q=0.7) applied to the mid-woofers, I get the following plot. I've included a second plot to show the null from reversing phase on the tweeter.

With 10us delay, 3.5KHz 18dB Butterworth filters, +2dB relative gain for the tweeter, and +6dB BSC (250Hz, Q=0.7) applied to the mid-woofers, I get the following plot. I've included a second plot to show the null from reversing phase on the tweeter.

Attachments

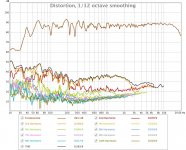

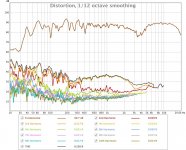

As a reference, here's my Infinity RS-5B. There's a huge hole at the crossover point between the big 10" woofer and the dome mid. The ribbon tweeter goes on forever, but it doesn't have much dynamic range.

There's very little difference in the bass depth between the sealed 10" poly infinity and the little 5.5" tl Ariels, except the Ariels are miles flatter.

There's very little difference in the bass depth between the sealed 10" poly infinity and the little 5.5" tl Ariels, except the Ariels are miles flatter.

Attachments

I was in-line with the tweeter for each measurement, with about 1m distance.

With the Infinity, that's only going to exacerbate any time alignment issues between the dome mid and cone bass driver.

With the Infinity, that's only going to exacerbate any time alignment issues between the dome mid and cone bass driver.

Would be interesting to observe a measurement of the Infinity with the mic between woofer and midrange.

What gating were you using Suzy? I'm wondering exactly what conclusions you can draw from the low frequency end of those curves.

Nice cabinet!

Graham.

Nice cabinet!

Graham.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Four Vifa p13wh00-08s and two Scan Speak d2905-950000