Well done Leob! I am envious. 🙂Time to build some plates!

View attachment 1285939

Had some friends over that is helping me build the subs, and after listening to the latest plates they want a bunch of them as well, so now I'm building a total of 26 plates 😅

I look forward to your feedback and reports.

Hello Leob, I had the opportunity to test various types of panels with different exciters, including the ones you just purchased. The clear impression is that, overall, the carbon-nomex composite performs better than any other. I mean, in terms of generated volume, it’s similar to yours, but it retains a greater amount of high frequencies. This is why I prefer it over your XPS panel. I must say that an aluminum sandwich panel and other materials used for creating advertising billboards have an even better response in the high frequencies, but their density reduces the overall sound volume too much. I just wanted to share my observations about the materials I’ve tested

“I apologize, you’re right—I misspoke. I indeed used EPS on XPS, but I meant to use the white version. The reason was that I wanted to try it immediately, and I couldn’t find the graphite version in the store. There are probably differences, so now I’ll order it. However, I’m not sure which thickness is better or if there are additional variations between manufacturers or other factors. It’s impossible to try everything, but unless there are significant differences between the two types of EPS, the composite seems to be the best compromise in terms of power, volume, and sound quality. With this, I also want to emphasize that the lack of very high frequencies is a greater issue than the bass frequencies, which we can later compensate for with traditional speakers. Tectonic had added a driver for the highs, but I believe that in one model (PL11), they left only the carbon panel. I started with carbon because, experimentally, it proved to be the best. Perhaps Tectonic has also developed specific exciters for this panel, and that might be the difference.”

I am really interested in comparisons with carbon composite and EPS, but would be great with more detail about what you actually have compared.

There are big variations in EPS quality, and coating is an important factor. If you picked up whatever EPS they have at the store it is very likely 20kg/m3 or less, which from what I seen everyone has reported bad results with. Graphite or not matters a lot less than the density. Typically it is graded by compressive strength and you want at least "EPS 150" to get good HF reproduction.

Having said that, the 25kg/m3 GPS I use will roll of quite a bit above 10kHz, but that roll of happens to be the same as I would apply to any PA to avoid it sounding fatiguing on high levels.

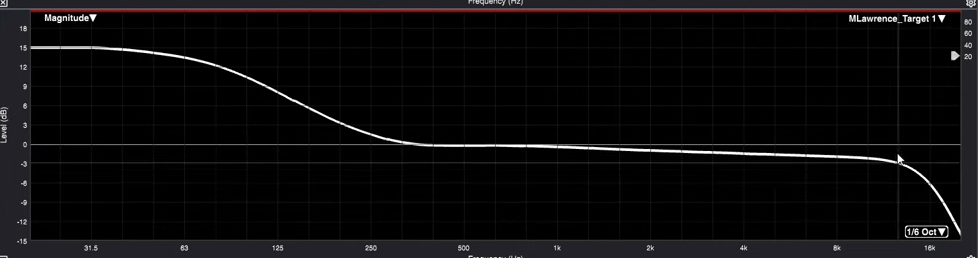

For example here is a commonly used target curve for tuning PA systems (Michael Lawrence target trace):

A flat response can sound good on lower levels, but at PA levels it will be unpleasant so most people will prefer roll off above 10k.

I think if you have great issues with HF reproduction with EPS I would say you are either using the wrong quality of EPS, mounting the exciters with the wrong adhesive, using wrong coating or have not actually tested the plates properly at war levels and think you need more treble than you actually do.

I think PL11 was an older model, the later Tectonic models does not have a separate tweeter.

There are big variations in EPS quality, and coating is an important factor. If you picked up whatever EPS they have at the store it is very likely 20kg/m3 or less, which from what I seen everyone has reported bad results with. Graphite or not matters a lot less than the density. Typically it is graded by compressive strength and you want at least "EPS 150" to get good HF reproduction.

Having said that, the 25kg/m3 GPS I use will roll of quite a bit above 10kHz, but that roll of happens to be the same as I would apply to any PA to avoid it sounding fatiguing on high levels.

For example here is a commonly used target curve for tuning PA systems (Michael Lawrence target trace):

A flat response can sound good on lower levels, but at PA levels it will be unpleasant so most people will prefer roll off above 10k.

I think if you have great issues with HF reproduction with EPS I would say you are either using the wrong quality of EPS, mounting the exciters with the wrong adhesive, using wrong coating or have not actually tested the plates properly at war levels and think you need more treble than you actually do.

I think PL11 was an older model, the later Tectonic models does not have a separate tweeter.

So I had a play today and tried 4 exciters on one HD EPS panel to see what sort of SPL I can get, they definitely go better at serious volume, especially with a bit of Eq. I did find that when I pushed them a couple pulled off the panel breaking the surface EPS they were attached too, the panel only had a light coat of 1/2 pva so perhaps I need to coat the surface with something else around the exciter area to give a better hold. Have you had issues with them ripping off the beads of EPS?

I had issue with exciters detaching a couple of times.

Once when I tried using a superglue to attach the exciters, which turned out to dissolve the EPS resulting in a bad bond.

The other time was when pushing the plates really hard for a long time, on plates where I tried to cover a larger area with epoxy around exciter. Instead of resulting in better bonding it resulted in worse sensitivity and exciters overheating which caused them to detach as the styrofoam melted.

So first of all I would check the adhesive you are using. Fast drying epoxy will become hot and can melt styrofoam as it cures and superglue dissolves it, so you want a relatively slow epoxy to get a good bond. And only glue the area that is needed, because while bonding area will be smaller you will get less issues with heat.

I only used PVA for a couple of tests, but found it inferior to hide glue. Doesn't sound as good, more expensive and slower to dry. Perhaps also gives worse bond for the exciter glue?

Once when I tried using a superglue to attach the exciters, which turned out to dissolve the EPS resulting in a bad bond.

The other time was when pushing the plates really hard for a long time, on plates where I tried to cover a larger area with epoxy around exciter. Instead of resulting in better bonding it resulted in worse sensitivity and exciters overheating which caused them to detach as the styrofoam melted.

So first of all I would check the adhesive you are using. Fast drying epoxy will become hot and can melt styrofoam as it cures and superglue dissolves it, so you want a relatively slow epoxy to get a good bond. And only glue the area that is needed, because while bonding area will be smaller you will get less issues with heat.

I only used PVA for a couple of tests, but found it inferior to hide glue. Doesn't sound as good, more expensive and slower to dry. Perhaps also gives worse bond for the exciter glue?

Thanks for the reply Leob, I have been using super glue with the activator spray to attach the exciters for a quick option and tests. I was worried the epoxy would melt the eps but will try the slower type. I'll also try and source some hide glue, I tried shellac on a few things but can't remember if I used it on eps.

Yes, that is the type I used as well. Very practical to apply nicely, but melts EPS.

As long as it is not extra fast epoxy I think it should be fine. I'm using regular gorilla epoxy now, and it is working well. Before I used lamination epoxy, but that was a bit unnecessarily slow.

Hide glue on its own is not a great surface because it doesn't repel moisture, which I think is the case with regular PVA as well. Shellac however protects against moisture and mold and also tightens up the surface remarkably well. Even a very thin highly diluted coat will bend a 25mm EPS plate if you only apply it on one side due to the tension created when it dries. Just make sure that for both you use 2x-3x the dilution usually recommended, and only apply a single thin coating. I usually roll on the hide glue and then brush on some shellac when that has dried properly.

As long as it is not extra fast epoxy I think it should be fine. I'm using regular gorilla epoxy now, and it is working well. Before I used lamination epoxy, but that was a bit unnecessarily slow.

Hide glue on its own is not a great surface because it doesn't repel moisture, which I think is the case with regular PVA as well. Shellac however protects against moisture and mold and also tightens up the surface remarkably well. Even a very thin highly diluted coat will bend a 25mm EPS plate if you only apply it on one side due to the tension created when it dries. Just make sure that for both you use 2x-3x the dilution usually recommended, and only apply a single thin coating. I usually roll on the hide glue and then brush on some shellac when that has dried properly.

Thanks for the coating tips Leob, I made a couple of panels in a similar style to yours with the front and back of the panel supported with closed cell foam. I uses Hide glue and Shellec as suggested and wow they are the best I've made/heard. Only one exciter each at present but the frequency response is so much smoother and highs much better than my previous PVA coating. I am using a HD EPS 500/320mm in size.

At first I measured and there was a steep drop off from 300HZ down but lots of highs. I gave them a sand front and back and now measure nicely down to 110HZ ish before they drop off. I must have coated too much Shellac and they were too stiff.

When the Excite exciters are back in stock I'll try a quad setup per panel but these are great for my workshop.

Thanks again.

At first I measured and there was a steep drop off from 300HZ down but lots of highs. I gave them a sand front and back and now measure nicely down to 110HZ ish before they drop off. I must have coated too much Shellac and they were too stiff.

When the Excite exciters are back in stock I'll try a quad setup per panel but these are great for my workshop.

Thanks again.

Hello Leob, I wanted to know if your EPS panels are also commonly called HDPE (High Density Polyethylene)? In any case, what thickness do you use? I know there are types of EPS 100, 150, 200, and even 500, but the common ones are those from 100. Actually, I don’t know where to find those from 200 or higher.I am really interested in comparisons with carbon composite and EPS, but would be great with more detail about what you actually have compared.

There are big variations in EPS quality, and coating is an important factor. If you picked up whatever EPS they have at the store it is very likely 20kg/m3 or less, which from what I seen everyone has reported bad results with. Graphite or not matters a lot less than the density. Typically it is graded by compressive strength and you want at least "EPS 150" to get good HF reproduction.

Having said that, the 25kg/m3 GPS I use will roll of quite a bit above 10kHz, but that roll of happens to be the same as I would apply to any PA to avoid it sounding fatiguing on high levels.

For example here is a commonly used target curve for tuning PA systems (Michael Lawrence target trace):

View attachment 1286664

A flat response can sound good on lower levels, but at PA levels it will be unpleasant so most people will prefer roll off above 10k.

I think if you have great issues with HF reproduction with EPS I would say you are either using the wrong quality of EPS, mounting the exciters with the wrong adhesive, using wrong coating or have not actually tested the plates properly at war levels and think you need more treble than you actually do.

I think PL11 was an older model, the later Tectonic models does not have a separate tweeter.

HDPE is no foam, It's the material that for instance plastic canoes are made of. Quite heavy and not stiff.

Small progress update : I tried to coax a FR from 100 Hz upwards from a dml plate, and didn't succeed. Now I settled for 40x42 cm, 4mm paper/nomex plates, with a small 8"sub doing the lowmid work up to about 130 Hz. Powered by a small 4 channel DSP with built in (not so good...) 4 x 50W amp.amp. It works and sounds good as a small PA for semi-acoustic bands. In total I made 4 identical panels, so I can experiment in bigger rooms (for instance the theater I work in). People are generally pleasantly surprised by the sound and of course the unfamliar sight of the panels. No negative reactions yet. I like them too - there's something special and nice about them.

Greetings from Amsterdam, Hans

Greetings from Amsterdam, Hans

Attachments

I bought mine here https://www.dekokopf.com/neopor-styroporplatten-3er-set-50x33x2-5cm.htmlHello Leob, I wanted to know if your EPS panels are also commonly called HDPE (High Density Polyethylene)? In any case, what thickness do you use? I know there are types of EPS 100, 150, 200, and even 500, but the common ones are those from 100. Actually, I don’t know where to find those from 200 or higher.

They are 25kg/m3, but not rated for compressive strength like for building material.

Seems hard to find high grade EPS from building suppliers unless you buy in bulk.

Hi Leob, Did you pick up your subs this weekend as planned? What Paraflex model did you end up building? I heard a paraflex system on the weekend, kicks and subs had great output but tops were lowfi and sounded like a bad crunchy PA sound not crisp and hifi, not sure if it was bad EQ or what but I wished they had had DML tops.

Yes, I did! They are the Type-O 2x12 with Ciare SW12.00 drivers, and have just done a quick test in my living room so far, but I'm really impressed and they sound extremely punchy and tight!

Also delivered some plates for the friends doing the build and got to listen to their C-2A sub and tried swapping their big heavy Warfdale tops for DML, and they where quite impressed how a single small plate perhaps weighing 1/10 seemed to be able to keep up with their old tops!

C-2A sounded impressive as well, but I'm now very confident that the Type-O 2x12 was the correct choice for me. Even at lower levels you still feel the impact and authority in the 60-90Hz range, which is so important for most dance music.

I think the C-2A sounds more natural, and of course goes a bit deeper being like 3x as large. But for a bit more hyped and punchy bass, the Type-O 2x12 seems hard to beat. And it does help that size is manageable for someone who is not a youngling any more when doing parties in the forest 🙂

Hope to get time soon to set everything up outdoors and start doing measurements and tuning!

Also delivered some plates for the friends doing the build and got to listen to their C-2A sub and tried swapping their big heavy Warfdale tops for DML, and they where quite impressed how a single small plate perhaps weighing 1/10 seemed to be able to keep up with their old tops!

C-2A sounded impressive as well, but I'm now very confident that the Type-O 2x12 was the correct choice for me. Even at lower levels you still feel the impact and authority in the 60-90Hz range, which is so important for most dance music.

I think the C-2A sounds more natural, and of course goes a bit deeper being like 3x as large. But for a bit more hyped and punchy bass, the Type-O 2x12 seems hard to beat. And it does help that size is manageable for someone who is not a youngling any more when doing parties in the forest 🙂

Hope to get time soon to set everything up outdoors and start doing measurements and tuning!

Fantastic, I'm glad they arrived after your last order experience. They sound like they will suit you well, the ones I heard the other night were 21" monsters that vibrated the concrete slab floor in the place, not easy to move around. Another friend has 2 x 1x12 paraflex subs with MEH tops that look great but I am yet to hear now that he's tuned them.

Sure is nice to be able too try out the whole set-up, been a long frustrating time with everything in place except the subs 🙂

I must say that I'm quite impressed with their capability to make things rattle despite their size. Even at quite modest levels, everything that can will rattle, even a couple of rooms away. While they drop off quickly below 35Hz, they do have a stronger response at that frequency than for example a common 2x18 reflex like the JBL SRX728 that we used a couple of times before. So seriously impressive for a dual 12".

The house is very well sound proofed with thick old massive timber and sound isolated triple glazing, so luckily I will not bother the neighbours too much, but this my wife recorded when coming home:

It is the cladding of the house vibrating 🙂

I must say that I'm quite impressed with their capability to make things rattle despite their size. Even at quite modest levels, everything that can will rattle, even a couple of rooms away. While they drop off quickly below 35Hz, they do have a stronger response at that frequency than for example a common 2x18 reflex like the JBL SRX728 that we used a couple of times before. So seriously impressive for a dual 12".

The house is very well sound proofed with thick old massive timber and sound isolated triple glazing, so luckily I will not bother the neighbours too much, but this my wife recorded when coming home:

Yes the good old structural rattles of deep bass! My workshop is a double garage with metal siding and has all kinds of rattles once I get above 95-100db ish in the bass department.

I'd be interested to know what sort of spl you are getting from a single plate before it's noticeably distorting? I remember you were talking of hundreds of watts into them high passed at 120hz? That was a stack of 16 exciters though.

With a single Excite exciter it seems a push to get above 95db for me, I'm not sure if it's the exciter itself or the way I've suspended the plate between blocks that is breaking up. What do you use for your blocks between the panel and frame? I have been using closed cell foam but it seems to loose it's spring after a while and apply less pressure.

I'd be interested to know what sort of spl you are getting from a single plate before it's noticeably distorting? I remember you were talking of hundreds of watts into them high passed at 120hz? That was a stack of 16 exciters though.

With a single Excite exciter it seems a push to get above 95db for me, I'm not sure if it's the exciter itself or the way I've suspended the plate between blocks that is breaking up. What do you use for your blocks between the panel and frame? I have been using closed cell foam but it seems to loose it's spring after a while and apply less pressure.

- Home

- Live Sound

- PA Systems

- DML PA systems