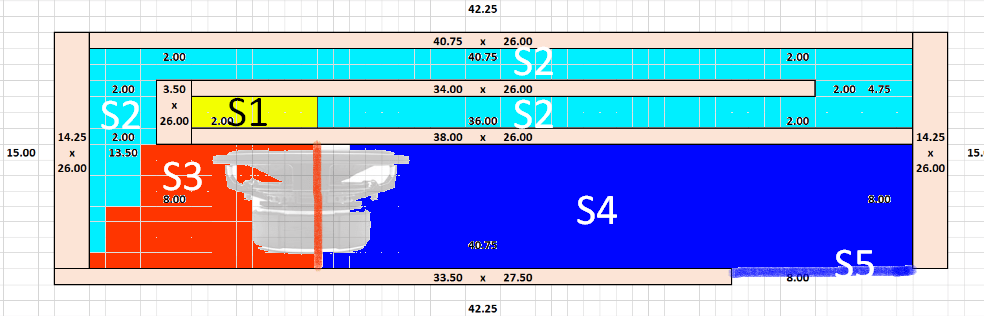

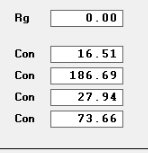

and S5 ??

S5 is the cross-sectional area at mouth of segment 4. That is, at the tapped horn mouth.

Don't confuse S1 to S5 (cross-sectional areas) with H1 to H4 (the four coloured horn segments).

Ohhhh!! ok so on the Sim i made s5 smaller, than means i need to make the mouth of the cabinet smaller

correct ?

and this needs to be

Par not Con... correct ?

Par not Con... correct ?

correct ?

and this needs to be

Last edited:

i need to make the mouth of the cabinet smaller

correct ?

Yes.

Last edited:

and this needs to be Par not Con... correct ?

Strictly speaking, yes for segment 4, although in practice it is unlikely to make much of a difference, given the dimensions.

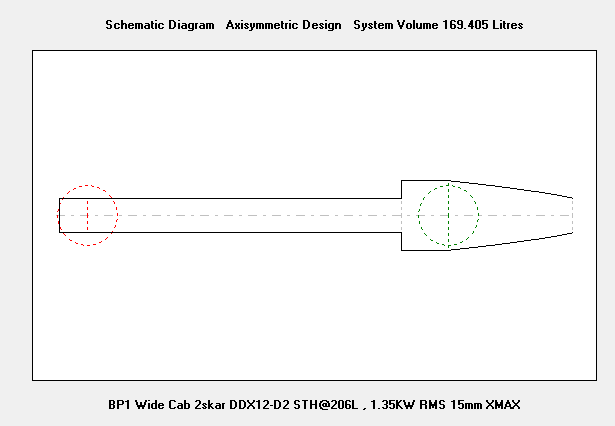

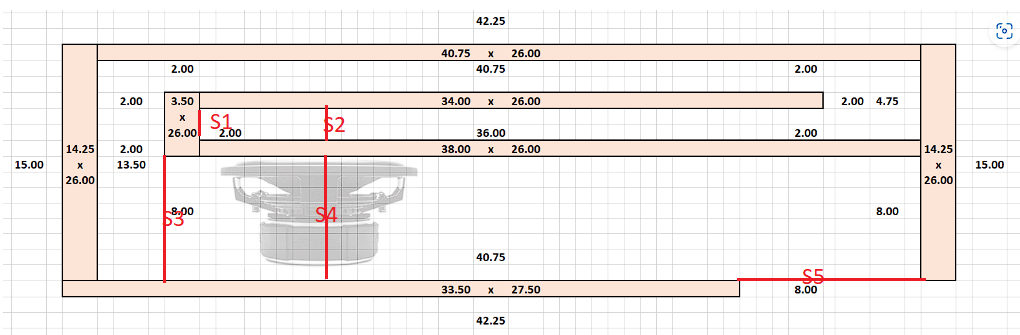

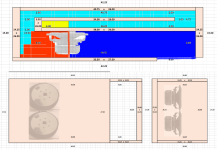

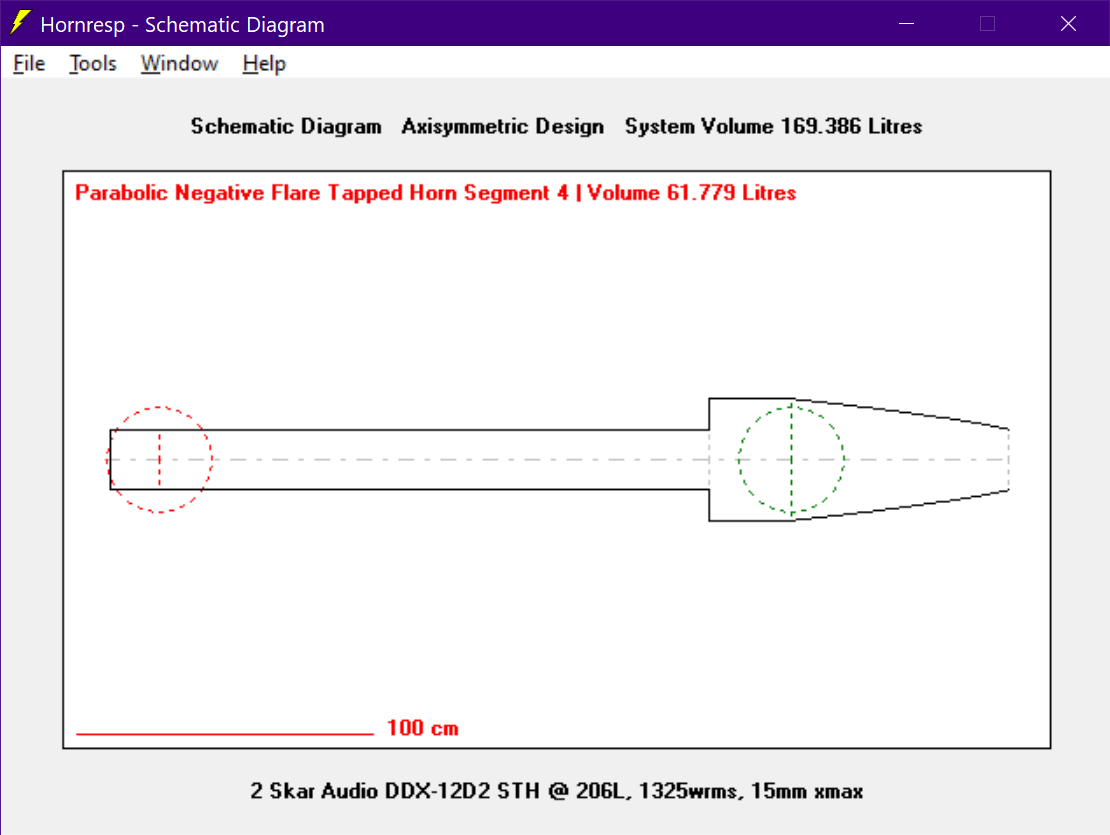

I don't think it's possible to model that layout in Hornresp. This is what I came up with, when I looked at the segments....

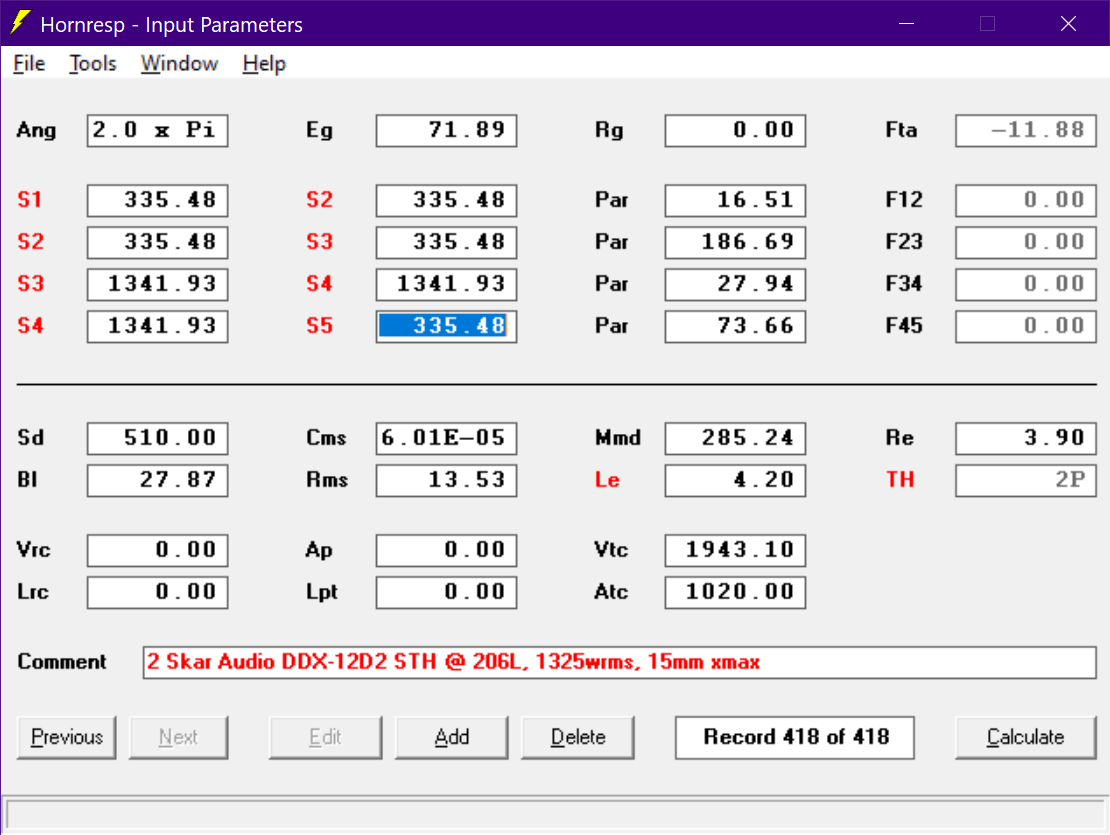

Note the position of S3 and S4. Taking the layout of the box into consideration, S3=S4 and S5=S4 must be true, otherwise the Hornresp model will not correctly model what's happening between S4 and S5 (as your model shows). In other words, the cross-sectional area of the mouth must match the cross-sectional area at the driver's position.

Note also that this is basically my BOXPLAN-BP6S2 layout, with the mouth (S5) moved to the side.

Note the position of S3 and S4. Taking the layout of the box into consideration, S3=S4 and S5=S4 must be true, otherwise the Hornresp model will not correctly model what's happening between S4 and S5 (as your model shows). In other words, the cross-sectional area of the mouth must match the cross-sectional area at the driver's position.

Note also that this is basically my BOXPLAN-BP6S2 layout, with the mouth (S5) moved to the side.

That's why I use my BOXPLAN workbooks, to make sure that the corresponding sim is representing something that can actually be built...

I don't think it's possible to model that layout in Hornresp.

I think you can get reasonably close though, which is why I decided not to complicate things by raising the issue 🙂.

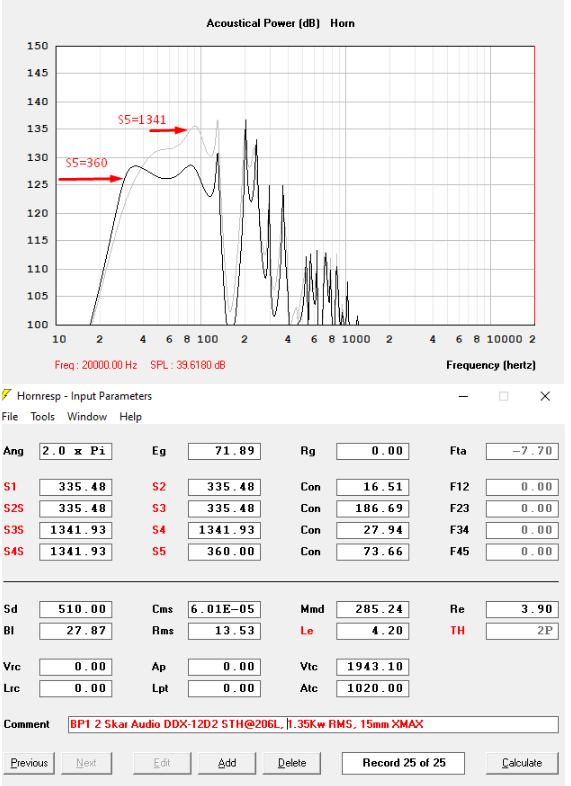

If segment 4 has a constant cross-sectional area of 1341.93 cm^2 and a length 73.66 cm, with a step constriction at the mouth reducing the area to 360 cm^2, then the overall performance of the system at low frequencies should not be dramatically different to that obtained assuming a final parabolic segment of throat area 1341.93 cm^2, mouth area 360 cm^2 and length 73.66 cm.

So I can make that mouth S5 of 360cm2 , I gain some more low extension and a little less around 60-80hz (-3db) that i can live with 🙂 , with 4 cabinets i can hit 140 still

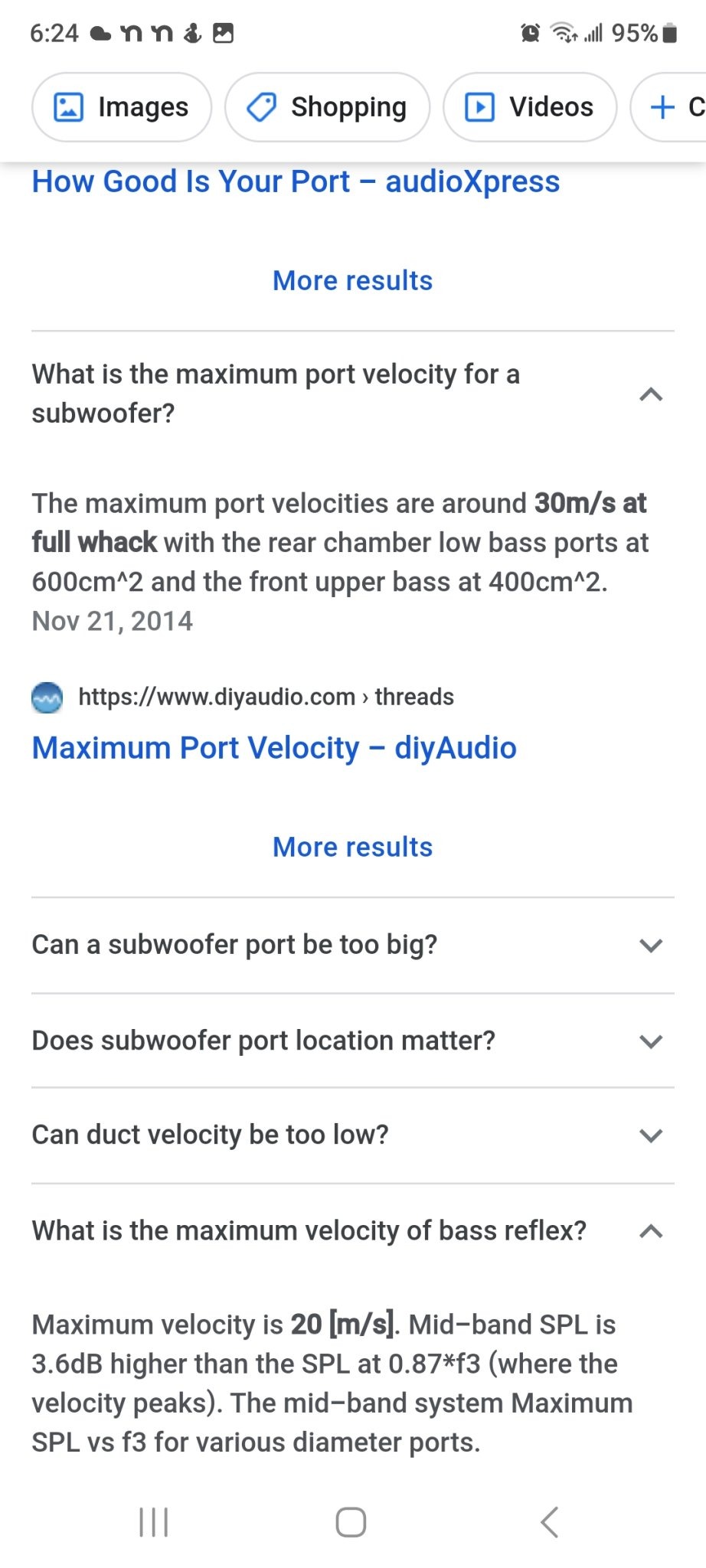

No, not necessarily, Look at port velocity in post 186🙈?

why not make a longer 1/4 wave path in an appropriate TL design?

why not make a longer 1/4 wave path in an appropriate TL design?

Last edited:

That's why I use my BOXPLAN workbooks

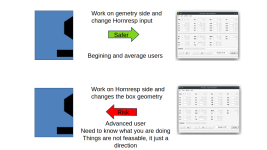

Advanced user are warning you many times. I hope at certain point you got convinced because It can save us all headache and time/money.

Hornresp has so simple interface and it's so simple to use that it traps users many times.

More complex is the box you are designing, less feasible are the improvement found at hornresp side that you can translate back to the box geometry, this is basically because hornresp allow you to modify each single input individually but in "reality" to change geometry you must change more then one dimension at the same time.

Look to your box and ask to yourself:

My box has parallel panels at H4 segment (dark blue) and this fact results in a constant cross section area requiring S4 to be equal to S5. How could I change only S5? Don't fool yourself.

Max, altering S5 forms a negative taper at L45. This is where HR needs a 5th segment.

Last edited:

Here is an EXCELLENT example of why you can't do that type of mouth setup.

WinISD trained me on being under 15m/s. Usually, no smaller than 1/3 of Sd does the trick.

Indeed, the pioneer's got it right the first time when they originally designed/built quasi BP4* drivers for H.E. wide BW horns. 😉As you'll see in the video, BP is CRUSHING all other types of enclosures so far!

*Reactance annulled (open back) BP4 with cotton stuffing originally, but the massive bug/rodent issues of the day forced a switch to fine (4/0?) SS wool and of course later switched to removable metal cover plates for mass production. For woofer horns they built slotted rear cover BP4 boxes as part of the horn.

The pioneer's did everything they could to do things acoustically to keep efficiency as high as practical, so it too was done acoustically. 😎

- Home

- Loudspeakers

- Subwoofers

- Dual Skar12 paraflex C CRAM