Hi Niffy,

Apologies for the confusion

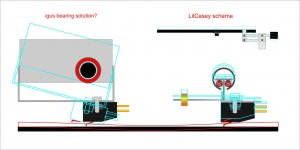

There is no vertical articulation- the idea is to tame the warping of the record, (vacuum, vice, weights hahahah) making vertical moves of the cartridge not necessary- if proven unfeasible, Then an short arm will be used

In case of thicker records, the whole arm assembly can be raised/lowered by knurled nuts and threaded bolts- can just be seen in the pic

The connection between the yellow plates is the original question for input 😉

The upper yellow plate will be glued to the red block

The long lower yellow plate- the shell- is shown long, to make sure there is space to move-once itnis known how the weight distribution turns out in practice, it will be adjusted

The blue bits- the vertical boxes are the microswitches (limits) for the up/down cartridge steppermotor- the upper blue box is the nut that takes the spindle

The sensor array for the arm is not shown

By copy to Ralf- you’re right- this is a bit more than simple, on the other hand, it is not the most complicated either 😀

Hope this helps,

Best

Coolerooney

Apologies for the confusion

There is no vertical articulation- the idea is to tame the warping of the record, (vacuum, vice, weights hahahah) making vertical moves of the cartridge not necessary- if proven unfeasible, Then an short arm will be used

In case of thicker records, the whole arm assembly can be raised/lowered by knurled nuts and threaded bolts- can just be seen in the pic

The connection between the yellow plates is the original question for input 😉

The upper yellow plate will be glued to the red block

The long lower yellow plate- the shell- is shown long, to make sure there is space to move-once itnis known how the weight distribution turns out in practice, it will be adjusted

The blue bits- the vertical boxes are the microswitches (limits) for the up/down cartridge steppermotor- the upper blue box is the nut that takes the spindle

The sensor array for the arm is not shown

By copy to Ralf- you’re right- this is a bit more than simple, on the other hand, it is not the most complicated either 😀

Hope this helps,

Best

Coolerooney

Last edited:

Like Niffy I have difficulty in understanding that drawing, but I fear that my Lil Casey has some guilt in your solution, maybe my drawings were not clear (hoping this new clarifies)

LilCasey has a radial rail exactly above the stylus, but there is a vertical movement of the whole (rail + carriage) due to the parallelogram: this must improve (reduction of the vert. mass, bearings) but works already acceptably (measures posted ). The tilting of my carriage is only a defect due to the need to make a rail + carriage system with very low weights: if I could build a feather weight double vee (no tilt) I would make it immediately: fortunately the self centering mechanism (round + T section) once balanced with that small weight it is more than enough to manage the small variations of the stylus drag during tracing.

Now: if you do not use the vertical articulation I do not understand the question on the fixed link between carriage and head shell. (Weight of the spacer? type of glue?) and then, if you do not use vert. articulation (but are you sure? seems dangerous) why the bearing can rotate? and - I repeat from a previous post - with a servo, what's the need to use a radial rail?

Carlo

just a curiosity, what types of TA have you built before?

LilCasey has a radial rail exactly above the stylus, but there is a vertical movement of the whole (rail + carriage) due to the parallelogram: this must improve (reduction of the vert. mass, bearings) but works already acceptably (measures posted ). The tilting of my carriage is only a defect due to the need to make a rail + carriage system with very low weights: if I could build a feather weight double vee (no tilt) I would make it immediately: fortunately the self centering mechanism (round + T section) once balanced with that small weight it is more than enough to manage the small variations of the stylus drag during tracing.

Now: if you do not use the vertical articulation I do not understand the question on the fixed link between carriage and head shell. (Weight of the spacer? type of glue?) and then, if you do not use vert. articulation (but are you sure? seems dangerous) why the bearing can rotate? and - I repeat from a previous post - with a servo, what's the need to use a radial rail?

Carlo

just a curiosity, what types of TA have you built before?

