super10018,

VERY, VERY nice job. You put a lot of time, thought, and craftsmanship into your arm---and It shows !!!! Even on youtube you can tell it sounds great.

VERY, VERY nice job. You put a lot of time, thought, and craftsmanship into your arm---and It shows !!!! Even on youtube you can tell it sounds great.

super 10018 , great architecture and a good to hear that MC cards are doing OK !

Cheers ,

Paul

Cheers ,

Paul

Thank you for all the encouraging words!

I have been learning a lot from this thread and getting advices form fellow diyers. Next thing I want to try to use high compliance cartridges. Denon DL-103R is a low compliance one.

I also have an idea for a new tone arm, but for now I just want to enjoy this arm.

Jim

I have been learning a lot from this thread and getting advices form fellow diyers. Next thing I want to try to use high compliance cartridges. Denon DL-103R is a low compliance one.

I also have an idea for a new tone arm, but for now I just want to enjoy this arm.

Jim

super10018,

Great "Building" and your You Tube item inspired me to listen to some more of Booker Ervin.

Hans.

Great "Building" and your You Tube item inspired me to listen to some more of Booker Ervin.

Hans.

your You Tube item inspired me to listen to some more of Booker Ervin.

Charlie Mingus for me. Although Irvin's "Book" series of records are really nice. Mingus records always remind me of Eric Dolphy.

A funny side note: I used to tune my system using Ornette Coleman records and always thought the horn was a little plasticky sounding as I wanted more metallic shine to it. Turned out Ornette was using a yellow plastic alto sax, just like the one Charlie Parker once used in the famous Massey Hall record! Duh!

Hi Hans and Super,

I've been sidetracked by another project for a while and haven't been following this thread as closely as I normally do. What a fantastic pair of heavy weight versions you have created. Hats off to both of you. I loved your youtube video Super. It looked like you superimposed a still photo of the arm onto a video of the deck running. That carriage stays rock steady.

Niffy

I've been sidetracked by another project for a while and haven't been following this thread as closely as I normally do. What a fantastic pair of heavy weight versions you have created. Hats off to both of you. I loved your youtube video Super. It looked like you superimposed a still photo of the arm onto a video of the deck running. That carriage stays rock steady.

Niffy

In making the two bearing, two tube design of this tonearm, is it wise to leave the inner race of the bearing free to spin on the carriage bolt as well, or is it okay for the center to to be pressure fit on the bolt?

Hi Morton.

I would recommend firmly mounting the inner race. Loosely mounting the bearings will not decrease lateral friction as the friction of the bearing would be much much lower than the friction between the inner race and the mounting bolt. It would have little effect on vertical movement as the amount of play in the bearing itself is sufficient for all but the most severe warps. All you would be adding with a loose fitting is another point where chatter can occur.

Niffy

I would recommend firmly mounting the inner race. Loosely mounting the bearings will not decrease lateral friction as the friction of the bearing would be much much lower than the friction between the inner race and the mounting bolt. It would have little effect on vertical movement as the amount of play in the bearing itself is sufficient for all but the most severe warps. All you would be adding with a loose fitting is another point where chatter can occur.

Niffy

Yes. Morton,

Like Niffy stated firmly mount the inner race for the two tube design. Super, how is the high compliance working out?, if you have had a chance to approach it yet?. Carriage would need to be quite light, but high compliance seemed to have died in the late 80's and we are left with mostly med to low compliance presently. IMHO I don't find this arm to be suited to high compliance including most passive lt arms, even a small glitch in the wiring dressing will cause issues on a high compliance cantilever.

Colin

Like Niffy stated firmly mount the inner race for the two tube design. Super, how is the high compliance working out?, if you have had a chance to approach it yet?. Carriage would need to be quite light, but high compliance seemed to have died in the late 80's and we are left with mostly med to low compliance presently. IMHO I don't find this arm to be suited to high compliance including most passive lt arms, even a small glitch in the wiring dressing will cause issues on a high compliance cantilever.

Colin

Colin and all

I think when you say high compliance, you may mean something else.

A cartridge compliance is its "springiness". A phono cartridge whose compliance is rated at 12 x l0ˉ6 or below, is considered low compliance. A cartridge whose compliance is rated between 13 x l0ˉ6 and 25 x l0ˉ6 is considered high to very high. So, most of modern MC cartridges are high compliance.

I have three high compliance cartridges in hand. I have tried them all on the diy arm. Here are the results.

1. zyx R-1000 Airy S MC. Compliance: 15 x l0ˉ6. Recommended Tracking Force: 2.0 g.

I have own this cartridge for at least 8 years already and use it a lot. Its damping system may not be as effective as new one. This cartridge still performs good on DIY arm. Its sound on the diy arm is natural and detailed. But for some tracks, it produces artificial buzz sound. I believe the buzz is caused by incomparability of the diy arm and the cartridge. Aged damping system on the zyx can cause the buzz sound too.

2. Dynavector 17D3 MC. Compliance: 15 x l0ˉ6. Recommended Tracking Force: 1.8-2.0 g.

This is the cartridge which works the best with the arm. The cartridge is fairly new. I always think it lacks bass when using it with Graham tonearm but not for the diy arm. I love this combo so far. However, it produce some distortion when the some of music passages get high dynamics although it doesn't happen too often.

3. Denon DL-S1 MC. Compliance: 14 x l0ˉ6. Recommended Tracking Force: 1.1-1.5 g.

This is a new cartridge. I bought the cartridge after reading user's review over internet. But I am somewhat disappointed. Its high and mid range sound thin to my ear. I understand the cartridge is not break-in yet. I set the tracking force 1.2-1.3 g at first. It can't track. The tracking force is at least 1.5 g for the diy arm to work. This cartridge produces distortion as 17D3 at loud music passage.

I also tried low compliance cartridge. It is Denon DL-103R. Compliance: 5 x l0ˉ6. Recommended Tracking Force: 2.3-2.7 g. The 103R tracks almost perfectly.

After carefully studying Clear Audio's arm, I think my diy arm has a problem with the weight distribution. On my arm, the headshell is about 24 g, bearing carriage is about 5 g. Clear Audio's is different. I guess their headshell should be about 6-10 g and bearing carriage is 10 g. Most of diyers in this thread are trying to reduce the weight of bearing carriage as much as possible. It may not be ideal. I plan to build third version of arm with 6 g head shell and 10 g bearing carriage.

I think when you say high compliance, you may mean something else.

A cartridge compliance is its "springiness". A phono cartridge whose compliance is rated at 12 x l0ˉ6 or below, is considered low compliance. A cartridge whose compliance is rated between 13 x l0ˉ6 and 25 x l0ˉ6 is considered high to very high. So, most of modern MC cartridges are high compliance.

I have three high compliance cartridges in hand. I have tried them all on the diy arm. Here are the results.

1. zyx R-1000 Airy S MC. Compliance: 15 x l0ˉ6. Recommended Tracking Force: 2.0 g.

I have own this cartridge for at least 8 years already and use it a lot. Its damping system may not be as effective as new one. This cartridge still performs good on DIY arm. Its sound on the diy arm is natural and detailed. But for some tracks, it produces artificial buzz sound. I believe the buzz is caused by incomparability of the diy arm and the cartridge. Aged damping system on the zyx can cause the buzz sound too.

2. Dynavector 17D3 MC. Compliance: 15 x l0ˉ6. Recommended Tracking Force: 1.8-2.0 g.

This is the cartridge which works the best with the arm. The cartridge is fairly new. I always think it lacks bass when using it with Graham tonearm but not for the diy arm. I love this combo so far. However, it produce some distortion when the some of music passages get high dynamics although it doesn't happen too often.

3. Denon DL-S1 MC. Compliance: 14 x l0ˉ6. Recommended Tracking Force: 1.1-1.5 g.

This is a new cartridge. I bought the cartridge after reading user's review over internet. But I am somewhat disappointed. Its high and mid range sound thin to my ear. I understand the cartridge is not break-in yet. I set the tracking force 1.2-1.3 g at first. It can't track. The tracking force is at least 1.5 g for the diy arm to work. This cartridge produces distortion as 17D3 at loud music passage.

I also tried low compliance cartridge. It is Denon DL-103R. Compliance: 5 x l0ˉ6. Recommended Tracking Force: 2.3-2.7 g. The 103R tracks almost perfectly.

After carefully studying Clear Audio's arm, I think my diy arm has a problem with the weight distribution. On my arm, the headshell is about 24 g, bearing carriage is about 5 g. Clear Audio's is different. I guess their headshell should be about 6-10 g and bearing carriage is 10 g. Most of diyers in this thread are trying to reduce the weight of bearing carriage as much as possible. It may not be ideal. I plan to build third version of arm with 6 g head shell and 10 g bearing carriage.

Has anyone tried a clearaudio cartridge like the artist or the performer on the diy arm?

Oh Yeah:

I used the Maëstro V2 in a Unify 14" sounded nice, but the same cartridge now in my diy LT.......................I`m really shocked how aweful good it sound.

IMHO: the most musical sounding MM cart. I`ve ever heard.

