A Jeshi inspired FF105WK TL

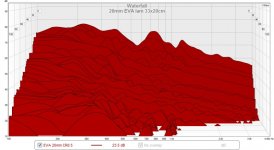

I liked the shape of Jeshi's EVA foam monitors so much, I decided to follow something similar with rounded edges and a trapezoidal baffle - this shape minimizes baffle diffraction effects. I have a set of FF105WK's that I wanted to use for this as Jeshi said she really likes how they work once some EQ is applied. However, i went for a different twist and rather than sealed, I made a tapered vent TL. The TL has a 3:2:1 proportion on the three internal passages which starts at 4in to 2.70in to 1.35in with 13in long for each segment and a 5.0in internal width. The sim on Akabak predicted a tuning frequency of 60Hz and flat response in the absence of baffle step losses.

Here is a photo of the internals before the side was capped:

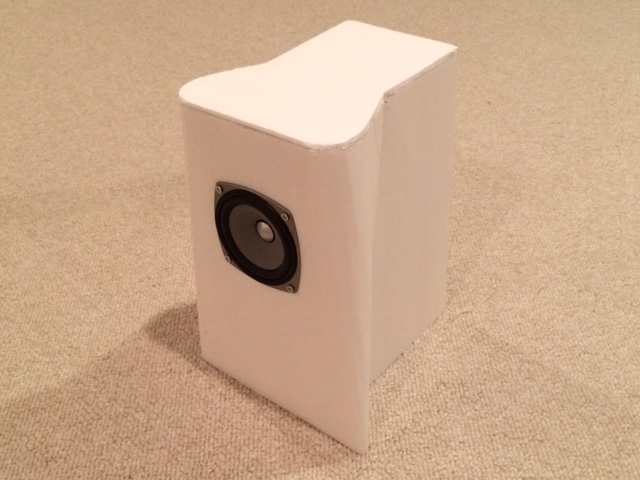

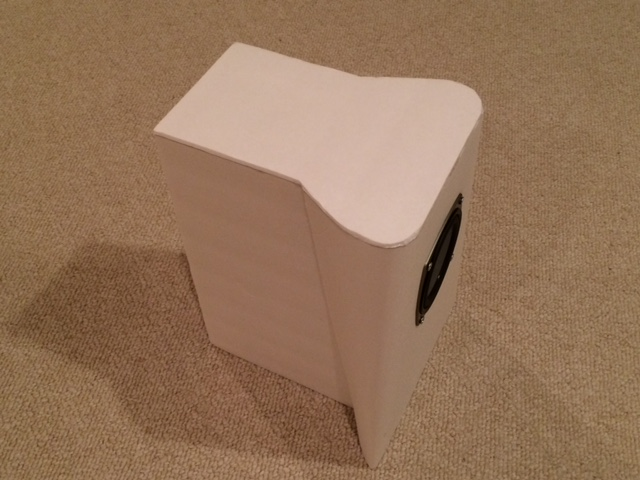

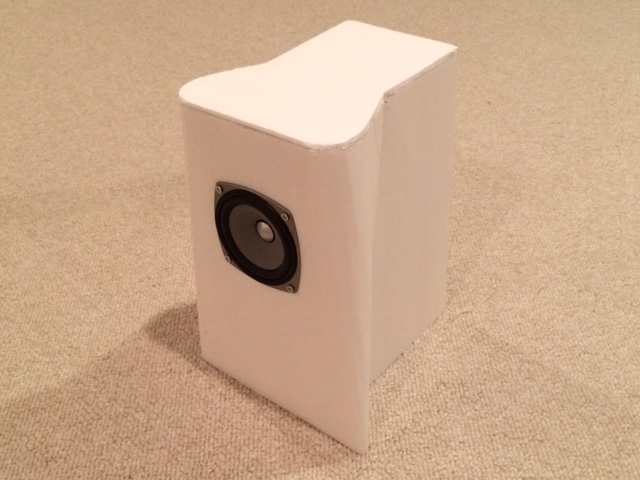

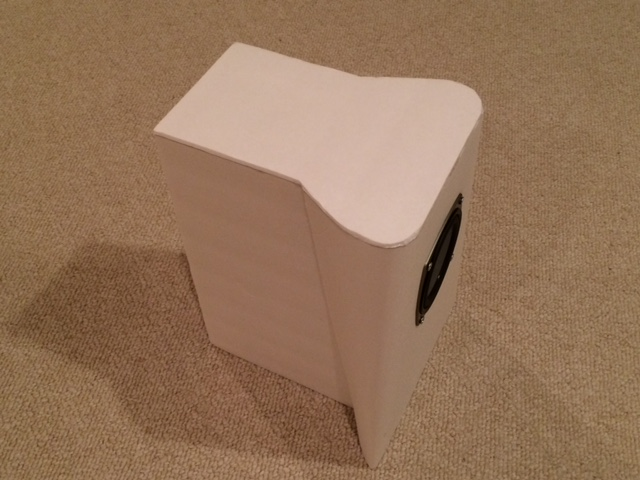

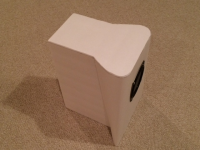

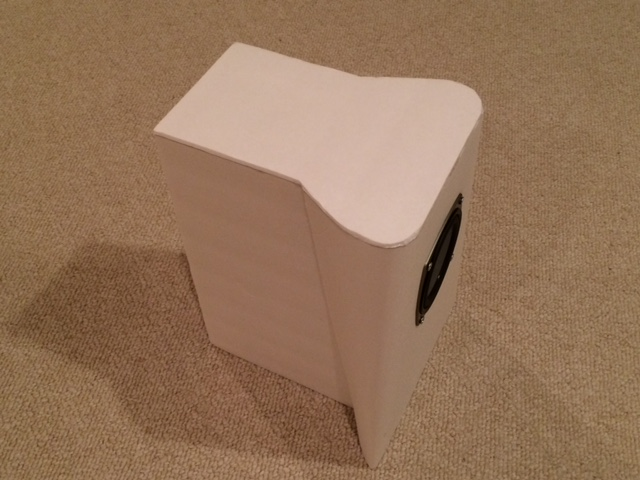

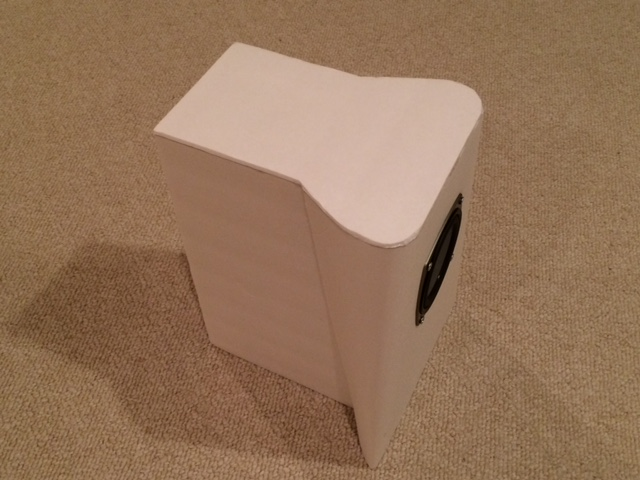

Here is the finished speaker with a compound curved baffle that has a large radius of curvature at the top and smaller at the bottom:

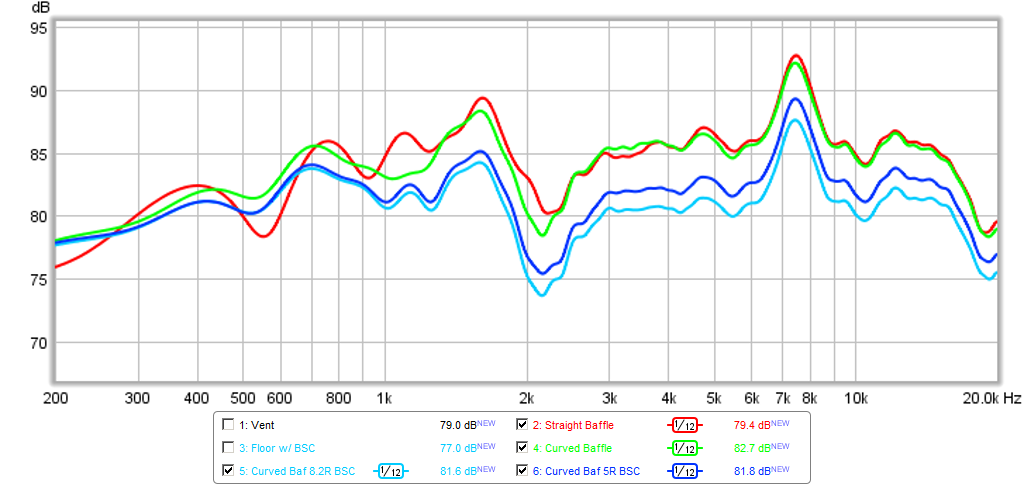

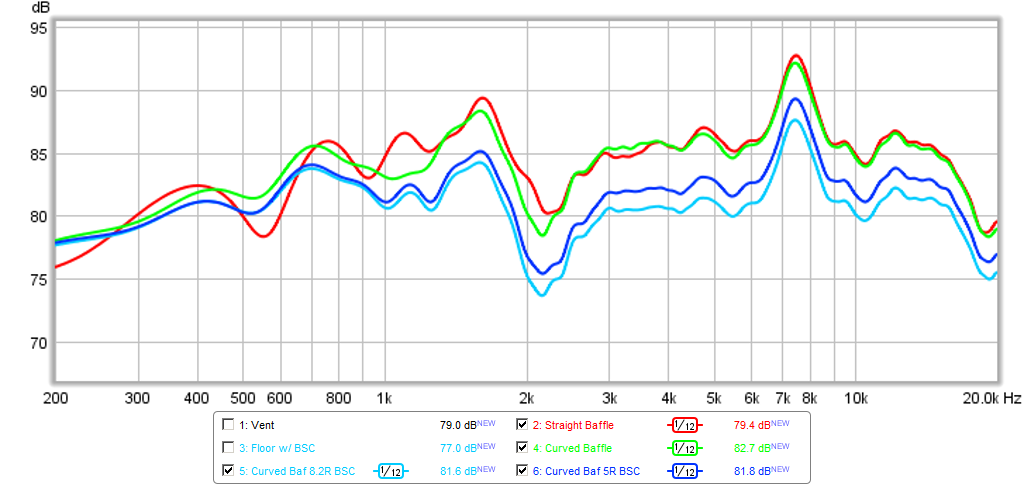

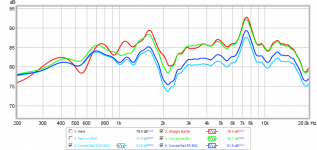

Here are the measurements before the curved baffle and with a few levels of BSC (5 ohms and 8.2ohms with a 1mH coil). I have not connected it to miniDSP yet and wanted to see how flat I could get it passively. This is with 5ms gate and mic was 0.5m away with speaker on 30in tall stand (red is before curved baffle, dark blue is with curved baffle and BSC - 1mH + 5R):

The dip at 2.1kHz and peak at 7.5kHz are inherent to the FF105WK (see manufacturer's response graph).

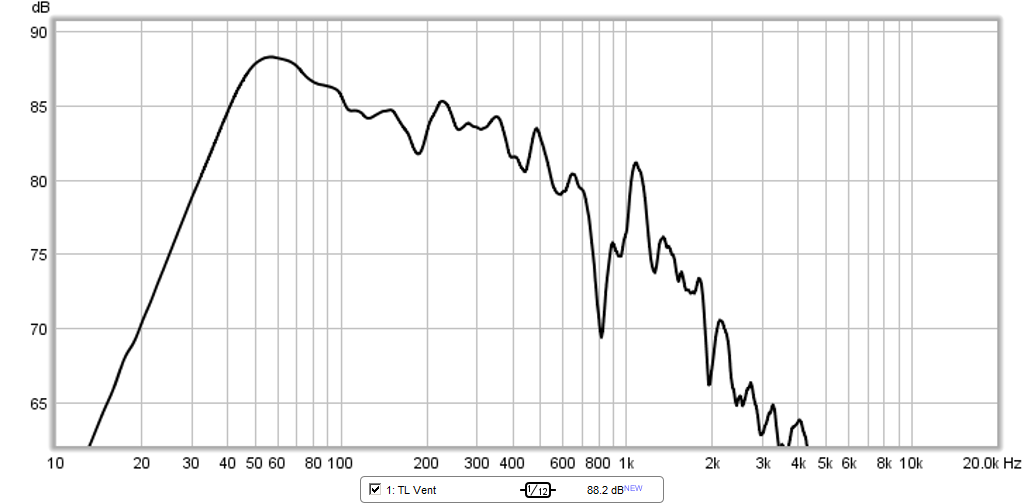

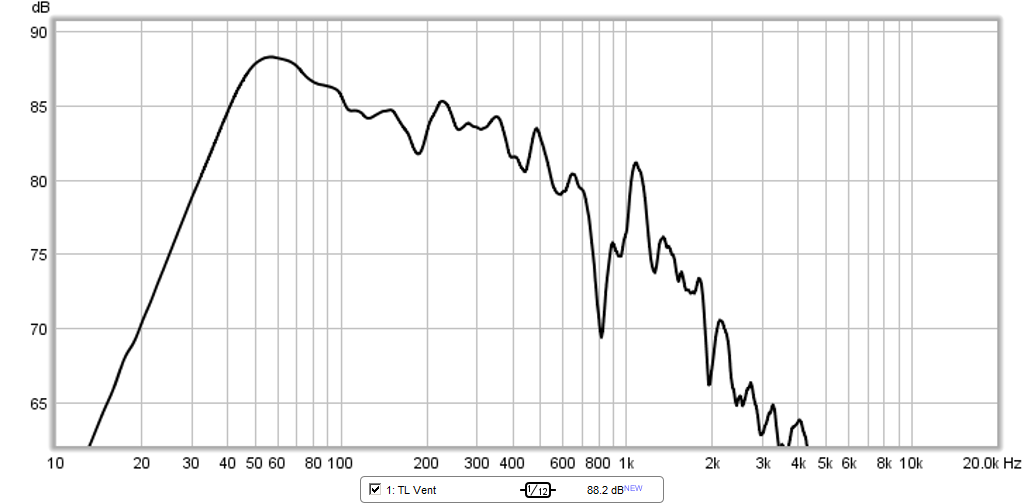

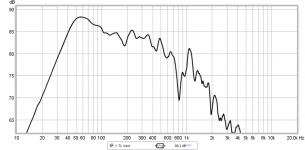

Here is the TL vent output (mic 2in from vent :

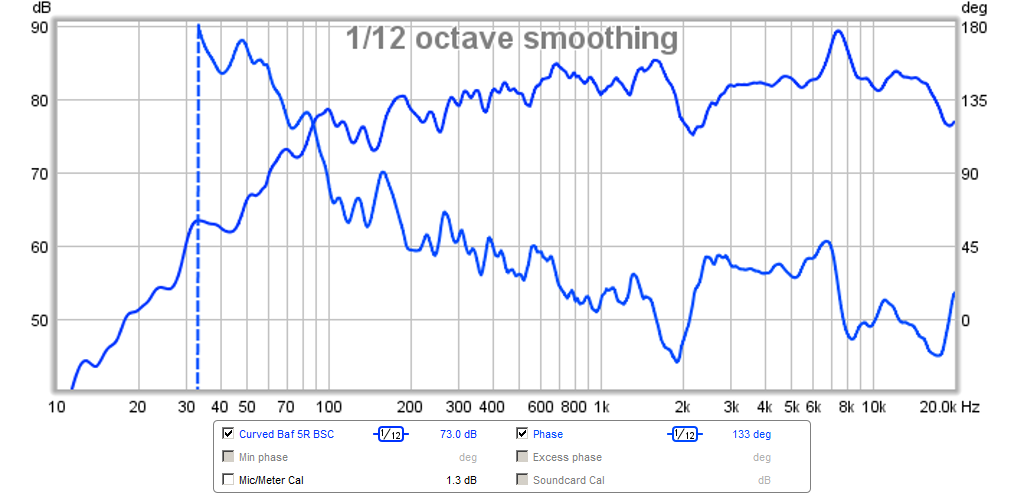

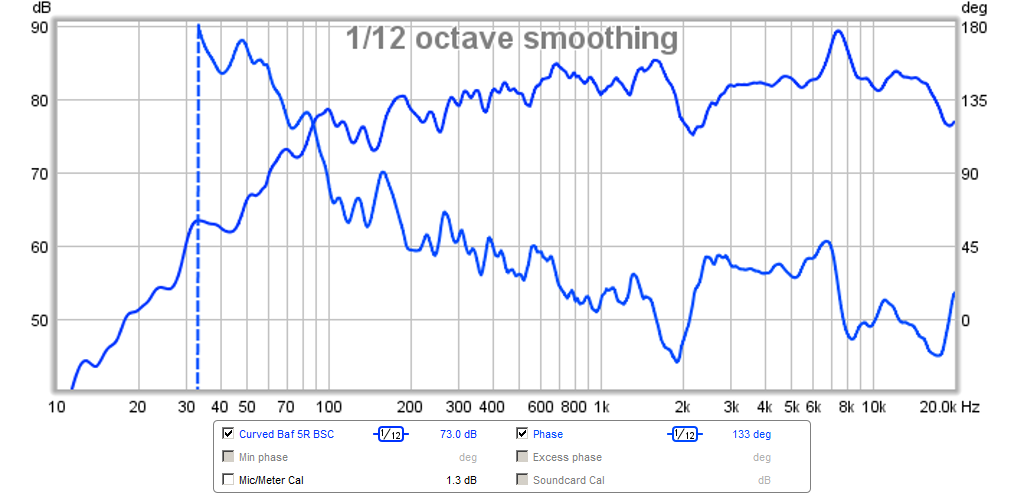

Here is the phase:

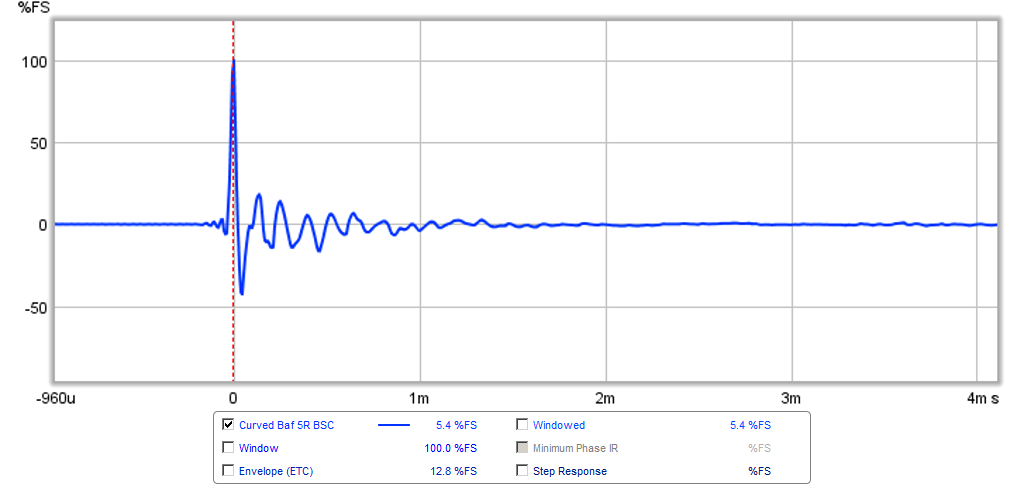

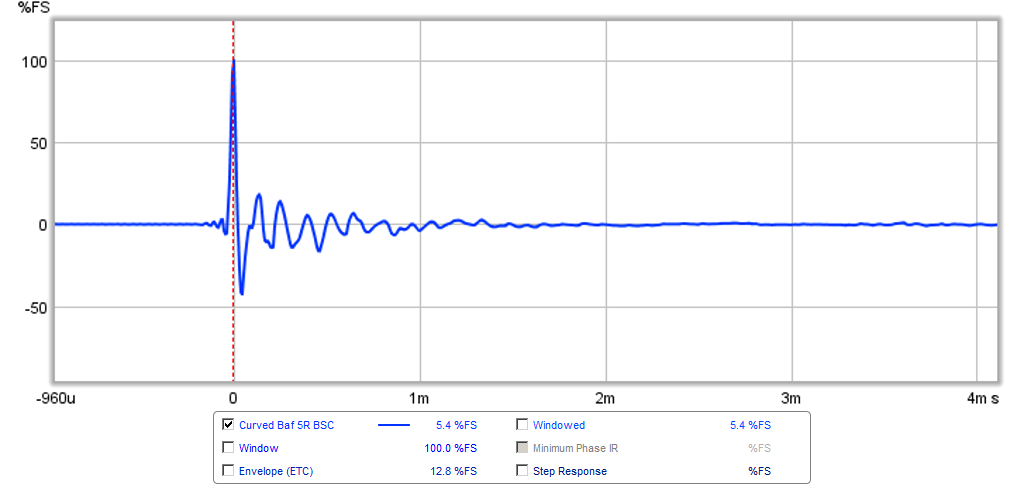

Here is the impulse response:

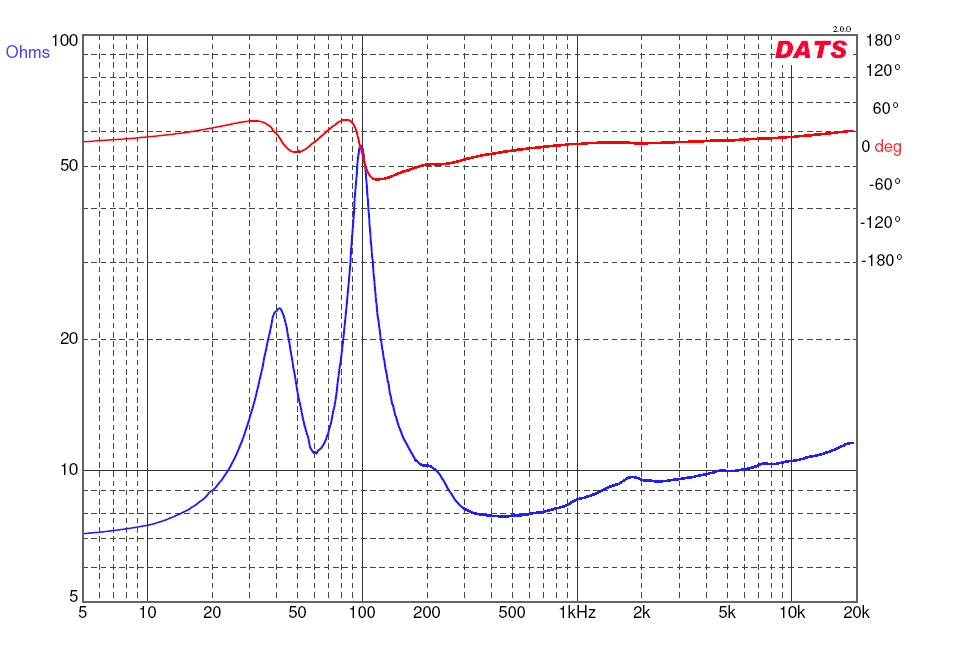

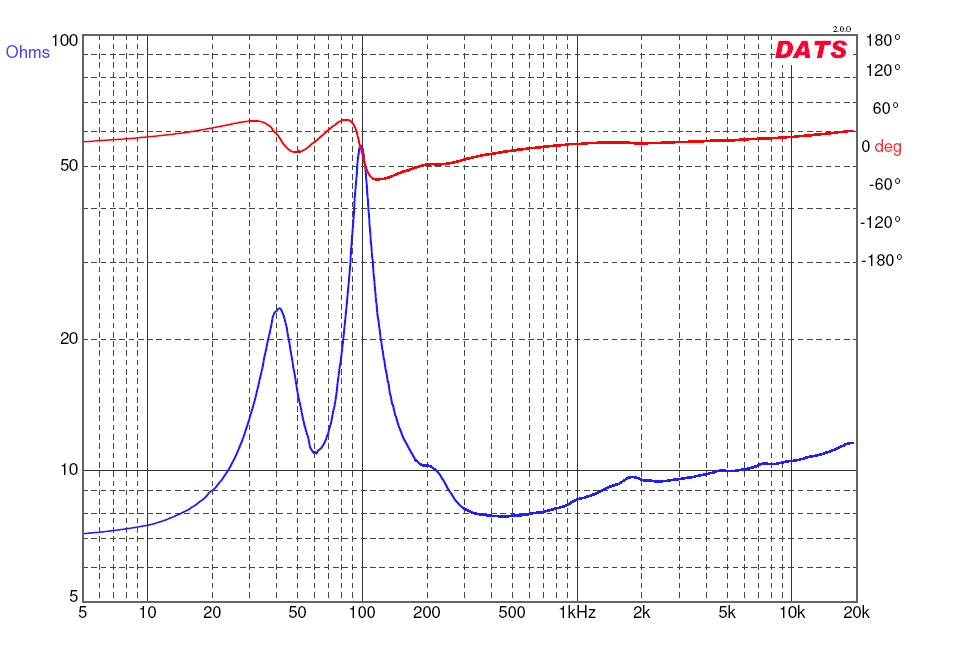

The vent output is pretty impressive as a lot of air is moved over a vent area that is about 84% of the area of the cone. When used on a desk near a back wall, there is a lot more bass gain and you can hear it down to about 60hz. When used in 4pi space the rear firing vent falls off quickly and bass extend to about 100Hz. Here is the measured impedance sweep showing the tuning frequency is 60Hz, matching the predicted value in the simulation on Akabak.

Here is measured impedance, showing fb matches predicted 60Hz tuning frequency:

I have not had a lot of listening time yet - but sounds quite nice - except for the 7.5kHz peak. So I can either notch that out or EQ it out.

I liked the shape of Jeshi's EVA foam monitors so much, I decided to follow something similar with rounded edges and a trapezoidal baffle - this shape minimizes baffle diffraction effects. I have a set of FF105WK's that I wanted to use for this as Jeshi said she really likes how they work once some EQ is applied. However, i went for a different twist and rather than sealed, I made a tapered vent TL. The TL has a 3:2:1 proportion on the three internal passages which starts at 4in to 2.70in to 1.35in with 13in long for each segment and a 5.0in internal width. The sim on Akabak predicted a tuning frequency of 60Hz and flat response in the absence of baffle step losses.

Here is a photo of the internals before the side was capped:

Here is the finished speaker with a compound curved baffle that has a large radius of curvature at the top and smaller at the bottom:

Here are the measurements before the curved baffle and with a few levels of BSC (5 ohms and 8.2ohms with a 1mH coil). I have not connected it to miniDSP yet and wanted to see how flat I could get it passively. This is with 5ms gate and mic was 0.5m away with speaker on 30in tall stand (red is before curved baffle, dark blue is with curved baffle and BSC - 1mH + 5R):

The dip at 2.1kHz and peak at 7.5kHz are inherent to the FF105WK (see manufacturer's response graph).

Here is the TL vent output (mic 2in from vent :

Here is the phase:

Here is the impulse response:

The vent output is pretty impressive as a lot of air is moved over a vent area that is about 84% of the area of the cone. When used on a desk near a back wall, there is a lot more bass gain and you can hear it down to about 60hz. When used in 4pi space the rear firing vent falls off quickly and bass extend to about 100Hz. Here is the measured impedance sweep showing the tuning frequency is 60Hz, matching the predicted value in the simulation on Akabak.

Here is measured impedance, showing fb matches predicted 60Hz tuning frequency:

I have not had a lot of listening time yet - but sounds quite nice - except for the 7.5kHz peak. So I can either notch that out or EQ it out.

Attachments

-

FF105WK-TL-Impedance.PNG51.7 KB · Views: 3,415

FF105WK-TL-Impedance.PNG51.7 KB · Views: 3,415 -

FF105WK-TL-Front-oblique.PNG413 KB · Views: 6,287

FF105WK-TL-Front-oblique.PNG413 KB · Views: 6,287 -

FF105WK-TL-Rear-oblique.PNG409.1 KB · Views: 5,371

FF105WK-TL-Rear-oblique.PNG409.1 KB · Views: 5,371 -

FF105WK-TL-Front-Curve-Detail.PNG433.9 KB · Views: 3,669

FF105WK-TL-Front-Curve-Detail.PNG433.9 KB · Views: 3,669 -

FF105WK-TL-Front-square.PNG371.7 KB · Views: 4,812

FF105WK-TL-Front-square.PNG371.7 KB · Views: 4,812 -

ff105wk-tl-curved-baffle-bsc-freq.png95.4 KB · Views: 3,499

ff105wk-tl-curved-baffle-bsc-freq.png95.4 KB · Views: 3,499 -

ff105wk-tl-curved-baffle-bsc-phase.png97.9 KB · Views: 3,478

ff105wk-tl-curved-baffle-bsc-phase.png97.9 KB · Views: 3,478 -

ff105wk-tl-curved-baffle-bsc-ir.png39.8 KB · Views: 3,449

ff105wk-tl-curved-baffle-bsc-ir.png39.8 KB · Views: 3,449 -

FF105WK-TL-Internals.PNG462.8 KB · Views: 8,492

FF105WK-TL-Internals.PNG462.8 KB · Views: 8,492 -

ff105wk-tl-vent.png61.1 KB · Views: 3,470

ff105wk-tl-vent.png61.1 KB · Views: 3,470

Last edited:

I love the look of these speakers and the TL seems to work really well with the FF105wk. I really want to build one of these now😀

I do really like the FF105wk (after EQ). They are really dynamic and with excellently low HD. I understand that they are not popular because of their problem frequency peaks and dips (3 to 5 depending on how much of a perfectionist one wants to be). I EQ out 5 of the peak/dips when using mine since I do everything through my DSP/TPA3116 box.

Building a TL or MLTL has been on my want-to-do list since I started this hobby and I am glad you made one with the FF105wk. cheers!!

I do really like the FF105wk (after EQ). They are really dynamic and with excellently low HD. I understand that they are not popular because of their problem frequency peaks and dips (3 to 5 depending on how much of a perfectionist one wants to be). I EQ out 5 of the peak/dips when using mine since I do everything through my DSP/TPA3116 box.

Building a TL or MLTL has been on my want-to-do list since I started this hobby and I am glad you made one with the FF105wk. cheers!!

I have been listening to this speaker a bit more as a near field monitor and really like its punchy crisp bass. I think this is my first all tapered TL build and it has a distinct sound. The movement of air is very snappy - completely different than what you get with a bass reflex port in an equivalent sized box. For one thing, the port CSA is huge - about 84% of Sd. Typical BR ports are 30% of Sd, so there is a lot of free unrestricted air movement with a lot of acceleration. I like the sound very much and will start a new thread for this box. Build plan will be included in case anyone wants to try.

I have been listening to this speaker a bit more as a near field monitor and really like its punchy crisp bass. I think this is my first all tapered TL build and it has a distinct sound. The movement of air is very snappy - completely different than what you get with a bass reflex port in an equivalent sized box. For one thing, the port CSA is huge - about 84% of Sd. Typical BR ports are 30% of Sd, so there is a lot of free unrestricted air movement with a lot of acceleration. I like the sound very much and will start a new thread for this box. Build plan will be included in case anyone wants to try.

nice😉 I actually find the FF105wk in a sealed box also has a crisp snappy bass. I am sure the TL is helping bring this quality of the driver out, but I also think the FF105wk has a lot to do with this. It really is a bit of an overlooked driver because of its frequency response peaks. There is nothing wrong with a little eq if afterwards the driver performs well (dynamics, clarity, low distortion). Really glad you are enjoying the FF105wk TL.

New thread for FF105WK TL

http://www.diyaudio.com/forums/full-range/279546-ff105wk-tl-desktop-bookshelf.html

http://www.diyaudio.com/forums/full-range/279546-ff105wk-tl-desktop-bookshelf.html

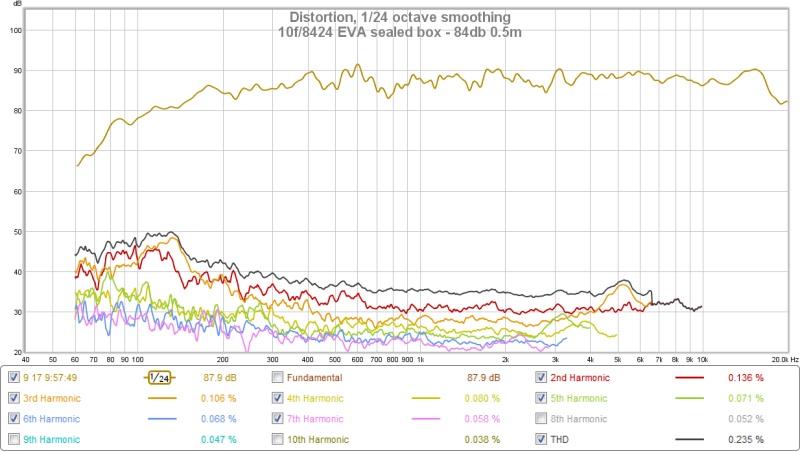

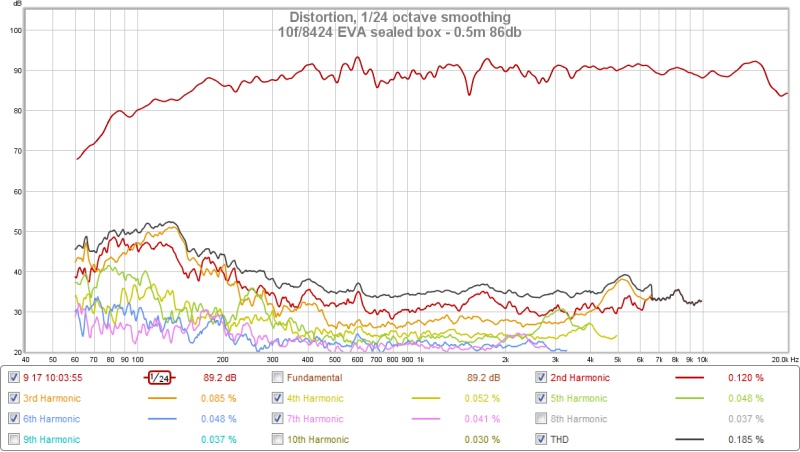

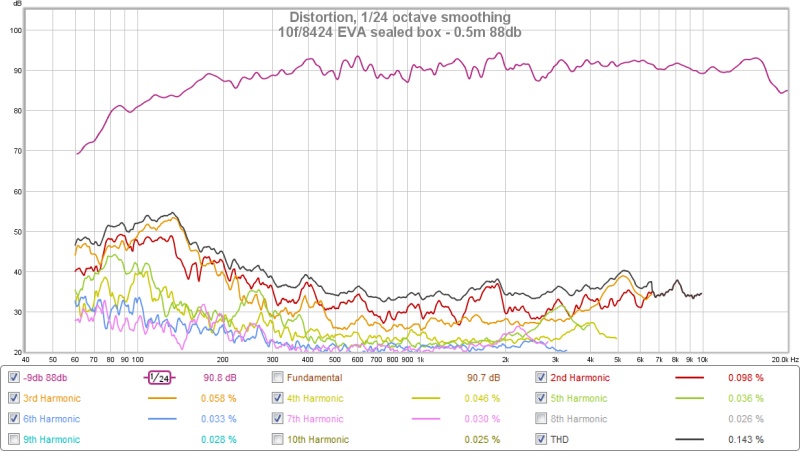

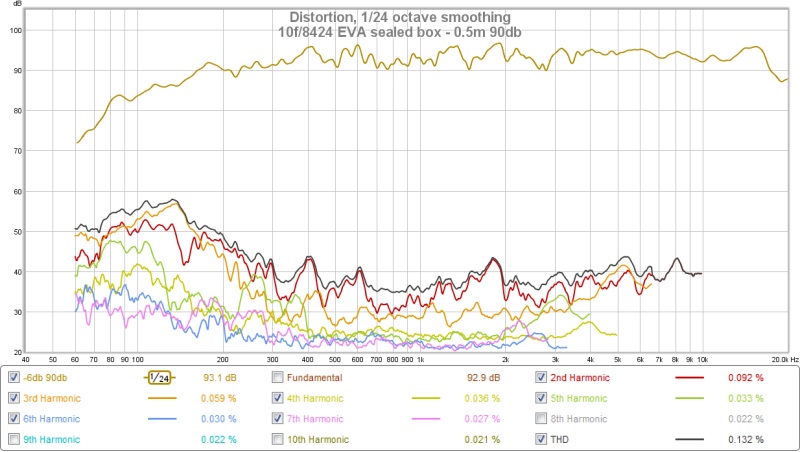

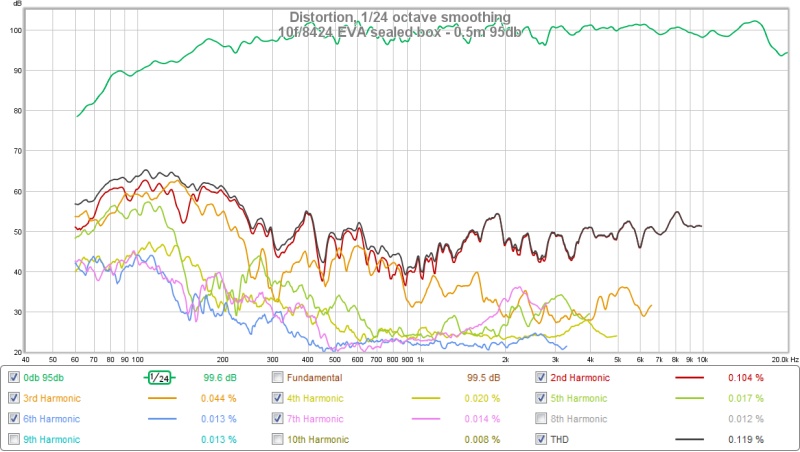

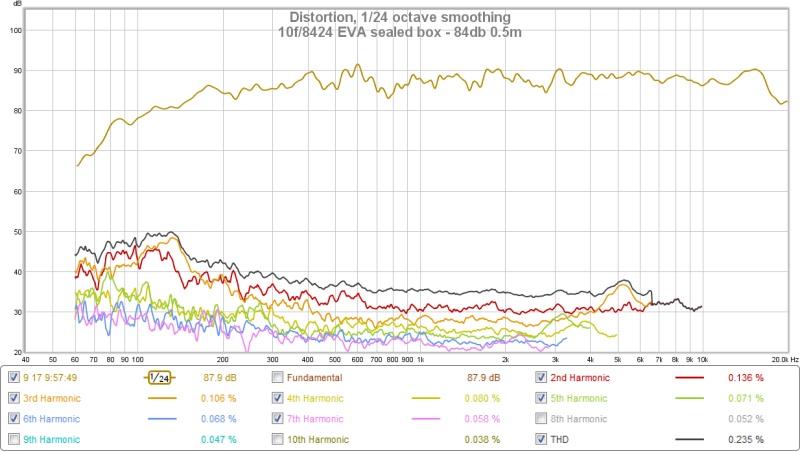

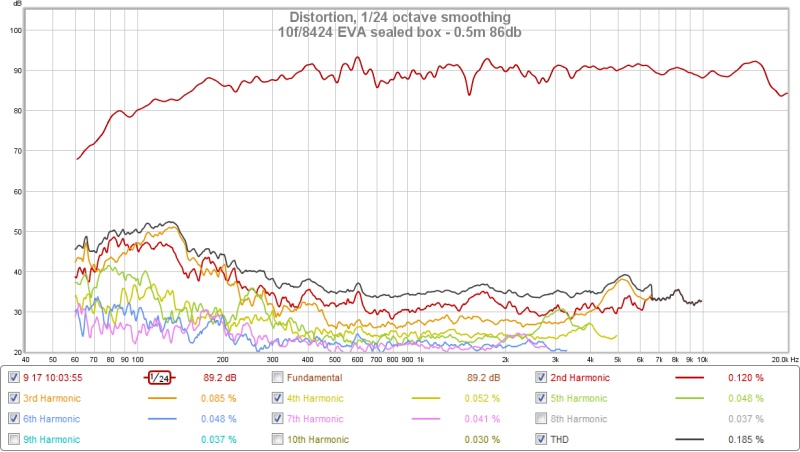

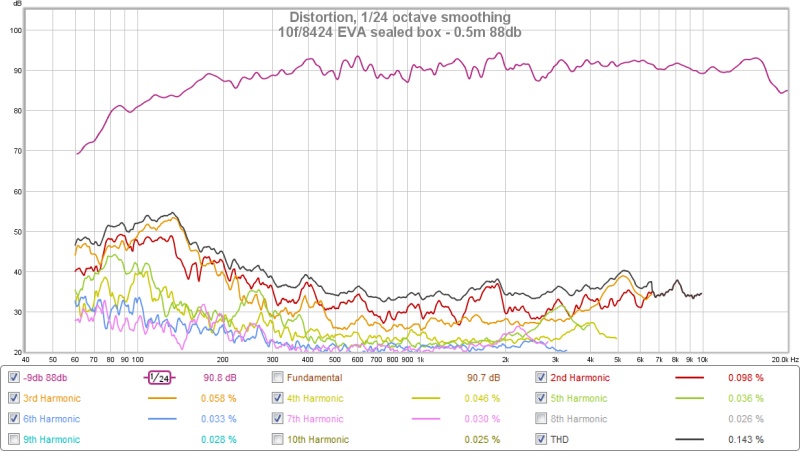

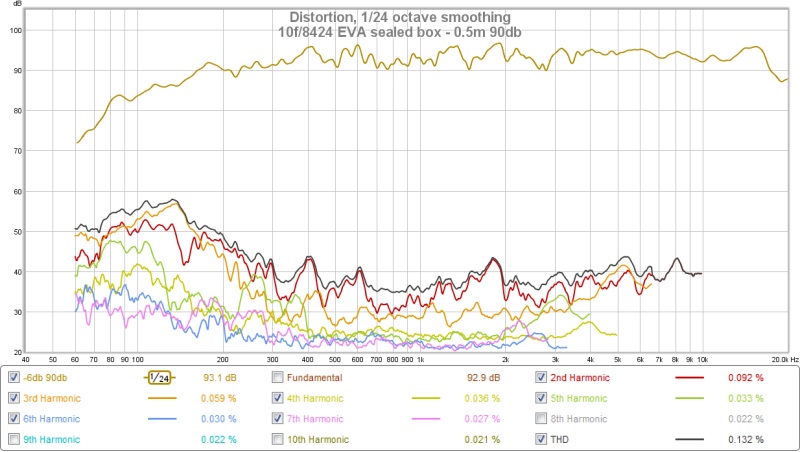

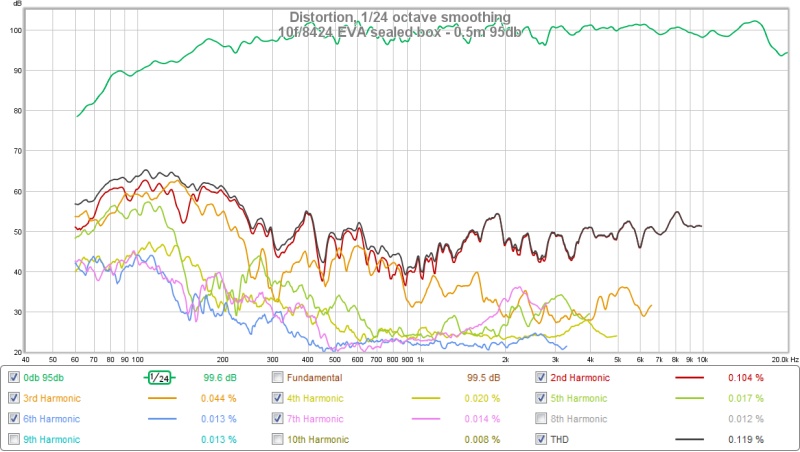

I made some new measurements on the 10F/8424 in my sealed EVA box. Wanted to test distortion at different SPL levels.

For these measurement I apply no bass boost, a bessel 80hz rolloff for protection, and a high shelf EQ to adjust for baffle step.

Tests are at 84db, 86db, 88db, 90db and 95db measured SPL at 0.5m

I achieved this my adjusting the input gain on my miniDSP by -12db=84db, -10db=86db, -9db=88db, -6db=90db, 0db=95db.

95db at 0.5m is the max volume I can get out of this speaker with my current TPA3116 amps.

The cursor is placed at 1khz so the numbers in the legend correspond to the 1khz mark.

-12db input 84db at 0.5m

-10db input 86db at 0.5m

-9db input 88db at 0.5m

-6db input 90db at 0.5m

0db input 95db at 0.5m

for normal listening I run it fullrange without the rolloff protection and usually in the 88-90db range

For these measurement I apply no bass boost, a bessel 80hz rolloff for protection, and a high shelf EQ to adjust for baffle step.

Tests are at 84db, 86db, 88db, 90db and 95db measured SPL at 0.5m

I achieved this my adjusting the input gain on my miniDSP by -12db=84db, -10db=86db, -9db=88db, -6db=90db, 0db=95db.

95db at 0.5m is the max volume I can get out of this speaker with my current TPA3116 amps.

The cursor is placed at 1khz so the numbers in the legend correspond to the 1khz mark.

-12db input 84db at 0.5m

-10db input 86db at 0.5m

-9db input 88db at 0.5m

-6db input 90db at 0.5m

0db input 95db at 0.5m

for normal listening I run it fullrange without the rolloff protection and usually in the 88-90db range

Attachments

Last edited:

Nice result! A pretty clean sounding driver even at 95dB and 0.5m (or 89dB at 1m). I think you can get more out of the TPA3116D2 if you have more pre-amp drive voltage. There is a rising HD peak near 1.8kHz - can you hear it, or does it bother you?

Nice result! A pretty clean sounding driver even at 95dB and 0.5m (or 89dB at 1m). I think you can get more out of the TPA3116D2 if you have more pre-amp drive voltage. There is a rising HD peak near 1.8kHz - can you hear it, or does it bother you?

I am not sure if I hear it yet. I can tell that the amps are not perfect, but have not narrowed it down yet. I normally listen at lower levels (88-90db) so maybe it doesn't appear so strongly.

I have been playing around with the idea of building some pass aleph30 amps though. Maybe a hybrid with the TPA doing the satori/bass and the aleph doing the fullrange/tweeter. Lets see. Amp building (especially classA like the aleph) is a completely different type of DIY.

A member in Australia who built an Aleph had friends over and they compared amps, he also had a TPA3116 with mods and they agreed it was better than the Aleph and his tube amps, and NAD. With some basic mods, it's tough to get an amp with this much value. You can try going into the custom chip amp like the Modulus-86 (3886 based with low noise servo loop op amp), which I have heard, is the best amp, at any price. This is one of the reasons I recently bought some inexpensive LM3886 amps to play with. I was going to build up an LM3886 based miniDSP box and compare it with my TPA3116 miniDSP box.

It can be very fun and rewarding to build your own amp though. The best TPA3116D2 amp right now is Gmarsh's Wiener. He may have some PCB's left. The new up and coming amp is the TPA3251D2 which has more power and newer advances. Currently, DrMord has built up a new PCB and it is in the testing phases now. It is the next 3116 from TI.

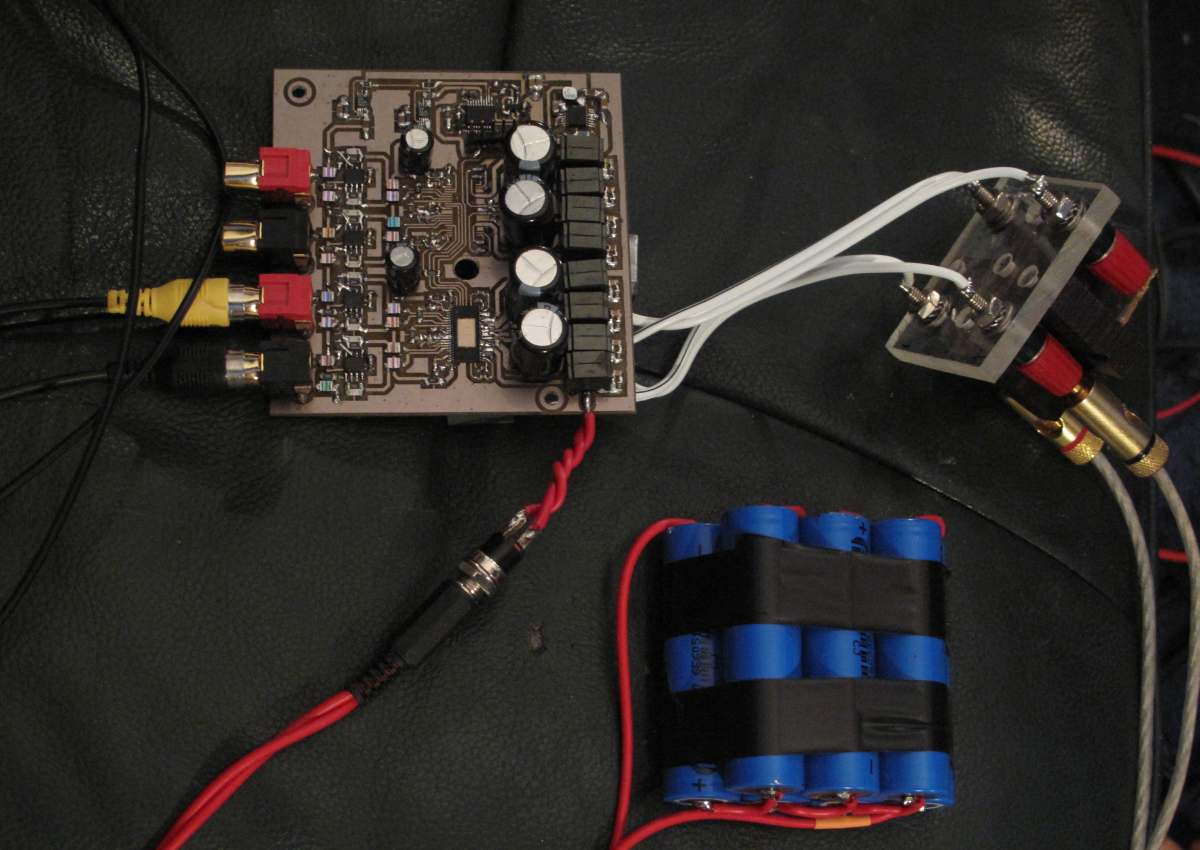

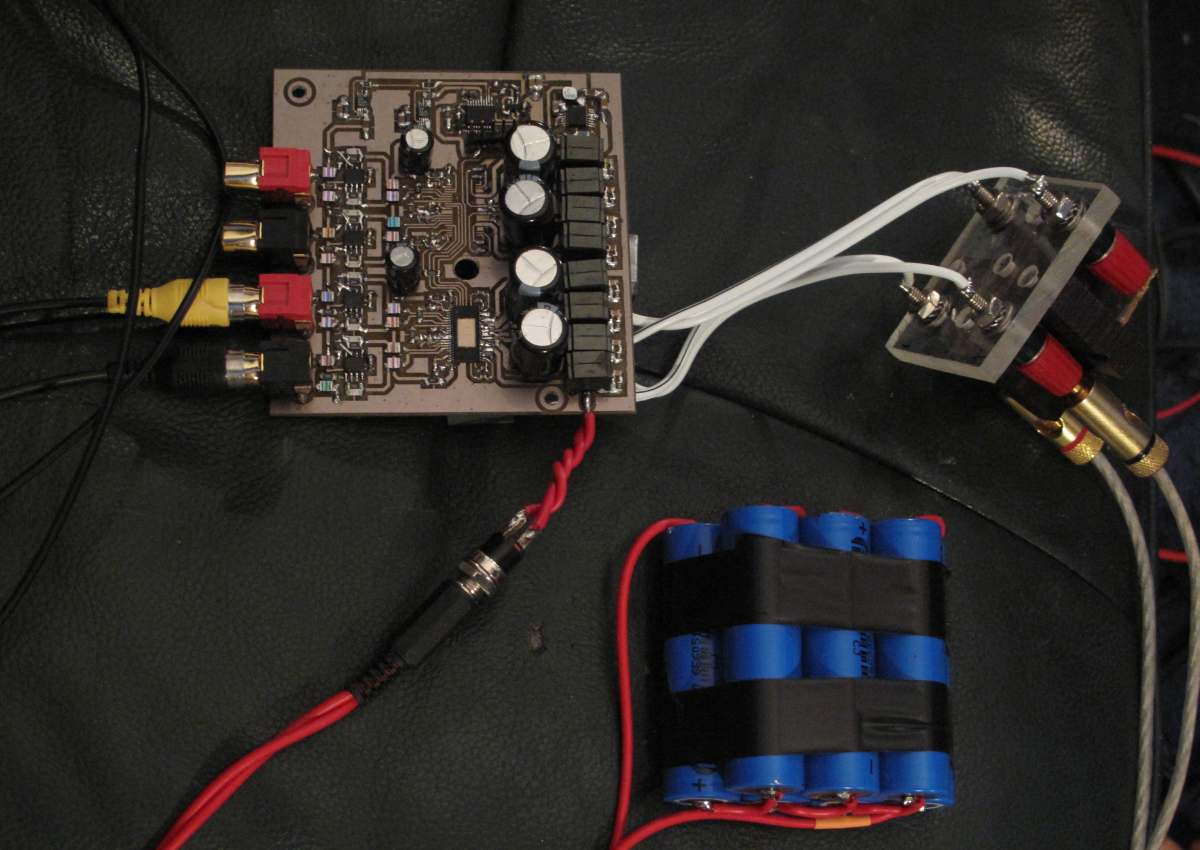

Here is DrMord's new amp as built by 5th element, undergoing initital trials:

Last I heard, they were pushing 85 clean watts/ch into 4ohm loads.

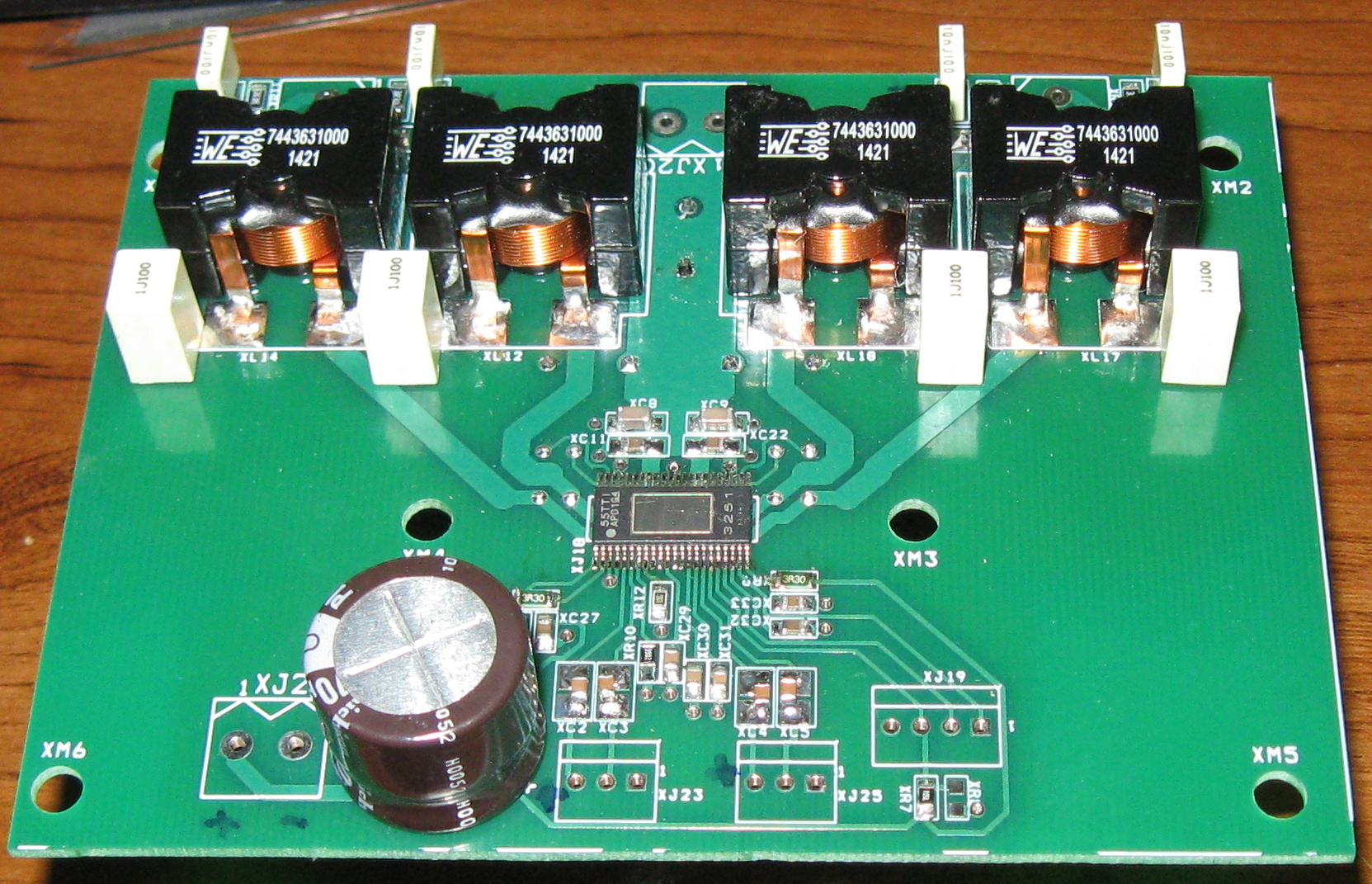

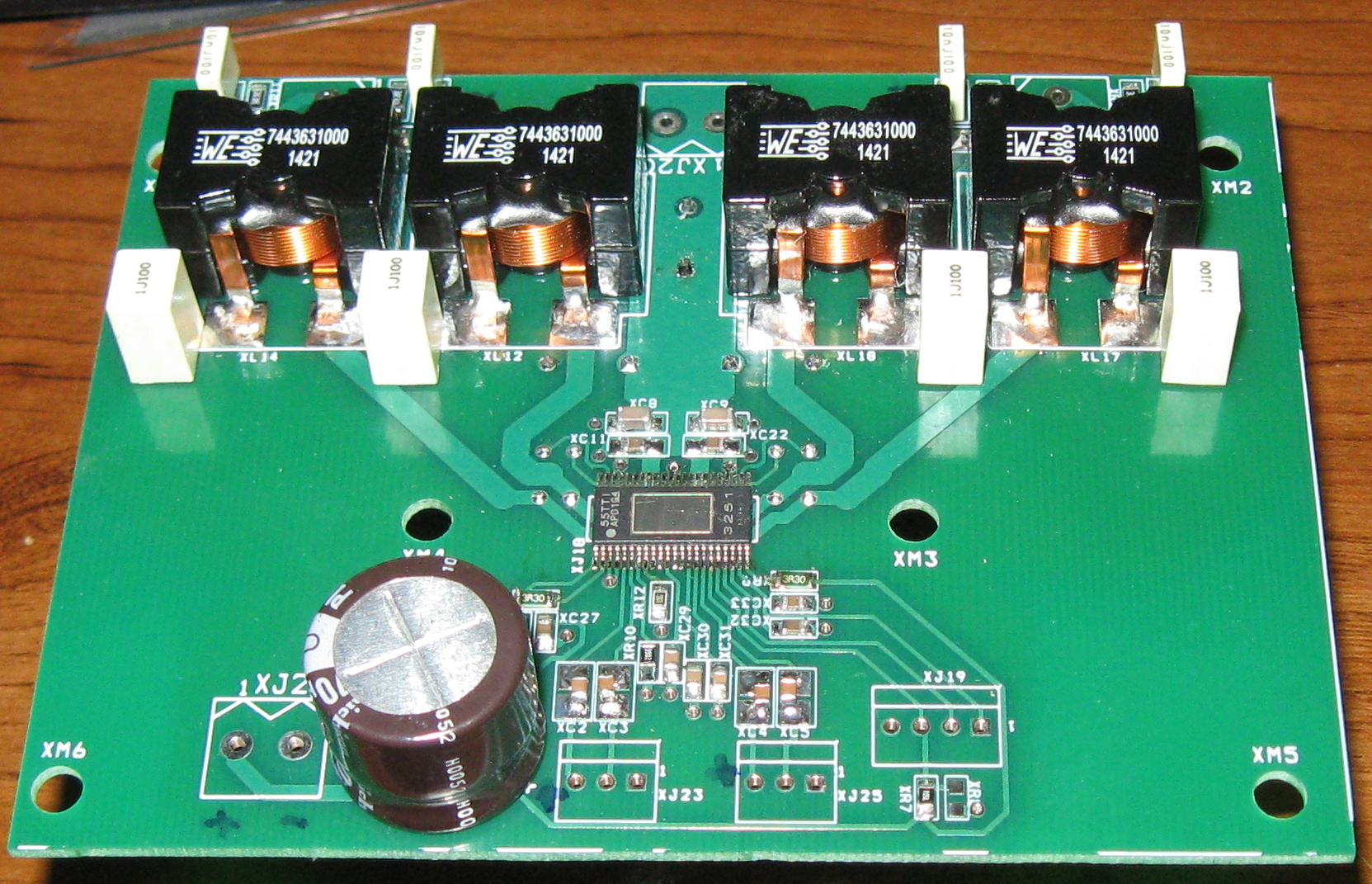

DUG, the original TPA3116D2 pcb designer on diyAudio, also has a new TPA3251D2 board:

Anyhow, this is the new evolution of the TPA3116.

It can be very fun and rewarding to build your own amp though. The best TPA3116D2 amp right now is Gmarsh's Wiener. He may have some PCB's left. The new up and coming amp is the TPA3251D2 which has more power and newer advances. Currently, DrMord has built up a new PCB and it is in the testing phases now. It is the next 3116 from TI.

Here is DrMord's new amp as built by 5th element, undergoing initital trials:

Last I heard, they were pushing 85 clean watts/ch into 4ohm loads.

DUG, the original TPA3116D2 pcb designer on diyAudio, also has a new TPA3251D2 board:

Anyhow, this is the new evolution of the TPA3116.

Last edited:

thanks for the great info. I haven't been following the TPA threads so closely. I have 3 different TPA boards now and no mods.

looking forward to when the new TPA3251D2 boards become available.

I guess next step on the amp side then is to mod my tpa3116 a little. overall I am really quite happy with the tpa3116 for my amp application

Sent from my iPhone using Tapatalk

looking forward to when the new TPA3251D2 boards become available.

I guess next step on the amp side then is to mod my tpa3116 a little. overall I am really quite happy with the tpa3116 for my amp application

Sent from my iPhone using Tapatalk

I have some comparable HD measurements of the 10F/8424 in the Dagger over in the other thread.

http://www.diyaudio.com/forums/full...2in-4in-drivers-round-4-a-54.html#post4454370

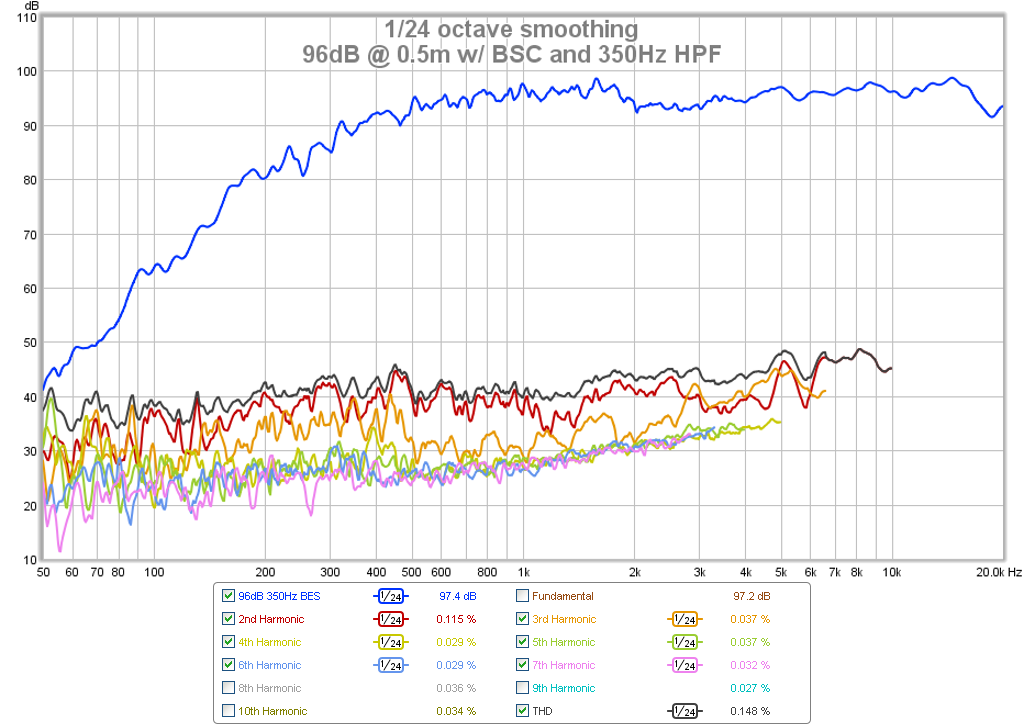

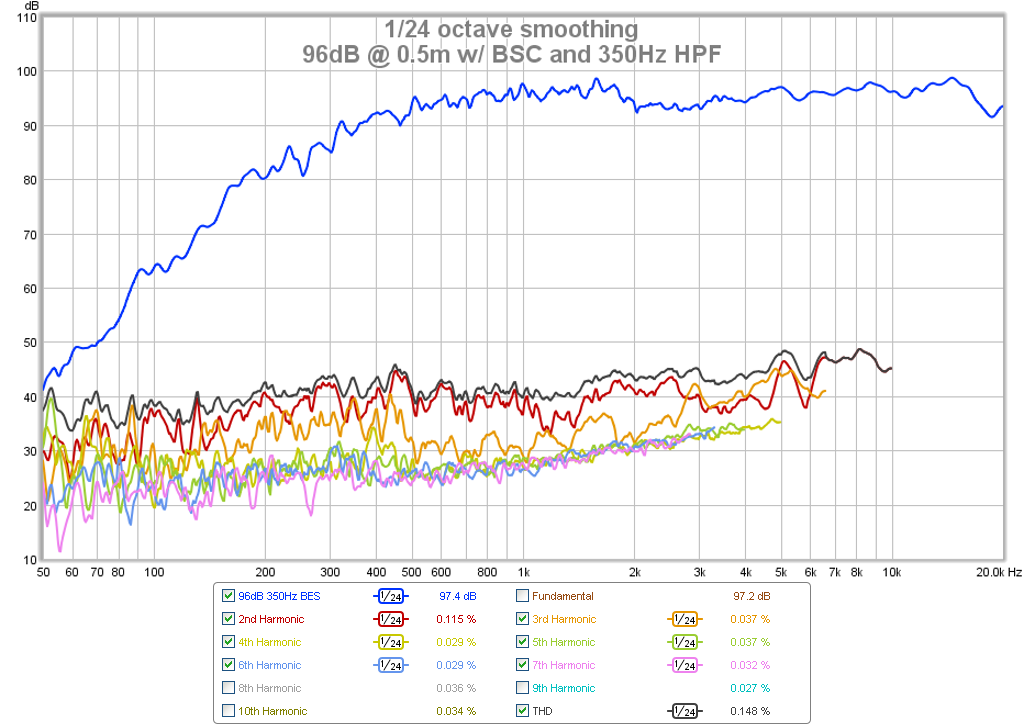

Here is 96dB at 0.5m with 350Hz HPF and BSC (cursor at 1khz):

The 10F is a clean driver, and the Dagger appears to be doing its job of keeping native HD low.

http://www.diyaudio.com/forums/full...2in-4in-drivers-round-4-a-54.html#post4454370

Here is 96dB at 0.5m with 350Hz HPF and BSC (cursor at 1khz):

The 10F is a clean driver, and the Dagger appears to be doing its job of keeping native HD low.

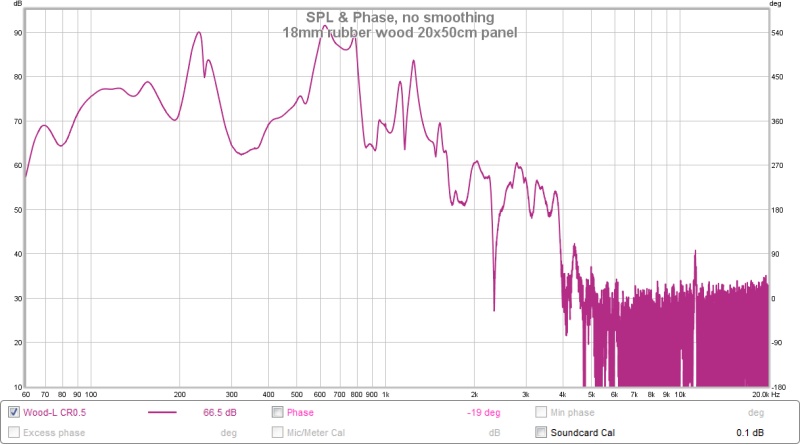

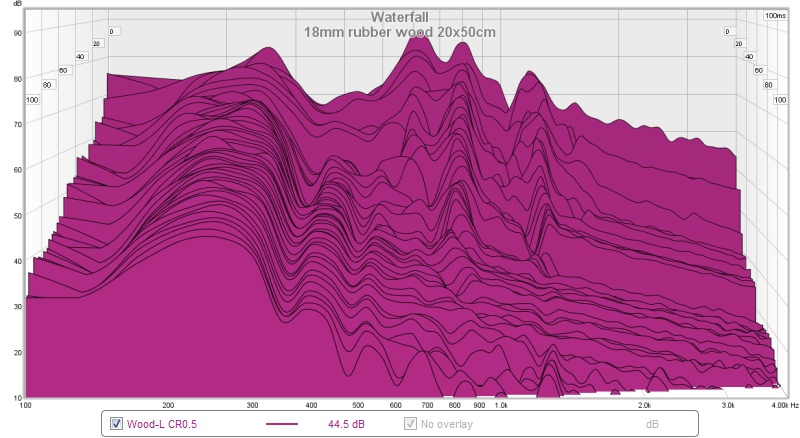

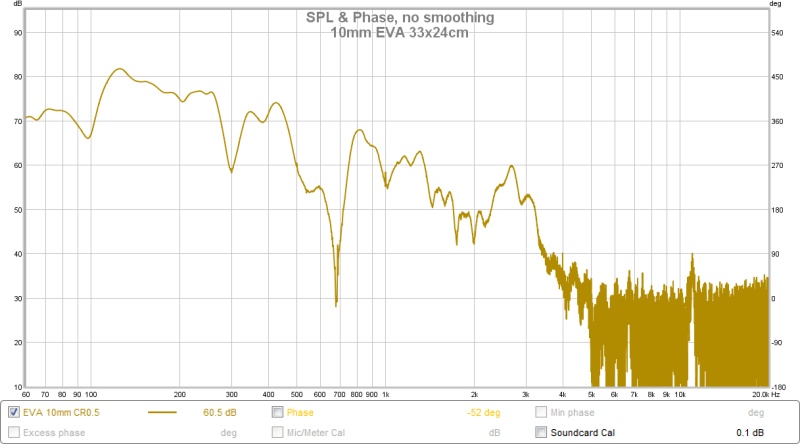

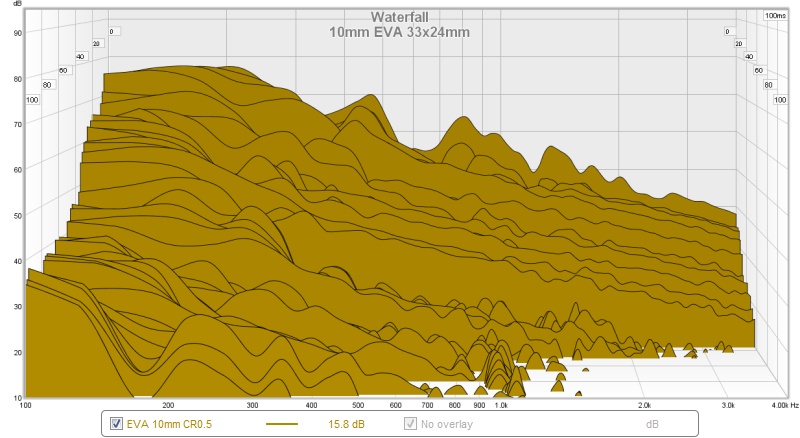

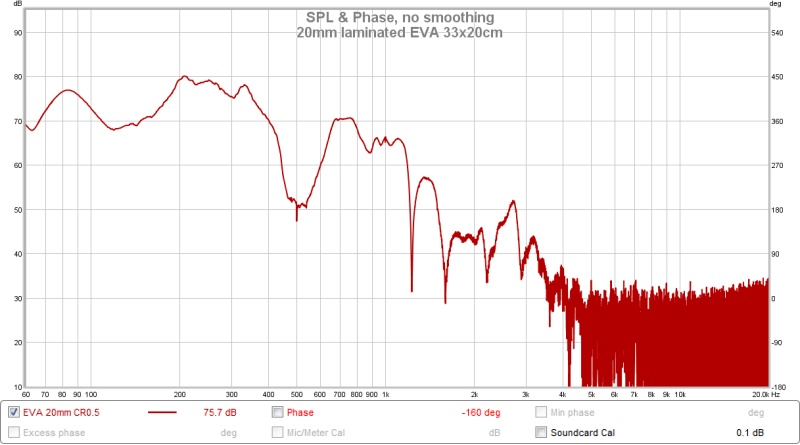

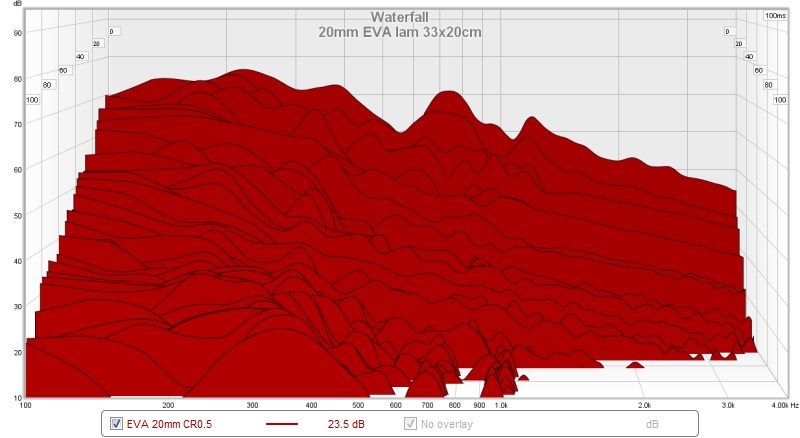

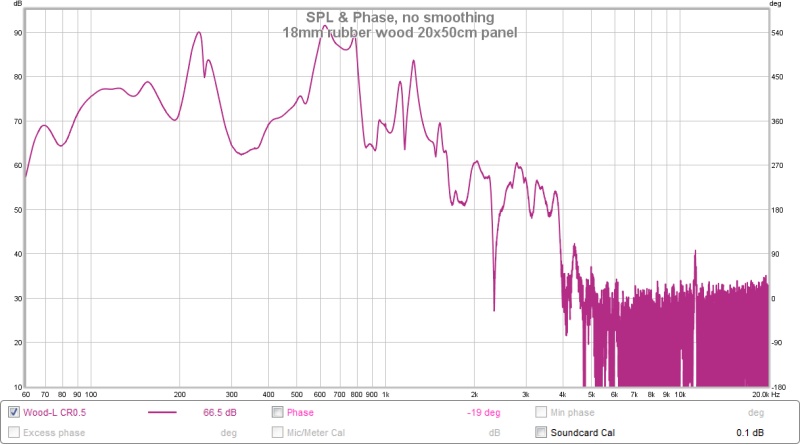

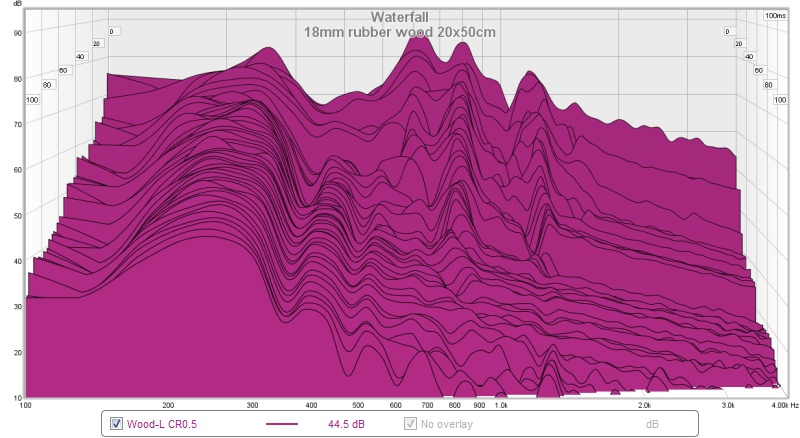

I have been playing around with some panel-resonance test ideas. This is still very preliminary, but I think the idea is reasonably sound.

The idea is to use a driver (my fostex FF105wk) to excite a panel (place a panel on top of a driver). Use a contact microphone (korg CM-200-BKRD) to record vibration transfer, ringing, decay, panel resonance. I have tried it with a few different materials and thicknesses and it does look promising. But I would be very interested to hear if there are any known methods we can use (without having to buy a laser interferometer)

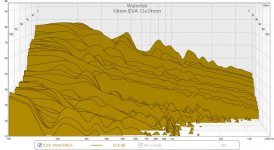

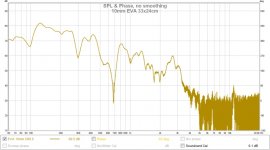

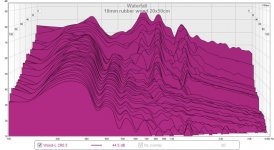

Well here are some results from these early tests. Not very scientific. I just used what I had available, so panels are not the same size (close, but not identical). Also this korg mic does not pickup frequency above 4khz and I doubt the response is flat, but it should be fine for comparison testing.