Attachments

Last edited:

Hi Carlo,

To start with your last question-no never built a TA before, hence my questions 😉

Apologized for my Noob-iness in all- hahahaha

True, I took cues from Lil Casey, like the elegance

My concept on the vertical articulation is to eliminate warp- then it is not necessary

If warped records cannot be tamed, then vertical moveability will required, by means of an longer arm

A round rail is used- Igus has square ones- they are easier to hook up to other bits

The connection between the 2 yellow plates is a question for me, reading too much about exotic materials😉😉

Best

Coolerooney

Just ordered up the Igus parts, had some wood sawed for a turntable mock up- will know soon 😀😀

To start with your last question-no never built a TA before, hence my questions 😉

Apologized for my Noob-iness in all- hahahaha

True, I took cues from Lil Casey, like the elegance

My concept on the vertical articulation is to eliminate warp- then it is not necessary

If warped records cannot be tamed, then vertical moveability will required, by means of an longer arm

A round rail is used- Igus has square ones- they are easier to hook up to other bits

The connection between the 2 yellow plates is a question for me, reading too much about exotic materials😉😉

Best

Coolerooney

Just ordered up the Igus parts, had some wood sawed for a turntable mock up- will know soon 😀😀

Last edited:

Sorry too late to edit-what is the relation between servo and radial (round shaft-right?) arm?

Hi Coolerooney,

You are assuming that each record has a constant thickness. When a record is pressed the stampers would need to be absolutely parallel for this to be the case. As they can't even get the hole absolutely central I'm under no illusion that they get the stampers perfectly aligned. (This is something that I'm currently tweeting my deck to overcome) By a similar process that causes warps to form as the record cools after pressing slight wrinkles can form within the surface of the vinyl that cause the record to vary slightly in thickness. This isn't something that I've seen documented but is something that I discovered to probably be case whilst measuring records in order to aid the design of my arm. Even with the best clamping system you will some warps that you can't completely flatten. You would also have to have a deck with no runout of the main bearing and the arm leveled to micron accurately. Adding all of these factors together could easily add up to a vertical movement of 20-50um even with the best clamping system possible. Distortion due to VTA error is at least twice as audible as that due to LTA errors.

(Think of how much difference raising the back of your arm by a couple of millimetres makes. This will change VTA by about half a degree yet it makes more difference than the changes in sound quality between the outer groove and the first null point. This is over a degree of LTA. Pivoted arm of course)

Your design relies on the suspension of the cartridge to accommodate all vertical movement. You could easily end up with distortion due to VTA error equivalent to a lateral error of over 2°.

Some form of vertical articulation is absolutely essential.

You could use the igus bearing to provide vertical movement as long as its friction is low enough. I would suggest moving the rails back a couple of inches and lowering the front one to being as close to the record surface as possible. The headshell can then be mounted to both the front and top of the igus bearing at the same time making a much more solid connection. This will also make queueing easier.

Alternatively make a mechanism similar to Carlos lil casey and have this servo controlled. If your going to servo control lateral movement then you might as well do vertical as well. The main problem that a servo aims to overcome is actually more of a problem in the vertical plane than the horizontal anyway. Or make something similar to the arm in the cool video you linked.

Niffy

You are assuming that each record has a constant thickness. When a record is pressed the stampers would need to be absolutely parallel for this to be the case. As they can't even get the hole absolutely central I'm under no illusion that they get the stampers perfectly aligned. (This is something that I'm currently tweeting my deck to overcome) By a similar process that causes warps to form as the record cools after pressing slight wrinkles can form within the surface of the vinyl that cause the record to vary slightly in thickness. This isn't something that I've seen documented but is something that I discovered to probably be case whilst measuring records in order to aid the design of my arm. Even with the best clamping system you will some warps that you can't completely flatten. You would also have to have a deck with no runout of the main bearing and the arm leveled to micron accurately. Adding all of these factors together could easily add up to a vertical movement of 20-50um even with the best clamping system possible. Distortion due to VTA error is at least twice as audible as that due to LTA errors.

