Because you refuse to address a clear design issue and actually post a picture of it , its crystal clear you are trying to move forward from a flawed foundation

Its tantamount to creating a square wheel and trying to smooth it out with suspension mods

Address the issue you created please

Its tantamount to creating a square wheel and trying to smooth it out with suspension mods

Address the issue you created please

Member

Joined 2019

I have provided detailed measurements and values. Which are brutally ignored. In my world - the academic one - this is not a behavior one can accept.

Because you refuse to address a clear design issue and actually post a picture of it , its crystal clear you are trying to move forward from a flawed foundation

Its tantamount to creating a square wheel and trying to smooth it out with suspension mods

Address the issue you created please

I cant say if you are right technically, but no reason to attack so agresively.

I have provided detailed measurements and values. Which are brutally ignored. In my world - the academic one - this is not a behavior one can accept.

We dont care about your academic merits. You know that proffesors have been fatally wrong with tragic consequenses. Flaunting degrees and experience is just a red cloth, to provoke more critisism. Stop doing it, and you will more respected

Member

Joined 2019

We dont care about your academic merits. You know that proffesors have been fatally wrong with tragic consequenses. Flaunting degrees and experience is just a red cloth, to provoke more critisism. Stop doing it, and you will more respected.

Guerilla, IT IS NOT a matter of respect to me, but respect to some basic scientific rules that every scientist has to follow. And some of us, working in universities, have to teach as well. I can not betray my science in order "to be respected" here! I do not need this respect!

I have posted a number of digital microscopy videos, answering the question about the magnitude of the vessel movements with a micron precision. These are called "pictures" and/or totally ignored! I do not need the respect of people ignoring measurements (experiments). I would rather feel bad with their respect.

Member

Joined 2019

Cool

I appreciate your moderation efforts. But "cooling" on certain cases leads to the Plane Earth, the Wrong Darwin, the airplanes which kill us with toxic chemicals and a lot of other quite popular stupidities, which are a sign of serious cultural degradation.

Member

Joined 2019

Later developments in the TTT project.

1. Magnet stabilizer. I have finalized the parameters of the adjustable magnet stabilizer. In "Stylus UP" position the distance between the magnet and the steel shaft is 4.8 mm and the attraction force - 4.3 p (pond, gram force). In "Stylus DOWN" position the distance magnet - shaft becomes 6.8 mm and magnetic force is reduced to 1.9 p. But now the stylus skating force is added, so the total attraction force is about 2.5 p. The static friction is about 20 dyn - a quite satisfactory value. It may be further reduced by changing the leading wheels bearings with new, of higher accuracy class and lower friction moment.

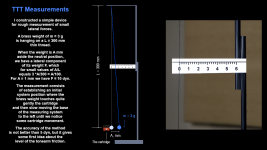

2. The method I use for rough determination of the friction force is shown in the attachment.

3. I have started a new series of measurements of the floating vessel displacements in various directions. In the first series I used intentionally an LP with higher eccentricity and vertical warps, in order to have an idea about the worst levels of the measured quantities. Now I use the procedure of eccentricity minimizing (with target of ±0.1 mm) and the internal disk stabilizer, to reduce the warps amplitude.

The results of the first measurement show variations of the vertical vessel position about ±25 microns and variations of the vessel's horizontality of the order of ±0.014 degrees - less than ±1 angular minute.

1. Magnet stabilizer. I have finalized the parameters of the adjustable magnet stabilizer. In "Stylus UP" position the distance between the magnet and the steel shaft is 4.8 mm and the attraction force - 4.3 p (pond, gram force). In "Stylus DOWN" position the distance magnet - shaft becomes 6.8 mm and magnetic force is reduced to 1.9 p. But now the stylus skating force is added, so the total attraction force is about 2.5 p. The static friction is about 20 dyn - a quite satisfactory value. It may be further reduced by changing the leading wheels bearings with new, of higher accuracy class and lower friction moment.

2. The method I use for rough determination of the friction force is shown in the attachment.

3. I have started a new series of measurements of the floating vessel displacements in various directions. In the first series I used intentionally an LP with higher eccentricity and vertical warps, in order to have an idea about the worst levels of the measured quantities. Now I use the procedure of eccentricity minimizing (with target of ±0.1 mm) and the internal disk stabilizer, to reduce the warps amplitude.

The results of the first measurement show variations of the vertical vessel position about ±25 microns and variations of the vessel's horizontality of the order of ±0.014 degrees - less than ±1 angular minute.

Attachments

Last edited:

Member

Joined 2019

But now the stylus skating force is added, so the total attraction force is about 2.5 p.

The skating force as known points toward the spindle, so it can not be added to the magnetic attraction force. Which force do you call skating force in this case?

You still don’t get it.

The bearing of the tonearm should NOT move at all. You think the bearing of your arm moves very little in all directions so it is ok. NO! It is not ok.

The physical distance of 1 kHz signal cycles is about 0.03 mm. The width of the groove is about 0.04-0.08 mm.

How scientific your method of measuring is very questionable. However, I assume they are all correct. So, your measurements are

Vertical movements=+/-0.03 mm

Lateral movements, dx=0.04 mm, dy=0.014 mm

In reality, all these movements on your arm base are combinations of these three. Your arm base moves in all directions. The magnitudes of your arm base movements are the same or larger than the size of the groove, and physical distance of 1 kHz signal, too. In reality, a lot of music information is above 1 kHz. So, the physical distances of signal cycles are getting very small. The movements of your arm base are much larger than the physical sizes of signal cycles.

Think about it. How possible to track groove accurately while its base moves in almost the same or larger magnitude and in all directions. Do a simple experiment. Try to put a stick into a small hole. If your hands are shaking constantly and in all directions, it will be difficult to put the stick into the hole. The vibrations from the cartridge are not effectively dampened by its base(bearing), so the stylus can’t track the groove correctly.

Think about it again. Have some common sense. Have you seen any tonearm manufacture say its arm bearing moves but in very small magnitudes?

In my previous post, I said the magnetic guiding mechanism may cause various VTF. You told me that constant VTF is not required for LP playing back. You want to rewrite the rules of tonearm design. What kind of logic is that!

You don’t have to reply to my post. But do your own favor. Think about what I said. Try to study other well-known arms.

The bearing of the tonearm should NOT move at all. You think the bearing of your arm moves very little in all directions so it is ok. NO! It is not ok.

The physical distance of 1 kHz signal cycles is about 0.03 mm. The width of the groove is about 0.04-0.08 mm.

How scientific your method of measuring is very questionable. However, I assume they are all correct. So, your measurements are

Vertical movements=+/-0.03 mm

Lateral movements, dx=0.04 mm, dy=0.014 mm

In reality, all these movements on your arm base are combinations of these three. Your arm base moves in all directions. The magnitudes of your arm base movements are the same or larger than the size of the groove, and physical distance of 1 kHz signal, too. In reality, a lot of music information is above 1 kHz. So, the physical distances of signal cycles are getting very small. The movements of your arm base are much larger than the physical sizes of signal cycles.

Think about it. How possible to track groove accurately while its base moves in almost the same or larger magnitude and in all directions. Do a simple experiment. Try to put a stick into a small hole. If your hands are shaking constantly and in all directions, it will be difficult to put the stick into the hole. The vibrations from the cartridge are not effectively dampened by its base(bearing), so the stylus can’t track the groove correctly.

Think about it again. Have some common sense. Have you seen any tonearm manufacture say its arm bearing moves but in very small magnitudes?

In my previous post, I said the magnetic guiding mechanism may cause various VTF. You told me that constant VTF is not required for LP playing back. You want to rewrite the rules of tonearm design. What kind of logic is that!

You don’t have to reply to my post. But do your own favor. Think about what I said. Try to study other well-known arms.

Last edited:

Member

Joined 2019

The skating force as known points toward the spindle, so it can not be added to the magnetic attraction force. Which force do you call skating force in this case?

The skating force is tangential to the groove in the point of contact with the stylus. What you name "skating force" is the lateral component of the actual skating force, which appears due to the offset angle of the cartridge with respect to the stylus rotation axis in the case of the classical pivoted tonearms. This component is partly compensated by the antiskating device, but the compensation can not be full, as long as it depends also on the level of the groove modulation.

A major benefit of the tangential tonearm (of any type) is that the lateral component of the skating force is practically 0 and no antiskating device is needed.

I will be happy to see you can improve the arm. But your attitude closes the door for improvements. You denied some basic principles of tonearm design. You are not in the position to deny these principles, but to follow these principles.

Member

Joined 2019

super10018, July 6.

You analysis neglect the fact that the main frequency of the observed vessel micro-movements is 0.555 Hz * - that of the 33.3 rpm rotation of the disk. They are very gentle and do not produce any audible artefacts. The tonearm does not 'ring' or 'jingle' in any audible frequencies and this is demonstrated by careful listening and waveform analysis of disk signals of sweeping frequency thorough the whole audible spectrum, but also with hundreds of hours of targeted listening to the sound.

* Due to this principal frequency, I would compare the 'problem' with that of a small length tangential tonearm, which axis of vertical rotation is necessarily well above the disk surface. Let's say a Clear Audio one. With a height of 15 mm above the disk and effective tonearm length of 100 mm, a disk warp of ±0.5 mm will cause a variation of the effective tonearm length of ±75 microns. A value much higher than the dY value observed in my TTT.

You analysis neglect the fact that the main frequency of the observed vessel micro-movements is 0.555 Hz * - that of the 33.3 rpm rotation of the disk. They are very gentle and do not produce any audible artefacts. The tonearm does not 'ring' or 'jingle' in any audible frequencies and this is demonstrated by careful listening and waveform analysis of disk signals of sweeping frequency thorough the whole audible spectrum, but also with hundreds of hours of targeted listening to the sound.

* Due to this principal frequency, I would compare the 'problem' with that of a small length tangential tonearm, which axis of vertical rotation is necessarily well above the disk surface. Let's say a Clear Audio one. With a height of 15 mm above the disk and effective tonearm length of 100 mm, a disk warp of ±0.5 mm will cause a variation of the effective tonearm length of ±75 microns. A value much higher than the dY value observed in my TTT.

Last edited:

Take a 1” alumium chassis and bolt a platter/ bearing on one end and on the other place a tonearm base.

Either a 4 point gimbal, LT air bearing, knife edge, or unipivot.

Under any condition of vibration either internal or external , those 2 points will not move. That important relationship should be unmovable

From the ball point of the platter to the point of tonearm pivot you have broken design rules

And claim “ accepted dogma and then ask why ?”

With every warp you have a counterweight mass that is pushing up and down on the centerpoint in the boat pivot and trying to displace the water

You built your house on sand and not a rockmass, get it yet ?

No amount of scientific/academic data will prove your boat and its pivot point is superior to the accepted and trusted solid unmovable designs

You cant wave your hand and brush it off so easily like your doing.

The plaque on the wall telling you “ good job “ should be removed

Along with evaporation, fungus, and mosquitos ? Time to admit water is lousy movable foundation under the best scientific analysis

Your still trying to move forward from a flawed foundation unfortunately .,.

Either a 4 point gimbal, LT air bearing, knife edge, or unipivot.

Under any condition of vibration either internal or external , those 2 points will not move. That important relationship should be unmovable

From the ball point of the platter to the point of tonearm pivot you have broken design rules

And claim “ accepted dogma and then ask why ?”

With every warp you have a counterweight mass that is pushing up and down on the centerpoint in the boat pivot and trying to displace the water

You built your house on sand and not a rockmass, get it yet ?

No amount of scientific/academic data will prove your boat and its pivot point is superior to the accepted and trusted solid unmovable designs

You cant wave your hand and brush it off so easily like your doing.

The plaque on the wall telling you “ good job “ should be removed

Along with evaporation, fungus, and mosquitos ? Time to admit water is lousy movable foundation under the best scientific analysis

Your still trying to move forward from a flawed foundation unfortunately .,.

Stick a "patchtype" microphone on the arm and see if it picks up music or nastyties. I dont know what they are called. Think they are piezo types. They resemble those wires they stick on you to monitor your heart at hospitals

You analysis neglect the fact that the main frequency of the observed vessel micro-movements is 0.555 Hz * - that of the 33.3 rpm rotation of the disk. They are very gentle and do not produce any audible artefacts. The tonearm does not 'ring' or 'jingle' in any audible frequencies and this is demonstrated by careful listening and waveform analysis of disk signals of sweeping frequency thorough the whole audible spectrum, but also with hundreds of hours of targeted listening to the sound.

Your logic is completely wrong. You think the corresponding frequency of base movements is 0.55 Hz, therefore, the movements of the base have an impact on 0.55 Hz only. You can’t hear or you can’t see it. It doesn’t mean it doesn’t exist. Once the base moves, the stylus can’t track the waveforms correctly.

Member

Joined 2019

Stick a "patchtype" microphone on the arm and see if it picks up music or nastyties. I dont know what they are called. Think they are piezo types. They resemble those wires they stick on you to monitor your heart at hospitals.

According to the Holy Bible, the tonearm should not vibrate at all. But it does.. Guerilla, I got two high quality microphones called 'ears'. Why I need to use other ones?

By the way, a question to you and to all: what is the dimension tolerance in the case of an air bearing tangential tolerance? I mean the tolerance of the cylinders.

- Home

- Source & Line

- Analogue Source

- Floating Tangential Tonearm