..today the third layer unbleached cotton...again take care that you have a thread following up your "cotton-turns" which need evenly dividing.

Each layer should be cut approximately 2-3 cm wide NOT WIDER.....and as long as possible....when wider you do not get it nicely fit on the silver.

The silk can easily be torn apart over a full lenght you do not need to worry.

Each layer should be cut approximately 2-3 cm wide NOT WIDER.....and as long as possible....when wider you do not get it nicely fit on the silver.

The silk can easily be torn apart over a full lenght you do not need to worry.

Attachments

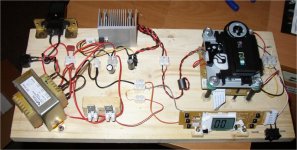

When I close the door switch, lens starts to move. It's ok, the problem is that it doesn't stop. When it arrives at the end (yellow arrow), motor (black arrow) continues to spin and the two white wheels (red arrows) start to sound very badly, and if I insist cogs will be damaged.

Can anyone help me?

Can anyone help me?

Attachments

m.massimo said:When I close the door switch, lens starts to move. It's ok, the problem is that it doesn't stop. When it arrives at the end (yellow arrow), motor (black arrow) continues to spin and the two white wheels (red arrows) start to sound very badly, and if I insist cogs will be damaged.

Can anyone help me?

Check the position of the limit switch, if the small rod like detail on the bottom of the sled does not contact the switch at end of travel, what you describe will be the result. Hopefully you have not removed it, damaged it, or obstructed it.. I bet there is something in the way like a capacitor for example.

Yes, there is a plastic bit on the laser sled that hits against a switch (clear plastic on the bottom PCB). If you spearated the PCB from the motors - and it looks like you did - thats your problem.

I sorted mine by drilling a tiny hole into the laser sled in the right place and then gluing in a piece of stiff wire. End of a 3W resistor or bit of cut off wire from a cap will work perfectly. You can bend it one the glue is set to tweak the stop setting. The switch doesn't take much force to act.

Fran

I sorted mine by drilling a tiny hole into the laser sled in the right place and then gluing in a piece of stiff wire. End of a 3W resistor or bit of cut off wire from a cap will work perfectly. You can bend it one the glue is set to tweak the stop setting. The switch doesn't take much force to act.

Fran

...very resourceful solution Fran.

The 2 answers are definitely the solution to your problem, but as Kevin says be careful I find the switch very vulnarable.

Sorry not to respond sooner but after I placed my pics I could not enlarge your photo''s to get a good look.....later on ...I found out that it was only a small problem..... I was no longer on line...

The 2 answers are definitely the solution to your problem, but as Kevin says be careful I find the switch very vulnarable.

Sorry not to respond sooner but after I placed my pics I could not enlarge your photo''s to get a good look.....later on ...I found out that it was only a small problem..... I was no longer on line...

Thank you guys for your analisys, it's correct.

Yes, I separated the board from motors plate in order to be ready for caps swap in the next step of this project. I didn't realize the new relative position of the microswitch. To say the truth, I didnt' realize the job of the switch!

However, everything is intact.

Yes, I separated the board from motors plate in order to be ready for caps swap in the next step of this project. I didn't realize the new relative position of the microswitch. To say the truth, I didnt' realize the job of the switch!

However, everything is intact.

Attachments

closing the switch manually with a screwdriver and everything work fine.

Fran solution is really interesting. I'll take into account. I'd like to add a sort of extension to the plastic bit. The switch is very easy to close, so a little bit of plastic glued to the original should be sufficient.

Thank you

Fran solution is really interesting. I'll take into account. I'd like to add a sort of extension to the plastic bit. The switch is very easy to close, so a little bit of plastic glued to the original should be sufficient.

Thank you

Attachments

I'm listening one of my favorite cd: Bobby Watson "Appointment in Milano" Red Records. I should say that shigaclone works very well, and it's the stock board and new. Next days a more comprehensive review.

Dout series 294, shunt 100

Thank you all guys for this little gem.

Dout series 294, shunt 100

Thank you all guys for this little gem.

Attachments

tubee said:What bothers me is the long cd shaft.....

Looks can be deceiving 😉 Besides, when screw on version of disc holder is installed, it goes over whole length of the shaft and the potential shaft length problem becomes less critical.

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story