18mm rubber wood

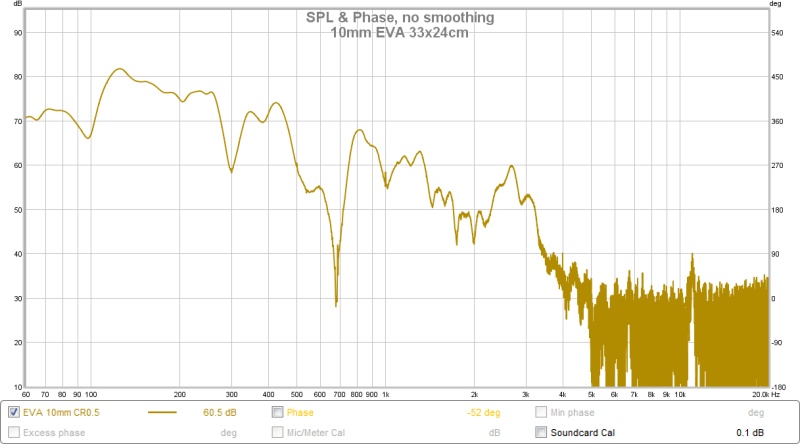

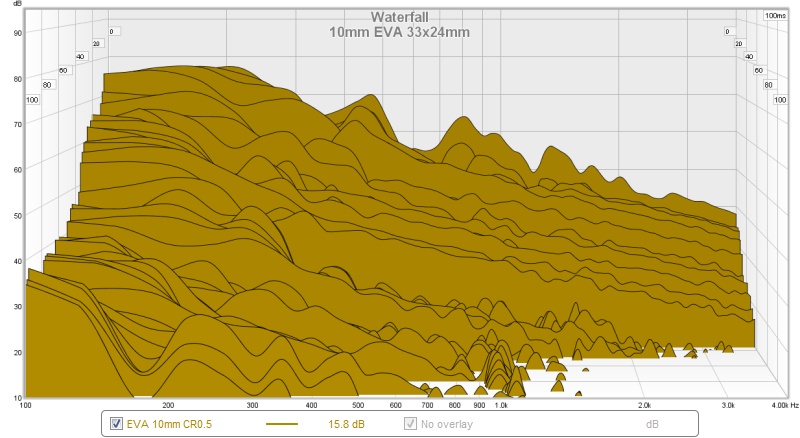

10mm EVA

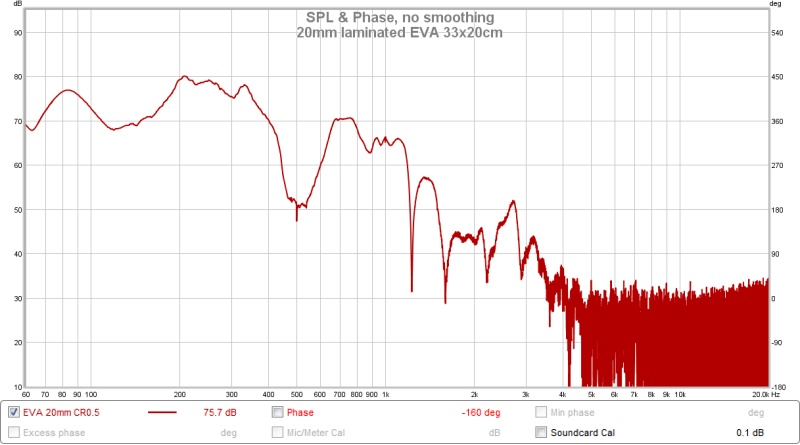

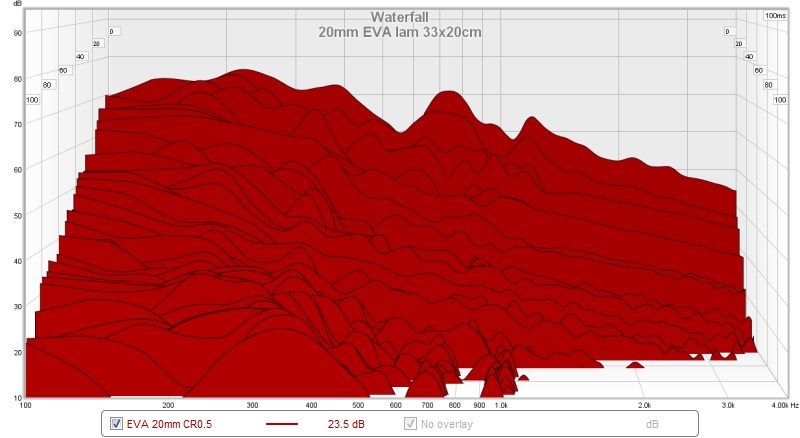

20MM laminated EVA (two 10mm panels laminated with rubber cement)

the wood transfers much more energy (higher DB response) to the mic, extends to higher frequencies, and has a longer decay especially in the lower frequencies. The 10mm and 20mm EVA are more damped than the wood. Total energy transferred into the panel and to the mic is less. More high frequencies are absorbed, and decays much faster with almost no ringing or resonance. The 20mm and 10mm show a slight difference in the frequencies they transfer and damp. 20mm seems to damp the low frequencies faster.

I want to eventually do this with a standard panel size, and common materials (12mm MDF, 20mm MDF, 20mm BB ply, foam core) and compare to 10/20/30mm EVA. But I only want to do this if the idea is sound since I would only buy the woods for the testing. But so far the EVA foam does look like it is performing better than rubber wood and doing what the manufactures say it does (sound absorbtion, resonance damping).

For the "standard size" I wonder if 300mm x 200mm would be ok, this seems to be around a common side panel size for many small boxes, and is not square. Plus 200mm wide wood is common and cheap to buy. Larger widths get more expensive. But I would be ok going bigger if people really like this idea.

The idea is to use a driver (my fostex FF105wk) to excite a panel (place a panel on top of a driver). Use a contact microphone (korg CM-200-BKRD) to record vibration transfer, ringing, decay, panel resonance. I have tried it with a few different materials and thicknesses and it does look promising. But I would be very interested to hear if there are any known methods we can use (without having to buy a laser interferometer)

Well here are some results from these early tests. Not very scientific. I just used what I had available, so panels are not the same size (close, but not identical). Also this korg mic does not pickup frequency above 4khz and I doubt the response is flat, but it should be fine for comparison testing.

18mm rubber wood

10mm EVA

20MM laminated EVA (two 10mm panels laminated with rubber cement)

the wood transfers much more energy (higher DB response) to the mic, extends to higher frequencies, and has a longer decay especially in the lower frequencies. The 10mm and 20mm EVA are more damped than the wood. Total energy transferred into the panel and to the mic is less. More high frequencies are absorbed, and decays much faster with almost no ringing or resonance. The 20mm and 10mm show a slight difference in the frequencies they transfer and damp. 20mm seems to damp the low frequencies faster.

I want to eventually do this with a standard panel size, and common materials (12mm MDF, 20mm MDF, 20mm BB ply, foam core) and compare to 10/20/30mm EVA. But I only want to do this if the idea is sound since I would only buy the woods for the testing. But so far the EVA foam does look like it is performing better than rubber wood and doing what the manufactures say it does (sound absorbtion, resonance damping).

For the "standard size" I wonder if 300mm x 200mm would be ok, this seems to be around a common side panel size for many small boxes, and is not square. Plus 200mm wide wood is common and cheap to buy. Larger widths get more expensive. But I would be ok going bigger if people really like this idea.

Attachments

Last edited:

for these panel resonance testing. I place the panel centered on the FF105wk driver. The driver is placed on an absorption material (I use a 5cm thick EVA yoga block). Driver is not inside an enclosure. The microphone is clipped to the corner of the panel, so it can only pick up sound that has been absorbed by the panel and that transfer inside the panel. These contact microphones can not pick up sound from the air. If the sound is absorbed and damped as it travels along the length of the panel it will show up as lower DB to the mic. But lower recorded level could also be due to the fact that the panel transmits more sound through and absorbs less. But in these cases I am fairly certain that the EVA is lower level because of absorption and damping.

To make these tests complete I want to complement with a reflection and transmission test. Similar to how one would test a two-way mirror (or beam spliter) - some light is reflected and some light is passed through. Like an 80:20 mirror would reflect 80% of the light, transmit 20% and absorb essentially 0%.

But at least from some anecdotal sound tests (play something and put wood or EVA to my ear or use as a sound mirror), the EVA does appear to absorb sound both when used as a reflective surface and as a transmission blocking surface.

To make these tests complete I want to complement with a reflection and transmission test. Similar to how one would test a two-way mirror (or beam spliter) - some light is reflected and some light is passed through. Like an 80:20 mirror would reflect 80% of the light, transmit 20% and absorb essentially 0%.

But at least from some anecdotal sound tests (play something and put wood or EVA to my ear or use as a sound mirror), the EVA does appear to absorb sound both when used as a reflective surface and as a transmission blocking surface.

Last edited:

Was inspired by XRK's measurements of the 10f/8424 in his Dagger closed-taper-TL so wanted to try to build one. But inspiration got the better of me (and some scrap EVA) which just begged me to try to make an aperiodic (fully stuffed) mini-TL for my SB65 and see if I can find an enclosure to make them happy.

So in honor of the Dagger-TL I present the Cannoli-TL (lol). This really is just for fun, but also to get some practical experience with rolled EVA and aperiodic TLs.

Two layers of slightly tapered EVA rolled into a circle on the driver end and then slowly transitioning to a slit on the open end. No modeling, just a free form shape to see what would happen.

End result, I actually like it and the SB65 also seems quite happy in an aperiodic TL! It is very fully stuffed so it is more like an aperiodic sealed box.

But I discovered that stuffing a small TL like this with the SB65 was a nightmare. I must have packed/measured/pull stuffing/repeat 10-12times. There was one time (almost the first time) that looked great, but I didn't realize it at the time, and I have not been able to recreate the level/pattern of low distortion since them. My current stuffing is good and I will try to not mess with it anymore.

For anyone who has seen an SB65 you will realize how tiny this thing is. I included a danz blue/black amp for scale. Made a little rhomboid front baffle (have no idea if it helps, but it looks nice).

So pics and measurements.

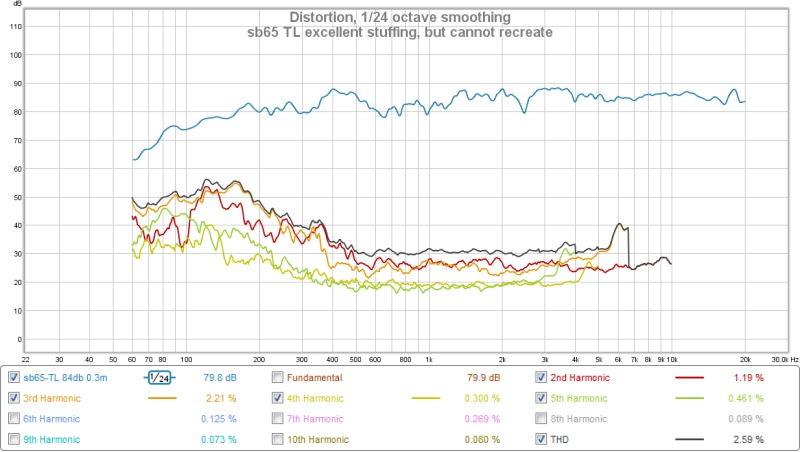

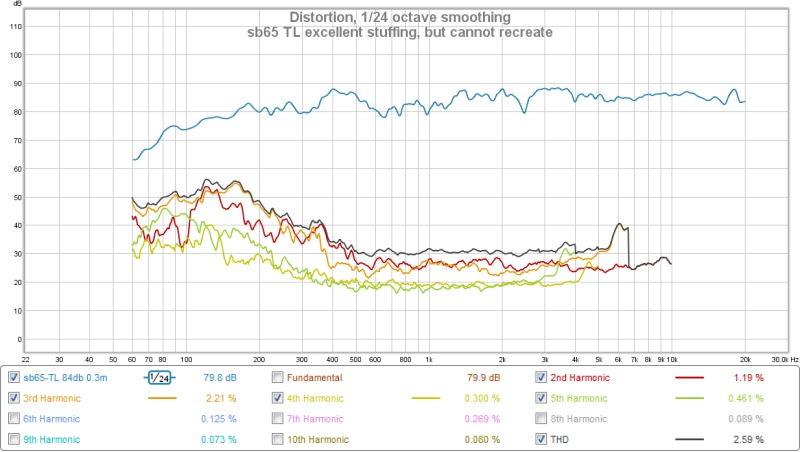

Here is the early measurement which I could not recreate. Seems after this there was always an elevated 3rd HD in the low frequencies which I could not get ride of

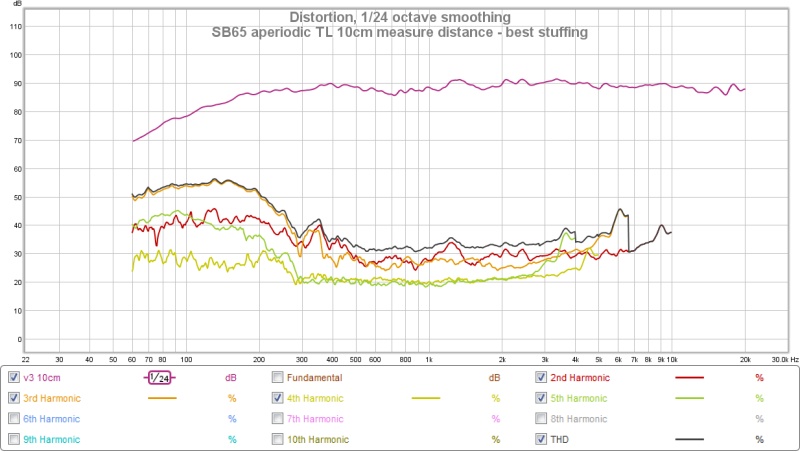

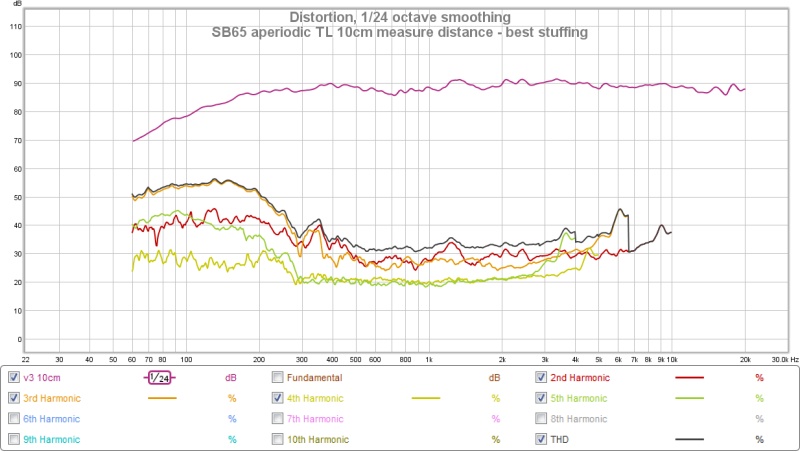

Here is the best I could recreate and what I am going to keep now

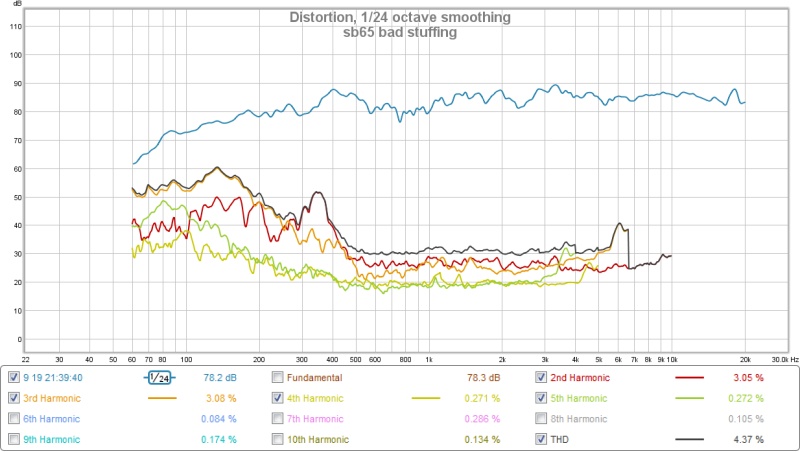

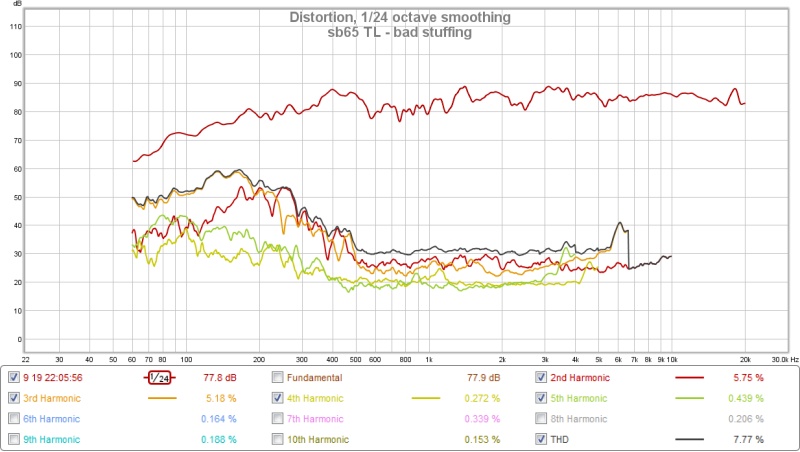

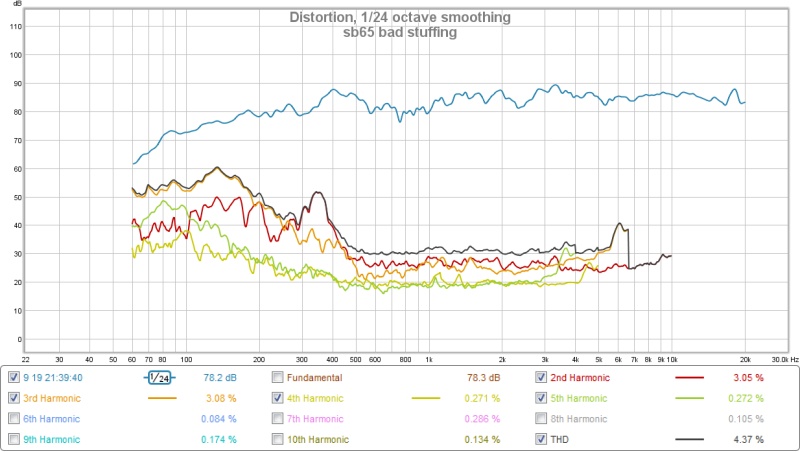

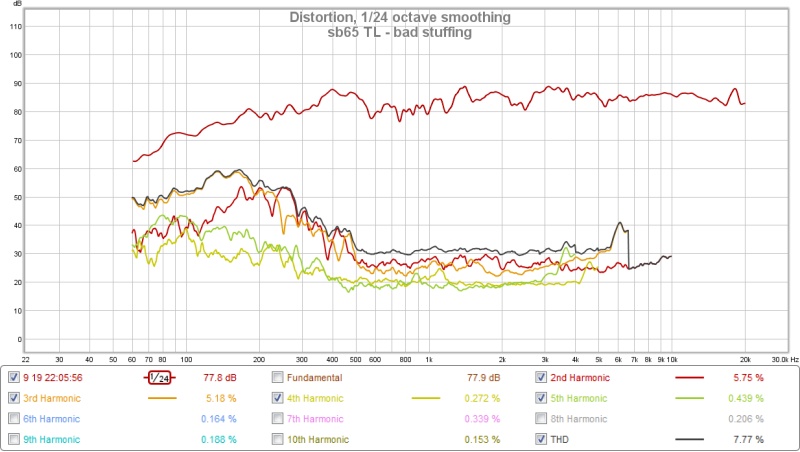

And here are some examples of bad stuffing that really messed up the distortion in the lower frequencies

If I would do this again, I would cut the edges of the two sheets in a rotating edge (0 deg at round end, 45deg at middle, 90deg at open end) so that the rolling and gluing would be easier and look nicer.

So in honor of the Dagger-TL I present the Cannoli-TL (lol). This really is just for fun, but also to get some practical experience with rolled EVA and aperiodic TLs.

Two layers of slightly tapered EVA rolled into a circle on the driver end and then slowly transitioning to a slit on the open end. No modeling, just a free form shape to see what would happen.

End result, I actually like it and the SB65 also seems quite happy in an aperiodic TL! It is very fully stuffed so it is more like an aperiodic sealed box.

But I discovered that stuffing a small TL like this with the SB65 was a nightmare. I must have packed/measured/pull stuffing/repeat 10-12times. There was one time (almost the first time) that looked great, but I didn't realize it at the time, and I have not been able to recreate the level/pattern of low distortion since them. My current stuffing is good and I will try to not mess with it anymore.

For anyone who has seen an SB65 you will realize how tiny this thing is. I included a danz blue/black amp for scale. Made a little rhomboid front baffle (have no idea if it helps, but it looks nice).

So pics and measurements.

Here is the early measurement which I could not recreate. Seems after this there was always an elevated 3rd HD in the low frequencies which I could not get ride of

Here is the best I could recreate and what I am going to keep now

And here are some examples of bad stuffing that really messed up the distortion in the lower frequencies

If I would do this again, I would cut the edges of the two sheets in a rotating edge (0 deg at round end, 45deg at middle, 90deg at open end) so that the rolling and gluing would be easier and look nicer.

Attachments

-

sb65-apTL-badstuffing2.jpg102.7 KB · Views: 790

sb65-apTL-badstuffing2.jpg102.7 KB · Views: 790 -

sb65-apTL-badstuffing1.jpg104.4 KB · Views: 799

sb65-apTL-badstuffing1.jpg104.4 KB · Views: 799 -

sb65-apTL-v1-nice-but-lost-way.jpg104.3 KB · Views: 1,019

sb65-apTL-v1-nice-but-lost-way.jpg104.3 KB · Views: 1,019 -

sb65-apTL-v3-nice.jpg97.9 KB · Views: 1,006

sb65-apTL-v3-nice.jpg97.9 KB · Views: 1,006 -

P1110519.jpg103.2 KB · Views: 120

P1110519.jpg103.2 KB · Views: 120 -

P1110518.jpg105.3 KB · Views: 1,418

P1110518.jpg105.3 KB · Views: 1,418 -

P1110522.jpg104.5 KB · Views: 802

P1110522.jpg104.5 KB · Views: 802 -

P1110521.jpg110 KB · Views: 110

P1110521.jpg110 KB · Views: 110 -

P1110520.jpg107 KB · Views: 818

P1110520.jpg107 KB · Views: 818

Last edited:

Very nice work Jeshi. That is a really compact enclosure to have low HD levels like that. The small trapezoidal baffle has rather low diffraction too. I will have to try this for my SB65 using foam core.

Love the name - I always think of this line though: "Leave the cannoli, take the gun!" 🙂

Love the name - I always think of this line though: "Leave the cannoli, take the gun!" 🙂

I didn't really plan this, it was just some scrap EVA foam which looked about the right size to play with. I know the scrap was 210mm long but the other dimensions kind of evolved as I built it.What are the dimensions of your baffle and length of the TL?

But measuring the completed shape it is about 205mm long (probably shrunk from me sanding it). So this is probably the TL length.

Trapezoid baffle appears to be 95mm along the bottom edge, 70mm along the top edge, and 98mm tall. The top has a slight curve to it (you can see in the pictures).

The two pieces that make up the body are the same. It appears to be about 285mm circumference at the front (circle) so about 143mm for each piece since they are bent and glued edge-to-edge to make a circle/tube. At the back end it is about 88mm wide (outside edges), maybe 90mm and then sanded down. The size of the "mouth" at the end is something I just played with: EVA is flexible so easy to squish it almost closed or flex it so that it opens up more. In my final tuning, it is quite thin, about 10mm in the center at the widest part.

here is a picture of the circular front before I glued on the baffle. I thought it looked a bit like an oboe reed hence the reed for scale.

It really is not a tuned TL. I stuff it very full and to get my final tuning, the back of the port is stuffed very tightly, like an aperiodic vent. I don't think this is showing any properties of a TL. Maybe just the angled, tapered walls helping with reflections, in the same way your closed Dagger helps with reflections, but is really just a closed/sealed enclosure.

hope that helps. If I make another one, I will try to use these measurements and document the process so that it can be duplicated by people.

But a lot of what I read about TLs is that even with good models, there is still usually some trial and error with getting the stuffing correct. So I took an empirical approach to this and just evolved this organically until I was happy.

Attachments

Last edited:

What difference in stuffing makes it look like the best vs the worst? Mine looks like the worst case right now. +/-5dB. Did you stuff it tighter to get it smoother?

I have been playing around with some panel-resonance test ideas. This is still very preliminary, but I think the idea is reasonably sound.

Cool test.

The problem with this sort of testing is deciding what the goal is, in other words what is the ideal characteristic of cabinet panel. Low resonance is obviously important, but it's not the only thing. If it was than silicone rubber would be best, or for that matter Play-Doh. As is often the case, the theoretical ideal panel would possess diametrically opposed qualities of infinite stiffness, infinite damping and infinite mass. That said, I think it has been demonstrated that lossy, low mass materials can work surprisingly well in certain situations, especially if bass extension is not required.

FYI there have been a of panel tests published in the past, unsurprisingly. I recall one in Audioxpress about 10-15 years ago that basically concluded that all common speaker panel materials resonate rather more severely than might be expected. IIRC, the best performers were constrained layer constructions, which again, is not surprising.

- Home

- Loudspeakers

- Full Range

- EVA foam for performance speaker enclosures