(Think of how much difference raising the back of your arm by a couple of millimetres makes. This will change VTA by about half a degree yet it makes more difference than the changes in sound quality between the outer groove and the first null point. This is over a degree of LTA. Pivoted arm of course)

Your design relies on the suspension of the cartridge to accommodate all vertical movement. You could easily end up with distortion due to VTA error equivalent to a lateral error of over 2°.

Some form of vertical articulation is absolutely essential.

You could use the igus bearing to provide vertical movement as long as its friction is low enough. I would suggest moving the rails back a couple of inches and lowering the front one to being as close to the record surface as possible. The headshell can then be mounted to both the front and top of the igus bearing at the same time making a much more solid connection. This will also make queueing easier.

Alternatively make a mechanism similar to Carlos lil casey and have this servo controlled. If your going to servo control lateral movement then you might as well do vertical as well. The main problem that a servo aims to overcome is actually more of a problem in the vertical plane than the horizontal anyway. Or make something similar to the arm in the cool video you linked.

Niffy

Nothing bad in this, Coolerooney, we are all newbie every time we do something different. But I can only quote Ray's advice: to face a problem we must isolate it, simplify, and then experiment, verify step by step.

Start please carefully studying what Niffy, Ralf, Ray, Dd and other experts suggest you, and take it into account, because it comes from precious knowledge and experience. Mine, knowing so few, can be only about constructive hints. The first? that of Ray, but with just one S

carlo.

elegance?: aesthetics is always the least of my problems (i'm a diyer, not a seller): that gadget is only the first verification of an "iconoclastic" hypothesis.

Start please carefully studying what Niffy, Ralf, Ray, Dd and other experts suggest you, and take it into account, because it comes from precious knowledge and experience. Mine, knowing so few, can be only about constructive hints. The first? that of Ray, but with just one S

carlo.

elegance?: aesthetics is always the least of my problems (i'm a diyer, not a seller): that gadget is only the first verification of an "iconoclastic" hypothesis.

Hi Carlo,

Yes working through the BB’s, commercial sellers, reviews, brochures, copied pics, papers and diagrams, etc etc- paying my dues😉

Agree to step wise improvement, but I work on “hunches” then one flows from the other as a logical sequence- afterall building TA is not dark magic 😀 - or maybe it is- judging by magazine/website reviewers “sound experience” comments that make no sense to me -hahahah

On elegance, is not necessarily about aesthetics- its about synergy and cleverly using components, designs, fabrication- once done, you usually wind up with something looking nice too 😉

Best

Coolerooney

Yes working through the BB’s, commercial sellers, reviews, brochures, copied pics, papers and diagrams, etc etc- paying my dues😉

Agree to step wise improvement, but I work on “hunches” then one flows from the other as a logical sequence- afterall building TA is not dark magic 😀 - or maybe it is- judging by magazine/website reviewers “sound experience” comments that make no sense to me -hahahah

On elegance, is not necessarily about aesthetics- its about synergy and cleverly using components, designs, fabrication- once done, you usually wind up with something looking nice too 😉

Best

Coolerooney

Hi Niffy,

Ok ok - I get the message 😉

The fall back position is to hinge the cartridge on the rear shaft, with a short arm, the axle to axle is 42 mm

The whole arm can be raised and lowered with the knurled nuts, but would require measuring thickness before playing

Measuring level of the surface of the record can be automatically done, but requires the movement of the platter or the arm

Putting a servo on it-hmm, not there yet

I would like again to thank you and the other contributors for the (patient) replies to my questions and proposals-it is greatly appreciated- the education is well received

Best

Coolerooney

Ok ok - I get the message 😉

The fall back position is to hinge the cartridge on the rear shaft, with a short arm, the axle to axle is 42 mm

The whole arm can be raised and lowered with the knurled nuts, but would require measuring thickness before playing

Measuring level of the surface of the record can be automatically done, but requires the movement of the platter or the arm

Putting a servo on it-hmm, not there yet

I would like again to thank you and the other contributors for the (patient) replies to my questions and proposals-it is greatly appreciated- the education is well received

Best

Coolerooney

Attachments

Looks like it's trying to eliminate VTA errors by having pistonic vertical motion. The problem with this approach is that the vast majority of warp induced VTA error is due to the slope of the record surface and not the tilting of the arm about the vertical pivot. It won't really make any difference to VTA.

The complexity of all the linkages will almost certainly have a much greater negative impact than any potential positive effects.

Oh well, back to the drawing board.

Niffy

Btw Niffy,

You mention hole eccentricity- are the grooves concentric independent of the hole?

Thx

Coolerooney

You mention hole eccentricity- are the grooves concentric independent of the hole?

Thx

Coolerooney

Btw Niffy,

You mention hole eccentricity- are the grooves concentric independent of the hole?

Thx

Coolerooney

Hi Coolerooney,

Yes, the groove is basically circular and concentric about a point. The eccentricity of the record is a measure of how far this point is away from the centre of the hole. My plan for a record centering system is dependent upon this and measures the runout groove to determine the vector of the eccentricity. An extra consideration is the size of the hole. If the hole is oversized then, even if the record is concentric, it can be made eccentric relative to the spindle if not positioned perfectly. The eccentricity of side A will not necessarily be the same as for side B for any particular record. Some records appear to be perfectly centred playing one side then the cartridge dances back and forth playing the other. Unfortunately you can't centre both sides of a record by modifying the hole.

Niffy

Hi niffy.

Is there anything you can share about your lp-centering idea. Would be fantastic to have a relatively simple way to focus the grooves more accurately.

A mechanical or electronic solution on your mind ?

Is there anything you can share about your lp-centering idea. Would be fantastic to have a relatively simple way to focus the grooves more accurately.

A mechanical or electronic solution on your mind ?

#2689 - Remarkable, Walter: where have you found? it would be interesting to know what is written there.

Looking at the drawing it seems that they managed to put even more joints than me (!) and in the worst possible position (directly above the cartridge). Considering the small size of that system, I do not envy those who will build it.

In short, seems more the umpteenth announcement of a virtual iper-tonearm, almost never followed by a real realization. Hope I'm wrong

carlo

the worst possible position: not only for resonances, in that position the whole weight of the system is added to the horizontal mass, and the stylus is far from the carriage: after eliminating the arm wand with the radial rail, it builds another one on the vertical: not so clever

Looking at the drawing it seems that they managed to put even more joints than me (!) and in the worst possible position (directly above the cartridge). Considering the small size of that system, I do not envy those who will build it.

In short, seems more the umpteenth announcement of a virtual iper-tonearm, almost never followed by a real realization. Hope I'm wrong

carlo

the worst possible position: not only for resonances, in that position the whole weight of the system is added to the horizontal mass, and the stylus is far from the carriage: after eliminating the arm wand with the radial rail, it builds another one on the vertical: not so clever

Last edited:

Hi Coolerooney,

Yes, the groove is basically circular and concentric about a point. The eccentricity of the record is a measure of how far this point is away from the centre of the hole. My plan for a record centering system is dependent upon this and measures the runout groove to determine the vector of the eccentricity. An extra consideration is the size of the hole. If the hole is oversized then, even if the record is concentric, it can be made eccentric relative to the spindle if not positioned perfectly. The eccentricity of side A will not necessarily be the same as for side B for any particular record. Some records appear to be perfectly centred playing one side then the cartridge dances back and forth playing the other. Unfortunately you can't centre both sides of a record by modifying the hole.

Niffy

Hi Niffy,

Just so I understand correctly: the groove is basically independent of any physical dimension?- with the physical limits of the vinyl and “some” adherence to the dimensional specification? So the hole msy be in the middle, but the groove is off center?😡

Thx

Coolerooney

#2689 - Remarkable, Walter: where have you found? it would be interesting to know what is written there.

Looking at the drawing it seems that they managed to put even more joints than me (!) and in the worst possible position (directly above the cartridge). Considering the small size of that system, I do not envy those who will build it.

Unfortunately, Japanese is not among the 4 languages, those I'm able to speak and read. Maybe, there are some useful ideas in that design, however, it is definitely not so clever, as Schroeder LT.Anyway, some more food for our brains...

Hi niffy.

Is there anything you can share about your lp-centering idea. Would be fantastic to have a relatively simple way to focus the grooves more accurately.

A mechanical or electronic solution on your mind ?

My record centering system is currently just an idea. I haven't worked out all the details yet.

When building my arm and deck everything was designed around controlling vibrational energy, both transverse bending waves and compression sound waves. Approaches like keeping the subchassis small and balancing the suspension system were all fine tuned to compliment each other. A record centering system would be the icing on the cake, a final polish. It's implementation must not impact the deck in any negative way. The operation of the centering system also needs to be easy to use and reasonably rapid as well as being repeatably accurate. Nakamichi made a deck that centred the record, it was a great proof of concept and did appear to centre the record accurately. It was a very complex system that measured the runout groove with a second arm. The platter was split into two layer. Actuators nudged the upper layer relative to the lower until the record was centred. The obvious problem with this deck is that there is no way that all that extra gubbins wasn't going to severely compromise the rest of the deck. Just for a starter the balance of the platter would be thrown off. It also took ages to centre a record.

My plan is to split the measurement and correction processes.

The measurement of the eccentricity would be carried out on a separate "deck" that is not connected to the main deck at all and could therefore not effect its performance. This would look a bit like a record player that would read just the runout groove. This could be either mechanical or electrical in operation. As I'm better at mechanics I have been thinking of mechanical approaches. This device would measure the magnitude and direction of the eccentricity. The correction system would set to correct for eccentricity of up to 750um. (this would be for a record where the stylus moves back and forth by 1.5mm). I would divide the measurement into 25 steps each 30um and label them A to Z, A being equivalent to 0. I would place a small sticker on the edge of the record label in a location that corresponds to the direction of the eccentricity and marked with the letter that matches the magnitude.

The correction device would be built into the record clamp. The decks spindle, over which the record sits, is made only 4mm diameter so there is a lot of movement available. This is threaded at the top to attach the screwdown clamp. The clamp has a tube sticking out the bottom that fits through the records hole. This would be slightly conical and compliantly mounted vertically to compensate for variation in hole size. The inside diameter would be 5.5mm to allow movement when fitted over the spindle. A dial on the clamp moves the tube relative to the rest of the clamp. The dial is marked A to Z to match the measurement device.

Each record would only be measured once and marked. The record is placed on the platter as normal. The clamp is set to the same letter as that marked on the record. It is placed over the spindle and aligned with the mark. The clamp is then screwed down.

This system should have no effect on the resonance characteristics of the deck and should have no negative effects on sound quality. Record changing should be reasonable rapid and easy. As only the record and a small part of the clamp are moved the dynamic balance of the platter shouldn't be effected. If you want to play a record that hasn't been measured then just set the clamp to "A" and use as normal. The accuracy is limited to 30um in my plan but there is no reason why more steps couldn't be used. I think 30um is plenty accurate enough as its much less than the groove pitch. The only major downside for me is the requirement of having to home the second measurement deck. It would have to be out permanently and I don't have the space for it. Some people might not like the idea of sticking stickers on their records.

Niffy

Last edited:

niffy[I said:;5686506]My record centering system is currently just an idea. I haven't worked out all the details yet.

When building my arm and deck everything was designed around controlling vibrational energy, both transverse bending waves and compression sound waves. Approaches like keeping the subchassis small and balancing the suspension system were all fine tuned to compliment each other. A record centering system would be the icing on the cake, a final polish. It's implementation must not impact the deck in any negative way. The operation of the centering system also needs to be easy to use and reasonably rapid as well as being repeatably accurate. Nakamichi made a deck that centred the record, it was a great proof of concept and did appear to centre the record accurately. It was a very complex system that measured the runout groove with a second arm. The platter was split into two layer. Actuators nudged the upper layer relative to the lower until the record was centred. The obvious problem with this deck is that there is no way that all that extra gubbins wasn't going to severely compromise the rest of the deck. Just for a starter the balance of the platter would be thrown off. It also took ages to centre a record.

[/I]Niffy, despite all the mentioned problems, Nakamichi system had much more sense in it, than most of the later ideas for hi-end decks, making tall and heavy monsters of 100-200 kg, with the same eccentricity problem still left intact (having wow and flatter measured in 2-3%, which is kind of absurd). Actually, I think it (Nakamichi Center Search System) could be substantially developed and improved. It is a pity, what it didn't catch up with others, and was forgotten.

As to your mechanical approach, it seems to be a very good and well though out concept. As to a measurement deck, it doesn't need to have a full size platter, neither be a full size deck.

Walter

Last edited:

My record centering system is currently just an idea. I haven't worked out all the details yet.

When building my arm and deck everything was designed around controlling vibrational energy, both transverse bending waves and compression sound waves. Approaches like keeping the subchassis small and balancing the suspension system were all fine tuned to compliment each other. A record centering system would be the icing on the cake, a final polish. It's implementation must not impact the deck in any negative way. The operation of the centering system also needs to be easy to use and reasonably rapid as well as being repeatably accurate. Nakamichi made a deck that centred the record, it was a great proof of concept and did appear to centre the record accurately. It was a very complex system that measured the runout groove with a second arm. The platter was split into two layer. Actuators nudged the upper layer relative to the lower until the record was centred. The obvious problem with this deck is that there is no way that all that extra gubbins wasn't going to severely compromise the rest of the deck. Just for a starter the balance of the platter would be thrown off. It also took ages to centre a record.

My plan is to split the measurement and correction processes.

The measurement of the eccentricity would be carried out on a separate "deck" that is not connected to the main deck at all and could therefore not effect its performance. This would look a bit like a record player that would read just the runout groove. This could be either mechanical or electrical in operation. As I'm better at mechanics I have been thinking of mechanical approaches. This device would measure the magnitude and direction of the eccentricity. The correction system would set to correct for eccentricity of up to 750um. (this would be for a record where the stylus moves back and forth by 1.5mm). I would divide the measurement into 25 steps each 30um and label them A to Z, A being equivalent to 0. I would place a small sticker on the edge of the record label in a location that corresponds to the direction of the eccentricity and marked with the letter that matches the magnitude.

The correction device would be built into the record clamp. The decks spindle, over which the record sits, is made only 4mm diameter so there is a lot of movement available. This is threaded at the top to attach the screwdown clamp. The clamp has a tube sticking out the bottom that fits through the records hole. This would be slightly conical and compliantly mounted vertically to compensate for variation in hole size. The inside diameter would be 5.5mm to allow movement when fitted over the spindle. A dial on the clamp moves the tube relative to the rest of the clamp. The dial is marked A to Z to match the measurement device.

Each record would only be measured once and marked. The record is placed on the platter as normal. The clamp is set to the same letter as that marked on the record. It is placed over the spindle and aligned with the mark. The clamp is then screwed down.

This system should have no effect on the resonance characteristics of the deck and should have no negative effects on sound quality. Record changing should be reasonable rapid and easy. As only the record and a small part of the clamp are moved the dynamic balance of the platter shouldn't be effected. If you want to play a record that hasn't been measured then just set the clamp to "A" and use as normal. The accuracy is limited to 30um in my plan but there is no reason why more steps couldn't be used. I think 30um is plenty accurate enough as its much less than the groove pitch. The only major downside for me is the requirement of having to home the second measurement deck. It would have to be out permanently and I don't have the space for it. Some people might not like the idea of sticking stickers on their records.

Niffy

How about punching a bigger hole in the record after measuring where the correct center should be , and then have a corresponding bigger center spindle on you regular playback turntable?

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm