By the way, I have just removed L4 and fed 5V to V4 through a Salas PSU giving 340mA.

Results? Two words for you....

HOLLY BATMAN!!!!!!!

Clarity is in a completely new level... Like going from 300euro player into 10000euro one... 😛

It s the biggest upgrade I have seen all day.

I did not have the chance to further test the PSU for ringing or any oscillations, but going electrolytic on its filters should keep it clean... And I have to either find a lower V trafo or a bigger heatsink, because the first mosfet gets hot really fast...

I ll post more tomorrow... it s getting late for sound tests...

Tomorrow I will also try to cannibalize the MSR860s and try them. BTW what do you think about MUR820?

By the way, with the dual PSU setup, the motors seem to run really really more efficiently. The sled moves OMG FAST and stopping/breaking actually stops the disk so fast that the puck jumps a little because of its mass/inertia 😛

If I keep this setup, I will need to make the puck a little less aggressive towards disks to prevent scratches...

Results? Two words for you....

HOLLY BATMAN!!!!!!!

Clarity is in a completely new level... Like going from 300euro player into 10000euro one... 😛

It s the biggest upgrade I have seen all day.

I did not have the chance to further test the PSU for ringing or any oscillations, but going electrolytic on its filters should keep it clean... And I have to either find a lower V trafo or a bigger heatsink, because the first mosfet gets hot really fast...

I ll post more tomorrow... it s getting late for sound tests...

Tomorrow I will also try to cannibalize the MSR860s and try them. BTW what do you think about MUR820?

By the way, with the dual PSU setup, the motors seem to run really really more efficiently. The sled moves OMG FAST and stopping/breaking actually stops the disk so fast that the puck jumps a little because of its mass/inertia 😛

If I keep this setup, I will need to make the puck a little less aggressive towards disks to prevent scratches...

Uncle Leon, I still have about 20 of those lowend BG PK, but I did your words for it - any BG is better than the best of th non-BG groups. I am sure there can be better result, but I like what I hear, thank you for the tips. I will use the BG on my second board. I already lifted the C10 pad from this board ad shall stop further damage 🙂

Dimkasta, I think Uncle Leon just refers to the bypass caps, not the main reservoir cap.

You are 10 steps ahead me 🙂 I also plan to remove L4 and feed a dedicate 5V into the digital circuit. Sounds like it will be my next weekend's project!!

Dimkasta, I think Uncle Leon just refers to the bypass caps, not the main reservoir cap.

You are 10 steps ahead me 🙂 I also plan to remove L4 and feed a dedicate 5V into the digital circuit. Sounds like it will be my next weekend's project!!

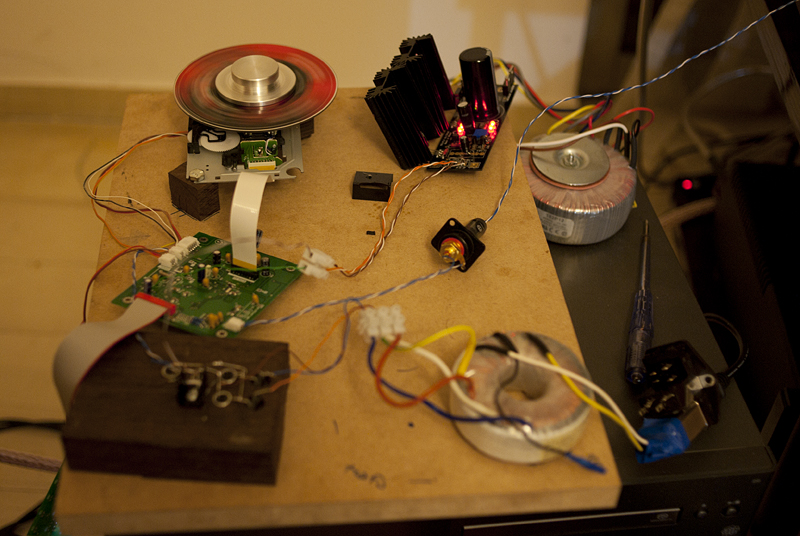

Nice one Tony 🙂 I would have used a bit thicker wood, but it looks very nice as it is 🙂

Nice calculated and well executed build 🙂

As opposed to mine which is a pile of cables for now... 😀

Thanks. I'm actually glad I didn't go any thicker - I just don't have all the tools to work with cutting through wood much thicker than this. I figure with maybe additional strengthening / damping spars in the right places it will help limit any resonances coming from using 1/4" panels.

I also plan to remove L4 and feed a dedicate 5V into the digital circuit. Sounds like it will be my next weekend's project!!

That's my plan as well. Don't forget - please try to take any customization discussions over to the other thread I started. 🙂

For anyone interested, attached you can find the settings I used for the salas psu.

Leds are 4 reds and one green (1,9V and 2,1V)

For R101 I used Caddock mp930

For filters I used Panasonic FRs, 1000uF in the led filter and 47uF electrolytic in the output (no zobel)

Main cap is a 10000uF panasonic at 50V (F5T leftover 😀 )

Leds are 4 reds and one green (1,9V and 2,1V)

For R101 I used Caddock mp930

For filters I used Panasonic FRs, 1000uF in the led filter and 47uF electrolytic in the output (no zobel)

Main cap is a 10000uF panasonic at 50V (F5T leftover 😀 )

Attachments

...

I also wanted to replace C10, but it is in a rather tightly populated area, so I d rather do it when I am less tired. By the way, Jaroslaw's guide suggests removing it altogether. Anyone tried it?

By the way, moding Tibi's PCB is not for the faint of heart... It ...

Thanks for sharing.

C10 is a very sensitive component. The quality of C10 is influencing both, laser and ASP and therefore the HF pattern quality.

I suggest to chose this part based on measurements, rather than listening.

Remove C10 and with a DSO scope make a FFT noise analysis and chose the cap based on datasheet specs.

C19 is part of laser current source. This part can not be removed and a low leakage cap is recommended. Tantalum is a preferable choice here.

You may try to replace C17 with silver-mica. This should remove some more HF noise.

Regards,

Tibi

...

Tibi, capacitor's ESR at 100kHz (or any other arbitrary frequency) has little correlation with the cap's performance in terms of sound. The noise profile, mechanical damping, interactions with other components and a multitude of other factors can affect the sound. I can bet big money that the Black Gate on your picture actually sounds a lot better than the Samxon, despite the poor measurements.

Yes, this is exacly what I want to point out. Every cap must be used for the application for which was designed.

In this case Samxon will do a better job than BG.

BG will sound better in an audio circuit, in signal path or decoupling, but not here.

Regards,

Tibi

By the way, I have just removed L4 and fed 5V to V4 through a Salas PSU giving 340mA.

Results? Two words for you....

HOLLY BATMAN!!!!!!!

Clarity is in a completely new level... Like going from 300euro player into 10000euro one... 😛

It s the biggest upgrade I have seen all day.

I did not have the chance to further test the PSU for ringing or any oscillations, but going electrolytic on its filters should keep it clean... And I have to either find a lower V trafo or a bigger heatsink, because the first mosfet gets hot really fast...

I ll post more tomorrow... it s getting late for sound tests...

Tomorrow I will also try to cannibalize the MSR860s and try them. BTW what do you think about MUR820?

By the way, with the dual PSU setup, the motors seem to run really really more efficiently. The sled moves OMG FAST and stopping/breaking actually stops the disk so fast that the puck jumps a little because of its mass/inertia 😛

If I keep this setup, I will need to make the puck a little less aggressive towards disks to prevent scratches...

Thanks, I´ll give it a try today with a Salas PSU.

Regards,

Tibi

Jaro you might want to revise your article on Studio Zey.

Granted, you clarify that the new version might act differently, but still it creates a certain urge to remove C10 too 🙂

Fair enough, I can see how it could be misleading... I have revised the wording.

Last edited:

I've been thinking about how to manage the top cover of my enclosure (see Post #6997 for a pic).

I'm using a 1/4" thick poplar panel, which will be cut to fit into the top perimeter of the enclosure. I'm doing this so the top can sit down enough to clear the transport platform. With the top panel inset so that it is level with the top edge of the sidewalls it will perfectly clear the platform.

So I was originally planning to glue in 3/8" square stringers along the inside edges of the box, at a height so that I could simply drop the top panel onto the stringers and it would just sit level with the top. It might work, but I'm a little uncomfortable with leaving the top unfastened. But if I want to fasten it to the rest of the box, how do I do it?

I'm dealing with 1/4" thick pieces of wood. Kind of thin to try and screw one piece into another - I can see things splintering very nicely if I try that! I could try and put very small holes around the poplar top and screw it into the stringers (the stringers will be epoxied in place so they should be quite secure). But I'm no expert cabinet maker; hoping others have some ideas I haven't thought of.

I'm using a 1/4" thick poplar panel, which will be cut to fit into the top perimeter of the enclosure. I'm doing this so the top can sit down enough to clear the transport platform. With the top panel inset so that it is level with the top edge of the sidewalls it will perfectly clear the platform.

So I was originally planning to glue in 3/8" square stringers along the inside edges of the box, at a height so that I could simply drop the top panel onto the stringers and it would just sit level with the top. It might work, but I'm a little uncomfortable with leaving the top unfastened. But if I want to fasten it to the rest of the box, how do I do it?

I'm dealing with 1/4" thick pieces of wood. Kind of thin to try and screw one piece into another - I can see things splintering very nicely if I try that! I could try and put very small holes around the poplar top and screw it into the stringers (the stringers will be epoxied in place so they should be quite secure). But I'm no expert cabinet maker; hoping others have some ideas I haven't thought of.

A few random thoughts after our latest changes.

Separating the digital PSU from the motors seems to have a dual effect. Obviously cleaner operation of the digital stuff and more efficient operation of the motors (if it s actual a positive influence, since Igor a few pages back was loving his slow sled)

My question now is how much of the big improvement is due to cleaner digitals and how much due to more efficient motors...

And since testing by Jarek and Eric showed that slowing down the motors with 100nF caps worsens things, my mind kind of goes towards finding more ways to make the sled even faster and more accurate.

One was already suggested by Tibi, to use even smaller polysterine caps like 1nF to suppress noise but not slow them significantly. Although the spindle motor's changes in speed are slower than the sled's, so I would expect it to behave better with the bigger cap. I will try to check the motors on the scope and get back to you if I find any weird stuff that we could prevent.

Oh and of course as Eric said, some lubrication on the plastic gears might also make things better. I think I have some thick lubricant that will not get splashed away by the speed of the gears.

One other thing was suggested earlier too. To use short twisted pair cables for each motor.

The last was something I came across reading past posts, where Tibi suggested that bigger voltage usage is possible for the motors, with the limitation that the chips will run hotter and will need heatsinks. I don t know if this is possible and within what limits, so I will need your opinion in this one before I test it.

Separating the digital PSU from the motors seems to have a dual effect. Obviously cleaner operation of the digital stuff and more efficient operation of the motors (if it s actual a positive influence, since Igor a few pages back was loving his slow sled)

My question now is how much of the big improvement is due to cleaner digitals and how much due to more efficient motors...

And since testing by Jarek and Eric showed that slowing down the motors with 100nF caps worsens things, my mind kind of goes towards finding more ways to make the sled even faster and more accurate.

One was already suggested by Tibi, to use even smaller polysterine caps like 1nF to suppress noise but not slow them significantly. Although the spindle motor's changes in speed are slower than the sled's, so I would expect it to behave better with the bigger cap. I will try to check the motors on the scope and get back to you if I find any weird stuff that we could prevent.

Oh and of course as Eric said, some lubrication on the plastic gears might also make things better. I think I have some thick lubricant that will not get splashed away by the speed of the gears.

One other thing was suggested earlier too. To use short twisted pair cables for each motor.

The last was something I came across reading past posts, where Tibi suggested that bigger voltage usage is possible for the motors, with the limitation that the chips will run hotter and will need heatsinks. I don t know if this is possible and within what limits, so I will need your opinion in this one before I test it.

Tony pre-drilling the wood and using screws with thin and wide threading should allow you to fasten it without problems.

Tony pre-drilling the wood and using screws with thin and wide threading should allow you to fasten it without problems.

Yes, that might work. I'm a little worried about splintering the poplar, drilling so close to the edge. I've learned that Red Oak (the sides and front) can get surface splinters very easily, even when using very nice Bosch drill bits.

Drill from the inside and put some scrap on the out side to avoid tearing by the drill when it comes out

For anyone interested, attached you can find the settings I used for the salas psu.

Leds are 4 reds and one green (1,9V and 2,1V)

For R101 I used Caddock mp930

For filters I used Panasonic FRs, 1000uF in the led filter and 47uF electrolytic in the output (no zobel)

Main cap is a 10000uF panasonic at 50V (F5T leftover 😀 )

Hi,

What is your current setting on the Salas shunt reg?

By the way, I have just removed L4 and fed 5V to V4 through a Salas PSU giving 340mA.

Results? Two words for you....

HOLLY BATMAN!!!!!!!

Clarity is in a completely new level... Like going from 300euro player into 10000euro one... 😛

It s the biggest upgrade I have seen all day.

Hi,

Where is the best place to connect the ground of the Salas PSU to for the 5V?

Check the excel for full details for the psu.

Full consumption setting is about 350mA for ~200mA needed

I connected the ground to the one of the 7808 psu.

Full consumption setting is about 350mA for ~200mA needed

I connected the ground to the one of the 7808 psu.

I have applied some thick general purpose grease to the plastic gears. I like this kind of grease for plastic stuff (used it a lot on my RC car with no problems). It stays where you put it and does not run or spill, and it is very easy to wipe any excess build-up with a cloth. Plus I haven t seen it dry yet, even after many many years...

I m sure there are many specialized greases out there, so I bet you can find something more suitable if you try. Especially for the metal bar of the sled.

Anyway, the movement of the sled is now really smooth and almost silent.

On the actual music side, the effect was rather subtle but I perceive it as an increase in the speed of dynamics, more obvious in drum sounds.

Like when the ride cymbal is hit along with the bass drum in many pink floyd songs. Their timing now seems almost perfect, giving you a very nice feeling

I m sure there are many specialized greases out there, so I bet you can find something more suitable if you try. Especially for the metal bar of the sled.

Anyway, the movement of the sled is now really smooth and almost silent.

On the actual music side, the effect was rather subtle but I perceive it as an increase in the speed of dynamics, more obvious in drum sounds.

Like when the ride cymbal is hit along with the bass drum in many pink floyd songs. Their timing now seems almost perfect, giving you a very nice feeling

I have applied some thick general purpose grease to the plastic gears. I like this kind of grease for plastic stuff (used it a lot on my RC car with no problems)....

Anyway, the movement of the sled is now really smooth and almost silent.

On the actual music side, the effect was rather subtle but I perceive it as an increase in the speed of dynamics, more obvious in drum sounds.

Interesting. I have similar sorts of lubricants that I use for model railroading. Worth a try. 🙂

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story