#4676 - Finally 5k$ well spent.

But pls explain to me what gets centered, the disk or the recording? I'm getting too old to understand.

The problem starts from the pressing procedure, not from drilling: the engraving above and the one below are never centered on each other, and therefore it is impossible for the hole to be perfectly centered. At most it could be for one face, not both.

Therefore reading the eccentricity of the disk seems to me completely useless. It should read the cartridge movements instead, not the disk

5k$ well spared, maybe

carlo

quote completely, Niffy.

doubt - if the graphite behaves somehow like vinyl, why not using the vinyl itself ? (ie PVC)

But pls explain to me what gets centered, the disk or the recording? I'm getting too old to understand.

The problem starts from the pressing procedure, not from drilling: the engraving above and the one below are never centered on each other, and therefore it is impossible for the hole to be perfectly centered. At most it could be for one face, not both.

Therefore reading the eccentricity of the disk seems to me completely useless. It should read the cartridge movements instead, not the disk

5k$ well spared, maybe

carlo

quote completely, Niffy.

doubt - if the graphite behaves somehow like vinyl, why not using the vinyl itself ? (ie PVC)

Last edited:

But pls explain to me what gets centered, the disk or the recording?

Last edited:

Forgive my few remaining neurons, Dd, but I still don't understand what is it for. (i had also the site translated by Google, hoping it was smarter than me)

Really I can't see with respect to what is that device positioned during the measuring procedure

spindle - hole - label - or what else?

These are the RIIA specs for a 12" LP

center hole mm 7.26 + - 0.25 Ø

groove runout tolerance <0,4 mm (ie 0.8 mm total cartridge movement)

stopping groove mm 106.4 + - 0.8 Ø

Usual spindles are 7.15 to 7.2 Ø mm, so the centering possibilities are 0.1 - 0.05 mm - ie < 1/4 of the grooves runout tolerance, And centering the hole with respect to the spindle has nothing to do with groove centering, which is what's needed, imo

ciao - carlo

Really I can't see with respect to what is that device positioned during the measuring procedure

spindle - hole - label - or what else?

These are the RIIA specs for a 12" LP

center hole mm 7.26 + - 0.25 Ø

groove runout tolerance <0,4 mm (ie 0.8 mm total cartridge movement)

stopping groove mm 106.4 + - 0.8 Ø

Usual spindles are 7.15 to 7.2 Ø mm, so the centering possibilities are 0.1 - 0.05 mm - ie < 1/4 of the grooves runout tolerance, And centering the hole with respect to the spindle has nothing to do with groove centering, which is what's needed, imo

ciao - carlo

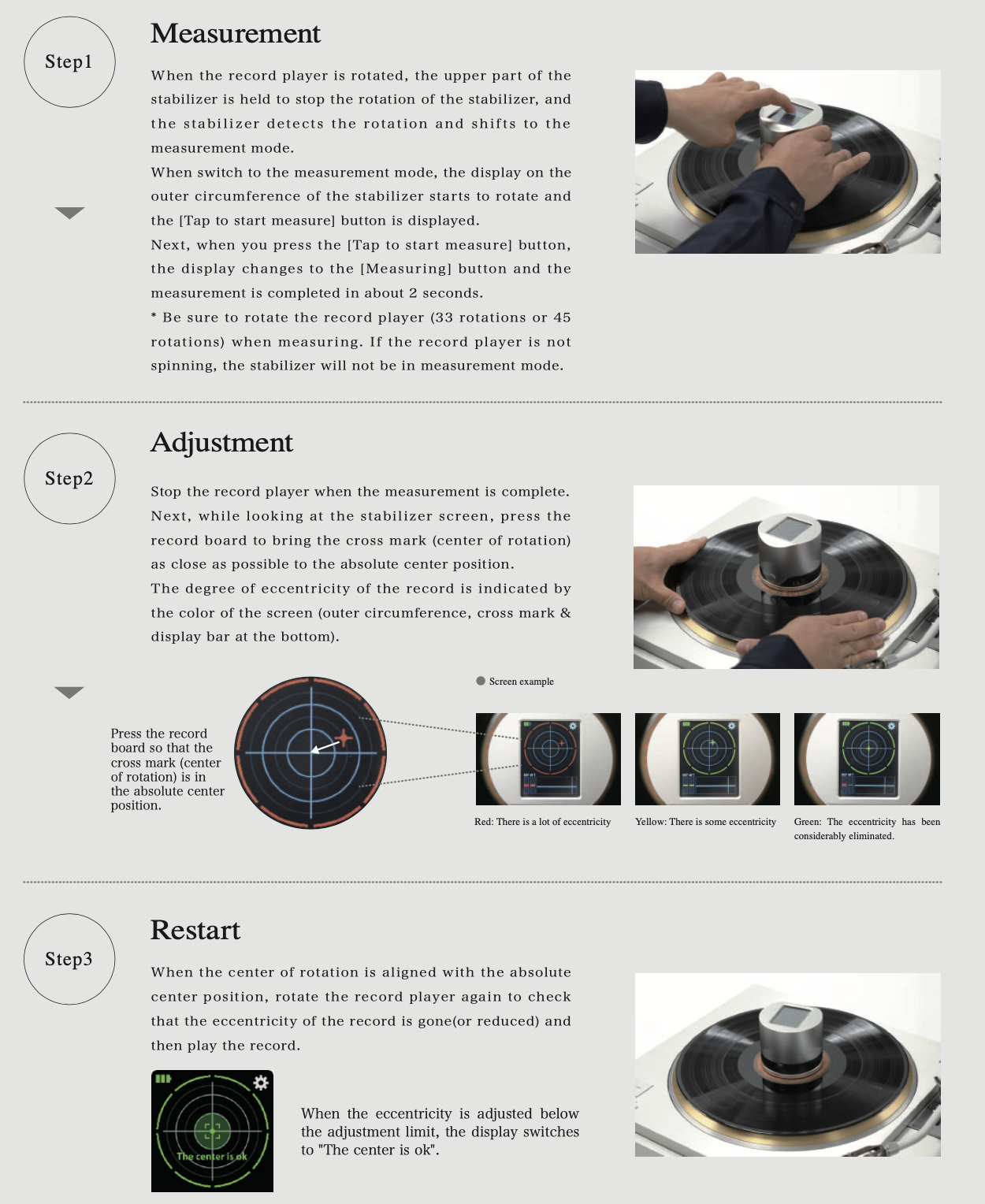

I've come up with a couple of record centering ideas over the years but all have been beyond my workshop's capabilities. My ideas have been purely mechanical as I'm not much of an electronics engineer.According to the website, this product can be a game changer, particularly for parallel tracking. Unfortunately, the price is 600,000 yen ($4,600 USD). Yikes! I think those 6 figure uber turntables should just give out such device as a freebie!

Besides the Nakamichi turntables, I'm surprised no one else thought of accessories like this. I do know a Frank Schroeder designed turntable had deliberate smaller diameter spindle at the bottom portion to allow room to shift the record for concentricity. Other than that, the so called "high end" world has not spent much time on a device like this except making bigger and heavier and brighter platters. Shouldn't turntable spindles be machined independently from the bearing shaft so they can be swapped out with different diameters and length?

This looks like a positive step forward. The next step might be to fit the device with actuators that can nudge the record a couple of microns at a time. Trying to manually move the record in such fine steps might get frustrating. Having it linked to a vacuum hold down would be the icing on the cake. Automatically centres then flattens. Heaven.

Niffy

From what I read, it provides a hole enlarging tool or a reamer that allows the user to shift the record to center it based on the detection of run out grove. You physically move the disc to get concentricity. Once you dialed in, the device would tell you it's locked in dead center. Think of it as a Nakamichi turntable but manually adjusting to concentricity. Another way is to sand down the spindle to slightly smaller diameter at the bottom portion so you don't have to enlarge every record holes.Dd, but I still don't understand what is it for.

If you look closer, you can tell the hole has been slightly enlarged.

I have always wanted the turntable makers to make the spindle independent from the bearing shaft. At least the spindle should be a part of the platter instead of the bearing shaft or subplatter. Even better is to make the spindle detachable like a screw-on device to the PLATTER. Why allow bearing vibrations to be transmitted all the way up to the spindle that touches the actual record? My friend had a P-brand turntable with clamps and every time I clamp the record down to the platter, I could heard the noise from the motor. Unclamped it and the noise was gone. And the incident prompted me to dislike clamping to spindles that's machined to the subplatter and/or bearing.This looks like a positive step forward.

Another accessory I can think of is to have two stiff platter mats to work with the detection device, one for playback on turntable and the other to get ready for the next disc. Obviously this dual mat system would require the turntable spindle to be smaller than usual if you were to do the centering away from the turntable, unless you want to enlarge every hole on your record collection.

Regardless of how one does the centering, making people and the industry to be aware of eccentricity is indeed a positive step forward. It might prompt them to come up with affordable accessories in the future. Heck, those expensive high end turntables should have an integrated system that does the centering for you!

Last edited:

yes - but how does that device know the runout of the grooves? The Nakamichi measured it with one small arm and centered the platter by consequence - No magic.

In the video this device instead is simply used above the spindle of an everyday TT and, by rotating, those recesses (laser+photocell?) measure the runout of the engraved area?

attachment - just my guess.

carlo

.... with a reamer - funny!

In the video this device instead is simply used above the spindle of an everyday TT and, by rotating, those recesses (laser+photocell?) measure the runout of the engraved area?

attachment - just my guess.

carlo

.... with a reamer - funny!

Attachments

I'm with you, nocdplz. I want to know how it works before I spend.

Guess it's time to listen to a few eccentric records and see how much it bothers me.

Guess it's time to listen to a few eccentric records and see how much it bothers me.

Those detecting holes on the device.how does that device know the runout of the grooves?

I guess the device uses optical light to detect final runout groove and then it determine the true center of the record. However I am not sure if you need to modify the records or the center spindle in order to use the device. If you have to modify the record or the spindle, the device is meaningless not to mentioning the price.

Glad you all are confirming that my #4686 hypothesis of the inner groove laser reading is correct*. And now i understand why it must be held steady at start.

But, knowing it, if you from start explained to me too, I saved you the waste of time and the off topic.

Sorry - carlo

*At first I thought of an inertial sensor and I was off the road.

But, knowing it, if you from start explained to me too, I saved you the waste of time and the off topic.

Sorry - carlo

*At first I thought of an inertial sensor and I was off the road.

Last edited:

As a newbie amongst experts i am pondering whether this achieves very much. I feel that the ambition is to take away sideload on the stylus caused by its movement to follow eccentricities and any consequent distortion of its ability to correctly trace the signal in the groove. Isn't the tolerance on concentricity of the grooves simply enormous in comparison to the signal recorded on them? consequently, whilst no eccentricity may well be desirable there are already bigger things afoot, further, the movement of a passive arm or the errors in an active ones movement are again huge in comparison the the deflection of the stylus in reading a recorded signal. Then consider the rate of movement due to tracing or eccentricity, acceleration, and again its in a different field/level. Now, as a newbie I expect that I miss the point completely please educate me folks!Glad you all are confirming that my #4686 hypothesis of the inner groove laser reading is correct*. And now i understand why it must be held steady at start.

But, knowing it, if you from start explained to me too, I saved you the waste of time and the off topic.

Sorry - carlo

*At first I thought of an inertial sensor and I was off the road.

M

You can hear it, Mike. A steady note, as from a piano, will wow. Some people can't stand that, others don't mind it much.

You can hear it, Mike. A steady note, as from a piano, will wow. Some people can't stand that, others don't mind it much.

OK, many thanks, that's very interesting, I thought we were worrying about the side load on the stylus. Wow from eccentrics, clearly its best avoided, but what variation can one actually hear? - and if we know that, how much eccentricity would cause that, is it a realistic or significant worry?

M

M

Haven't correlated eccentricity to wow in a quantitative way, but it is clearly audible to me when I look for it. Doesn't bother me much, obviously - singers train to do it, trombonists train to do it, strings train to do it. I think it's all about the difficulties of nailing a note on an imprecise instrument. But I'm ready to be corrected about this.

It can depend on the type of music you listen to. If it's very rhythmic like dance music, it would be less noticeable. If you listen to sound that has continuous tone like a violin solo or piano sustaining notes you can hear the wobble, which can drive me insane! If one doesn't listen to classical music, it's probably not that important. I listen to it along with punk rock so I like to not have to listen to wobbling tone.

I mainly listen to classical - but it doesn't bother me much. I'm mainly concerned with how closely the system downstairs mimics the grand piano upstairs - in everything but wow, it seems.

Yes, we have real instruments as well as recordings as well. Piano, flute, bugle etc, I am still way away from the day when I might mistake the reproduced recording for the real thing..............I mainly listen to classical - but it doesn't bother me much. I'm mainly concerned with how closely the system downstairs mimics the grand piano upstairs - in everything but wow, it seems.

I read lots of reports when people say they cannot tell the difference................

I can listen and feel involved, believe its well reproduced, understand the placing, imaging etc, but I have never yet heard any reproduction that one could mistake for the real thing...........

My aim is simply to get as close as i can!!

M

BTW, if i listen to say Tocattaca and fugue on the organ, it has no discernible wow to me but its miles away from walking into the church and hearing it live!!

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm