That looks very innovative as far as I can tell. The only thing that would worry me is twice the wear on the records with two cartridges.

Carlo, your mind never stops looking for innovative solutions!

The servo driven arm has appealed to lots of builders, to try to put the reading stylus correctly central in the groove.

The reference point of central is going to be important as well as the transmission and drive to the reading arm.

Lots have used external references and power, this uses the records own reference and power.

Intriguing.

It will be very interesting to see how folk who are active on this thread respond to your ideas

The servo driven arm has appealed to lots of builders, to try to put the reading stylus correctly central in the groove.

The reference point of central is going to be important as well as the transmission and drive to the reading arm.

Lots have used external references and power, this uses the records own reference and power.

Intriguing.

It will be very interesting to see how folk who are active on this thread respond to your ideas

Just kicking the box, as usual - thanks H+M

I thought of posting this sketch remembering of the poor Syrinx PT TA: I had to build it, and very well, to smash my face on the stupid mistakes I had done.

This is a damn complicated contraption that probably isn't worth building, but with the help of the real experts in this thread maybe some of the heavier problems can be seen and overcome. Who knows, even the Peaucellier Easy Pi seemed impossible to many, and instead works flawlessly.

c

Double wear? seems optimistic Horneydude; we need more VTF and more offset angle than usual to build up the force needed to move the cart. But for the Science...

I thought of posting this sketch remembering of the poor Syrinx PT TA: I had to build it, and very well, to smash my face on the stupid mistakes I had done.

This is a damn complicated contraption that probably isn't worth building, but with the help of the real experts in this thread maybe some of the heavier problems can be seen and overcome. Who knows, even the Peaucellier Easy Pi seemed impossible to many, and instead works flawlessly.

c

Double wear? seems optimistic Horneydude; we need more VTF and more offset angle than usual to build up the force needed to move the cart. But for the Science...

Yes, it is an interesting experiment and hope for an outcome you can build upon! Don't use your favorite records though 😉But for the Science...

Uhm, the turning radius of the arm is slightly larger so it does not line up with the spindle?small detail

Sorry, that's simply called overhang - together with the offset angle at basis of pivoted tonearms geometry-

stay tuned - c

stay tuned - c

Some problems with the Internet. Couldn't log in to the forum.

Hello Carlo.

You never cease to amaze me with the vigor of your thoughts.

As we sing in one song:"our indignant mind is boiling..."

You generated so many cubes that one of them will definitely roll into the target.

Your talking cricket Pinocchio had a hard fate, but in the end, a happy ending.

In your new design, you propose to transfer all the "dirty" work to the rotary tonearm.

This design reminded me of the HiFiction Thales AV tonearm, but it has one cartridge, and you have two.

It seems to me that the first thing you need to do is get an answer to a simple question, the answer to which may not be simple at all.

How to synchronize the operation of these two cartridges?

Having received an answer to this question, you can move on.

When I came to the conclusion as a result of my reflections that the priority should be given to equal pressure on both walls of the groove, then I asked myself the question: "Is it possible to create a mechanism that automatically creates such conditions?"

I put the issue of the tangential position in second place, since all the advantages of the tangential position are reduced to zero when the needle does not have stable contact with both sides of the groove.

In my opinion, this is how the question should be put, and not the priority should be given to the issue of obtaining a tangential position at any cost.

AG.

Hello Carlo.

You never cease to amaze me with the vigor of your thoughts.

As we sing in one song:"our indignant mind is boiling..."

You generated so many cubes that one of them will definitely roll into the target.

Your talking cricket Pinocchio had a hard fate, but in the end, a happy ending.

In your new design, you propose to transfer all the "dirty" work to the rotary tonearm.

This design reminded me of the HiFiction Thales AV tonearm, but it has one cartridge, and you have two.

It seems to me that the first thing you need to do is get an answer to a simple question, the answer to which may not be simple at all.

How to synchronize the operation of these two cartridges?

Having received an answer to this question, you can move on.

When I came to the conclusion as a result of my reflections that the priority should be given to equal pressure on both walls of the groove, then I asked myself the question: "Is it possible to create a mechanism that automatically creates such conditions?"

I put the issue of the tangential position in second place, since all the advantages of the tangential position are reduced to zero when the needle does not have stable contact with both sides of the groove.

In my opinion, this is how the question should be put, and not the priority should be given to the issue of obtaining a tangential position at any cost.

AG.

How to synchronize the operation of these two cartridges?

They simply play the same music at the same time (which depends just from platter speed): of course the connection must be proper and rigid. as clearly written.

Issues may come from the imperfection of our sad, sad world.

c

so many cubes - i like to build working TAs (ca 20 different, till now) , carefully designed and calculated. When kicking the box i try to aim as well as i can.

They simply play the same music at the same time (which depends just from platter speed): of course the connection must be proper and rigid. as clearly written.

Issues may come from the imperfection of our sad, sad world.

c

so many cubes - i like to build working TAs (ca 20 different, till now) , carefully designed and calculated. When kicking the box i try to aim as well as i can.

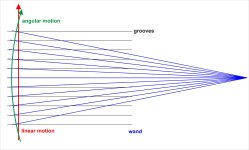

The relationship between the angular movement of the "driving" arm and the linear movement of the "reading" arm is non-linear, so the mechanism linking them is non-evident.

The music is the same, but not quite.

It's a quarter turn different.

Plus, the control cartridge is after, not before.

I accidentally thought hard here and came to the conclusion that your idea could result in an excellent linear tonearm without the flaw we're talking about.

Even if it's only in words.

It's a quarter turn different.

Plus, the control cartridge is after, not before.

I accidentally thought hard here and came to the conclusion that your idea could result in an excellent linear tonearm without the flaw we're talking about.

Even if it's only in words.

The relationship # 5490

This brings us much closer to problems, thanks Alighiszem.

At first sight I also feared the same, to need a cam or something like. But thinking better, the two tips travel, turn after turn on the same groove - so the relationship between angular and linear motion should not vary. I use the conditional because at this stage the theoretical and verification work is still completely to be done.

What is important is that the two tips stay as close as possible. I posted that sketch because it highlighted the problems to the maximum, so much that Mike immediately identified the main one, the elephant in the room that I hadn't seen.

Now this new one, in which I understood that, applying the force directly to the cart, the radial rail is not useful. So the relative positioning may be much freer

let's go on,

C

This brings us much closer to problems, thanks Alighiszem.

At first sight I also feared the same, to need a cam or something like. But thinking better, the two tips travel, turn after turn on the same groove - so the relationship between angular and linear motion should not vary. I use the conditional because at this stage the theoretical and verification work is still completely to be done.

What is important is that the two tips stay as close as possible. I posted that sketch because it highlighted the problems to the maximum, so much that Mike immediately identified the main one, the elephant in the room that I hadn't seen.

Now this new one, in which I understood that, applying the force directly to the cart, the radial rail is not useful. So the relative positioning may be much freer

let's go on,

C

Attachments

Last edited:

"the two tips travel, turn after turn on the same groove "

This is true, but in the case of the driving arm the length of the arc between grooves varies. It is longer at the beginning and the end and shortest in the middle.

This is true, but in the case of the driving arm the length of the arc between grooves varies. It is longer at the beginning and the end and shortest in the middle.

Your observation is also correct, to which we can add that since the pitch is variable, the rotation of the wand will also be variable, but so should be the linear one's too. I hope that if the "proper connexion ratio" gives us the length of the chord instead of the arc, the precision (nothing is perfect in TAs) could be quite acceptable -

I have a page full of problems - starting with whether the skating that could be built up will be sufficient to move the carriage, given that the ratio for a 9" is 1/15.

But before I would like to know if anyone sees the "elephant", which could really prevent the functioning. That is a problem (with maybe another acceptable solution ?)

Too complicated, imo, to get so few advantages, but a fun passtime, better than crosswords

ciao - carlo

I have a page full of problems - starting with whether the skating that could be built up will be sufficient to move the carriage, given that the ratio for a 9" is 1/15.

But before I would like to know if anyone sees the "elephant", which could really prevent the functioning. That is a problem (with maybe another acceptable solution ?)

Too complicated, imo, to get so few advantages, but a fun passtime, better than crosswords

ciao - carlo

I'm starting to get serious about designing and building two linear arms; one for my son and one for me. I had planned to use a single glass rod and ball bearings, just to keep it simple. This is mostly because this project is already very late, but also because my access to machining equipment is very limited. That said, I'm intrigued by the possibility of significant performance improvements by going with the sapphire bearing / tungsten carbide rod upgrades. Is there a way to do so using as much off the shelf parts as possible? What are good sources for the sapphire bearing parts and the tungsten rods? Lastly, should I start a new thread for this? I don't want to create problems by having too many conversations going on in this thread.

It’s intriguing to read thought provoking content from a very experienced designer and builder Carlo. Thankyou. One knows it will be full of valid and innovative ideas and practical solutions.

I feel that the linear: radial progression point was well made above and it may be, as Carlo says that in the general play of the record that the difference is negligible, as demonstrated in the diagram by Carlo. However it could readily be resolved with a suitable oval drive wheel between the two to compensate.

I had considered the idea of an opposed RTA drive set at 180 degrees to the reading cartridge already but this brings me to the key point of my todays random thought.

Whilst in the play of the record a groove of offset occasionally might make little difference and be negligible, when one or other cartridge hits the lead out groove the other one better be there as well! Observation suggests these progress around 5mm per rotation, the lead in grooves less but also much more than the recorded section.

This also reminds me to mention the point Carlo already referred to concerning the point around the groove at which the two styli are working. They might be acceptable slightly displaced in some ways, but in order to drive the reader cartridge correctly while following eccentricities they need to be close to the same angle around the disc or the eccentricity will be out of phase.

So that negates my consideration of two RTA’s one on each side or one stylus would, at that point, be leading the other by around 2.5mm at the end of the recording!

I think it also confirms the styli need to be as close to coincident as possible.

M

I feel that the linear: radial progression point was well made above and it may be, as Carlo says that in the general play of the record that the difference is negligible, as demonstrated in the diagram by Carlo. However it could readily be resolved with a suitable oval drive wheel between the two to compensate.

I had considered the idea of an opposed RTA drive set at 180 degrees to the reading cartridge already but this brings me to the key point of my todays random thought.

Whilst in the play of the record a groove of offset occasionally might make little difference and be negligible, when one or other cartridge hits the lead out groove the other one better be there as well! Observation suggests these progress around 5mm per rotation, the lead in grooves less but also much more than the recorded section.

This also reminds me to mention the point Carlo already referred to concerning the point around the groove at which the two styli are working. They might be acceptable slightly displaced in some ways, but in order to drive the reader cartridge correctly while following eccentricities they need to be close to the same angle around the disc or the eccentricity will be out of phase.

So that negates my consideration of two RTA’s one on each side or one stylus would, at that point, be leading the other by around 2.5mm at the end of the recording!

I think it also confirms the styli need to be as close to coincident as possible.

M

Hi Paul, i built numerous experiments without any machining equipment at all, and i am sure many others the same.I'm starting to get serious about designing and building two linear arms; one for my son and one for me. I had planned to use a single glass rod and ball bearings, just to keep it simple. This is mostly because this project is already very late, but also because my access to machining equipment is very limited. That said, I'm intrigued by the possibility of significant performance improvements by going with the sapphire bearing / tungsten carbide rod upgrades. Is there a way to do so using as much off the shelf parts as possible? What are good sources for the sapphire bearing parts and the tungsten rods? Lastly, should I start a new thread for this? I don't want to create problems by having too many conversations going on in this thread.

Don't be daunted by that!

I chose non recirculating balls on anodised aluminium rails to avoid recirculating ball bearings and glass rails (where i also started).

Its an elegant and simple solution allowing low resistance with simple bought in parts.

M

The pauses between tracks would begin earlier for the reading arm and would end earlier too. The reading stylus would be pushed inwards and the moving stylus would not let it move.

Good afternoon Alighiszem, its an intriguing one this, isnt it?

It seems a brilliant simple mechanical servo drive to unload the reading cartridge of the progression duties, and the variations that appear disc by disc.

I think its fair to say that on each revolution, left to their own devices each cartridge would move across one groove.

Is that a linear progression on the radius, is each groove the same width?

If it is we could assume that progression is linear, in terms of the spiral that is theoretically on the record.

Even if that isn't accurate we are considering having a guide to tell it where to go, say in eccentricity or inaccuracy. That's brilliant!

Now the guide will for sure move one groove per rev.

There will be a mathematical curve for the drive stylus that defines the rotation of the pivot end per groove.

If that is taken into account in constructing the drive ratio, probably with a shaped cam belt drive, then all will be consistent?

M

It seems a brilliant simple mechanical servo drive to unload the reading cartridge of the progression duties, and the variations that appear disc by disc.

I think its fair to say that on each revolution, left to their own devices each cartridge would move across one groove.

Is that a linear progression on the radius, is each groove the same width?

If it is we could assume that progression is linear, in terms of the spiral that is theoretically on the record.

Even if that isn't accurate we are considering having a guide to tell it where to go, say in eccentricity or inaccuracy. That's brilliant!

Now the guide will for sure move one groove per rev.

There will be a mathematical curve for the drive stylus that defines the rotation of the pivot end per groove.

If that is taken into account in constructing the drive ratio, probably with a shaped cam belt drive, then all will be consistent?

M

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm