Chuck,

An important thing to understand about this process with regard to the cone material is the speed of the wave through the material. The wave through an untreated paper cone is going to be slower than through a metal cone. They teach this in material science. Back to this in a moment.

The EnABL pattern ejects energy out of/off of the surface.

The conformal coating (gloss coat) increases the speed of transmission through/on the surface. Throw a boundary layer into the mix as well.

If my understanding is correct, what we have grown accustomed to hearing from speakers all these years is a combination of things: the original source material, the "smeared" sound that exits the cone slightly after the original source material (and out of phase with it), and the intermodulated (distorted) sound resulting from standing wave interference around the material transitions (voice coil to cone or the v.c. cap, cone to surround) of the driver.

Yes, and I wish it were as simple as that. The EnABL pattern will take different forms on different drivers of the same material. I think the biggest change for different cone materials will be in the application of the conformal coat. A metal dome won't have as much phase-lag as a paper cone. Generally speaking, a metal dome won't need as much gloss (conformal) coat as a paper cone.

How'd I do Mongo? ..... Mongo? ... I hope I got the right.

An important thing to understand about this process with regard to the cone material is the speed of the wave through the material. The wave through an untreated paper cone is going to be slower than through a metal cone. They teach this in material science. Back to this in a moment.

The EnABL pattern ejects energy out of/off of the surface.

The conformal coating (gloss coat) increases the speed of transmission through/on the surface. Throw a boundary layer into the mix as well.

If my understanding is correct, what we have grown accustomed to hearing from speakers all these years is a combination of things: the original source material, the "smeared" sound that exits the cone slightly after the original source material (and out of phase with it), and the intermodulated (distorted) sound resulting from standing wave interference around the material transitions (voice coil to cone or the v.c. cap, cone to surround) of the driver.

Does the driver material make a difference in the paint pattern?

Yes, and I wish it were as simple as that. The EnABL pattern will take different forms on different drivers of the same material. I think the biggest change for different cone materials will be in the application of the conformal coat. A metal dome won't have as much phase-lag as a paper cone. Generally speaking, a metal dome won't need as much gloss (conformal) coat as a paper cone.

How'd I do Mongo? ..... Mongo? ... I hope I got the right.

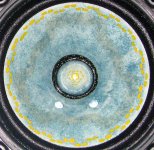

Here is the a photo of the drivers I want to do first

I took some meausrements as references, as I am not sure where the ring of dots will go, considering all that rubber.

Any help?

Also where can I get a scaleable template that I can use?

As you can see the cone is paper, coated in something like vinyl on the face side, it is very stiff

An externally hosted image should be here but it was not working when we last tested it.

I took some meausrements as references, as I am not sure where the ring of dots will go, considering all that rubber.

Any help?

Also where can I get a scaleable template that I can use?

As you can see the cone is paper, coated in something like vinyl on the face side, it is very stiff

EnABL 101

Ahh, yes...pattern/template

http://pharm.kuleuven.be/pharbio/gpaper.htm

There is a routine there that allows the printing of many graphs...including polar...with 36 radial divisions...that's 10 degrees. Go there...get one...Within that 10 degrees is contained a pair of blocks. Each block spans 4 degrees with a 2 degree space btween them.

A "ring" of blocks consists of an inner and outer row.

Each row is seperated by a space that is scalar equivalent to 2 degrees at that radius.

The inner (or outer)-most row is located away from the boundary by a similar 2 degree space.

Each "block" is a rectangle whose dimensions scale to 4 degrees x 2 degrees.

When you get to graduate-level coursework, you start to wonder about specific placement of the rings and their effect in the frequency/time response domain. I think soonqsc did some research in this area and found some interesting effects. I hope his work continues.

edit: I'm missing 2 degrees somewhere...

Ahh, yes...pattern/template

http://pharm.kuleuven.be/pharbio/gpaper.htm

There is a routine there that allows the printing of many graphs...including polar...with 36 radial divisions...that's 10 degrees. Go there...get one...Within that 10 degrees is contained a pair of blocks. Each block spans 4 degrees with a 2 degree space btween them.

A "ring" of blocks consists of an inner and outer row.

Each row is seperated by a space that is scalar equivalent to 2 degrees at that radius.

The inner (or outer)-most row is located away from the boundary by a similar 2 degree space.

Each "block" is a rectangle whose dimensions scale to 4 degrees x 2 degrees.

When you get to graduate-level coursework, you start to wonder about specific placement of the rings and their effect in the frequency/time response domain. I think soonqsc did some research in this area and found some interesting effects. I hope his work continues.

edit: I'm missing 2 degrees somewhere...

Each row is seperated by a space that is scalar equivalent to 2 degrees at that radius.

Can you ask Mongo to explain how to calculate this useing the sizes I provided, if you are too busy?

Your not missing 2 degrees, just haveing visualisation problems, rember each 2 dots is in an alternate ring

Can you ask Mongo to explain how to calculate this useing the sizes I provided, if you are too busy?

Your not missing 2 degrees, just haveing visualisation problems, rember each 2 dots is in an alternate ring

Mongo, this is EnABL. I would like to enable Mongo

To do so would require special Ed. Remember, his fingers are like clubs...so I got the calculator out anyway.

to wit: 145 mm diameter, circumference=pi (dia.) = ~ 455 mm

1/36 circumference = ~ 12.65 mm = ~ 10 degrees

watch the decimal equivalent here:

2 degree scalar equivalent is 12.65 (.2) = ~ 2.5 mm spaces

4 degree scalar equivalent is 12.65 (.4) = ~5 mm blocks

Now, bear in mind that a reduction in radius results in an equivalent decrease in block sizes & spacing. One must decide how small their bullseye is. Or, as Mongo likes to say: "Anal is as analytical does". Ticks me off when he does that.

Bud has let us off the hook here. Many times he has stated there is no appreciable loss in effect for sloppy (my term) work. Bud's never met Mongo.

To do so would require special Ed. Remember, his fingers are like clubs...so I got the calculator out anyway.

to wit: 145 mm diameter, circumference=pi (dia.) = ~ 455 mm

1/36 circumference = ~ 12.65 mm = ~ 10 degrees

watch the decimal equivalent here:

2 degree scalar equivalent is 12.65 (.2) = ~ 2.5 mm spaces

4 degree scalar equivalent is 12.65 (.4) = ~5 mm blocks

Now, bear in mind that a reduction in radius results in an equivalent decrease in block sizes & spacing. One must decide how small their bullseye is. Or, as Mongo likes to say: "Anal is as analytical does". Ticks me off when he does that.

Bud has let us off the hook here. Many times he has stated there is no appreciable loss in effect for sloppy (my term) work. Bud's never met Mongo.

My wife loves Special Ed.

I'm Special Ed Yeeeaaaaaaaaaaay!

http://www.ifilm.com/video/2796201/show/17674

I think Mongo and I went to the same school...

I took 360 deg divided by ten to get to the 10deg divisions.

but to make marking easier I went up to 5degrees.

easy enough to split those roughly in 5 with a pen then colour 4 blocks l.e. 4 degrees, leave 2 open then colour 4 again, switch to other ring and do it again.

Are you saying the blocks would be half as high as wide roughly?

I somehow got to 50 rings on my first try, wich gives quite thin bands about 1.5mm high

If I am to understand the aproximate hight of the blocks would be 2.5mm, I would need to make it 29 rings rather? (72.5/2.5)

I'm Special Ed Yeeeaaaaaaaaaaay!

http://www.ifilm.com/video/2796201/show/17674

I think Mongo and I went to the same school...

I took 360 deg divided by ten to get to the 10deg divisions.

but to make marking easier I went up to 5degrees.

easy enough to split those roughly in 5 with a pen then colour 4 blocks l.e. 4 degrees, leave 2 open then colour 4 again, switch to other ring and do it again.

Are you saying the blocks would be half as high as wide roughly?

I somehow got to 50 rings on my first try, wich gives quite thin bands about 1.5mm high

If I am to understand the aproximate hight of the blocks would be 2.5mm, I would need to make it 29 rings rather? (72.5/2.5)

the blocks would be half as high as wide roughly?

Yes

I would need to make it 29 rings rather?

Yes, and approaching warp speed...

UK Microscale supplier

I've just ordered a bottle of microscale gloss from

http://www.modelsinmotion.co.uk/category.asp?catcode=130&tamiya=273

Took a while to find a uK supplier, but this lot are selling it discounted at the moment!

I've just ordered a bottle of microscale gloss from

http://www.modelsinmotion.co.uk/category.asp?catcode=130&tamiya=273

Took a while to find a uK supplier, but this lot are selling it discounted at the moment!

Re: Mongo, this is EnABL. I would like to enable Mongo

Here is a diagram of the angular spacing. Block height is specified as "2 degrees"

Lots of room for slop... actually one could theorize that a "perfect" pattern might not work as well as a more chaotic one.

dave

Here is a diagram of the angular spacing. Block height is specified as "2 degrees"

Lots of room for slop... actually one could theorize that a "perfect" pattern might not work as well as a more chaotic one.

dave

Attachments

Nordic,

Here is how you want your patterns to appear on the cones.

The outer rings are about 2 degrees from the edge of the surround to cone glue joint.

Note that the dome to cone pattern is only three rings and that the center ring is right on top of the joint between cone and dome.

The little six ring set at the tip of the dome is there to suppress beaming, not damp it, just redistribute the energy across the cone surface. Net effect will be to increase dispersion.

I can scale and combine a flat pattern array onto the face on picture, if these do not provide you with enough information to work from.

Bud

Here is how you want your patterns to appear on the cones.

The outer rings are about 2 degrees from the edge of the surround to cone glue joint.

Note that the dome to cone pattern is only three rings and that the center ring is right on top of the joint between cone and dome.

The little six ring set at the tip of the dome is there to suppress beaming, not damp it, just redistribute the energy across the cone surface. Net effect will be to increase dispersion.

I can scale and combine a flat pattern array onto the face on picture, if these do not provide you with enough information to work from.

Bud

Attachments

diagram of the angular spacing

Dave, Thanks for the clarification. I realized I had 2 too many degrees when I got into it. Your sketch is very helpful...and easier than words.

Sources of supply

*Speedball type "A" pen points

Mister Art 800-721-3015 12/$17.56

Sax web contact 12/ $18.71

Reuels's web contact $1.88 ea.

*Floquil/PolyScale by Testors

Phoenix-Model

Micro Mark

Scale Model 651-646-7781

Squadron 877-414-0434

*MicroScale Gloss coat

Bare Metal Foil

*Speedball type "A" pen points

Mister Art 800-721-3015 12/$17.56

Sax web contact 12/ $18.71

Reuels's web contact $1.88 ea.

*Floquil/PolyScale by Testors

Phoenix-Model

Micro Mark

Scale Model 651-646-7781

Squadron 877-414-0434

*MicroScale Gloss coat

Bare Metal Foil

Hi All

Well, if you look closely at Dave's drawing, there are openings between ends of blocks in a set, in adjacent rows. This could confuse the issue, if you are trying to make those extra spaces add up to a 10 degree interval, with each set of blocks worth 4 degrees and each space worth 2 degrees. Here is the flat template I use, dimensioned for this portrayal, to scale and cut from, though it is done in Corel Draw and printed, rather than Adobe PDF.

Again this is one of those mathematically induced paranoia items. The patterns themselves will be somewhere between what Dave is showing and what I am showing and will work just fine regardless of how many hairs are split with these various layout templates.

Bud

Well, if you look closely at Dave's drawing, there are openings between ends of blocks in a set, in adjacent rows. This could confuse the issue, if you are trying to make those extra spaces add up to a 10 degree interval, with each set of blocks worth 4 degrees and each space worth 2 degrees. Here is the flat template I use, dimensioned for this portrayal, to scale and cut from, though it is done in Corel Draw and printed, rather than Adobe PDF.

Again this is one of those mathematically induced paranoia items. The patterns themselves will be somewhere between what Dave is showing and what I am showing and will work just fine regardless of how many hairs are split with these various layout templates.

Bud

Attachments

Its ******* difficult to do hey... parcticeing on some polar graph paper... my pen's nib is not wide enough though, its only a no.2.

The width as we worked out, needs to be 2.5mm so I guess I need something just smaller than that.

I'm just practising with ink at the moment... still have to look for the model masking tape... it should work perfectly as it is used to mask of areas for painting. Thinking of masking the boundaries of the rings with it.

The width as we worked out, needs to be 2.5mm so I guess I need something just smaller than that.

I'm just practising with ink at the moment... still have to look for the model masking tape... it should work perfectly as it is used to mask of areas for painting. Thinking of masking the boundaries of the rings with it.

Guess i need to rev my templates

I don't think so. Yours are actually more likely to allow a correct, finished on cone pattern, than mine are. We want the adjacent row ends to line up, but not overlap, if possible. A small overlap is not a problem, but your patterns do allow for paint spread and so, less overlap than mine.

I put the patterns up just to clear up the confusion about arc distances adding up properly. What you are doing is fine, mostly because it works and probably better than what I use, in the hands of someone new to this.

Your patterns do show why you end up with a pattern that is slightly tighter in inter block and inter ring spacing than mine typically are. Since your center area is smaller, it appears you may be using this as the key to the spacing of the rings and this is what pulls your rings slightly closer together. However, this is not a problem, obviously, since your cones work just fine.

Bud

Bud, about those middle rings... the concave shape goes on there instead of the normal convex dustcap....

Also it stiff and like one piece with the rest of the cone, the connection with the spider is little over an inch in diameter... but is connected to the back of the rigid dustcap/cone assembly...

These drivers are cleverly designed I think, very nice range of 30Hz to 3KHz, downside isI am useing them in a 2way system, which asks alot from the tweeter I guess. I intend putting them in more appropriate boxes and cross over at about 2k2.

There is a range in some female vocals that just sounds wrong still (to my ear), but I lack the term to describe the phenomena... its like a distortion over sounds in that frequency band, which does not seem to effect the rest of the frequencies...

It was much worse in retrospect, before I added the zobels, but because of the added calrity and the now somewhat smaller evil audio band is more noticeable. The casual listener they would not pick it up without being told what to listen for (oh, yeah it is also somewhat prominent with playing brass wind instruments).

Also it stiff and like one piece with the rest of the cone, the connection with the spider is little over an inch in diameter... but is connected to the back of the rigid dustcap/cone assembly...

These drivers are cleverly designed I think, very nice range of 30Hz to 3KHz, downside isI am useing them in a 2way system, which asks alot from the tweeter I guess. I intend putting them in more appropriate boxes and cross over at about 2k2.

There is a range in some female vocals that just sounds wrong still (to my ear), but I lack the term to describe the phenomena... its like a distortion over sounds in that frequency band, which does not seem to effect the rest of the frequencies...

It was much worse in retrospect, before I added the zobels, but because of the added calrity and the now somewhat smaller evil audio band is more noticeable. The casual listener they would not pick it up without being told what to listen for (oh, yeah it is also somewhat prominent with playing brass wind instruments).

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- EnABL Processes