Agree as xrk971 said, in that the data you share looks really good enjoy the listening 🙂 thanks.

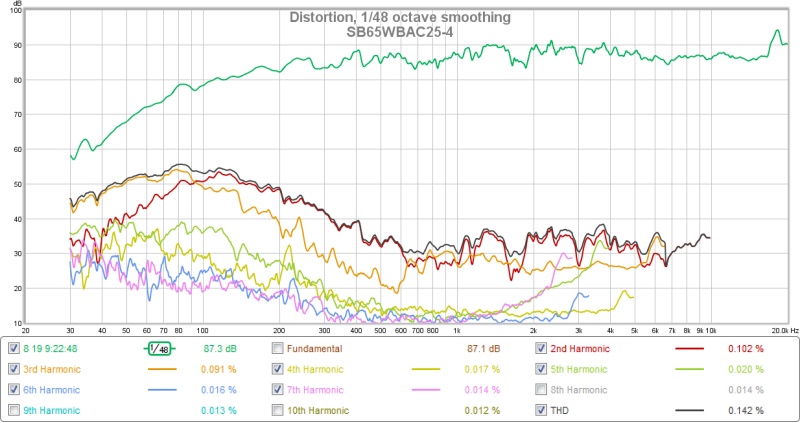

The new baffle you mention is that with your new SB65WBAC25-4 as tweeter, a lower XO point and chance to get rid of on axis dip in highest octave 😀.

The new baffle you mention is that with your new SB65WBAC25-4 as tweeter, a lower XO point and chance to get rid of on axis dip in highest octave 😀.

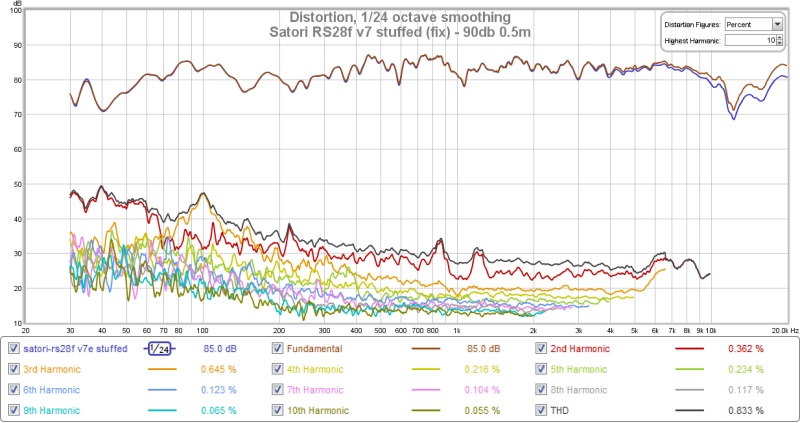

That treble dip (>10khz) is caused by my messed up "waveguide". The RS28f is really flat by itself. My next baffle is going to be another attempt to rear mount the RS28f, keep the 120mm center-center spacing but with a 20cm deep simple 45deg cone. The current baffle has the RS28f 30cm back from the satori to get the time alignment physically, but this causes all the problems in the treble. The 20cm offset will require me to slightly adjust the time alignment digitally in the DSP. I may also build a 3rd front as a stepped-baffle like Troels Gravesen often uses.

I will definitely make a baffle for a satori / SB65WBAC25-4 at some point soon. I just got a new batch of EVA foam. I think I might be able to get away with a 20cm think baffle (2 layers of foam) for an SB65/satori baffle since it will be front mounted. But this satori speaker is meant to be a working studio monitor and I really need the detail of a dome tweeter. Even though the SB65 measures flatter, to my ears the RS28f (even with the broken waveguide) still offers cleaner more detailed and dynamic treble. But I will definitely try the SB65.

My long term plan for the SB65 (and 10f 8424) is to make another box with a slot-loaded OB 8" woofer FAST. The satori has such beautiful midrange I really don't want to loose that, and it seems silly to cross a satori/SB65 at 900hz or 1000hz.

I will definitely make a baffle for a satori / SB65WBAC25-4 at some point soon. I just got a new batch of EVA foam. I think I might be able to get away with a 20cm think baffle (2 layers of foam) for an SB65/satori baffle since it will be front mounted. But this satori speaker is meant to be a working studio monitor and I really need the detail of a dome tweeter. Even though the SB65 measures flatter, to my ears the RS28f (even with the broken waveguide) still offers cleaner more detailed and dynamic treble. But I will definitely try the SB65.

My long term plan for the SB65 (and 10f 8424) is to make another box with a slot-loaded OB 8" woofer FAST. The satori has such beautiful midrange I really don't want to loose that, and it seems silly to cross a satori/SB65 at 900hz or 1000hz.

Thanks for this thread!

I'm a little late to the party, but I was on vacation.

I was contemplating options whenever I will start a new array, and this EVA thing might just be something that I needed, because I wasn't planning to do a whole new set out of wood, and the dust...

I'm pretty sure the arrays (with about 25 drivers each) would bend from the weight, but I also dabble in making surfboards, so I could laminate the finished form (before adding the drivers) with something like fiberglass.

something to cogitate for me...

I'm a little late to the party, but I was on vacation.

I was contemplating options whenever I will start a new array, and this EVA thing might just be something that I needed, because I wasn't planning to do a whole new set out of wood, and the dust...

I'm pretty sure the arrays (with about 25 drivers each) would bend from the weight, but I also dabble in making surfboards, so I could laminate the finished form (before adding the drivers) with something like fiberglass.

something to cogitate for me...

Thanks for this thread!

I'm a little late to the party, but I was on vacation.

I was contemplating options whenever I will start a new array, and this EVA thing might just be something that I needed, because I wasn't planning to do a whole new set out of wood, and the dust...

I'm pretty sure the arrays (with about 25 drivers each) would bend from the weight, but I also dabble in making surfboards, so I could laminate the finished form (before adding the drivers) with something like fiberglass.

something to cogitate for me...

yeah if you are thinking of doing a 25 driver array with EVA it would need to be very thick layers or a higher density grade of panel, otherwise it would bend. But when EVA gets to about 4cm to 5cm thick it is actually quite strong. And it also is quite strong when glued in I-beam or T-bracing. You would also need a fair amount of foam for such a large project which could add up. Fiberglassing (or kevlar or carbon) would make for a very cool speaker though.

I haven't posted about this yet, but I tried some of those cheap EVA foam floor tiles we can easily find on amazon or home improvement stores. Like this style

Well those bumps are a real pain to sand flat. And since I really like to laminate my EVA, I need a flat surface to make good lamination glue contact. Bumps are usually only on one side, but it appears that it is coated in another type of plastic to hold the bump. I am still working on hand sanding my pieces. Just a bit of a warning about this style of EVA tiles. I guess a random orbit sander might be able to sand these bumps off more easily, but I am thinking I should just buy the more expensive and higher quality koyo-softboard instead from now on.

For a large project like you are thinking, you might be best considering ordering foam from a place like this.

https://www.foamorder.com/closed-cell-foam.html

EVA or even the cross-linked polyethylene foam is not really cheap stuff.

40" × 80" × 0.5" (101.6 × 203.2 × 1.3 cm) sheets are ~$35

40" × 80" × 1" (101.6 × 203.2 × 2.5 cm) sheets are ~$59

The koyo-softboard I buy in Japan comes in 66.6 x 100 x 1cm sheets at about $13 each.

here is another cross-linked polyethylene foam company

Crosslinked Polyethylene Foam, XLPE, Microcell, Volara, Zotefoams

EVA is polyethylene vinyl acetate and is one of the polyethylene types.

I am also starting to I think that the koyo-softboard that I am buying in Japan might be something between EVA and a custom polyethylene formula. All they say about the formula is "Koyo Soft Board is a foam board made from polyolefin resin and inorganic matter." which could mean EVA or xlinked polyethylene or something custom in between. I think either of these types will behave similarly. I have several types of PE and EVA foam now with different types of density, and they seem quite similar, but the more dense versions are more rigid while the lower density ones are more squishing. I will try to explore several types of these kinds of EVA and PE foams.

Last edited:

We have a lot of those tiles here in Taiwan.

I have one kind at home now that is flat EVA on one side, and some kind of felt on the other side... That could take care of some of the lining. Adding only a bit of polyfill inside.

I found a place online that sells 240x150cm panels of EVA in 12, 20, 24, 30, 40, 50mm. 50mm is about $100.

That would work for the arrays. Using a 50mm panel, grinding some internal grooves inside to take care of reflections, and bending into the shape I want.

Sounds like a cool project!

Now, I need to get my hands on some cool but not too pricey drivers. The VIFA TC9FD is not easy to get over here. I'll try my contact at Tang Band, see if they would have something to sell at a discount!

I have one kind at home now that is flat EVA on one side, and some kind of felt on the other side... That could take care of some of the lining. Adding only a bit of polyfill inside.

I found a place online that sells 240x150cm panels of EVA in 12, 20, 24, 30, 40, 50mm. 50mm is about $100.

That would work for the arrays. Using a 50mm panel, grinding some internal grooves inside to take care of reflections, and bending into the shape I want.

Sounds like a cool project!

Now, I need to get my hands on some cool but not too pricey drivers. The VIFA TC9FD is not easy to get over here. I'll try my contact at Tang Band, see if they would have something to sell at a discount!

Yeah for your project, starting with 50mm panels would be ideal. I have some 50mm EVA yoga blocks I use for exercise and they can hold my weight no problem.

I am also finding that Vifa/peerless are really hard to get in Japan (and very expensive when I do find them).

Did you see this thread http://www.diyaudio.com/forums/full...ind-comparison-2in-4in-drivers-round-3-a.html

The Tang Band W3-1364SA 3in was included and I thought it sounded quite good. Might be an option to consider.

Too bad UsherAudio doesn't make a high quality fullrange driver. I am very impressed with their drivers.

I am also finding that Vifa/peerless are really hard to get in Japan (and very expensive when I do find them).

Did you see this thread http://www.diyaudio.com/forums/full...ind-comparison-2in-4in-drivers-round-3-a.html

The Tang Band W3-1364SA 3in was included and I thought it sounded quite good. Might be an option to consider.

Too bad UsherAudio doesn't make a high quality fullrange driver. I am very impressed with their drivers.

I really like Usher as well. I had great listening sessions with some of their products, including the very cheap s520, which sounded amazing for the price and size. I wish they would do a full range.

The TB W3-1364A looks interesting, besides the drop at 15kHz, where in an array, you would like a rising response to counteract the comb filtering.

But,... it is almost 4 times the price of the VIFA TC9FD... not something interesting when looking at buying 50ish of them!

The TB W3-1364A looks interesting, besides the drop at 15kHz, where in an array, you would like a rising response to counteract the comb filtering.

But,... it is almost 4 times the price of the VIFA TC9FD... not something interesting when looking at buying 50ish of them!

BTW, what kind of glue did you use for the EVA panels?

I guess, before going all out on a pair of arrays, I should get comfy with something smaller! I have a few 3" drivers laying around... I'd like to make some enclosures for them, just to test it out.

I guess, before going all out on a pair of arrays, I should get comfy with something smaller! I have a few 3" drivers laying around... I'd like to make some enclosures for them, just to test it out.

I did the same thing. My first enclosure was a small sealed box for a fostex ff105. I would definitely recommend getting a 10mm or 20mm sheet and build something simple for your 3" driver to get familiar with the material.

I use a contact cement (rubber cement) called G17 (and here) but I think any type of rubber cement will do. I also use hot glue gun for some joints where I need the bond to setup quickly, like when I am bending the material. I do all my lamination with the G17 rubber cement though. I think it forms a better bond, but it takes much longer to set. I also run a bead of hot-glue around the inside edges to make sure I get perfect air-tight joints.

There are a few Tang Band W3 drivers which look interesting to me, but I have not tried yet. Like the W3-881SJ, W3-881SJF, W3-1319SA, maybe the W3-582SC. These are actually quite cheap here in Japan too. The W3-881SJ has nice reviews at parts-express. But nothing here is as cheap as the $12 Vifa TC9 they can buy in America.

I use a contact cement (rubber cement) called G17 (and here) but I think any type of rubber cement will do. I also use hot glue gun for some joints where I need the bond to setup quickly, like when I am bending the material. I do all my lamination with the G17 rubber cement though. I think it forms a better bond, but it takes much longer to set. I also run a bead of hot-glue around the inside edges to make sure I get perfect air-tight joints.

There are a few Tang Band W3 drivers which look interesting to me, but I have not tried yet. Like the W3-881SJ, W3-881SJF, W3-1319SA, maybe the W3-582SC. These are actually quite cheap here in Japan too. The W3-881SJ has nice reviews at parts-express. But nothing here is as cheap as the $12 Vifa TC9 they can buy in America.

Last edited:

I bet 3M Fastack 77 spray on contact cement would be ideal. It is a soft adhesive that sticks like crazy a very strong bond. The softness may allow some CLD action. I use it to glue EVA sheets for shoe repair so you know it's a strong bond. Just make sure you turn the can upside down to clear nozzle after each use or you won't have a spray head past one use.

.... and chance to get rid of on axis dip in highest octave 😀.

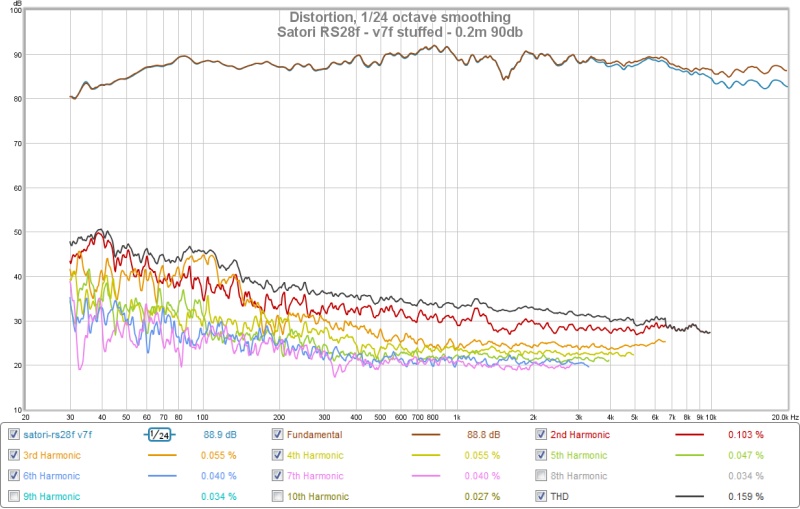

Here is another measurement at 0.2m 90db of my latest configuration with the fiberglass stuffing. This is measured at 0.2m and the level is dropped very low so that it measures on my SPL meter as 90db at 0.2m. This SPL level is close to my normal listening level but rather quiet (about 75db at my listening position). I am doing this to show how getting closer and optimizing the mic placement can cause that >10hz dip to disappear (my "broken" waveguide). Also at this low level and close distance almost all the room artifacts (<1khz) disappear. Also this is too close causing an artifact (close to the crossover point) to appears around 1.7khz. This 1.7khz dip is not real and is only heard at this close distance.

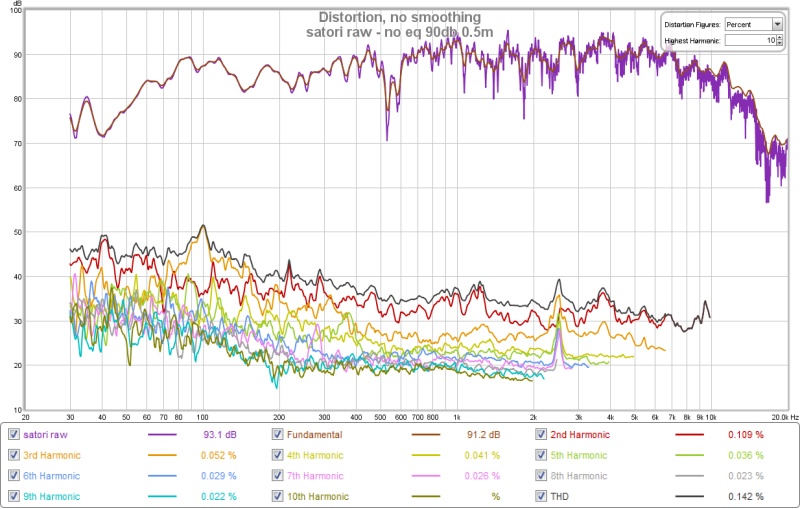

compared to the same speaker at 90db at 0.5m

Changing my measurements to 0.5m has made me realize that something is terribly wrong with my "waveguide" and why I want to make a new front baffle for the RS28f/satori.

I was initially doing all my measurements at 0.2m to remove all the room artifacts, but now I think this is too close for a 2way (the angle to individual driver is rather extreme). Now I am not sure I trust if this close a measurement is accurately describing what I hear at 0.75m-1m. I am certain my ears/brain know my room and make also sorts of adjustments to compensate.

Just shows how different mic placement, distance, room effects, SPL... can dramatically alter the measurements (recording). We don't have anechoic chambers. Maybe one day when I get very close to a final configuration, I will take the speaker to an open field for a "room free" measurement

But BRYTT you have motivated me so I think I will make the SB65/Satori baffle first 🙂

Attachments

Last edited:

I bet 3M Fastack 77 spray on contact cement would be ideal. It is a soft adhesive that sticks like crazy a very strong bond. The softness may allow some CLD action. I use it to glue EVA sheets for shoe repair so you know it's a strong bond. Just make sure you turn the can upside down to clear nozzle after each use or you won't have a spray head past one use.

I have that adhesive at home. I might give it a shot. But, it will need some hot glue to seal the joints, as that spray glue does not go uniformly.

I need to go to the city to get my EVA panels, then I can try to build something.

This is why I love DIY.. and this community!

Just shows how different mic placement, distance, room effects, SPL... can dramatically alter the measurements (recording). We don't have anechoic chambers.

My room is a mess of multi-phasing, reflection-happy orgy!

Still, it is the one available to me, and I have to make the best I can do with what I got.

I doubt I will ever be able to get a real musically centric room (lifestyle choices) but I will still enjoy music in the best fashion I can afford and build.

nice! I saw similar EVA tiles here in Tokyo and was wondering if they might work well. I also saw some here with a cork top layer which could be quite interesting. I think these will be nice to work with since they don't have those nasty bumps which will need to be sanded flat.

What driver are you thinking about using for your test build?

What driver are you thinking about using for your test build?

I have a few 3inchers at home to test. Especially an Aucharm that has really bad distorsion. Will see if an EVA enclosure would help it.

Perceval,

Looking forward to seeing a first followup EVA build in this thread. I like the look of the Aucharms, did not know they were bad in HD area... Next time I am in Taiwan, will surely bring a pair of TC9FD's for you. All the Dayton drivers are sourced from Taiwan - it's too bad they won't sell it straight from the factory for you. The PA130-8, PS95-8, RS100-4, RS100P-4, RS225-8, RS28F-8, DS28F-8, are all nice drivers.

Looking forward to seeing a first followup EVA build in this thread. I like the look of the Aucharms, did not know they were bad in HD area... Next time I am in Taiwan, will surely bring a pair of TC9FD's for you. All the Dayton drivers are sourced from Taiwan - it's too bad they won't sell it straight from the factory for you. The PA130-8, PS95-8, RS100-4, RS100P-4, RS225-8, RS28F-8, DS28F-8, are all nice drivers.

Sorry! My bad!

I am getting mixed up in the names here!

I meant the AuraSound, not the Aucharm... need to buy a couple of those to test.

The AuraSound I got, with the "suede" surround have terrible distorsion.

I am getting mixed up in the names here!

I meant the AuraSound, not the Aucharm... need to buy a couple of those to test.

The AuraSound I got, with the "suede" surround have terrible distorsion.

I think I found a project to use my EVA panels.

I've been wanting to make a portable "boominator". I think the EVA panels will be interesting as they would sustain the bumps and bruises of a portable system, as jeshi's says his small desktops can be tossed across the room with no damage.

Should be fun!

I've been wanting to make a portable "boominator". I think the EVA panels will be interesting as they would sustain the bumps and bruises of a portable system, as jeshi's says his small desktops can be tossed across the room with no damage.

Should be fun!

- Home

- Loudspeakers

- Full Range

- EVA foam for performance speaker enclosures