hmm another thought came to me regarding those floppy EVA mats (yoga mat or the sleeping pad linked above). It might be interesting to explore a very floppy enclosure. Use a rigid space-frame to define a lattice and perimeter shape (dowels, plastic rods) and then cover in the floppy EVA and seal to make an airtight enclosure. Might work for 2"-4" drivers, maybe even for larger drivers but would require lots more lattice work. But it also seems like a lot of effort.

jeshi,

Like to try a small EVA foam build and found below EVA sleeping pad 180x50x0,8 cm cost 8€ is that okay if one laminate to 16mm.

Thougts was a desktop full ranger with RS100P-4 cause it have 4mm Xmax can take a mild linkwitz transform and at then at close range low SPL be fair wideband.

BYRTT, the more I look at the picture of the EVA mat, it actually looks to be semi rigid and maybe slightly more dense than a yoga mat. It is being held into the roll very tightly by some serious straps, which leads me to believe it might unroll by itself. It might actually work ok if you laminate it to 16mm. For 8euro I would personally buy it and try using it. Even if it doesn't work, it is not a lot of wasted money. But then again I am happy to experiment with different materials

OK here are some photos to show the semi-rigid nature of the EVA that I am working with. The white is the koyo-softboard EVA. The orange is a cheap EVA floor tile. The koyo softboard is 10mm and the orange EVA is 12mm. The orange is lower density, more flexible and less rigid.

Attachments

jeshi,

Thanks as you say not a lot of wasted money and should it work it will be a cheap enclosure, will go to town couple of days and buy that 8mm one plus some glue and share experience if the EVA type will be too floppy and jump around and/or off the computer table. Will start some simple i can handle and if it works good i never forget gmad and xrk971 hupercube builds which should be doable in this material.

Link to original by gmad and crazy nice plots (first picture) http://www.diyaudio.com/forums/full-range/265053-hypercube-loudspeakers-48.html.

Link to excellent sound clip 1 xrk971 build (second picture) http://www.diyaudio.com/forums/full-range/268037-fast-tl-8.html#post4192688.

Thanks as you say not a lot of wasted money and should it work it will be a cheap enclosure, will go to town couple of days and buy that 8mm one plus some glue and share experience if the EVA type will be too floppy and jump around and/or off the computer table. Will start some simple i can handle and if it works good i never forget gmad and xrk971 hupercube builds which should be doable in this material.

Link to original by gmad and crazy nice plots (first picture) http://www.diyaudio.com/forums/full-range/265053-hypercube-loudspeakers-48.html.

Link to excellent sound clip 1 xrk971 build (second picture) http://www.diyaudio.com/forums/full-range/268037-fast-tl-8.html#post4192688.

Attachments

Why not laminate some very thin but still strong layer between the mats? Somethin like thin alumimum or even some thin wood or strong paper would make the boards stiffer. Those materials would limit the flex of the sheet, and if used on both sides of the inner foam it would make the structure rigid.

It might be interesting to explore a very floppy enclosure. Use a rigid space-frame to define a lattice and perimeter shape (dowels, plastic rods) and then cover in the floppy EVA and seal to make an airtight enclosure.

Space frame could be fabricated with 3D-printing, or some of the open-frame stands primarily sold for use in kitchens could be re-appropriated. Or perhaps a wire mesh basket, tray or strainer. Tokyu-Hands or DIY home improvement stores should provide plenty of inspiration.

If the space-frame can be counted on to provide sufficient stiffness, the outer skin could be made thinner and floppier.

jonathan

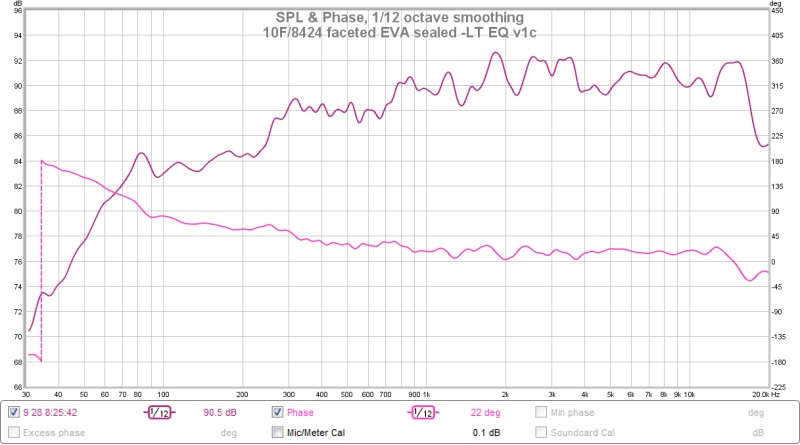

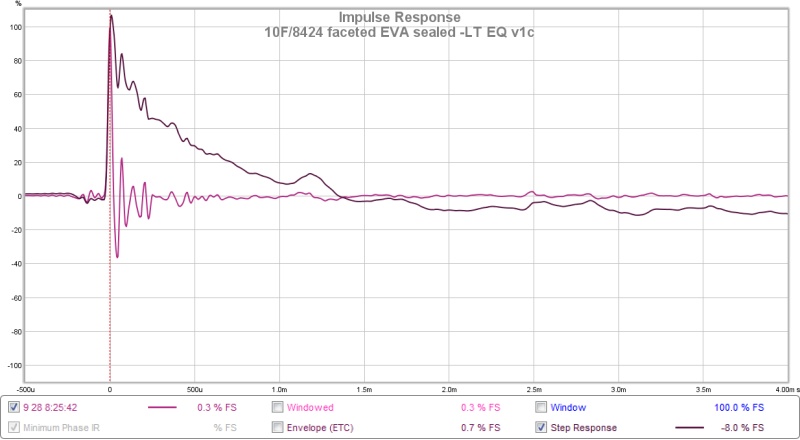

I finished the black painted faceted sealed box for my 10f/8424.They are looking really good and I am very happy with them!

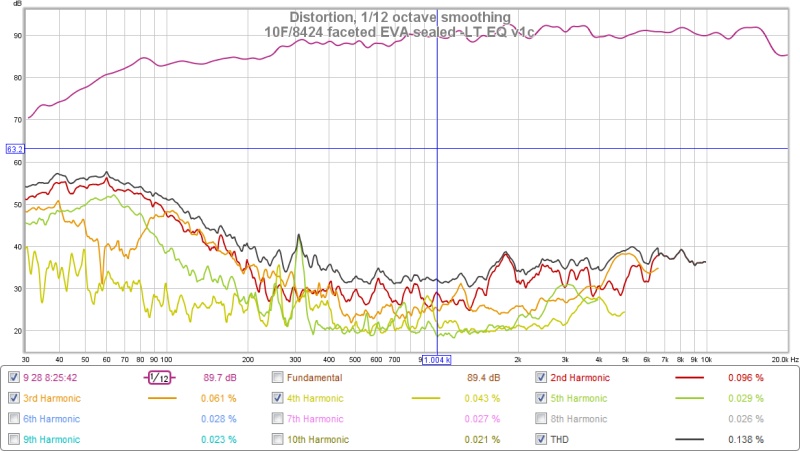

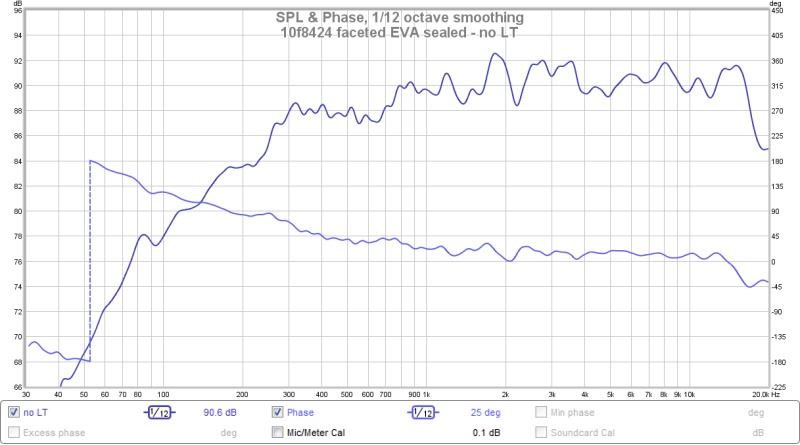

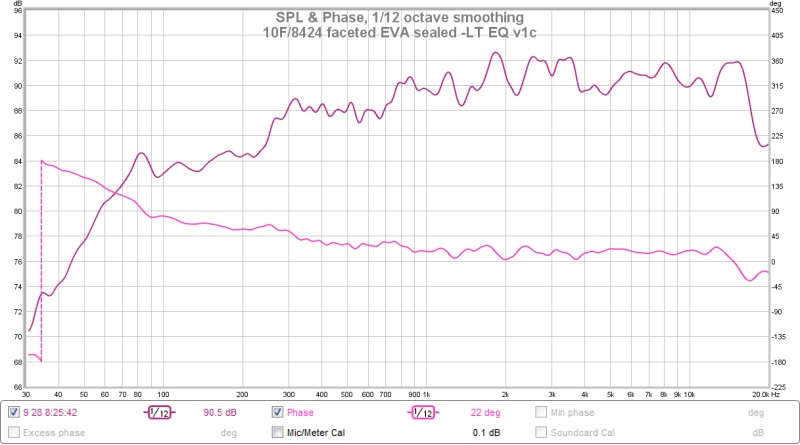

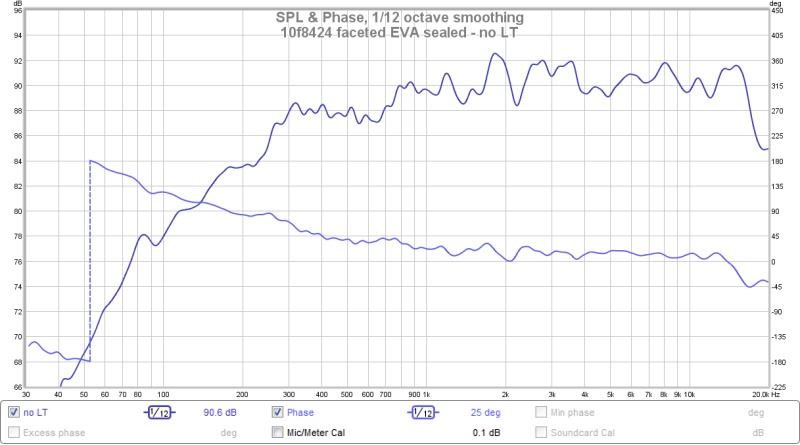

The faceted baffle fixed a baffle-step problem with the original, and it seems to give a very smooth response. With this geometry box (1.6L no parallel walls, truncated pyramid with rounded top) and faceted baffle, I get an excellent one-driver speaker that approaches the LS3/5a small monitors. This was my target : one-driver small monitor, sealed box, LT, 80-20khz response, clean low distortion.

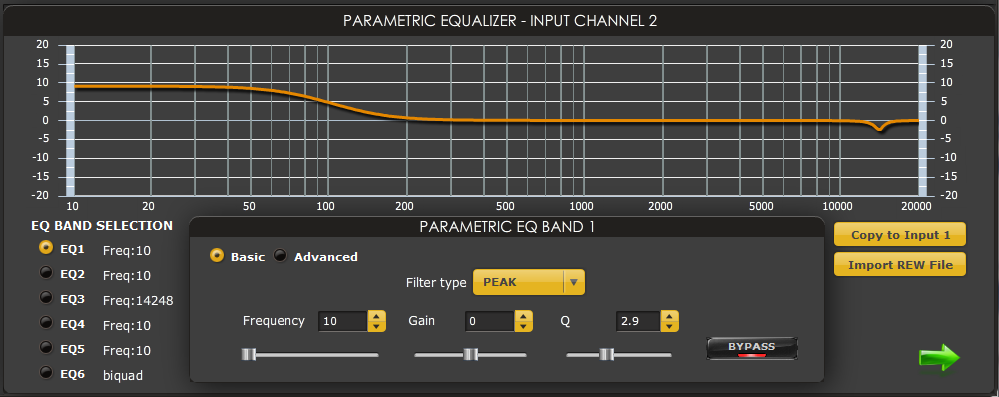

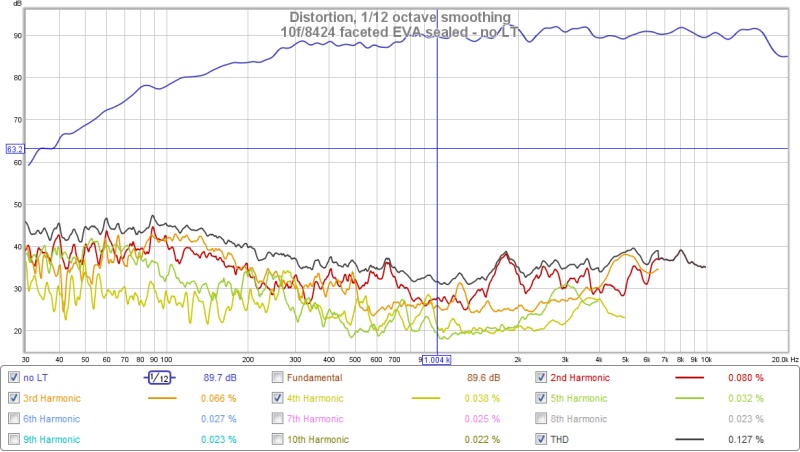

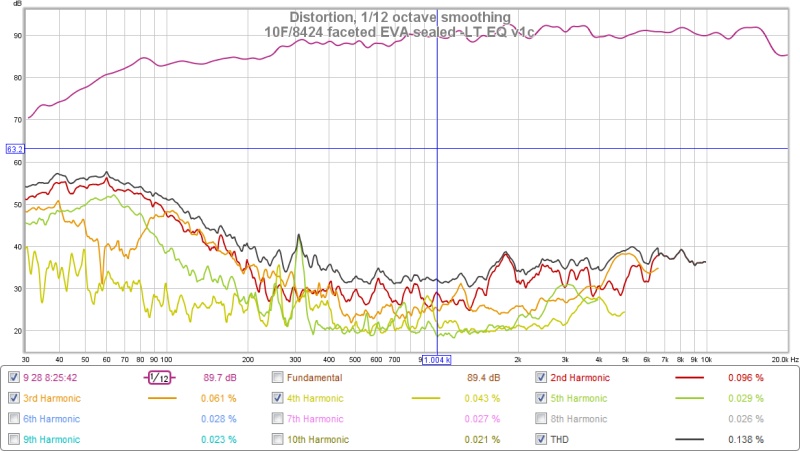

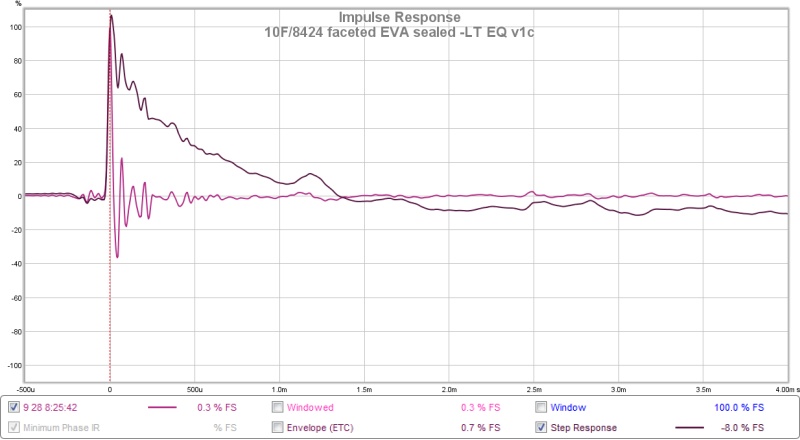

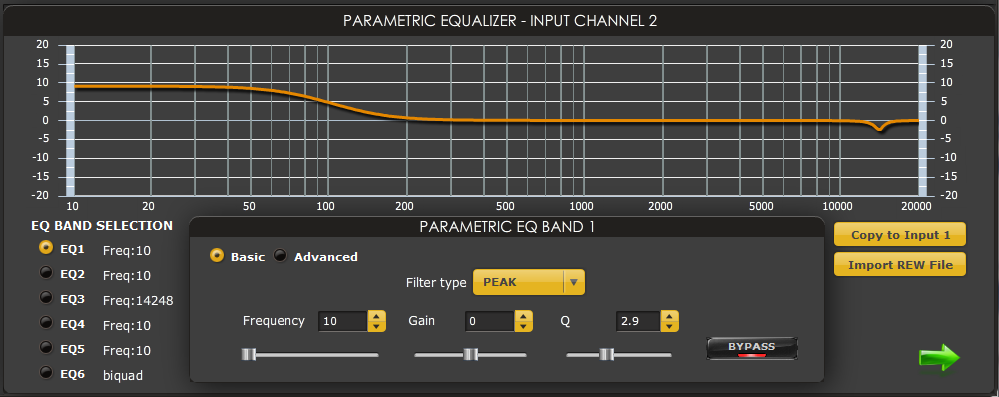

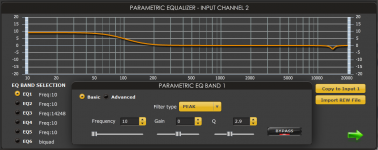

For this I apply a linkwitz transform to lift the bass and a single EQ peak at 14300hz to tame the high end a little. But this second EQ is right on the edge of my hearing range so maybe not critical, but it does seem to help and makes it easier to listen to the speaker for longer sessions. The 10f/8424 has such low distortion and excellent driver control that it responds very well to LT without causing distortion problems.

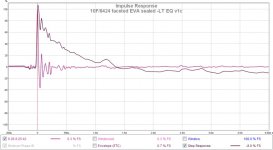

Measurements are at 20cm and calibrated response shown in graphs is accurate. very very happy.

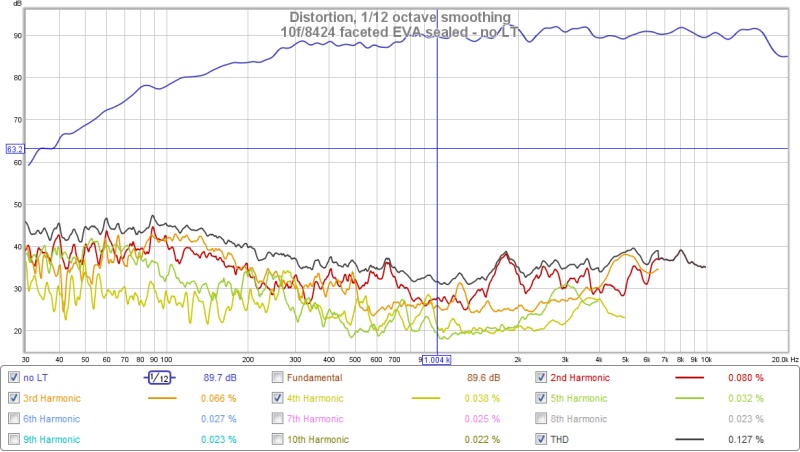

and without the linkwitz transform to show the low distortion. I may play with the LT in the future to see if I can get a better balance of extension to 80hz and low distortion.

The faceted baffle fixed a baffle-step problem with the original, and it seems to give a very smooth response. With this geometry box (1.6L no parallel walls, truncated pyramid with rounded top) and faceted baffle, I get an excellent one-driver speaker that approaches the LS3/5a small monitors. This was my target : one-driver small monitor, sealed box, LT, 80-20khz response, clean low distortion.

For this I apply a linkwitz transform to lift the bass and a single EQ peak at 14300hz to tame the high end a little. But this second EQ is right on the edge of my hearing range so maybe not critical, but it does seem to help and makes it easier to listen to the speaker for longer sessions. The 10f/8424 has such low distortion and excellent driver control that it responds very well to LT without causing distortion problems.

Measurements are at 20cm and calibrated response shown in graphs is accurate. very very happy.

and without the linkwitz transform to show the low distortion. I may play with the LT in the future to see if I can get a better balance of extension to 80hz and low distortion.

Attachments

-

10f-8424-faceted-sealed-EQ.PNG59.7 KB · Views: 803

10f-8424-faceted-sealed-EQ.PNG59.7 KB · Views: 803 -

10f-8424-black-facet-LTEQ-v1b-IMP.jpg66.1 KB · Views: 793

10f-8424-black-facet-LTEQ-v1b-IMP.jpg66.1 KB · Views: 793 -

10f-8424-black-facet-LTEQ-v1b-HD.jpg112.1 KB · Views: 1,567

10f-8424-black-facet-LTEQ-v1b-HD.jpg112.1 KB · Views: 1,567 -

10f-8424-black-facet-LTEQ-v1b-FR.jpg88.2 KB · Views: 849

10f-8424-black-facet-LTEQ-v1b-FR.jpg88.2 KB · Views: 849 -

P1110593.jpg107 KB · Views: 1,556

P1110593.jpg107 KB · Views: 1,556 -

10f-8424-black-facet-EQ-noLT-v1c-FR.jpg87.1 KB · Views: 800

10f-8424-black-facet-EQ-noLT-v1c-FR.jpg87.1 KB · Views: 800 -

10f-8424-black-facet-EQ-noLT-v1c-HD.jpg111.1 KB · Views: 779

10f-8424-black-facet-EQ-noLT-v1c-HD.jpg111.1 KB · Views: 779

Last edited:

That's a beautiful looking and great performing speaker you made there. The measurements all look fantastic. Must sound wonderful.

Thanks sharing jeshi, agree what X said also the version without LT if placed upon your Satori woofer could probably make nice extended bandwidth sound result.

Nice work! Both appearance and measurements look very good. Have you had a chance to listen at length?

Nice work! Both appearance and measurements look very good. Have you had a chance to listen at length?

Well I only have the one speaker built at this time, so I don't have proper impressions of stereo yet (imaging, 3d depth). But I have listened in mono for a fair amount and did a little listening with my Focal CMS40 doing the left and the 10f/8424 doing the right. At this point I can just say that they sound good enough that I definitely want to build a pair.

I also was working on some vocal composing (vocaloid) on a pop style track last week and used the 10f/8424 for a couple hours and it immediately felt normal. I could easily hear enough details to make fine adjustments to the vocals, and I was able to work with them for a few hours without any fatigue. I checked the result on my Focals and stax afterwards and it sounded good. With female vocals, the range of this 10f was more than enough to give a perfect impression/window on the sound (no need for more bass weight below 80hz).

So overall they are looking very promising. Give me a little more time before I pass final judgement (like are they better at X than my other speakers, or do I prefer them for Y, or good but I prefer using Z....). So far I would say they are competent monitors that work excellently in the midrange (female vocals, acoustic guitars, piano melodies). I am also fairly certain that I prefer them over the (eqed) FF105wk in the same box. But still want to spend more time with them all (10f, FF105wk, SB65).

Last edited:

In case anyone is curious. I use this program to simulate baffle diffraction and why I ended up with the trapezoid shape that I did for these small truncated pyramids

Baffle Diffraction Simulator

The front baffle on these is 210mm tall, 170mm at the bottom, 100mm at the top, with the driver centered at 100mm up from the bottom.

Here is this trapezoid design with the 10f/8424 and resulting diffraction simulation. Here I use a 12mm facet chamfer which is very close to the final. The only difference is that I did not cut a facet on the bottom of the baffle.

And here is what a 210mm x 140mm rectangular baffle with 2mm of rounded over edge would look like.

One thing I learned from this simulator is that there will always be a baffle step and diffraction, so the best we can do is minimize it and control it. This facet and trapezoid shape is about the best I ever simulated.

Baffle Diffraction Simulator

The front baffle on these is 210mm tall, 170mm at the bottom, 100mm at the top, with the driver centered at 100mm up from the bottom.

Here is this trapezoid design with the 10f/8424 and resulting diffraction simulation. Here I use a 12mm facet chamfer which is very close to the final. The only difference is that I did not cut a facet on the bottom of the baffle.

And here is what a 210mm x 140mm rectangular baffle with 2mm of rounded over edge would look like.

One thing I learned from this simulator is that there will always be a baffle step and diffraction, so the best we can do is minimize it and control it. This facet and trapezoid shape is about the best I ever simulated.

Attachments

Last edited:

Well, a very large baffle like an IEC 268-5 that is 53in wide x 65in tall with a 6.0in (h) and 9in (v) offset for the driver does very well and hardly has any baffle step or large wiggles. But then it is huge, so you are saying for a nice compact baffle. Or a flush wall mounted IB is good too.

It's interesting the dimensions you have on your trapezoid are very similar in proportions to the one I made for the Subjective Blind tests: 10in wide base by 7in wide top by about 12in tall.

It's interesting the dimensions you have on your trapezoid are very similar in proportions to the one I made for the Subjective Blind tests: 10in wide base by 7in wide top by about 12in tall.

Last edited:

Thanks for the bafle diffraction soft !

Is it not possible to make half a sphere with EVA sheets and a hot air pulsed gun ? (don't know the real name in English of this common tool for remove painting from wood !)

I imagine with an aluminium salad big bowl from Ikea for the shape, a 4" could work, how to do the load with acurrate volume can be a problem though !

So half a sphere on a cubic enclosure, make the difference with the volume of half-sphere by filling with the same volume the cubic box to have the correct calculated volume with only the box and its driver ! 🙄

With some Platre de Paris it could work too, but less fun than with EVA !

Is it not possible to make half a sphere with EVA sheets and a hot air pulsed gun ? (don't know the real name in English of this common tool for remove painting from wood !)

I imagine with an aluminium salad big bowl from Ikea for the shape, a 4" could work, how to do the load with acurrate volume can be a problem though !

So half a sphere on a cubic enclosure, make the difference with the volume of half-sphere by filling with the same volume the cubic box to have the correct calculated volume with only the box and its driver ! 🙄

With some Platre de Paris it could work too, but less fun than with EVA !

Well those turned out very well. 😀 First thing I noticed was the exceptional lack of baffle diffraction wiggles, especially on a relatively small baffle. Chamfered trapezoids rock. 😉 I suspect that the relative roughness of the EVA may be helpful too. Even though it's closed cell foam, it's got to be a better surface than the usual glossy finished wood.

Personally I like the unpainted foam better cuz it looks like Kermit, but I have weird aesthetic taste. Both looks are nice in their own way.

Personally I like the unpainted foam better cuz it looks like Kermit, but I have weird aesthetic taste. Both looks are nice in their own way.

Thanks for the bafle diffraction soft !

Is it not possible to make half a sphere with EVA sheets and a hot air pulsed gun ? (don't know the real name in English of this common tool for remove painting from wood !)

"heat gun"

I've never worked with EVA so I can't tell you if it would work. I'm sure some 'maker' websited will be full of tips. Most foams carve easily with a hot wire knife. You can make your own or buy one from a hobby shop. Electric carving knives are pretty good on styrofoam.

With some Platre de Paris it could work too, but less fun than with EVA !

I don't know about that. Plaster of Paris is great fun. You get to make a mess and it makes you feel like a ten year old. 😀 Seriously, it is a good material. If reinforced with burlap it is very strong. I wonder why more folks don't use it as it is an easy way to create complex shapes, and it is not toxic and smelly like fiberglass resin.

The trapezoidal is near from a famous speaker from Wilson Audio 🙂 : althoug the bafle step was tilted to the ceilling (for progressive time alignment with the tweeter I assume or for some polar map reason in relation with the choosed drivers !). And also a famous JBL !

Nice I will try the soft with trapezoidal form and a 10" and 12" to see how it works for such bafle !

For sure, the EVA, especially with complex shape like a horn could make also a good fast mold for Plaster from Paris ! I read than even with wood, horns needs some painting/varnish to sounds better than raw wood ! Myth ?

That's nice, EVA is maybe as good to make some small cabinets as molds if no wood skill and expensive wood Tools are needed for heavier enclosures !

I saw Gedlee use a "plastic" material for front bafle ! And in some months 3D printing should be less and less costy with huger design possibilities (3D printers with mortar materials already exist !)

Really a mess thin EVA is hard to find in our country for non Professional people, I would like to try it around my tweeter and the mechanical filter of my mids in the Boston Lynnfield 400 L !

It could be usefull to know from which frequency the energy wave goes through an EVA sheet in relation to its thickness ? If the sheet in itself doesn't radiate as wood, maybe low frequencies can pass ??? With less and less dB loss as the FR is going to the low end ?

Nice I will try the soft with trapezoidal form and a 10" and 12" to see how it works for such bafle !

For sure, the EVA, especially with complex shape like a horn could make also a good fast mold for Plaster from Paris ! I read than even with wood, horns needs some painting/varnish to sounds better than raw wood ! Myth ?

That's nice, EVA is maybe as good to make some small cabinets as molds if no wood skill and expensive wood Tools are needed for heavier enclosures !

I saw Gedlee use a "plastic" material for front bafle ! And in some months 3D printing should be less and less costy with huger design possibilities (3D printers with mortar materials already exist !)

Really a mess thin EVA is hard to find in our country for non Professional people, I would like to try it around my tweeter and the mechanical filter of my mids in the Boston Lynnfield 400 L !

It could be usefull to know from which frequency the energy wave goes through an EVA sheet in relation to its thickness ? If the sheet in itself doesn't radiate as wood, maybe low frequencies can pass ??? With less and less dB loss as the FR is going to the low end ?

Last edited:

The trapezoidal is near from a famous speaker from Wilson Audio 🙂 : althoug the bafle step was tilted to the ceilling (for progressive time alignment with the tweeter I assume or for some polar map reason in relation with the choosed drivers !). And also a famous JBL !

Nice I will try the soft with trapezoidal form and a 10" and 12" to see how it works for such bafle !

For sure, the EVA, especially with complex shape like a horn could make also a good fast mold for Plaster from Paris ! I read than even with wood, horns needs some painting/varnish to sounds better than raw wood ! Myth ?

That's nice, EVA is maybe as good to make some small cabinets as molds if no wood skill and expensive wood Tools are needed for heavier enclosures !

I saw Gedlee use a "plastic" material for front bafle ! And in some months 3D printing should be less and less costy with huger design possibilities (3D printers with mortar materials already exist !)

Really a mess thin EVA is hard to find in our country for non Professional people, I would like to try it around my tweeter and the mechanical filter of my mids in the Boston Lynnfield 400 L !

Yes the Wilson WATT was a big inspiration for me 😉 I really liked the pyramid shape of the WATT. My enclosures also have a slight ceiling sloping front baffle. My idea was that many full range drivers have slightly smoother frequency response slightly off axis.

Sorry you are having such trouble finding EVA in France.

It could be usefull to know from which frequency the energy wave goes through an EVA sheet in relation to its thickness ? If the sheet in itself doesn't radiate as wood, maybe low frequencies can pass ??? With less and less dB loss as the FR is going to the low end ?

It is in my plans to do these sorts of tests. I wanted to do something a little more scientific on the next round of testing to help convince people. But I can also do something quick and less rigorous if it will help give some impressions? I still don't have MDF or other common materials to compare to. Ok maybe I can pick up a small piece of MDF on the way home from work tonight.

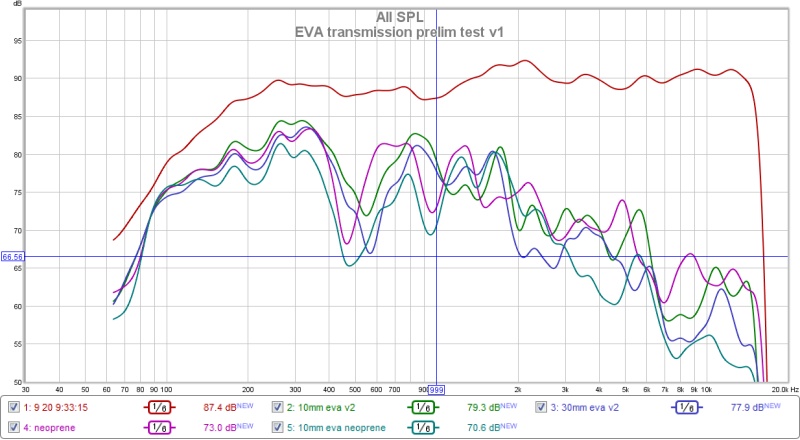

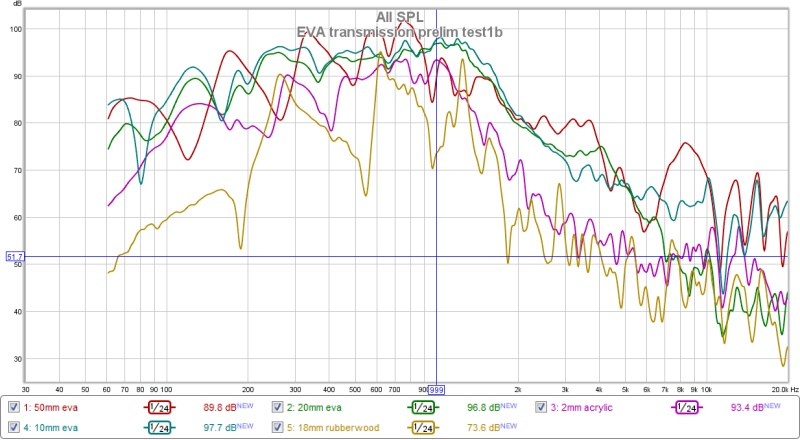

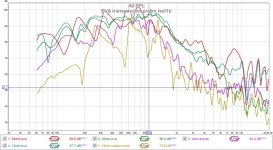

Here are some preliminary transmission measurements I did awhile back. The sound can leak around the sides of the panels so it needs to be looked at in a relative manner. I used my SB65 as the sound source, pointed up, set up mic at about 15cm distance (enough space to insert panel), and then I held a panel between the speaker and the mic (not touching). So just compare to the reference plot or to others.

PLEASE take these as very preliminary

I will also include another plot which I took earlier without the reference (no panel) measurement.

The 50mm EVA is a yoga block so it is a different material/manufacturer than the other EVA sheets (10mm,20mm,30mm koyo softboard).

So the EVA does appear quit similar to other materials, and in the 3khz and up region we are seeing 30-40db of attenuation which should be enough no matter the material.

The rubberwood does appear a little better at attenuating lower frequencies though. The 2mm acrylic/plastic seems to attenuate the high frequency a little better than EVA but probably no difference below that. EVA is a much smoother attenuation than the rubberwood, so the wood would probably add more "color" to the sound even though it attenuates some frequencies better.

Attachments

-

EVA-transmission-prelim-test1.jpg108.1 KB · Views: 1,185

EVA-transmission-prelim-test1.jpg108.1 KB · Views: 1,185 -

EVA-transmission-prelim-test1-10vs30.jpg94.4 KB · Views: 98

EVA-transmission-prelim-test1-10vs30.jpg94.4 KB · Views: 98 -

EVA-transmission-prelim-test1-10vsneoprene.jpg95.6 KB · Views: 93

EVA-transmission-prelim-test1-10vsneoprene.jpg95.6 KB · Views: 93 -

EVA-transmission-prelim-test1-30-vs-10+neoprene.jpg94.5 KB · Views: 96

EVA-transmission-prelim-test1-30-vs-10+neoprene.jpg94.5 KB · Views: 96 -

EVA-transmission-prelim-test1b.jpg116.2 KB · Views: 1,209

EVA-transmission-prelim-test1b.jpg116.2 KB · Views: 1,209

Last edited:

"heat gun"

I've never worked with EVA so I can't tell you if it would work. I'm sure some 'maker' websited will be full of tips. Most foams carve easily with a hot wire knife. You can make your own or buy one from a hobby shop. Electric carving knives are pretty good on styrofoam.

Actually you don't want to use a hot wire (electric carving knife) with EVA, it does not work. That only works with styrofoam. EVA is heat resistant so the hot wire just slowly burns the EVA and makes a mess.

Here is a video on cutting EVA foam

https://www.youtube.com/watch?v=q1h7J9JZQWs

But yes EVA does respond to heatguns to soften the material and shape it. It can be easily molded into bowls and curves. Here is a video about forming EVA foam

https://www.youtube.com/watch?v=hNLKvlYcgmM

you can see from these videos that they mostly use those 10-12mm thick floor tiles (smooth on one side, bumps on the other side)

Last edited:

- Home

- Loudspeakers

- Full Range

- EVA foam for performance speaker enclosures