Was inspired by XRK's measurements of the 10f/8424 in his Dagger closed-taper-TL so wanted to try to build one. But inspiration got the better of me (and some scrap EVA) which just begged me to try to make an aperiodic (fully stuffed) mini-TL for my SB65 and see if I can find an enclosure to make them happy.

So in honor of the Dagger-TL I present the Cannoli-TL (lol). This really is just for fun, but also to get some practical experience with rolled EVA and aperiodic TLs.

Another cool experiment. 😀 I assume you are using some sort of subwoofer or bass module with this?

The thing I can't avoid thinking about these EVA 'cabinets', is that they look like Muppets. Not that that is bad. I would have a hard time resisting the temptation to add a couple of eyes.

.....

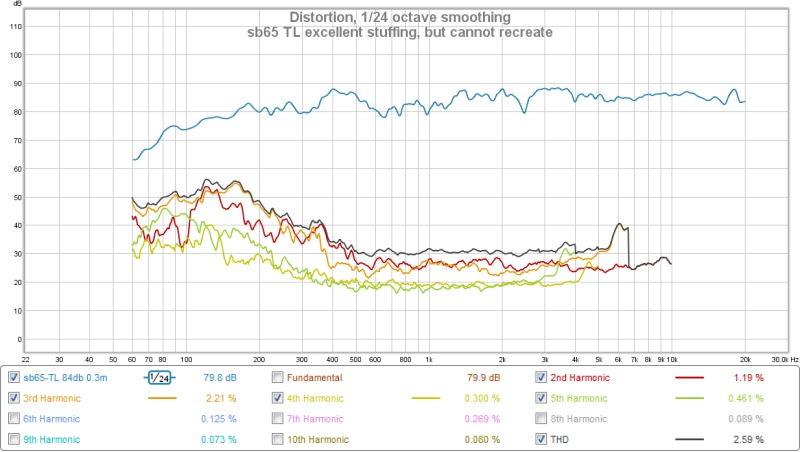

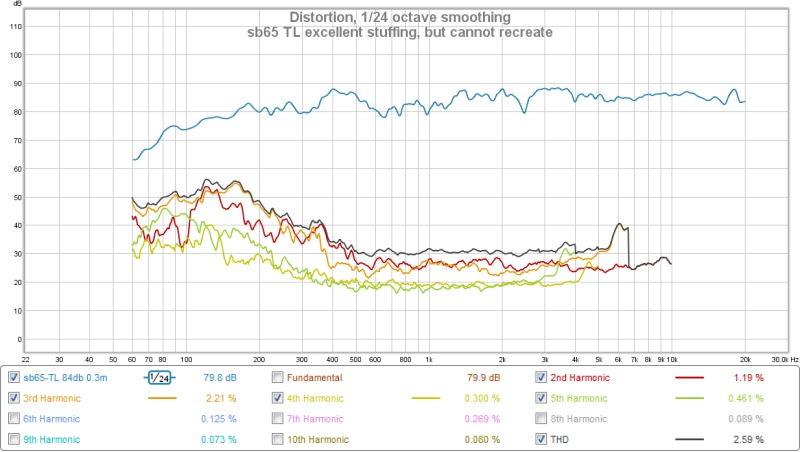

Here is the early measurement which I could not recreate. Seems after this there was always an elevated 3rd HD in the low frequencies which I could not get ride of

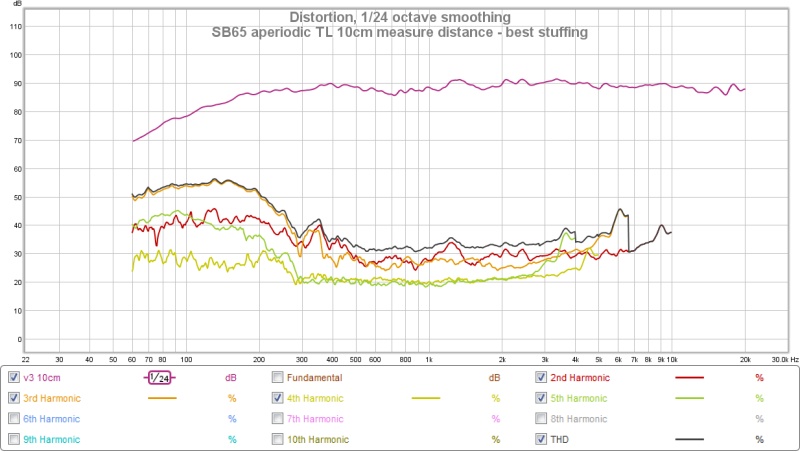

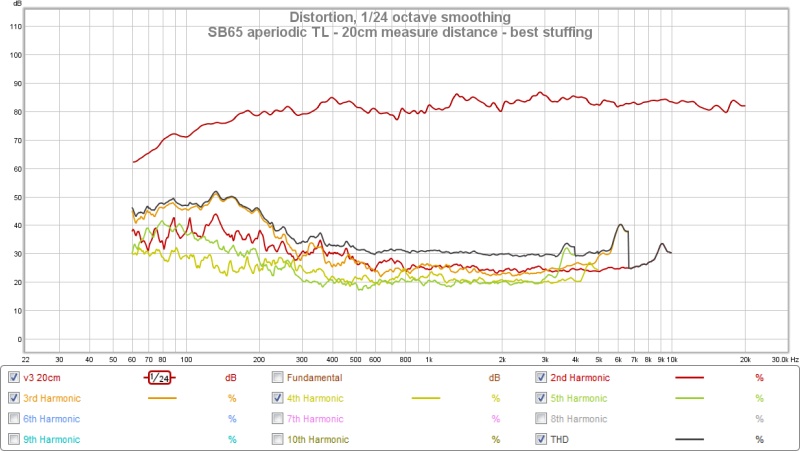

Here is the best I could recreate and what I am going to keep now

.....

Plot "the best i could recreate" seems like having FRQ response EQed compared plot "cannot recreate" speculate if that EQ is turned off maybe it gets closer to missed one.

Cool test.

The problem with this sort of testing is deciding what the goal is, in other words what is the ideal characteristic of cabinet panel. Low resonance is obviously important, but it's not the only thing. If it was than silicone rubber would be best, or for that matter Play-Doh. As is often the case, the theoretical ideal panel would possess diametrically opposed qualities of infinite stiffness, infinite damping and infinite mass. That said, I think it has been demonstrated that lossy, low mass materials can work surprisingly well in certain situations, especially if bass extension is not required.

FYI there have been a of panel tests published in the past, unsurprisingly. I recall one in Audioxpress about 10-15 years ago that basically concluded that all common speaker panel materials resonate rather more severely than might be expected. IIRC, the best performers were constrained layer constructions, which again, is not surprising.

I agree that most common speaker panel materials resonate rather severely and that constrained layer construction is an excellent performer. What I hope to explore is some unconventional speaker materials.

If we step back and think about what an enclosure should do, I think it really only has two purposes

1) to define a volume of air

2) to absorb all the back energy of the driver

So I think the ideal enclosure should be defined by what it does rather than how it should be made. So to expand, I think the ideal enclosure should be

- zero resonance

- infinite sound absorption

I don't think that infinite stiffness and infinite mass are actually ideal quality. I would think that a zero mass enclosure would be more ideal than one made from a black hole. I think high mass enclosures are preferred now because of how they effect box resonance, not because high mass has any inherently ideal acoustic quality. The same with stiffness, but of course we need enough stiffness to have structure to define the volume of air. Stiffer panels will shift the resonant frequency to higher frequencies in the same way that tightening the skin of a drum makes it higher pitch (this was shown by the early celestion speakers which are very high stiffness). But higher mass can also lead to energy retention (which was shown in the celestion research), which can lead to delayed energy release causing ringing and time delay effects.

And I disagree that low mass material like EVA foam or XPS foam can not do a bass enclosure. Again I think the "common consensus" that bass speakers need to be high mass and high stiffness is that this works reasonably well for creating low resonance in a bass speaker. But that does not make high mass ideal.

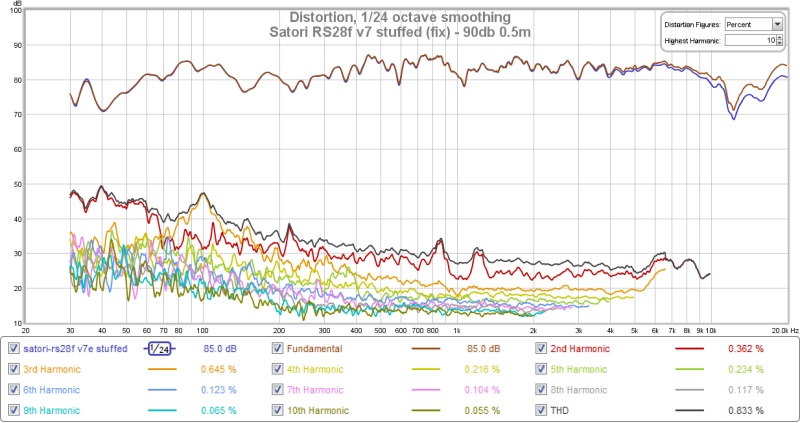

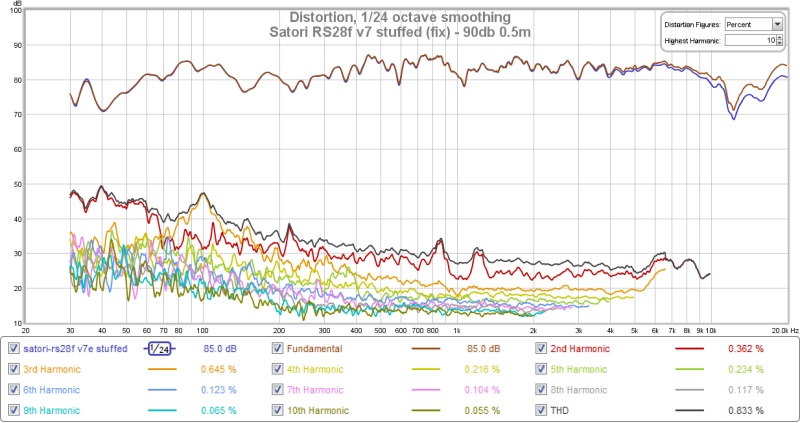

Look at my Satori/RS28f speaker. This speaker is a sealed box (most difficult enclosure type to deal with bass) and with my LinkWitz transform I an getting basically flat to 35hz (I have a room mode at 40hz which sucks out the bass a little with every speaker I use) with very well controlled distortion.

What I want to explore here is some "Out of box" thinking (sorry no pun intended) to rethink what an ideal enclosure should be and then to open up the possibilities for other unconventional materials which might end up more "ideal".

And as an aside, my favorite speakers still are my acoustat 1+1 electrostatic loudspeakers which are boxless: a perimeter frame holds the electrostatic panels suspended in air. And these speakers can output serious high SPL bass (without a subwoofer) easily down to 30hz range in my room, which is very musical and tuneful. So I do appreciate the uncolored "boxless" sound, and thus have a very high "ideal" to which I compare my diy speaker projects.

And these panel resonance tests are very preliminary and I want to complement them with transmission/transparancy tests and reflection tests.

At this point, I hope that these tests just shows that EVA is showing some interesting properties worth further exploration.

Another cool experiment. 😀 I assume you are using some sort of subwoofer or bass module with this?

The thing I can't avoid thinking about these EVA 'cabinets', is that they look like Muppets. Not that that is bad. I would have a hard time resisting the temptation to add a couple of eyes.

Actually I am not using a subwoofer/bass module with these small speakers. My goal with my fullrange speakers (ff105wk, 10f, sb65) is to create something like the old LS3/5a which was considered ideal for mixing and tracking vocals and acoustic instruments. The LS3/5a only really covered 100-20khz flat response but had pristine midrange/treble. By going with a modern single-driver (and avoid all crossovers, even to a subwoofer), I hope to get even better. I have other speakers which I use when I want 50-20khz or 30-20khz range. I don't need one-speaker-to-rule-them-all🙄

And yes this enclosure in particular (especially the rear vent) does look like a muppet 😀. It looks a lot like a mouth with a tongue. As much as I am enjoying working with EVA and creating these white organic shapes, I realize this aesthetic might not appeal to many. At some point I will buy some black gesso and make one in black. I might also make one eventually with sharp facets, and then if that was covered in black gesso, it would look very stealth fighter or batman like. Hmmmm maybe I can make one of my small pyramids in a faceted black style rather than round/organic. Would look cool with the all black 10f/8424. OK this sounds cool and I just finished cutting EVA for some new boxes for the 10fs,

Plot "the best i could recreate" seems like having FRQ response EQed compared plot "cannot recreate" speculate if that EQ is turned off maybe it gets closer to missed one.

actually the main difference you see between the plots was the recording distance. The "cannot recreate" and "bad" were all recorded at a longer distance (20cm). My final one was recorded at 5cm, 10cm, and 20cm but I only posted the 10cm distance version.

All of them have the same EQ applied. I do a broad q1.2 -3db flattening at 2000hz and then some treatment in the 15,000hz and above region to tame the rising treble of the SB65. I think I may have adjust the 15-20khz eq slightly between the early "cannot recreate" and the final but it will only effect the 15-20khz range.

Here is the "final" one at 20cm which shows more room effects. Maybe I am playing this at 1db or 2db softer level than the early recording too. This final one was recorded after I got this working and then listened to some music and then recorded these.

and the early one

really I was just adjusting the stuffing material. Same total mass of material, just adjusting where along the tube that I packed it tightly and where I fluffed it up. Maybe I would pack tightly by the driver and then looser as I approached the vent, or tight at the vent loose by the driver, loose all along, tight all along... these sorts of adjustments. Really the frequency response difference and distortion differences are just from changing the packing density of the alpaca wool fibers.

Attachments

Last edited:

I agree that most common speaker panel materials resonate rather severely and that constrained layer construction is an excellent performer. What I hope to explore is some unconventional speaker materials.

If we step back and think about what an enclosure should do, I think it really only has two purposes

1) to define a volume of air

2) to absorb all the back energy of the driver

So I think the ideal enclosure should be defined by what it does rather than how it should be made. So to expand, I think the ideal enclosure should be

- zero resonance

- infinite sound absorption

I don't think that infinite stiffness and infinite mass are actually ideal quality. I would think that a zero mass enclosure would be more ideal than one made from a black hole. I think high mass enclosures are preferred now because of how they effect box resonance, not because high mass has any inherently ideal acoustic quality. The same with stiffness, but of course we need enough stiffness to have structure to define the volume of air. Stiffer panels will shift the resonant frequency to higher frequencies in the same way that tightening the skin of a drum makes it higher pitch (this was shown by the early celestion speakers which are very high stiffness). But higher mass can also lead to energy retention (which was shown in the celestion research), which can lead to delayed energy release causing ringing and time delay effects.

And I disagree that low mass material like EVA foam or XPS foam can not do a bass enclosure. Again I think the "common consensus" that bass speakers need to be high mass and high stiffness is that this works reasonably well for creating low resonance in a bass speaker. But that does not make high mass ideal.

Look at my Satori/RS28f speaker. This speaker is a sealed box (most difficult enclosure type to deal with bass) and with my LinkWitz transform I an getting basically flat to 35hz (I have a room mode at 40hz which sucks out the bass a little with every speaker I use) with very well controlled distortion.

What I want to explore here is some "Out of box" thinking (sorry no pun intended) to rethink what an ideal enclosure should be and then to open up the possibilities for other unconventional materials which might end up more "ideal".

And as an aside, my favorite speakers still are my acoustat 1+1 electrostatic loudspeakers which are boxless: a perimeter frame holds the electrostatic panels suspended in air. And these speakers can output serious high SPL bass (without a subwoofer) easily down to 30hz range in my room, which is very musical and tuneful. So I do appreciate the uncolored "boxless" sound, and thus have a very high "ideal" to which I compare my diy speaker projects.

And these panel resonance tests are very preliminary and I want to complement them with transmission/transparancy tests and reflection tests.

At this point, I hope that these tests just shows that EVA is showing some interesting properties worth further exploration.

I totally agree we need to think outside of the Baltic Birch and MDF "box" around here. When I first started my foam core thread nearly 3 years ago, I don't think I or anyone else would have realized how good sounding foam core speakers can sound. In many cases, they provide additional dampening of resonances, and yes they can do higher SPL bass and sub duties too. 🙂

Keep up the new explorations!

If I read the experiment right, the test panel is placed on top of the driver and then the test run. If this is so....

This is not how a panel is used in a speaker cabinet. The edges of the panel are severely restrained by the (usually) four bounding side panels. An unbounded panel is going to have totally different resonant modes than a bounded panel.

It's the same as bell modes in driver baskets. Hold a driver by the magnet and tap the basket. It will ring. Press the driver into a table and tap the basked. Not ringing. Note: I am not saying that a bounded panel won't have resonant modes, just different from an unbounded panel.

Bob

This is not how a panel is used in a speaker cabinet. The edges of the panel are severely restrained by the (usually) four bounding side panels. An unbounded panel is going to have totally different resonant modes than a bounded panel.

It's the same as bell modes in driver baskets. Hold a driver by the magnet and tap the basket. It will ring. Press the driver into a table and tap the basked. Not ringing. Note: I am not saying that a bounded panel won't have resonant modes, just different from an unbounded panel.

Bob

Another thought that might help explain my thinking. Imagine a car's suspension. The idea is to absorb all the energy and bumps from the road and not transmit that vibration into the body of the car. It does this not my making the suspension super stiff, it is a careful balance of stiffness, absorption and damping. And if we watch the wheels of a car they are actually moving up and down a lot to absorb the vibration energy of the road. Yet these vibrations are not transmitted into the car.

So maybe if we have a speaker box which flexes and moves (like the suspension of a car) to absorb and quickly damp the sound energy it might not matter if it is visually moving to do its job as long at that movement does not re-transmit sound energy. By correlation the rear sound of the driver is the road creating unwanted energy, the enclosure (walls,stuffing) is the suspension of the car, and the air outside the enclosure is the body of the car where we do not want the excess energy to be transmitted.

So maybe if we have a speaker box which flexes and moves (like the suspension of a car) to absorb and quickly damp the sound energy it might not matter if it is visually moving to do its job as long at that movement does not re-transmit sound energy. By correlation the rear sound of the driver is the road creating unwanted energy, the enclosure (walls,stuffing) is the suspension of the car, and the air outside the enclosure is the body of the car where we do not want the excess energy to be transmitted.

If I read the experiment right, the test panel is placed on top of the driver and then the test run. If this is so....

This is not how a panel is used in a speaker cabinet. The edges of the panel are severely restrained by the (usually) four bounding side panels. An unbounded panel is going to have totally different resonant modes than a bounded panel.

It's the same as bell modes in driver baskets. Hold a driver by the magnet and tap the basket. It will ring. Press the driver into a table and tap the basked. Not ringing. Note: I am not saying that a bounded panel won't have resonant modes, just different from an unbounded panel.

Bob

yes you understand this experiment correctly. And I agree that the resonance modes are different from a panel constrained by mounting on the edges. Also changing the shape of the panel or where I place the pickup microphone changes the resonance modes (frequency response pattern).

But I think the inherent absorption and damping properties of the materials can be elucidated from a test like this. Just not the actual frequency of the resonance mode. If the test is run in a consistent manner then I think the absorption and damping can be compared. And that is why I am looking mostly at the waterfall decay data not the frequency response data.

I am not really interested in the resonance modes (frequency of ringing) since I think those are more controlled by things like shape, geometry, thickness, and bracing which is true for any material used. I want to explore more intrinsic absorption and damping properties of the materials: time length and decay rate of the ringing. Then if a particular geometry which would induce a bell ringing at freq X in material 1, it might not show up in material2 because it has fast damping and strong absorption properties.

And in fact I would almost want to use the panel in a non-ideal geometry (like without boundary restraint, freely placed on top of an energy exciter) to create as many resonance frequency modes as possible.

I admit and said before that these are very preliminary tests. The panels were not the same shape (I just used what I had available). Please take this as a first exploration of the idea and some interesting preliminary data.

Right now I am thinking that a better setup would be to suspend the panel from strings and excite with just sound waves (not physically touching). Or maybe to rest the panel on some thin poles and excite with sound waves. Or maybe to use a tactile transducer instead of a speaker driver to excite vibration in the panel (tactile transducer held solid, and panel allowed to freely flex).

https://www.parts-express.com/cat/tactile-transducers-exciters-bass-shakers/18

Or maybe to build a fiberglass panel box with one open side, place driver inside and place panel gently (not bound) across the open end. Or maybe try all of these.

Any test apparatus will induce its own geometry to the panels and alter the resonance frequency modes, but as long as it is a controlled experiment then maybe we can induce the absorption and damping properties.

Last edited:

If people want me to be more scientific with these tests then need to decide on a panel geometry since I want to buy some MDF, plywood, particle board in this size. I need to have the shop cut it for me since I do not have wood tools.

Would a 300mm x 200mm panel be OK for everyone? Or will people criticize that it is too small, wrong aspect ratio....

I am thinking to get:

MDF 12mm thick

MDF 18mm or 20mm thick depending on what I can find

plywood (maybe 12mm)

particle board (maybe 12mm)

foamcore 10mm

and if someone would be willing to ship me a piece of baltic birch in this size then I can test that too. I can not find baltic birch in Tokyo.

Would a 300mm x 200mm panel be OK for everyone? Or will people criticize that it is too small, wrong aspect ratio....

I am thinking to get:

MDF 12mm thick

MDF 18mm or 20mm thick depending on what I can find

plywood (maybe 12mm)

particle board (maybe 12mm)

foamcore 10mm

and if someone would be willing to ship me a piece of baltic birch in this size then I can test that too. I can not find baltic birch in Tokyo.

yes an audio exciter like that.

But I would use it for testing absorption and damping properties of different panel materials.

I just need an energy source to induce resonance modes into the panel material. I can use sound waves, physical contact with speaker (like this preliminary test) or a tactile exciter.

But right now I am leaning toward using an FF105wk to excite the air and test panel absorption/damping of sounds from the air. Later I can test absorption/damping from physical contact (like transfer of energy from a driver mounted on a baffle).

Last edited:

If people want me to be more scientific with these tests then need to decide on a panel geometry since I want to buy some MDF, plywood, particle board in this size. I need to have the shop cut it for me since I do not have wood tools.

Would a 300mm x 200mm panel be OK for everyone? Or will people criticize that it is too small, wrong aspect ratio....

I am thinking to get:

MDF 12mm thick

MDF 18mm or 20mm thick depending on what I can find

plywood (maybe 12mm)

particle board (maybe 12mm)

foamcore 10mm

and if someone would be willing to ship me a piece of baltic birch in this size then I can test that too. I can not find baltic birch in Tokyo.

Additional CLD cases to consider:

* 10mm EVA - rubber cement - 10mm EVA CLD

* foamcore - latex caulking - foamcore CLD

* MDF - butyl rubber sheet (pond liner) bonded with contact cement - MDF CLD

* Carburized laminated bamboo (flooring material) - butyl rubber bonded with contact cement - carburized bamboo

* Honeycomb core plywood

Last edited:

X and Jeshi

The bbc on speaker cabinet walls back in 1977.

Factors in the design of loudspeaker cabinets. - BBC R&D

Might be of interest.

Jay

The bbc on speaker cabinet walls back in 1977.

Factors in the design of loudspeaker cabinets. - BBC R&D

Might be of interest.

Jay

Additional CLD cases to consider:

* 10mm EVA - rubber cement - 10mm EVA CLD

* foamcore - latex caulking - foamcore CLD

* MDF - butyl rubber sheet (pond liner) bonded with contact cement - MDF CLD

* Carburized laminated bamboo (flooring material) - butyl rubber bonded with contact cement - carburized bamboo

* Honeycomb core plywood

yes!! thank you.

Of course I will include my EVA panels 🙂

10MM EVA,

20MM EVA laminate (10mm - rubber cement - 10mm)

30mm EVA laminate (10mm - rubber cement -10mm -rubber cement - 10mm)

50mm EVA (yoga blocks solid EVA)

I would need to modify my contact microphone clip slightly to measure materials thicker than 30mm though. But it should not be difficult with a simple c-clamp.

One reason I am leaning toward 300mm x 200mm is that this is a reasonable size and seems to be about the size we would use in 10-12L boxes.

X and Jeshi

The bbc on speaker cabinet walls back in 1977.

Factors in the design of loudspeaker cabinets. - BBC R&D

Might be of interest.

Jay

thank you! I read that a long time ago, but I need to re-read in more detail.

I agree that most common speaker panel materials resonate rather severely and that constrained layer construction is an excellent performer. What I hope to explore is some unconventional speaker materials.

If we step back and think about what an enclosure should do, I think it really only has two purposes

1) to define a volume of air

2) to absorb all the back energy of the driver

So I think the ideal enclosure should be defined by what it does rather than how it should be made. So to expand, I think the ideal enclosure should be

- zero resonance

- infinite sound absorption

I don't think that infinite stiffness and infinite mass are actually ideal quality. I would think that a zero mass enclosure would be more ideal than one made from a black hole. I think high mass enclosures are preferred now because of how they effect box resonance, not because high mass has any inherently ideal acoustic quality.

The behavior of a dynamic speaker is essentially that of a motor. It pushes a diaphragm/cone assembly against the air. To push against something requires a reactive force. If a speaker had zero mass, it would not be able to push (or pull) the air. Newton's third law. Of course in real life even if an enclosure is nearly weightless, it will still make sound, but that is due to the mass of the driver structure, as well as the earth, which it is coupled to by friction and gravity.

I think if you decide that zero mass enclosure is ideal, what you have really done is decide that whatever mass that the driver happens to inherently possess is good enough. A driver and cabinet is a system really. They should be considered together. Obviously, bass will not disappear if a cabinet has no or nearly no mass, because the driver itself has mass. The lighter the enclosure/driver is, the more it is going to shake around and absorb energy that would otherwise go into the air through the cone.

Forgetting about ideals, it's pretty obvious from experience (mine and others) that very lightweight enclosures can still work. It doesn't take that much mass to oppose the weight of air. However, I have found a decrease in bass extension when building equivalent enclosures in both wood and cardboard. Sorry I've not tried foam yet. Whether or not this may be offset by other benefits or is trivial enough to ignore is an interesting question and worth exploring for sure. So I am not denigrating your approach at all. I think it is worthy of experiment.

I'm sure I could make similar arguments for and against stiffness, but my lunch is over and I have to go... 😱😀

BTW I concede your point that a speaker made out of infinite mass, ie a black hole, would not be that useful, since nothing could escape. 😉

Just think like Newton not Einstein and ignore that pesky gravity side effect.

Just think like Newton not Einstein and ignore that pesky gravity side effect.

- Home

- Loudspeakers

- Full Range

- EVA foam for performance speaker enclosures