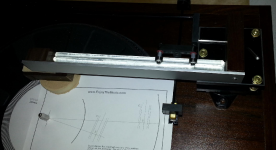

My first linear arm

Guy,

I finally finish my linear arm after reading this tread multiple times. I don't know if it would work the first time, since I still have to finish my Lenco TT before trying. I still have to make a phono amp to try on this arm.

I'm new on analog play back. I have been playing around with CD for the last 30 years and all in a sudden a friend of mind gave me a MM cartridge, Pickering V15-625e, and I start everything from this. I have some small choke with me. I wonder if the wire inside is small enough to do the job ??

Please do advice.

Albert

Guy,

I finally finish my linear arm after reading this tread multiple times. I don't know if it would work the first time, since I still have to finish my Lenco TT before trying. I still have to make a phono amp to try on this arm.

I'm new on analog play back. I have been playing around with CD for the last 30 years and all in a sudden a friend of mind gave me a MM cartridge, Pickering V15-625e, and I start everything from this. I have some small choke with me. I wonder if the wire inside is small enough to do the job ??

Please do advice.

Albert

Attachments

Last edited:

Hi Moray,

The non magnetic bolts are more applicable to MC cartridges since they use massive magnets to induce a small signal from tiny coils. It's debatable whether a difference would apply for a MM such as I use. if I can find some titanium 4~40 3/8" socket bolts I'll surely grab them locally.

Colin

The non magnetic bolts are more applicable to MC cartridges since they use massive magnets to induce a small signal from tiny coils. It's debatable whether a difference would apply for a MM such as I use. if I can find some titanium 4~40 3/8" socket bolts I'll surely grab them locally.

Colin

I heard the difference on my set up with several mm cartridges. Worth the cost for a couple of machine screws and with ti you save weight for what that is worth. Best regards Moray James.

Hi moray,

I'm looking into it, seems they are a common rc part so it's do able. Weight is not an issue granted, but if you say you have noticed a difference with mm it's worth a try since the investment is minimal. The linear arm as I have taken it is such a giant sonic leap, some non magnetic bolts can't hurt as long as they aren't nylon 🙂.

Colin

I'm looking into it, seems they are a common rc part so it's do able. Weight is not an issue granted, but if you say you have noticed a difference with mm it's worth a try since the investment is minimal. The linear arm as I have taken it is such a giant sonic leap, some non magnetic bolts can't hurt as long as they aren't nylon 🙂.

Colin

If you use the regular aluminium screws (the lightest) or you gen get stainless steel machine screws on ebay (non magnetic).

I also saw on ebay M3 titanium screws but a bit price, of course it worth that investment.

If you use standard screws you can get brass from Canadian Tire

At last no more magnetic problem

Greetings

I also saw on ebay M3 titanium screws but a bit price, of course it worth that investment.

If you use standard screws you can get brass from Canadian Tire

At last no more magnetic problem

Greetings

Last edited:

Hi moray,

I'm looking into it, seems they are a common rc part so it's do able. Weight is not an issue granted, but if you say you have noticed a difference with mm it's worth a try since the investment is minimal. The linear arm as I have taken it is such a giant sonic leap, some non magnetic bolts can't hurt as long as they aren't nylon 🙂.

Colin

Why "not nylon" ?

Why "not nylon" ?

Too soft. You won't be able to firmly mate the cartridge to the headshell. You'll likely shear the bolts in the headshell before they're tight enough.

Niffy

But the body of the cartridge is not so stiff and the nylon acts as a kind of spring, and you do not want to warp the cartridge.

If you use a silicon grease to lubricate the thread you can tight it enough I think.

If you use a silicon grease to lubricate the thread you can tight it enough I think.

Hi Arch.

In my opinion the ideal mounting should join the arm and cartridge body into a single rigid unit. The last thing you want is any kind of spring between them. The tweaks that put a compliant interface between cartridge and headshell only work if the arm has serious resonance problems, the main advantage of our short armtubes is lack of resonance problems. An m2.5 nylon bolt would seriously deform or shear long before enough force was applied to deform the cartridges body. But as both nylon and stainless bolts in this size are inexpensive there's no harm in experimentation

Niffy

In my opinion the ideal mounting should join the arm and cartridge body into a single rigid unit. The last thing you want is any kind of spring between them. The tweaks that put a compliant interface between cartridge and headshell only work if the arm has serious resonance problems, the main advantage of our short armtubes is lack of resonance problems. An m2.5 nylon bolt would seriously deform or shear long before enough force was applied to deform the cartridges body. But as both nylon and stainless bolts in this size are inexpensive there's no harm in experimentation

Niffy

I also read about cartridge weight. Somebody talked about this and even give exact weight on his cart, like 1.6g or 1.7g. How can you do this, or there is a device available on market ??

Hi Arch.

In my opinion the ideal mounting should join the arm and cartridge body into a single rigid unit. The last thing you want is any kind of spring between them. The tweaks that put a compliant interface between cartridge and headshell only work if the arm has serious resonance problems, the main advantage of our short armtubes is lack of resonance problems. An m2.5 nylon bolt would seriously deform or shear long before enough force was applied to deform the cartridges body. But as both nylon and stainless bolts in this size are inexpensive there's no harm in experimentation

Niffy

You understand very well that there is no spring BETWEEN the cartridge and the shell.

There is a link, firm enough I think, pressed by the spring effect done by the deformation of the nylon screw, avoiding the twisting of the body that you can have with a hard screw.

Sorry Arch.

The mention of "spring" in cartridge mounting sent my head down the wrong track. I do see your point. As long as the tension in the bolts is below their elastic limit they won't fail and do indeed act like a spring. . We probably have all had the experience of perfectly aligning a cartridge then tweaking the bolts up tight only to find the cartridge has twisted, so fair point there. I do think steel bolts give a more solid mounting and are preferable.

Niffy

The mention of "spring" in cartridge mounting sent my head down the wrong track. I do see your point. As long as the tension in the bolts is below their elastic limit they won't fail and do indeed act like a spring. . We probably have all had the experience of perfectly aligning a cartridge then tweaking the bolts up tight only to find the cartridge has twisted, so fair point there. I do think steel bolts give a more solid mounting and are preferable.

Niffy

Regarding nylon bolts, at these sizes they are very easy to strip threads on. I also like the socket head as they are easier in my opinion to apply non damaging torque and less chance of slipping and messing up a cartridge. Having a nice and firm connection also helps draw away excess energy away from the cartridge which benefits inner detail, anything preventing energy from being released back into the cartridge is good.

Colin

Colin

It's perfectly working

Colin, and all,

I have to thanks those guys especially Colin for his hard job. This arm works perfectly from the very start and I can't tell what the different between this and the other, for this is the first tonearm I make to coupe with my Lenco TT. I don't have any experience in analog playback, so don't know how to compare. I know my work is not 100% perfect, but I'll keep learning n hope I could tweak it to another level someday.

Thanks again

Albert

Colin, and all,

I have to thanks those guys especially Colin for his hard job. This arm works perfectly from the very start and I can't tell what the different between this and the other, for this is the first tonearm I make to coupe with my Lenco TT. I don't have any experience in analog playback, so don't know how to compare. I know my work is not 100% perfect, but I'll keep learning n hope I could tweak it to another level someday.

Thanks again

Albert

Attachments

Albert,

Congrats on building a great linear arm!. You would have to spend much more to even come close to its potential, but make changes along the way and hear the differences for yourself. Knowledge learnt on the ground hands on makes more of a difference than the crutch of theory 🙂.

Colin

Congrats on building a great linear arm!. You would have to spend much more to even come close to its potential, but make changes along the way and hear the differences for yourself. Knowledge learnt on the ground hands on makes more of a difference than the crutch of theory 🙂.

Colin

Albert,

Congrats on building a great linear arm!. You would have to spend much more to even come close to its potential, but make changes along the way and hear the differences for yourself. Knowledge learnt on the ground hands on makes more of a difference than the crutch of theory 🙂.

Colin

Colin,

Thanks so much for your encouragement. I certainly will follow this thread for tweaking. I thought what I'll need now is the tonearm wire. What I have now is some 30 awg. single wire from one old choke. It's too stiff and it even limits the swing of the cartridge. I will go for the Cardas 33 awg. from parts connexion.

Albert

I did 2nd try. It is almost perfect cut this time. I use a 12 OD 10 ID glass tubing instead of 16 OD 11 ID glass tubing .

Attachments

Last edited:

Hi Albert.

Welcome to the wonderful world of LT.

Nicely done. It looks like you have followed Colins design pretty closely. A smart move considering the amount of experimentation, fine tuning and hard work our mentor has put into this design.

Colin.

I've just tried your frequency sweep test tone test. You're right it is dead simple. All I heard was a perfectly smooth progression through the entire range. No peaks or resonant modes in the audible range at all. Just as I had hoped considering the amount of work I did to push the arms resonant frequency out of the audio bandwidth its a nice conformation. Thanks for the tip. I've nearly finished my light weight carriage and will hopefully be able to report on what differences it makes soon.

Super.

Nice clean cuts. I bet you were sweating buy the end. I look forward to hearing how it compares to the two tube design.

Niffy

Welcome to the wonderful world of LT.

Nicely done. It looks like you have followed Colins design pretty closely. A smart move considering the amount of experimentation, fine tuning and hard work our mentor has put into this design.

Colin.

I've just tried your frequency sweep test tone test. You're right it is dead simple. All I heard was a perfectly smooth progression through the entire range. No peaks or resonant modes in the audible range at all. Just as I had hoped considering the amount of work I did to push the arms resonant frequency out of the audio bandwidth its a nice conformation. Thanks for the tip. I've nearly finished my light weight carriage and will hopefully be able to report on what differences it makes soon.

Super.

Nice clean cuts. I bet you were sweating buy the end. I look forward to hearing how it compares to the two tube design.

Niffy

Hi niffy,

Yes, you're right. A better off for a newbie like me is to copy/ follow the original design. I have been playing with cd for the last 30 years n analog playback is completely new to me. I'm now upgrading my audio chain. I will keep reading the post n keep tweaking.

Regards

Albert

Yes, you're right. A better off for a newbie like me is to copy/ follow the original design. I have been playing with cd for the last 30 years n analog playback is completely new to me. I'm now upgrading my audio chain. I will keep reading the post n keep tweaking.

Regards

Albert

Albert,

We all start off copying, and that's just fine. The whole goal of this thread was to share an idea I got working, and documented my changes along with being inspired by others ideas that have been interjected into this thread 🙂. One idea is great, but the creative input from others turn it into something even better 🙂. One is a fool to be so stubborn as to think their idea is the end all be all and the openness to suggestions is what makes a better mousetrap.

Colin

We all start off copying, and that's just fine. The whole goal of this thread was to share an idea I got working, and documented my changes along with being inspired by others ideas that have been interjected into this thread 🙂. One idea is great, but the creative input from others turn it into something even better 🙂. One is a fool to be so stubborn as to think their idea is the end all be all and the openness to suggestions is what makes a better mousetrap.

Colin

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm