Aweloi - One addition: the earthing of this board has a flaw, and what I did was disconnect one layer of the earth circuit feom the other channel. I know it can’t be the source of a big hum, but I do not have the link here. However I showed a picture of where I cut a trace , on the Lencoheaven.

I see you have with a lot of dilligence made a metal chassis.

An alternative is thin copper or alu foil that can be glued to the wood . .

albert

I see you have with a lot of dilligence made a metal chassis.

An alternative is thin copper or alu foil that can be glued to the wood . .

albert

Hi. Tin aluminum plate as you used are good for RF shielding, but won’t do anything for line AC signal 50-60hz. You need much beefier alu shielding to be effective at AC line frequency, probably at least 1/4 inch thickness, read this from John Curl years ago.

for effective shielding you need steel or mu-metal. An other thing you can try is to rotate your power transformer, had to fine tuned my toroid transformer for the lowest noise in one of my tube preamp, even if the transfo had shield.

As some other said this big switch to select the inputs is a very bad idea on a phono preamp, by the look at it is a main power on switch. You’ll need at least a low signal relay to switch these very low signal inputs. Your large switch can also degrade the sound.

By using the Step up transformer on the highest gain setting may also contribute to your noise. With the preamp gain, the lowest setting on your step up transformer is probably more than adequate. past a certain gain from the phono section, it is better to increase the preamp volume, than to boost the phono gain too much, because the phono gain will also amplify the noise, which won’t be an issue if you rather amplify the phono output with the preamp.

SB

for effective shielding you need steel or mu-metal. An other thing you can try is to rotate your power transformer, had to fine tuned my toroid transformer for the lowest noise in one of my tube preamp, even if the transfo had shield.

As some other said this big switch to select the inputs is a very bad idea on a phono preamp, by the look at it is a main power on switch. You’ll need at least a low signal relay to switch these very low signal inputs. Your large switch can also degrade the sound.

By using the Step up transformer on the highest gain setting may also contribute to your noise. With the preamp gain, the lowest setting on your step up transformer is probably more than adequate. past a certain gain from the phono section, it is better to increase the preamp volume, than to boost the phono gain too much, because the phono gain will also amplify the noise, which won’t be an issue if you rather amplify the phono output with the preamp.

SB

from ‘All about circuits’ forum:

If you are looking for reduction from hum - that is hum caused by local magnetic fields - you need to provide a path for the magnetic fields causing the hum to be shunted around or away from the sensitive circuit that is susceptible to magnetic pickup. To do that effectively the 'shield' needs to be of a material that has high permeability or low reluctance (they are reciprocal like resistance and conductance). The permeability of iron is .25 and the permeabilitu of aluminum is 1.25 x 10>-6. Nearly a million times less able to reduce magnetically induced hum. Bottom line? Aluminum works fairly well on electric fields (RF), but it's very weak about magnetic fields (ac)

So alu is nearly a million time less effective to reduce ac magnetic field than steel…

If you are looking for reduction from hum - that is hum caused by local magnetic fields - you need to provide a path for the magnetic fields causing the hum to be shunted around or away from the sensitive circuit that is susceptible to magnetic pickup. To do that effectively the 'shield' needs to be of a material that has high permeability or low reluctance (they are reciprocal like resistance and conductance). The permeability of iron is .25 and the permeabilitu of aluminum is 1.25 x 10>-6. Nearly a million times less able to reduce magnetically induced hum. Bottom line? Aluminum works fairly well on electric fields (RF), but it's very weak about magnetic fields (ac)

So alu is nearly a million time less effective to reduce ac magnetic field than steel…

Even if the separation plate is steel, any mechanical vibrations from the transformers will be heard on the output. This is because they are mounted on the same chassis. Such vibrations are typically at the mains frequency.

This is one of the main reasons I moved over to toroidal transformers (for Phono amps) which could be mounted with some softer rubber insulator. Another option is to build the power supply in a separate box.

The OP can try temporarily re-locating the mains transformer outside the phono box.

This is one of the main reasons I moved over to toroidal transformers (for Phono amps) which could be mounted with some softer rubber insulator. Another option is to build the power supply in a separate box.

The OP can try temporarily re-locating the mains transformer outside the phono box.

I hear you guys. It sounds like building a new enclosure is the way to go. And ditch the switch.

Well, I will probably do that If I know myself, but not now.

Well, I will probably do that If I know myself, but not now.

Wait a moment.

1) There is a lot of info on hum loops. These are created because there are large 'openings' in the loops that are in the circuit.

- you might very well ahve such loops. Check out the info.

2) you now have an earthed shield on the input and output; but I would advise that the output only has one connection to the main circuit ground, so the shield is left floating at the RCA terminal. I would do the same with the input.

[I have easytalking. I have a power amp in which one channel connected is OK; connect the second one, hum. I understand your frustration :-|)

And turning the transformer 90 degrees (or almost) is not hard; it might just make the magnetic coupling with some circuit loops less. Hopefully less than your threshold.

I agree with Algar and so the next tip is: take a 'conservenblik' (you might naturally understand our word) and push that over the transformer . . .

1) There is a lot of info on hum loops. These are created because there are large 'openings' in the loops that are in the circuit.

- you might very well ahve such loops. Check out the info.

2) you now have an earthed shield on the input and output; but I would advise that the output only has one connection to the main circuit ground, so the shield is left floating at the RCA terminal. I would do the same with the input.

[I have easytalking. I have a power amp in which one channel connected is OK; connect the second one, hum. I understand your frustration :-|)

And turning the transformer 90 degrees (or almost) is not hard; it might just make the magnetic coupling with some circuit loops less. Hopefully less than your threshold.

I agree with Algar and so the next tip is: take a 'conservenblik' (you might naturally understand our word) and push that over the transformer . . .

And something I found on Internet:

High Permeability 1J85 Permalloy Foil 0.02-0.5mm per meter - WOW that will give a very good magnetic isolation!

I once sold my old non-working scope - and the beuyer did it for the permalloy of the screen shield, that is of course the cheapest source for Mu metal.

High Permeability 1J85 Permalloy Foil 0.02-0.5mm per meter - WOW that will give a very good magnetic isolation!

I once sold my old non-working scope - and the beuyer did it for the permalloy of the screen shield, that is of course the cheapest source for Mu metal.

Ok, I have done a few more things now to tackle hum. First I put an aluminium back wall instead of wood at the back and cut a square hole in the back of the wood so that I could put the inputs and outputs directly on the aluminium. Then I glued a thin mumetal all around the main board and the SUTs. I also removed the input switch completely. This reduced the hum somewhat. However I still had hum. One thing changed though. Earlier when I switched off the amp the hum would remain while caps discharged which made me exclude the transformer as the culprit. Now when I did this test again with all the changes made, the hum disappeared directly when I turned off the amp. So maybe I had both a shielding problem and a transformer problem.

I ordered a torodial transformer with metal casing from Antek to see if that would help. It did, but not completely. It's better but can still hear hum on louder listening levels, but not from listening position anymore. I can hear it from within aprox 1.5 meters in a quiet room on louder listening volume levels.

I'm not sure if I have the energy to try anything more for a while. It's pretty quiet.

I ordered a torodial transformer with metal casing from Antek to see if that would help. It did, but not completely. It's better but can still hear hum on louder listening levels, but not from listening position anymore. I can hear it from within aprox 1.5 meters in a quiet room on louder listening volume levels.

I'm not sure if I have the energy to try anything more for a while. It's pretty quiet.

I read somewhere the other day that a filament supply problem can cause 100hz hum (if having 230V). I had a short early on in the build that damaged the transistor which I had to replace. I also replaced the bridge rectifier just in case. Could anything else in the PS have been damaged? What parts are sensitive to shorts? Caps? Diodes? Resitsors?

I always have to ask: how loud is this hum? Is this like "Whoa I can't even hear the music" hum or "At full volume with my ear 2 inches from the speaker I kinda hear something?" hum.

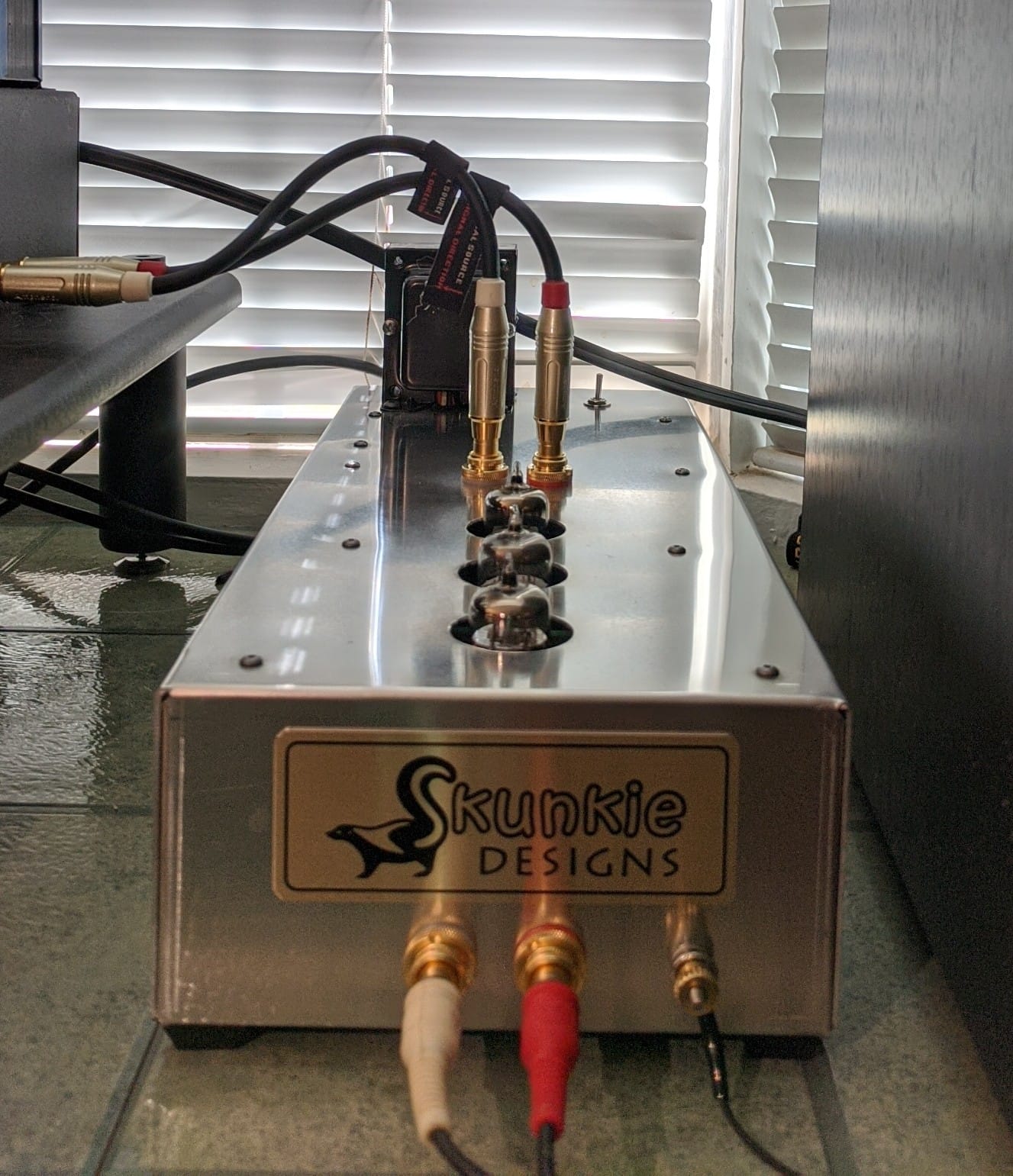

I've built about a dozen of these for folks, I don't even snap the board apart, put them in a 6X14X3 alum Hammond chassis, mounting an EI power transformer with end bells on top. Insolate the RCA jacks from the chassis and put the jacks where they will have >super short leads<. On the grounding, I just use the front one straight to the chassis on the same stud the turntable ground goes to. I ground the IEC to the chassis in the back. Using 7025 tubes they are silent at listening levels with a touch of tube hiss if you crank the volume with nothing playing.

I do have a Nclayton SUT box for my MC. I ground the TT to the SUT box and let it ground through one RCA to the phono stage. Below is the first one I built. I've since started painting them textured black but use the same layout. I do hand test all the parts, use mica 110pf/330pf RIAA caps and mundorf alum oil coupling caps. They really do sound fantastic.

I've built about a dozen of these for folks, I don't even snap the board apart, put them in a 6X14X3 alum Hammond chassis, mounting an EI power transformer with end bells on top. Insolate the RCA jacks from the chassis and put the jacks where they will have >super short leads<. On the grounding, I just use the front one straight to the chassis on the same stud the turntable ground goes to. I ground the IEC to the chassis in the back. Using 7025 tubes they are silent at listening levels with a touch of tube hiss if you crank the volume with nothing playing.

I do have a Nclayton SUT box for my MC. I ground the TT to the SUT box and let it ground through one RCA to the phono stage. Below is the first one I built. I've since started painting them textured black but use the same layout. I do hand test all the parts, use mica 110pf/330pf RIAA caps and mundorf alum oil coupling caps. They really do sound fantastic.

I have one of these PC boards. Maybe this winter I can get it built. Thanks for all the input.

John

John

The hum is kinda loud and it is not tube hiss either. It is 100hz hum. If I turn up the volyme to what I would describe as a louder listening level, I can hear this hum from quite far away (like two meters away) if I do not have any music on. If it was only when I put my ears close to the drivers I would not mind but this feels off to me. I am suspecting that it has to do with the power supply. Also, the 6.3v are only puttning out 5.9v with a load. I had a short early on during the build that blew the transistor. I change it and also the bridge rectifier just in case, but perhaps something else went bad too?I always have to ask: how loud is this hum? Is this like "Whoa I can't even hear the music" hum or "At full volume with my ear 2 inches from the speaker I kinda hear something?" hum.

I've built about a dozen of these for folks, I don't even snap the board apart, put them in a 6X14X3 alum Hammond chassis, mounting an EI power transformer with end bells on top. Insolate the RCA jacks from the chassis and put the jacks where they will have >super short leads<. On the grounding, I just use the front one straight to the chassis on the same stud the turntable ground goes to. I ground the IEC to the chassis in the back. Using 7025 tubes they are silent at listening levels with a touch of tube hiss if you crank the volume with nothing playing.

I do have a Nclayton SUT box for my MC. I ground the TT to the SUT box and let it ground through one RCA to the phono stage. Below is the first one I built. I've since started painting them textured black but use the same layout. I do hand test all the parts, use mica 110pf/330pf RIAA caps and mundorf alum oil coupling caps. They really do sound fantastic.

View attachment 1188864

And love your Youtube channel btw! 😃

Last edited:

And, just to be clear, this hum occurs with shorting plugs across the inputs? And is insensitive to the preamp's location? (Doesn't vary if moved.)

All good fortune,

Chris

All good fortune,

Chris

It is not very hard to take out the transformer from box using some longer wires ... this is the first thing to do .

Yes to both questions. And I have also taken out the transformer and used long cables. Did not help.And, just to be clear, this hum occurs with shorting plugs across the inputs? And is insensitive to the preamp's location? (Doesn't vary if moved.)

All good fortune,

Chris

Also, the 6.3v are only puttning out 5.9v with a load. I had a short early on during the build that blew the transistor. I change it and also the bridge rectifier just in case, but perhaps something else went bad too?

And love your Youtube channel btw! 😃

Thanks and the heater voltage doesn't involve the transistor or those zener diodes, that is all done via the larger 4 pin bridge rectifier. Have you checked the AC voltage going into the board?

256 AC in to PSU.

285 DC out to main board.

6.25 AC in to PSU.

5.9 DC out to heaters.

If some component is bad, could some AC leak trough and cause hum?

285 DC out to main board.

6.25 AC in to PSU.

5.9 DC out to heaters.

If some component is bad, could some AC leak trough and cause hum?

The voltages seems to be OK . Probably the zeners are ok too .

In theory no component you could damaged with a simple short can cause hum , if the B+ is ripple free ... you could try to measure with the multimeter on AC the DC out voltage to see if there is ripple voltage

The filament voltage is not important , lower or even using AC the hum should be very low . Just to be done like in schematic .

Maybe this hum was there before but masked by the lack of shielding , if not you have to think what you did , maybe a ( wiring ) mistake

You can pull out the tubes begining with the RIAA input to see what is changing

In theory no component you could damaged with a simple short can cause hum , if the B+ is ripple free ... you could try to measure with the multimeter on AC the DC out voltage to see if there is ripple voltage

The filament voltage is not important , lower or even using AC the hum should be very low . Just to be done like in schematic .

Maybe this hum was there before but masked by the lack of shielding , if not you have to think what you did , maybe a ( wiring ) mistake

You can pull out the tubes begining with the RIAA input to see what is changing

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- EAR834p clone with hum. Would appreciate some help