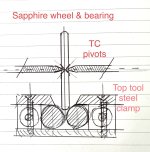

Hello everyone, I feel I’m very late to this party but I’ve been enthralled by this thread for months, some truly ingenious ideas! I’ve finally gathered together some materials and commenced on a variation/combination of Niffy and Warrjon’s design, see progress so far. The plan is to use this LTA on my Garrard 401 with some kind of custom plinth. I’m having trouble sourcing the vee bearings as from reading in previous posts many of you have experienced similar problems. I’m based in the UK and Truepoint’s website keeps redirecting me somewhere else? Have any of you found alternatives in the UK or have any of you over ordered and have spares which I could purchase? Also @warrjon a few threads ago, I see you machined a pocket carrier for the 4mm TC rods after experiencing adhesion problems with the epoxy. I was literally about to mix up the araldite when I read this! Is it due to the extremely smooth surface finish on the rods, @niffy are you seeing similar on your composite rail block or should I just throw caution to the wind!?

Sether

Hi @Sether again welcome to the party, it's never too late. I've just built an SP10mk2 for a friend and was listening to this with a Technics EPA-100, which I swapped back to my SP10mk2 before playing the same LP with the LTA. The LTA was just streets ahead of the EPA-100.

I suspect it was the polished finish. For my new rail, I polished the TC rods but before gluing them into the rail carrier I stuck the rods to a bit of masking tape and roughed the underside of the rods with 80 grit sand paper. sticking them to the tape ensured I had the smooth side up when they were glued into the AL carrier.

The other issue I found is the lack of concentricity in the carbide rings. I bought a few sets and none of them were round and they all varied in thickness. For my next iteration the wheels will be made from M200 tool steel and hardened, it won't be quite as hard as carbide but concentricity will be far better.

I ended up buying sapphire Vee's from Swiss Jewel. Postage is a bit steep but I bit the bullet and ordered them. For the pivot pin, 2mm carbide rod was used which I ground and radiused the point in a lathe, before polishing.

These ones

https://www.swissjewel.com/product/jewel-bearings/vee-jewels/v2-00q/

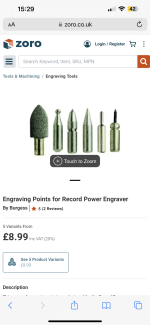

Carbide cutter tips? the vertical articulation on my RTA requires 8 little pivots, 4 pairs at the corners of the paralelogram, these are currently the tips of carbide tipped cutters, like you describe and prompted by one of the contributors on here, i bought them on ebay for about £1-£2 each and thought that was expensive because i actually had to buy a cutter with spare tips, i know they can be found for less, maybe you know the source?Hi Mike, thank you for the kind response. The knowledge which all the contributors have is simply incredible, it’s such a shame i came across this thread so late. In the true spirit of diy audio I can see many similarities to the Clear Audio design but with significant gains through group prototyping and subsequent improvements, truly astonishing…and on a budget! Reading back through the thread I can’t help thinking about the pin bearings and that something I use with my work would have perhaps been an option which is TC tipped engraving tips, the type used for cleaning fossils?! This is of course before the implementation of the far more accurate sapphire vees and TC pivots. I might have to try these if i fail to source from the UK. My interest in HiFi is quite broad, from restoring vintage speakers to complete speaker builds. I attach image of a horn which I’m working on utilising a planar magnetic mid/tweeter. However, my current setup which is sounding quite beautiful is a pair of 50 year old KLH model 28 omnidirectional speakers with a pair of omnidirectional super tweeters which I’ve built using AMT drivers.

S

View attachment 1226107

Attachments

Yes, that’s the sort, that price is pretty good to be honest. There are many variants, there’s quite a sharp point version but unfortunately it’s normally mounted in a way which is centred terribly. I’ve used in previous projects diamond tipped 60deg engraving points but these might prove too hard for your application see pic

S

S

Attachments

I don’t know how far back in the thread it was but I think it was @warrjon who came up with the idea for using sapphire windows as the wheels. I had a thought about this and could the sapphire window be used as both the wheel and the bearing, where two vees on opposite sides of the window. I of course I realised it wouldn’t work as the bearing assembly is totally wrong, the pin should ride in the vee and not the other way around..shame! It would have been an interesting streamlining of components, I thought I’d post anyway. There could be an inexpensive way of trying the sapphire window idea by using porcelain jewellery enamelling disks/blanks, the entire wheel would be extremely hard/stiff.

@warrjon regarding the TC rail assembly, I think I’ll add a top tool steel GFS clamp. Physically clamping the rods, effectively creating a sandwich. I’m still keen on @niffy implementation of composite materials for optimum stiffness and ringing suppression.

@warrjon regarding the TC rail assembly, I think I’ll add a top tool steel GFS clamp. Physically clamping the rods, effectively creating a sandwich. I’m still keen on @niffy implementation of composite materials for optimum stiffness and ringing suppression.

Attachments

interesting Sether, whats the source on those please?Yes, that’s the sort, that price is pretty good to be honest. There are many variants, there’s quite a sharp point version but unfortunately it’s normally mounted in a way which is centred terribly. I’ve used in previous projects diamond tipped 60deg engraving points but these might prove too hard for your application see pic

S

M

Sorry @Mike56 i didn’t read your post accurately, have you ground the point yourself onto a carbide rotary cutter? The engraving points I had in mind were these, see photo.

Hi Sether, no these are hand scriber tips cut down in length. search on carbide scriber or similar.Sorry @Mike56 i didn’t read your post accurately, have you ground the point yourself onto a carbide rotary cutter? The engraving points I had in mind were these, see photo.

S

https://www.amazon.co.uk/KINBOM-2pc...hvlocphy=&hvtargid=pla-4583589123576146&psc=1

This type of thing, wasnt exactly the one i bought but very similar, if no better source i will try these again.

M

Thanks Mike56, much more cost effective than the TC engraving tips. The diamond tipped versions are from AliExpress, there’s a number of sellers on there, just search diamond engraving bit. The quality is very high, very difficult to photograph though, I attach pics.

S

S

Attachments

@warrjon many thanks for the link to Swiss jewel. Regarding the sapphire window wheel idea, I’ve found these on AliExpress, I can only find 1/2” x 2mm and 18 x 2mm. You mentioned machining your own wheels from M200 steel, out of curiosity what OD have you decided on, like you I could only get hold of 18mm OD wedding rings?

S.

S.

Attachments

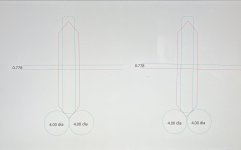

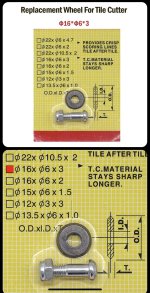

@warrjon 16mm x 2 mm seems to be the optimum? I’ve managed to polish the TC 4mm diameter rods to an extremely high polish, could the same not be done to these glass cutting wheels? (£2.97each eBay). I’ve done a quick cad drawing see pic where the 16mm wheel with 0.5 radius vs 16mm x 3mm TC glass cutter @50deg. There is more surface contact than the 0.5mm radius (detrimental perhaps?) but there is a lowering of axle height by 0.778mm, therefore COG.

S

S

Attachments

I don't think such construction is ideal. Personally, I have never been completely satisfied with Niffy's rail construction. Here is a suggestion for the rail by utilizing glass cutting wheels. I would use 13.5 mm wheels to reduce the mass. I also like to mention that you need to plan a mechanism to prevent the carriage dropping off the rail. It is very important if you don't want to damage your cartridge.16mm x 2 mm seems to be the optimum? I’ve managed to polish the TC 4mm diameter rods to an extremely high polish, could the same not be done to these glass cutting wheels? (£2.97each eBay). I’ve done a quick cad drawing see pic where the 16mm wheel with 0.5 radius vs 16mm x 3mm TC glass cutter @50deg. There is more surface contact than the 0.5mm radius (detrimental perhaps?) but there is a lowering of axle height by 0.778mm, therefore COG.

S

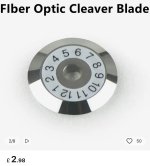

Thank you @super10018 for the information. I like this idea, but there might be a practical drawback with dust collecting in the v channel? I have seen some very nicely finished TC fibre optic cleaving blades see pic but no smaller than 20mm diameter which would make good wheels. Could these glass cutter wheels not run on the TC rods, avoiding the dust? I will definitely make sure that the carriage has some kind of stay to protect from falling.

S.

S.

Attachments

Dust is never a problem in my experience. If dust is a problem in your environment, all the rails will have the same problem no matter what kind of construction it is. However, cleaning the rail once a month is more than enough here in the upstate of New York in my experience. Even in the city of New York, once a month should be ok in my opinion.

I have never seen such fiber optic cleaving blades. It seems like a nice one for the wheels. But I am not sure how sharp the blade is. If the edge is very sharp, I will modify it so the edge is about .5 mm rounded edge.

I have never seen such fiber optic cleaving blades. It seems like a nice one for the wheels. But I am not sure how sharp the blade is. If the edge is very sharp, I will modify it so the edge is about .5 mm rounded edge.

@super10018 yes the cleaving blades look rather nicely finished and apparently accurate. However, I can’t seem to find them any smaller than 20mm diameter. Wouldn’t this push the COG too high?

S.

S.

I think 20 mm should be ok. It also depends on how you design the headshell and the carriage.

In the @niffy designed carriage yes it will place the COG way too high. I struggled to lower COG with 18mm wheels to be under the pivot.@super10018 yes the cleaving blades look rather nicely finished and apparently accurate. However, I can’t seem to find them any smaller than 20mm diameter. Wouldn’t this push the COG too high?

S.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm