I am almost finished with a new box for my 10f/8424. Made it with a faceted baffle like Troels Ellam Flex or an Usher Dancer miniX

And I am painting it with black gesso to give it a stealth fighter / batman style look. Paint is drying. But here are some pics of the front baffle facets before painting and with two coats of gesso. If it works out well, I will make a pair for the 10f/8424.

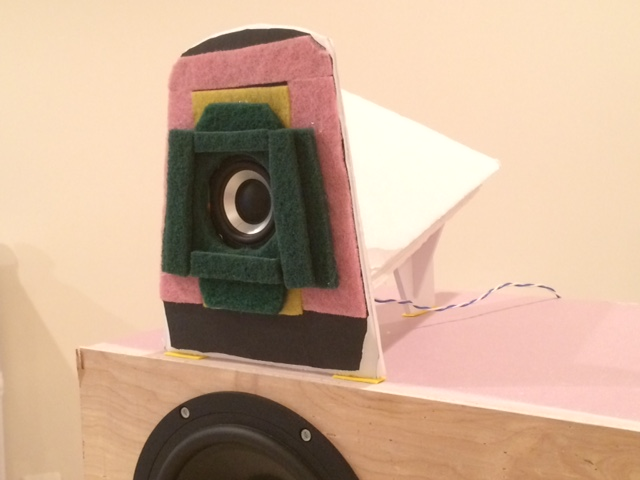

Also my little SB65 cannoli-TL is sounding really excellent! I still think the 10f/8424 is better all around, but the SB65 is really liking the aperiodic tapered TL and it is a great little near-field single driver speaker now. It has very surprising bass: just enough weigh, but very tight and tuneful and sounds much more in controller with lower distortion than when it was in a just a sealed box. The rolloff is very gentle.

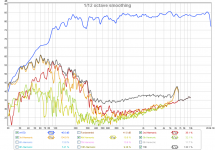

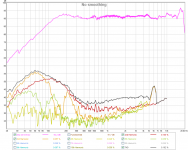

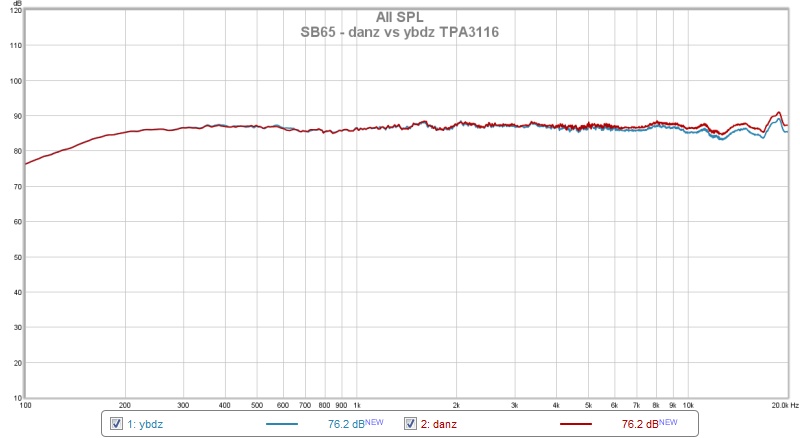

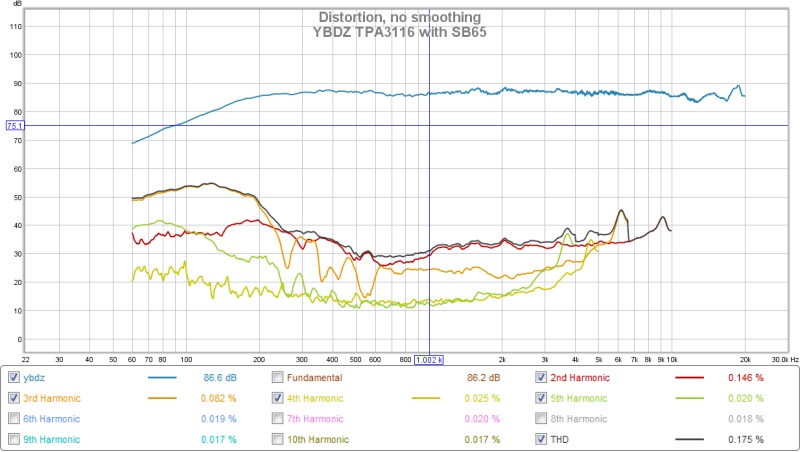

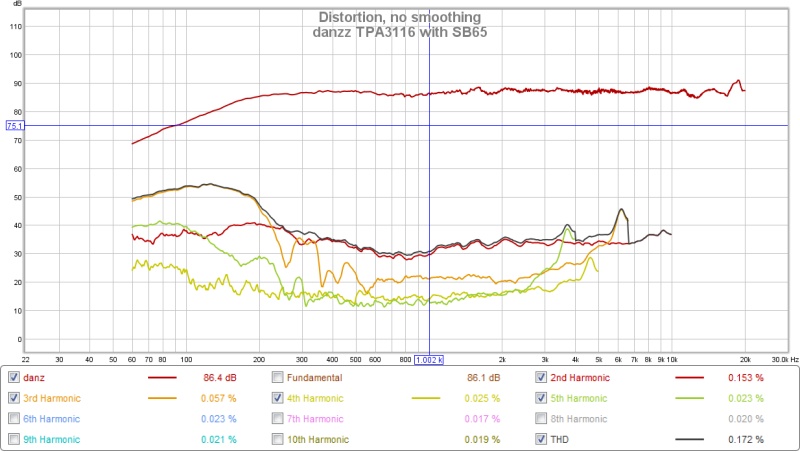

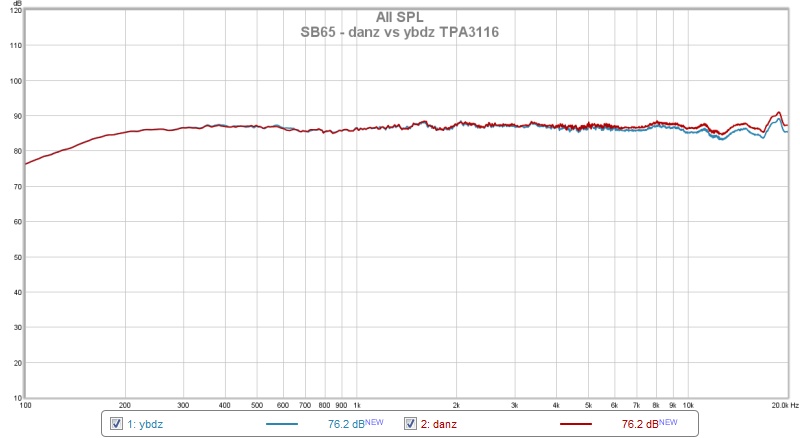

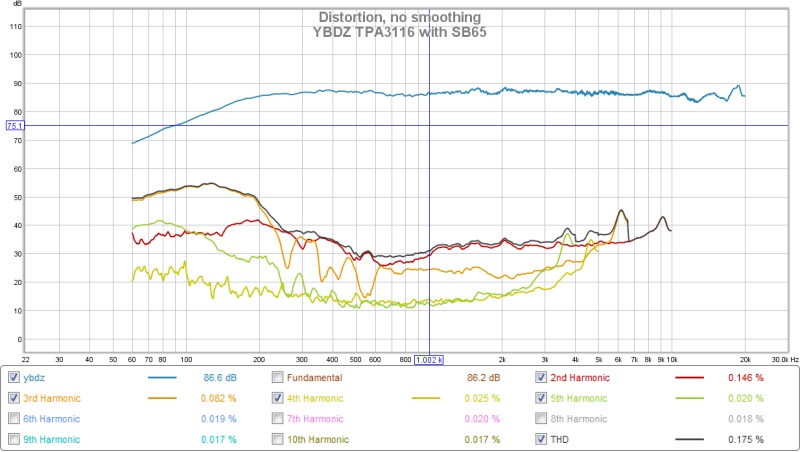

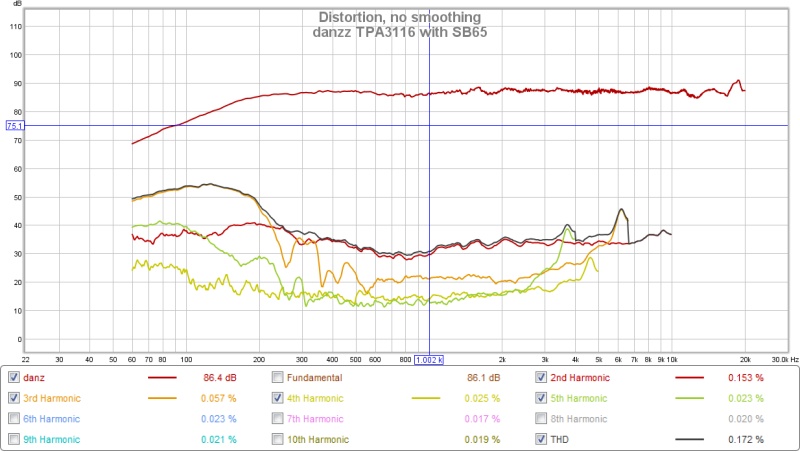

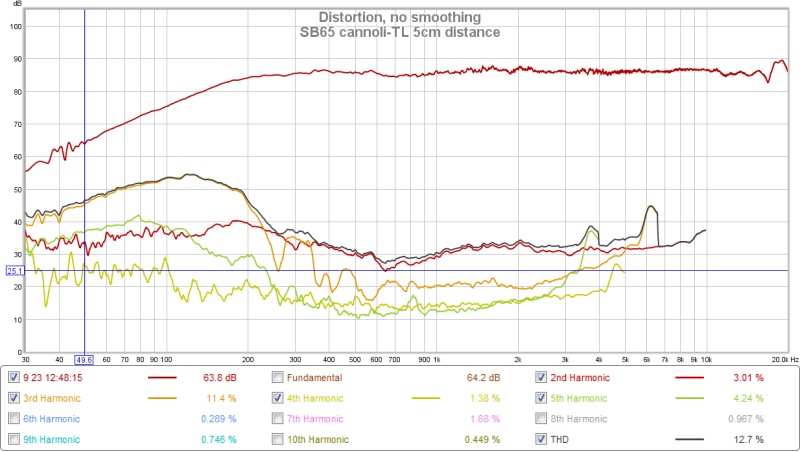

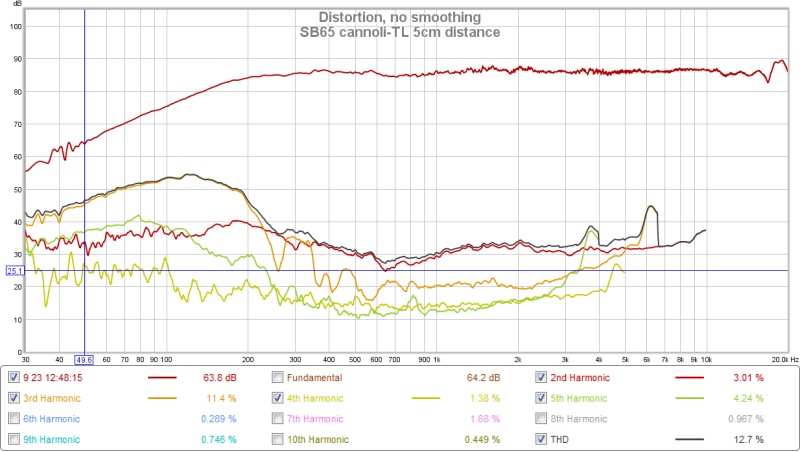

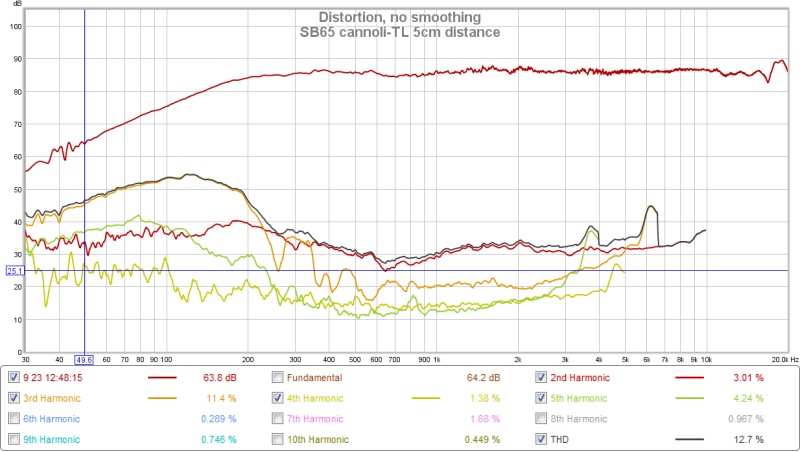

I also did some quick measurements of two of my favorite TPA3116 amps: the danzz YB blue/black amp verses the ybdz. I am starting to think I actually prefer the danzz blue/black amp more now. Seems a little cleaner sounding to me than the ybdz. Both are unmodified at this point. Here are some measurements at 5cm distance and a low SPL of the two amps with the SB65 cannoli-TL. You can also see that the amps have a very slightly different treble response and maybe the danzz has a little lower distortion. I did the measurements several times (switching back and forth) to make sure I was not accidentally moving the speaker. I just swapping cables between the amps.

And I am painting it with black gesso to give it a stealth fighter / batman style look. Paint is drying. But here are some pics of the front baffle facets before painting and with two coats of gesso. If it works out well, I will make a pair for the 10f/8424.

Also my little SB65 cannoli-TL is sounding really excellent! I still think the 10f/8424 is better all around, but the SB65 is really liking the aperiodic tapered TL and it is a great little near-field single driver speaker now. It has very surprising bass: just enough weigh, but very tight and tuneful and sounds much more in controller with lower distortion than when it was in a just a sealed box. The rolloff is very gentle.

I also did some quick measurements of two of my favorite TPA3116 amps: the danzz YB blue/black amp verses the ybdz. I am starting to think I actually prefer the danzz blue/black amp more now. Seems a little cleaner sounding to me than the ybdz. Both are unmodified at this point. Here are some measurements at 5cm distance and a low SPL of the two amps with the SB65 cannoli-TL. You can also see that the amps have a very slightly different treble response and maybe the danzz has a little lower distortion. I did the measurements several times (switching back and forth) to make sure I was not accidentally moving the speaker. I just swapping cables between the amps.

Attachments

-

SB65-dantz-ybdz-FR.jpg61.9 KB · Views: 607

SB65-dantz-ybdz-FR.jpg61.9 KB · Views: 607 -

SB65-ybdz-HD.jpg102.1 KB · Views: 633

SB65-ybdz-HD.jpg102.1 KB · Views: 633 -

SB65-danzz-HD.jpg103 KB · Views: 590

SB65-danzz-HD.jpg103 KB · Views: 590 -

P1110528.jpg80.9 KB · Views: 102

P1110528.jpg80.9 KB · Views: 102 -

P1110527.jpg88.3 KB · Views: 96

P1110527.jpg88.3 KB · Views: 96 -

P1110525.jpg108.1 KB · Views: 662

P1110525.jpg108.1 KB · Views: 662 -

P1110524.jpg94.9 KB · Views: 1,237

P1110524.jpg94.9 KB · Views: 1,237 -

P1110523.jpg106.1 KB · Views: 106

P1110523.jpg106.1 KB · Views: 106 -

P1110529.jpg111.9 KB · Views: 686

P1110529.jpg111.9 KB · Views: 686

Last edited:

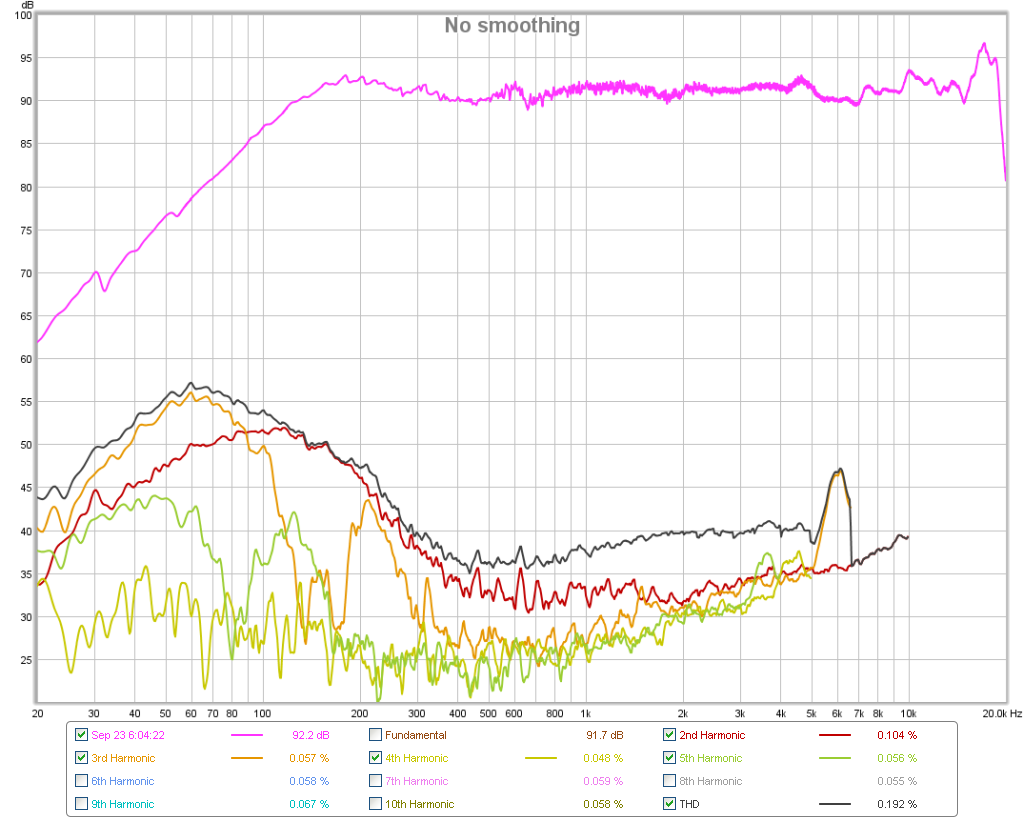

Here is an extended sweep going down to 30hz of the SB65 cannoli-TL. Even at 30hz and 40hz the driver cone motion is very well damped in this aperiodic TL. There is no need for applying any rolloff "protection" filters.

I wouldn't call this "reference level" but it sounds surprisingly good. And even though I am applying a tiny amount of EQ, it really does not need any.

The fact that the bass rolls off at such an even steady rate allows our ears to compensate easily. No it is not the same level as the satori/RS28f nor the 10f/8424 but it is a speaker I am really enjoying using when I want to keep the volume down. These can definitely play loud enough to watch a movie at night 2meters away from the speaker and hear a full sound without excess bass that would disturb the neighbors. And they do sound wonderful on acoustic music and female vocals.

I wouldn't call this "reference level" but it sounds surprisingly good. And even though I am applying a tiny amount of EQ, it really does not need any.

The fact that the bass rolls off at such an even steady rate allows our ears to compensate easily. No it is not the same level as the satori/RS28f nor the 10f/8424 but it is a speaker I am really enjoying using when I want to keep the volume down. These can definitely play loud enough to watch a movie at night 2meters away from the speaker and hear a full sound without excess bass that would disturb the neighbors. And they do sound wonderful on acoustic music and female vocals.

Attachments

Last edited:

jeshi

I may have missed it but how do attach the driver to the eva foam?

Jay

If the driver is heavier like the SB acoustics Satori MW16p, then I use hard inserts. I use a local japanese version of this for softwood.

Threaded Inserts for Soft Wood | E-Z LOK

http://www.diyaudio.com/forums/full...ormance-speaker-enclosures-5.html#post4401340

But in all cases I cut a recess for the drivers (like you can see above). I cut the recess a fraction on the small size so that when I push the driver into the foam, it will compress slightly and hold the driver (and form a better air seal). The EVA is soft and compressible so this works really well, kind of a press-fit seal. So with small 2.5"-3.5" drivers the pressfit is almost enough, but I still run threaded bolts or wood screws through the foam to add more friction. On this next 10f/8424 box I am going to try to glue some M3 nuts into the foam. I am not sure if there are M3 sized threaded inserts.

Thank you. That was quick. Thank you for the links as well. Do you use sharp blades to cut the to cut the foam like X does with his foam core or are other tools more appropriate?

Jeshi,

Great work on the new box - love the faceted look. That EVA takes to being sanded like nothing I have seen except maybe plaster of Paris. 🙂

On your amps I think the ybdz had 22uH inductors (suited for 8R) and Danzz has 10uH (4R) and SB65 is 4R. This may be causing the pronounced differences in upper treble. They are like very different amps with oscon and bootstrap snubber mods. Noticeably better sounding immediately. So give those a try - you are one of the few people I know still using ybdz - one of my favorite amps still.

The frequency response on the Canolli looks very nice. How much EQ are you using? Just goes to show that an aperiodic vented TL suits it very well. I will try to make a small vented TL for it and repeat my measurments. There was a reason we both ended up picking it for Round 3.

Great work on the new box - love the faceted look. That EVA takes to being sanded like nothing I have seen except maybe plaster of Paris. 🙂

On your amps I think the ybdz had 22uH inductors (suited for 8R) and Danzz has 10uH (4R) and SB65 is 4R. This may be causing the pronounced differences in upper treble. They are like very different amps with oscon and bootstrap snubber mods. Noticeably better sounding immediately. So give those a try - you are one of the few people I know still using ybdz - one of my favorite amps still.

The frequency response on the Canolli looks very nice. How much EQ are you using? Just goes to show that an aperiodic vented TL suits it very well. I will try to make a small vented TL for it and repeat my measurments. There was a reason we both ended up picking it for Round 3.

I just use an exacto like knife with reasonably sharp blades. I will not put in a new blade every time, but I do try to change then reasonably often.

I am using an OLFA AK-4 which is a really excellent art knife.

I am using an OLFA AK-4 which is a really excellent art knife.

An externally hosted image should be here but it was not working when we last tested it.

I use the small break off tip utility knives - 3 pack for $1 from dollar store 🙂 I also use an Xacto with blade #11 that I resharpen periodically with a ceramic stone. I switch to fresh snap off blade when starting a new major project (about every 3 speakers).

jeshi and X, thank you both. And I'm sure all the accoutrements needed to cut and abrade soft wood or foam. Off to google. And stock up on bandages.

Jay

Jay

The frequency response on the Canolli looks very nice. How much EQ are you using? Just goes to show that an aperiodic vented TL suits it very well. I will try to make a small vented TL for it and repeat my measurments. There was a reason we both ended up picking it for Round 3.

Looking forward to hear what you think of the SB65 in a small vented aperiodic TL. Mine was probably a happy accident, so please consider modeling it better.

There is only a tiny amount of EQ. Maybe the small trapezoid baffle is causing some diffraction effects. Some around the 2khz range, and then a lot of taming of the 15khz-20khz region which is inherent in the driver.

2000hz -3db q1.2

1586hz +2db q5

18400hz -6db q4

biquad (BW6 low pass 18500hz)

Attachments

Very precise look there Jeshi. Do you use any helping implements other than just freehand cutting and a ruler?

One nice way to finish these would be with cloth. Like felt or densely woven wool.

It would cover the small imperfections without the need for a lot of sanding and spackling.

It would also contribute to the dampening abilities of the foam, and not crack under stress like a thick layer of paint.

One nice way to finish these would be with cloth. Like felt or densely woven wool.

It would cover the small imperfections without the need for a lot of sanding and spackling.

It would also contribute to the dampening abilities of the foam, and not crack under stress like a thick layer of paint.

Here is an extended sweep going down to 30hz of the SB65 cannoli-TL. Even at 30hz and 40hz the driver cone motion is very well damped in this aperiodic TL. There is no need for applying any rolloff "protection" filters.

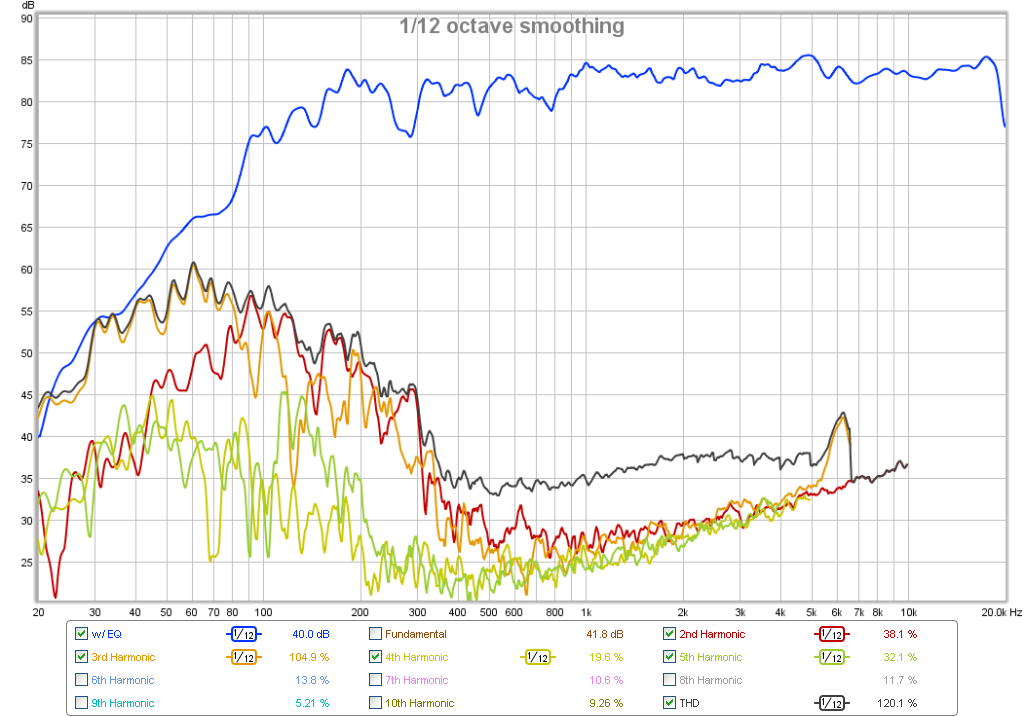

Your Canolli works exceptionally well, my Dagger with Scotchbrite can't seem to get as smooth even with EQ. It may be the stuffing - I have not played with it yet and its pretty loose inside. My measurement is at 50cm, maybe 5cm makes it look smoother?

Edit: here is 5cm data with EQ:

Attachments

Last edited:

Very precise look there Jeshi. Do you use any helping implements other than just freehand cutting and a ruler?

One nice way to finish these would be with cloth. Like felt or densely woven wool.

It would cover the small imperfections without the need for a lot of sanding and spackling.

It would also contribute to the dampening abilities of the foam, and not crack under stress like a thick layer of paint.

thanks, all free hand. I have a nice ruler with a mirrored edge to help cut straight lines. I have a pretty steady hand so I can free hand cut at an angle. For these facets, I marked the top and sides at 12mm so that I could follow the line both at the top and tip of my xacto blade and get a nice 45deg facet. And then I use a sanding block to get very flat edges. I prefer hand tools and doing things free hand. Feels more like sculpting. And I actually enjoy the sanding part a lot. Watching the rough shape start to change into its final form.

These are so small, that I prefer the look of the sculpted foam. I really don't want to cover it. But some paint is ok for me. I may try lining these with neoprene, or I might just stick with natural fiber stuffing (wool, alpaca) like my other small speakers.

Last edited:

I understand that EVA might be difficult to find. The easiest source are those foam interlocking floor tiles, but they usually have some dimples which are difficult to sand off. But you are right they are much more expensive in France than America or Asia.

LOT DE 6 TAPIS DE SOL EN MOUSSE EVA TAPIS DE GYM MAISON OU BUREAU NOIR 24 M ²: Amazon.fr: Cuisine & Maison

But I am not sure I can really recommend these tiles. I bought some and the bumps make them very difficult to work with. Also the floor tiles I have bought are much lower density (more air, more squishy) than the art-supply koyo-softbaord grade I mostly use.

The more I explore these flexible, soft, bendable, closed-cell foams (like EVA) I realize that there is a family of materials that are very similar. polyethylene (PE) foam is also flexible, closed cell and very similar to EVA (polyethylene vinyl acetate). Either type should be ok. But they do appear to come in different formulas and densities. When I eventually do my panel testing I will include several different manufactures and grade of PE and EVA foam.

Thanks,

I just find such same things that you linked, but it's quite thick, maybe to damp Inside a wood cabinet ! But not so to make the cabinet itself IMO.

Does a hard flexible rubber like the one made for big garbadge (50 liters to 150 liters) is a good material according to you for bigger drivers (10" to 15") : could the voice coils mvt and wave energy disturb such EVA or rubber bafle with the lowest requencies (below the 200 hz) ?

this one is funny in the same family, for cabinet 😉 : http://www.amazon.fr/tendre-dalles-...ttwSKQxL&dpSrc=sims&preST=_AC_UL160_SR160,160_

Back to the drivers moving the cabinet, I was around a home theater set-up with light weight subs. I went over and sat on one, and it wanted to throw me off. I couldn't believe how much force was transmitted to my body. Obviously, we are not dealing with sub freq. or the same amount of moving mass, but Newton was having his way. For every action, there was indeed an equal and opposite reaction. This was not subtle. If high freq drivers shared this cabinet, they would become a moving target. This was macro, what about micro? Fix the drivers in space somehow. That's my take-away. Sorry for the anecdotal non-science.

Thanks,

I just find such same things that you linked, but it's quite thick, maybe to damp Inside a wood cabinet ! But not so to make the cabinet itself IMO.

Does a hard flexible rubber like the one made for big garbadge (50 liters to 150 liters) is a good material according to you for bigger drivers (10" to 15") : could the voice coils mvt and wave energy disturb such EVA or rubber bafle with the lowest requencies (below the 200 hz) ?

this one is funny in the same family, for cabinet 😉 : Bois tendre dalles emboîtables en mousse Tapis de sol en mousse EVA 8.64 9 dalles 12 m ² Marron): Amazon.fr: Sports et Loisirs_

Are they really that thick? Most of these floor tiles are 10-12mm thick. When building with wood 18mm, 24mm or even 36mm is considered good practice (with 12mm considered minimum) for wall thickness. When I work with 2.5"-4" drivers I use 10mm walls and 20mm front baffles. When working with 6.5" drivers I use 20mm walls and 30mm front baffles. I laminate 10mm sheets of EVA foam with rubber cement to get the 20mm and 30mm panels.

But my personal thinking is more that if a material would make a good drum (hit it and it resonates) then it is not a good enclosure material. You will always have to use other techniques to fight the resonance (geometry, bracing, thickness, extra damping materials...). I think a good enclosure should be made from non-resonant materials. I think thin plastic like in garbage bins, actually resonates a lot if you hit the sides of it. I always thought that garbage bins make really good drums.

If you can't find EVA or PE flexible foam, then there has been great success previously with foam-core boards and XPS foam which can be found very easily in dollar stores and home improvement stores.

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures.html

Ok back to the mass of enclosure discussion. I was having some good discussions offline (jcarr) and will share some thinking from those. I am not saying that a 115:1 counterweight ratio (in the TC9 example) will result in zero motion. These drivers will move slightly and definitely vibrate, and those vibrations need to be damped. Mass is one way to damp, foam or rubber is another way to damp. I was just trying to use analogy to show that a 115:1 counter weight ratio is actually reasonable high and might be enough.

Maybe force cancellation is a better approach than mass.

I use the analogy of motorcycle engine designs. I hope some people here have some first hand experience with motorcycles so they can appreciate the analogy. Inline 4 engines have lots of vibrations because all the cylinders are firing independently in the same plane. The design requires counterweights to the crankshafts to tame the vibrations, but it only works up to a point. Anyone who as ridden on an inline4 will know what I am talking about. But V-twin, V4 can tame the vibrations better with smaller (or no) counterweights because the forces are applied at oblique angles. And the flat-twins, don't need any counterweights because forces are perfectly opposed and these engines have very low vibrations.

I am working on a dual 8" slot loaded open baffle subwoofer right now. It is going slow since I am preferring to work with my 10f/8424 and SB65 and satori/rs28f right now. The Nelson Pass design The Slot Loaded Open Baffle Project Article By Nelson Pass

This has the woofers in a force cancellation arrangement firing into a slot. The opposite forces should cancel out most of the excess vibration and if the EVA foam works like I suspect, it should cancel out the remaining vibrations. So with a very low mass enclosure I should have vibrations and "movement" under control.

XRK had made similar slot-loaded woofers with XPS foam previously like this

http://www.diyaudio.com/forums/subwoofers/258433-light-air-slot-loaded-band-pass-sub.html

Maybe force cancellation is a better approach than mass.

I use the analogy of motorcycle engine designs. I hope some people here have some first hand experience with motorcycles so they can appreciate the analogy. Inline 4 engines have lots of vibrations because all the cylinders are firing independently in the same plane. The design requires counterweights to the crankshafts to tame the vibrations, but it only works up to a point. Anyone who as ridden on an inline4 will know what I am talking about. But V-twin, V4 can tame the vibrations better with smaller (or no) counterweights because the forces are applied at oblique angles. And the flat-twins, don't need any counterweights because forces are perfectly opposed and these engines have very low vibrations.

I am working on a dual 8" slot loaded open baffle subwoofer right now. It is going slow since I am preferring to work with my 10f/8424 and SB65 and satori/rs28f right now. The Nelson Pass design The Slot Loaded Open Baffle Project Article By Nelson Pass

This has the woofers in a force cancellation arrangement firing into a slot. The opposite forces should cancel out most of the excess vibration and if the EVA foam works like I suspect, it should cancel out the remaining vibrations. So with a very low mass enclosure I should have vibrations and "movement" under control.

XRK had made similar slot-loaded woofers with XPS foam previously like this

http://www.diyaudio.com/forums/subwoofers/258433-light-air-slot-loaded-band-pass-sub.html

Last edited:

jeshi,

Like to try a small EVA foam build and found below EVA sleeping pad 180x50x0,8 cm cost 8€ is that okay if one laminate to 16mm.

Thougts was a desktop full ranger with RS100P-4 cause it have 4mm Xmax can take a mild linkwitz transform and at then at close range low SPL be fair wideband.

Like to try a small EVA foam build and found below EVA sleeping pad 180x50x0,8 cm cost 8€ is that okay if one laminate to 16mm.

Thougts was a desktop full ranger with RS100P-4 cause it have 4mm Xmax can take a mild linkwitz transform and at then at close range low SPL be fair wideband.

Attachments

As an example of speaker enclosures using thick walls, I tend to use Troels Gravesen's designs as a reference point. Like his Ellem Flex 3way

http://www.troelsgravesen.dk/Ellam-3W/ellam-flex-3w-cabinet-large.png

He builds with baltic birch ply mostly, but sometimes with MDF.

He uses 22mm thick panels in the midwoofer box, recommends 32mm for the woofer box, internal panels in the transmission line are 16mm and the front baffles are 30-50mm thick

http://www.troelsgravesen.dk/Ellam-3W/ellam-flex-3w-cabinet-large.png

He builds with baltic birch ply mostly, but sometimes with MDF.

He uses 22mm thick panels in the midwoofer box, recommends 32mm for the woofer box, internal panels in the transmission line are 16mm and the front baffles are 30-50mm thick

jeshi,

Like to try a small EVA foam build and found below EVA sleeping pad 180x50x0,8 cm cost 8€ is that okay if one laminate to 16mm.

Thougts was a desktop full ranger with RS100P-4 cause it have 4mm Xmax can take a mild linkwitz transform and at then at close range low SPL be fair wideband.

The EVA I have worked with seems to come in several densities. Yoga mats are one type of EVA that is very flexible, while yoga blocks are a much more stiff and ridge form of EVA. EVA floor tiles falls in the middle, and the koyo-softboard is a little more dense than those, but not as dense as the yoga blocks. I have been tempted to try to work with this more flexible types like the mat you link to. But I worry that it will be too floppy to hold a semi-rigid shape, even when laminated. The type of EVA (PE) that I use is also sold in 3mm thickness and it is still ridged enough to hold its shape and not collapse. Sorry link is in Japanese but maybe you can use google translate

http://www.amazon.co.jp/455/dp/B004D1W55U/ref=pd_sim_21_4?ie=UTF8&refRID=0D2CEHP5QSRZF386WE3T

I suspect that mat will be very low density, lots more air and not be rigid enough. But if you are open to experimenting then it could really help others if you want to try. But i suspect that you will need to laminate that density of EVA to more like 30mm to get it rigid enough.

Last edited:

- Home

- Loudspeakers

- Full Range

- EVA foam for performance speaker enclosures