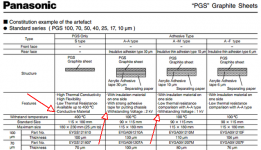

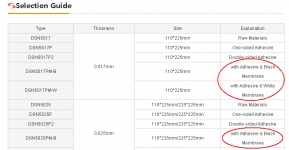

Out of looking for something better than MICA i found this:

http://industrial.panasonic.com/www-data/pdf/AYA0000/AYA0000CE2.pdf

Digikey has it. The specs are beyond impressive : 1950 W/(m·K) conductivity !

But at $27 a pad....

Not so bad, I'm seeing that price per sheet not pad. Several pads can be cut from a 90 X 110 mm sheet (as one example).

Steve Z

Did a quick calc with IRFP240 dims on a little larger sheet and got 34 pads @ ~ $0.97. Might be worth investigating if planning to do several amps - or a couple members doing a split.

Last edited:

Use a copper that is .250 inches thick and use clamps over the device instead of the through hole. The .250 thick allows for tapped holes for the clamp.

jn

jn

Yea, I saw that also. Looks like A-A type could be the minimum used, but not sure which orientation of the paper would be best. Though "Withstand 1K - 2K voltage" is impressive.

Attachments

Last edited:

Panasonic film looks like its electrically conductive ?

Yes, but when I did some math, for a piece of 18mm x 21mm of 50um thick PGS with electrical conductivity of 10000S/cm, the resistance is 1.3x10^-7 Ohms. (0.00000013 Ohms)

Somebody check my math!?

10^-3 x 10^-3 / 10^-6 =1

(18 * 21)/50 = (36 * 21)/100 = 7.56m

10000S/cm = 10^4 S/cm = 10^6 S/m

1/7.5 = 2/15 = 4/30 = 0.133

7.56 differs 7.5 by 0.8%.

1/7.56 ~ 0.132

0.132 * 10^-6 ~ 1.32 *10^-7 ohm.

(18 * 21)/50 = (36 * 21)/100 = 7.56m

10000S/cm = 10^4 S/cm = 10^6 S/m

1/7.5 = 2/15 = 4/30 = 0.133

7.56 differs 7.5 by 0.8%.

1/7.56 ~ 0.132

0.132 * 10^-6 ~ 1.32 *10^-7 ohm.

it has been confirmed that it works

maybe the added goo grease does the trick

but they also say just one little tiny 'something' jammed between device an heatsink, and it may all be over fast

other than that, I wonder if the very low insulation resistance could cause instability issues ?

maybe the added goo grease does the trick

but they also say just one little tiny 'something' jammed between device an heatsink, and it may all be over fast

other than that, I wonder if the very low insulation resistance could cause instability issues ?

very good

but a big problem is still the usual uneven heatsink surface

might be the worst problem of all

but light sanding of back of transistors matching the bent heatsink might work

but a big problem is still the usual uneven heatsink surface

might be the worst problem of all

but light sanding of back of transistors matching the bent heatsink might work

I suspect that membrane might be more compliant than mica as the product is stated to 'flexible' - not sure. I usually scrape the heatsink stock I get from HS-USA with an old fashioned single edge razor blade, comes out close to a mirror surface. Never used any of the pieces from the forum store so I don't know how smooth they are.

Here is a good source for heatsink insulator techniques

ESP - Heatsink design and transistor mounting

ESP - Heatsink design and transistor mounting

Decision - Alu Oxide vs Mica pads

I purchased some Alu Oxide pads for the IRFP's

They are 2mm thick and have a thermal conductivity of 15.06 W/mK at 75°C

On the other hand Mica is 0.05 to 0.1mm thick (random) and has crappy thermal conductivity in the range of 0.5 W/mK

That means that if my Mica is 0.05mm then they are 40 times thinner but if they are 0.1mm they are only 20 times thinner.

One one hand they could be 50% worse than the AlO (if Mica is thick) or 50% better (if Mica is thin) in terms of thermal conductivity.

With the AlO there would be some risk of cracking them, but they look nice 🙂

Safe route (Mica) or AlO?

I purchased some Alu Oxide pads for the IRFP's

They are 2mm thick and have a thermal conductivity of 15.06 W/mK at 75°C

On the other hand Mica is 0.05 to 0.1mm thick (random) and has crappy thermal conductivity in the range of 0.5 W/mK

That means that if my Mica is 0.05mm then they are 40 times thinner but if they are 0.1mm they are only 20 times thinner.

One one hand they could be 50% worse than the AlO (if Mica is thick) or 50% better (if Mica is thin) in terms of thermal conductivity.

With the AlO there would be some risk of cracking them, but they look nice 🙂

Safe route (Mica) or AlO?

Great article !

Thanks !

Thanks !

Problem is that my Al2O3 are 2mm think hence close to the Mica... (since their conductivity will halve ? compared to the 1mm in the table p25)

At the size of To-247, I can only find 2mm thick insulators.

The Keratherm 86/82 seems hard to get ...

At the size of To-247, I can only find 2mm thick insulators.

The Keratherm 86/82 seems hard to get ...

Alternative is to look for the best mica and shave it as thin as you can.

Mica quality varies, depending on the origin location.

Does require patience and a steady hand.

(by coincidence, I eyeballed a lot of mica at the geology faculty of the Amsterdam university, studied physical geography there)

Mica quality varies, depending on the origin location.

Does require patience and a steady hand.

(by coincidence, I eyeballed a lot of mica at the geology faculty of the Amsterdam university, studied physical geography there)

Thanks for the link.

But Out of Stock - no news since Sept 2013

But Out of Stock - no news since Sept 2013

- Home

- Amplifiers

- Pass Labs

- F5 power amplifier