Outside of the wiring, what else didn't you like about your monos?I don't like monoblocks. They're ungainly, wires everywhere.

Hi All,

So I've built a F5M, took my time with the biasing, getting it stable @ 517/-3 and 519/+1 for a good 20 mins.

Moving to my existing stereo system, I've played some music but with some old speakers, volume about 4/10. I connect up the F5M and heard nothing, turn it to about 9/10 and if i place my ear near the speaker, hear faint/distorted music.

Is there any quick checks I can run before I put it apart and re-do any solder not perfect??

that close..... sigh!

thx!

So I've built a F5M, took my time with the biasing, getting it stable @ 517/-3 and 519/+1 for a good 20 mins.

Moving to my existing stereo system, I've played some music but with some old speakers, volume about 4/10. I connect up the F5M and heard nothing, turn it to about 9/10 and if i place my ear near the speaker, hear faint/distorted music.

Is there any quick checks I can run before I put it apart and re-do any solder not perfect??

that close..... sigh!

thx!

Last edited:

Post pics of your build from various angles.

First thing I'd check is to see if the full signal is getting to the amp boards. I like to use a phone / signal generator app as a source to make life a little easier.

First thing I'd check is to see if the full signal is getting to the amp boards. I like to use a phone / signal generator app as a source to make life a little easier.

As a general matter, I was taught that one starts by verifying power (which you already have as you have proper bias, then verify the output connections, then input connections.

If nothing is identified, I was taught to that one approach is to apply signal at input and start moving forward until signal cannot be identified. At that point, an issue exists.

Accordingly: first verify that the amp board is properly connected to the output binding posts. Visually confirm this first; and then turn power off, and do a continuity check from each binding post to each board output pad (signal and ground).

If nothing is identified, I was taught to that one approach is to apply signal at input and start moving forward until signal cannot be identified. At that point, an issue exists.

Accordingly: first verify that the amp board is properly connected to the output binding posts. Visually confirm this first; and then turn power off, and do a continuity check from each binding post to each board output pad (signal and ground).

Last edited:

I may try to add a quick video to the build guide. Your question isn't uncommon, and I may not have been terribly clear. Mainly this and what @Halauhula suggests helps to narrow the focus of troubleshooting tremendously. Oversimplified, since your boards biased up properly:input?

- Is is something on both boards?

- Is it the wiring?

Wiring (in my experience) trips up people more often than they'd like to admit, and it's the most easy to fix, so I try to rule it out first.

-------

For me... before I put the lid on an amplifier, or even hook it up to test speakers, I do a few very basic checks with my DMM and my phone.

With an app like this (or similar) ...

https://apps.apple.com/mk/app/tone-generator-audio-sound-hz/id1206449238

I set the frequency to 60Hz and measure the voltage input using my DMM set to ACV.

- Probes literally right on the interior side of the jack.

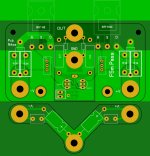

- Probes at the most convenient place on the amp PCBs that should have a full input signal. I this case... right on the "top" of R1 or R2 (see the schematic and board layout) for the signal and right on the "top" of R5 for GND.

That lets you know that your input wiring is correct if the voltages match. If they don't...

Then...

- probes literally on the binding post tabs.

The voltage multiple should be the gain of the amplifier. In this case, about 16.5 dB => 6.6X

So, if your input voltage is around 0.3VAC, then your output voltage should be around 2VAC.

Hope that helps... I typed this up pretty quickly, so if I made any errors / omissions, apologies.

I'll try to get something into the guide within a couple weeks if I have time. I am horrible at videos.

Last edited:

Hi.

I would like to build this amplifier. I have two pairs of 8.92-8.92 8.97-8.94 ma idss jfets that can be used without any modifications?

IRFP9140 or IRFP9240?

Cap multiplier PSU or classic PSU V1R1? any audible difference?

Thanks my friends .

I would like to build this amplifier. I have two pairs of 8.92-8.92 8.97-8.94 ma idss jfets that can be used without any modifications?

IRFP9140 or IRFP9240?

Cap multiplier PSU or classic PSU V1R1? any audible difference?

Thanks my friends .

Last edited:

For my system and listening style, they are unnecessary.Outside of the wiring, what else didn't you like about your monos?

Read Papa's bit on the ACA mini, and the associated thread. It has a similar push-pull architecture to the F5.Hi.

I would like to build this amplifier. I have two pairs of 8.92-8.92 8.97-8.94 ma idss jfets that can be used without any modifications?

IRFP9140 or IRFP9240?

Cap multiplier PSU or classic PSU V1R1? any audible difference?

Thanks my friends .

In it, there will be allusion to the idea that the transconductance profiles of the N and P channel output devices are what construct the sonic signature of the output. Zen Mod has said as much in his threads describing amps of similar architecture. The specific pairing of N's and P's in these kinds of output stages is important to the sound.

9140 is generally preferred unless the supplies get above +/-40v or so.

A Common Source 2nd stage usually gives a negative phase 2nd harmonic which

Is popular in your lower power amplifiers, delivering a nice soundstage.

A Common Source 2nd stage usually gives a negative phase 2nd harmonic which

Is popular in your lower power amplifiers, delivering a nice soundstage.

One more question .....

Is this amplifier compatible for 4Ω speakers ? or needs some mods to keep same harmonic profile same with 8Ω load ... ("resistors gain"?

Is this amplifier compatible for 4Ω speakers ? or needs some mods to keep same harmonic profile same with 8Ω load ... ("resistors gain"?

^ I am not sure what you mean by "made" for 4 ohm speakers. I use all three variants of mine with 4 ohm speakers quite frequently. I think it's wonderful.

How efficient are your speakers? How loud do you listen? How big is room?Is there anyone who has made this amplifier for 4 ohm speakers?

In one room I have a set of X:s XSD speakers, 4 ohm load. They are 92 dB efficient. They really like dampening factor, the F5m was at its limit. Did well at lower volumes, better than AlephJ on same speaks. BA3 drives them no problem, zenmods XA252 drove them with ease to great effect. Will be trying it's little brother, PoP next

Why not ordering the one from the DIYaudio shop?

Plus it comes with all the J & MosFets.

What is it you are trying to achieve?

Plus it comes with all the J & MosFets.

What is it you are trying to achieve?

Why not ordering the one from the DIYaudio shop?

Plus it comes with all the J & MosFets.

What is it you are trying to achieve?

DIY? maybe a better pcb?

Also i have the J & MosFets.

Plus shipping cost and import taxes.

Last edited:

Hi My name is William and I would like to share my experience as well as some lessons learned that led to the completion of my amazing sounding F5M amplifier! Thanks to @Nelsonpass @ItsAllInMyHead @birdbox and all in the awesome people in this forum

I know wiring is not as fancy and neat as other people on the forum. And sorry guys I used solid core wire for the speaker outs. Found it easy to solder.

I know wiring is not as fancy and neat as other people on the forum. And sorry guys I used solid core wire for the speaker outs. Found it easy to solder.

I almost don’t want to show the back panel I cut and drilled, but it is a cautionary tale (you’re going to get more of these in this post). Be confident you have proper technique before ever picking up a jigsaw (or your PEM mounting hole will look like mine). Also, spend a little extra and skip drilling your own holes, and instead buy the Deluxe Chassis from the diyaudio store, or Modushop (wish I knew that Modushop sold them before I made my purchase). This is a 4U 300mm chassis for reference.

The bias on my F5m is a little higher than my original target of 1.3A (.611V across the 0.47R resistor(s)) with near zero DC offset. I found it not too difficult to bring the offset to zero if you let the amp get fully warmed up and reach the point where voltage across R6/R7 stays stable, and if you not even nudge, but more so apply slight pressure on the pots in the direction towards zero offset it can coax the offset in the direction you want with minimal change in bias across R6\R7.

Now for another cautionary tale for anyone like myself who is a complete novice to amp building. Don’t take shortcuts and don’t try to speed up the process. You also need some kind of test equipment. Some people may use a Variac if that's something they have or can procure. I used a Dim Bulb Tester (DBT) because it is extremely cheap and easy to build a super basic one. All you need in order to build it is a light bulb socket, incandescent light bulb(s) and an extension cord (I used an power cable which I could plug directly into the amp). Here is an Amazon shopping list with all the parts I used: https://a.co/hFIsSQD

You can build it by wiring the bulb socket in series with the hot wire of an extension cord (if you don't know what that means, then definitely ask before you start fabricating it). I recommend soldering the wires together (although a good crimp technique is also feasible), use heat shrink over the soldered connection, and fold the socket wiring over itself and tape it down with lots of electrical tape to prevent movement or anything getting yanked.

How a DBT works is it is a current limiting device that basically will let you know if you have any shorts without having to find out from the smoke leaving your amp. If you don’t have a short the bulb will glow and quickly dim (from the capacitors in the PSU charging up). If you do have a short the bulb will glow brightly and will sustain the glow indicating you need to power down and troubleshoot.

Whenever I get around to completing my Aleph J Zen Mod build, I will explain why I came to the conclusion that a DBT, or some kind of limiting or test equipment, is needed.

Here's another precautionary tale which led me to having to replace a few parts of the F5m boards during my first attempt (thanks to @birdbox for being generous enough to supply some spare parts). I don’t know if my MOSFETs were not screwed down tight enough (I was able to turn the big fender washer which is a sign the MOSFET wasn't tightened down firmly), or if there was a short to the heat sink. I don’t know for sure, but the DBT didn’t indicate a short before I applied power. However, in the midst of biasing the left channel PCB, I had left the room shortly after making an adjustment, and when I came back there was light smoke and a burnt up MOSFET and two resistors that looked like they have seen better days. My theory is that I may have made too big of an adjustment on the pots and it caused the voltage to rise too high beyond what the board could handle, however, it was also suggested a slightly loose MOSFET would overheat quickly and be the cause of releasing the magic smoke. My conclusion and lesson learned is to be careful to make sure there are no potential shorts, the MOSFETs are screwed down tight, electrically insulated from the heatsink, and when you make adjustments to bias, make small adjustments. Carefully watch what is going on for a few minutes to make sure nothing goes out of wack (runaway), and if it does you can quickly bring it back down, or quickly shut off power if you need to.

I will also share this just for anyone that this could potentially help. Make sure you don’t have shorts between input pair. I had no sound for a minute until I contacted @birdbox who pointed out I had a short on my Neutrik RCA post. Once I removed the solder short, then music played.

If you are able to take all of these precautions and most importantly FOLLOW THE BUILD GUIDES and read them 5x over (if you have to). If you follow the build guide and take your time to do it right the first time, you will be enjoying the best sounding amp (at least that I have ever heard) like I am right now! Thank you all for being so kind and generous and for helping me out with my total noob-ness. Thank you!

I almost don’t want to show the back panel I cut and drilled, but it is a cautionary tale (you’re going to get more of these in this post). Be confident you have proper technique before ever picking up a jigsaw (or your PEM mounting hole will look like mine). Also, spend a little extra and skip drilling your own holes, and instead buy the Deluxe Chassis from the diyaudio store, or Modushop (wish I knew that Modushop sold them before I made my purchase). This is a 4U 300mm chassis for reference.

The bias on my F5m is a little higher than my original target of 1.3A (.611V across the 0.47R resistor(s)) with near zero DC offset. I found it not too difficult to bring the offset to zero if you let the amp get fully warmed up and reach the point where voltage across R6/R7 stays stable, and if you not even nudge, but more so apply slight pressure on the pots in the direction towards zero offset it can coax the offset in the direction you want with minimal change in bias across R6\R7.

Now for another cautionary tale for anyone like myself who is a complete novice to amp building. Don’t take shortcuts and don’t try to speed up the process. You also need some kind of test equipment. Some people may use a Variac if that's something they have or can procure. I used a Dim Bulb Tester (DBT) because it is extremely cheap and easy to build a super basic one. All you need in order to build it is a light bulb socket, incandescent light bulb(s) and an extension cord (I used an power cable which I could plug directly into the amp). Here is an Amazon shopping list with all the parts I used: https://a.co/hFIsSQD

You can build it by wiring the bulb socket in series with the hot wire of an extension cord (if you don't know what that means, then definitely ask before you start fabricating it). I recommend soldering the wires together (although a good crimp technique is also feasible), use heat shrink over the soldered connection, and fold the socket wiring over itself and tape it down with lots of electrical tape to prevent movement or anything getting yanked.

How a DBT works is it is a current limiting device that basically will let you know if you have any shorts without having to find out from the smoke leaving your amp. If you don’t have a short the bulb will glow and quickly dim (from the capacitors in the PSU charging up). If you do have a short the bulb will glow brightly and will sustain the glow indicating you need to power down and troubleshoot.

Whenever I get around to completing my Aleph J Zen Mod build, I will explain why I came to the conclusion that a DBT, or some kind of limiting or test equipment, is needed.

Here's another precautionary tale which led me to having to replace a few parts of the F5m boards during my first attempt (thanks to @birdbox for being generous enough to supply some spare parts). I don’t know if my MOSFETs were not screwed down tight enough (I was able to turn the big fender washer which is a sign the MOSFET wasn't tightened down firmly), or if there was a short to the heat sink. I don’t know for sure, but the DBT didn’t indicate a short before I applied power. However, in the midst of biasing the left channel PCB, I had left the room shortly after making an adjustment, and when I came back there was light smoke and a burnt up MOSFET and two resistors that looked like they have seen better days. My theory is that I may have made too big of an adjustment on the pots and it caused the voltage to rise too high beyond what the board could handle, however, it was also suggested a slightly loose MOSFET would overheat quickly and be the cause of releasing the magic smoke. My conclusion and lesson learned is to be careful to make sure there are no potential shorts, the MOSFETs are screwed down tight, electrically insulated from the heatsink, and when you make adjustments to bias, make small adjustments. Carefully watch what is going on for a few minutes to make sure nothing goes out of wack (runaway), and if it does you can quickly bring it back down, or quickly shut off power if you need to.

I will also share this just for anyone that this could potentially help. Make sure you don’t have shorts between input pair. I had no sound for a minute until I contacted @birdbox who pointed out I had a short on my Neutrik RCA post. Once I removed the solder short, then music played.

If you are able to take all of these precautions and most importantly FOLLOW THE BUILD GUIDES and read them 5x over (if you have to). If you follow the build guide and take your time to do it right the first time, you will be enjoying the best sounding amp (at least that I have ever heard) like I am right now! Thank you all for being so kind and generous and for helping me out with my total noob-ness. Thank you!

^ Congratulations! Well done. In my opinion, it's pretty fantastic how you stuck with it and got your first First Watt up and running. Don't sweat the small stuff. Metal work.... argh. Some folks make it look easy. You should see the first back panel I tried to do for a pre-amplifier.

Congratulations for your amplifier.my amazing sounding F5M amplifier!

Can you tell us a few words more about how its sounding?

Last edited:

- Home

- Amplifiers

- Pass Labs

- F5m kit