Hans. ( completely lost in his new tonearm )

After carefully studying Clear Audio's arm, I think my diy arm has a problem with the weight distribution. On my arm, the headshell is about 24 g, bearing carriage is about 5 g. Clear Audio's is different. I guess their headshell should be about 6-10 g and bearing carriage is 10 g. Most of diyers in this thread are trying to reduce the weight of bearing carriage as much as possible. It may not be ideal. I plan to build third version of arm with 6 g head shell and 10 g bearing carriage.

think I have pointed this out a while ago too . so very curious how this works out , please let us know .

Regards ,

Paul

Right now I am soaking my bearings in acetone to get rid of any of the "light lubricant" that is in there. I soak them for a day, take them out, spin the crap out of them for about 10 seconds with a dremel tool, put them back in. Hopefully will be able to start my build soon.

Hi Super.

A 24g headshell would give a massive vertical effective mass, especially when you consider the extra mass needed to counter balance it. Dropping the total carriage mass too very low levels also caused problems for many of the builders in this thread if I remember correctly.I think the overall consensus was about 25g being ideal, though my 50g carriage works flawlessly.

Niffy

A 24g headshell would give a massive vertical effective mass, especially when you consider the extra mass needed to counter balance it. Dropping the total carriage mass too very low levels also caused problems for many of the builders in this thread if I remember correctly.I think the overall consensus was about 25g being ideal, though my 50g carriage works flawlessly.

Niffy

Soaking them that Lol ng won't do much. Ultrasonic with acetone is better. If they are steel and not stainless, you dont have to worry about the lubricant diffusioning into the metal. I would seriously consider baking though. Dull blast n the oven for an hour is so. Then clean again

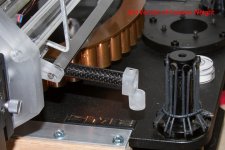

I finished 3rd revision of my diy arm.

The headshell is now 7.5 g and bearing carriage is 12 g. I made a small bucket for counter weight. It is filled with lead shots. The lead pellets are weighted .05 g each. I can also move the counter weight back and forth to adjust tracking force. Please see attached photo. I did four different kinds of counter weights. The bottom of 1st version is about 3/4 inch lower than record surface. I believed that counter weight should be lower than record surface and the lower, the better. However, I found that it is not necessary and not desirable. The bottom of final version of counter weight is on the same level as record surface. A counter weight should be on the same level as the needle of cartridge in order to track nicely.

I tried Denon DL-S1 and zyx Airy on the new version of the arm.

The recommended tracking force is 1.1-1.3 g for Denon DL-S1. I could not track at 1.3 g with old arm, but no problem with the new arm. I set the VTF at 1.3 g. The cartridge tracks perfectly. My only complain is the sound of Denon DL-S1 is on thin side. It sounds wonderful when it plays jazz, but not classical. In my opinion, classical music is the most difficult music to play back on a vinyl system.

For Zyx Airy, it tracks very nice as well. I spent a lot of time to try to get ride of buzz when it plays classical music with high dynamics. I tried different combos of VTF, VTA and did 4 different versions of counter weights. Finally, I get the sound which I like the most. It is my favorite cartridge and diy arm combo now.

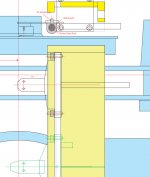

At this point, I think I am done with this Cantus style rail diy arm. Personally, I am not fond of so called "knife edge" theory. I really suspect the validity of such theory and plan to build my own version diy arm. Here is the plan. Please see attached drawing.

Here are two videos.

https://www.youtube.com/watch?v=-nEQz_6UB4o

https://www.youtube.com/watch?v=p8UcE6XzDe8

Both videos show Denon DL-S1 playing.

The headshell is now 7.5 g and bearing carriage is 12 g. I made a small bucket for counter weight. It is filled with lead shots. The lead pellets are weighted .05 g each. I can also move the counter weight back and forth to adjust tracking force. Please see attached photo. I did four different kinds of counter weights. The bottom of 1st version is about 3/4 inch lower than record surface. I believed that counter weight should be lower than record surface and the lower, the better. However, I found that it is not necessary and not desirable. The bottom of final version of counter weight is on the same level as record surface. A counter weight should be on the same level as the needle of cartridge in order to track nicely.

I tried Denon DL-S1 and zyx Airy on the new version of the arm.

The recommended tracking force is 1.1-1.3 g for Denon DL-S1. I could not track at 1.3 g with old arm, but no problem with the new arm. I set the VTF at 1.3 g. The cartridge tracks perfectly. My only complain is the sound of Denon DL-S1 is on thin side. It sounds wonderful when it plays jazz, but not classical. In my opinion, classical music is the most difficult music to play back on a vinyl system.

For Zyx Airy, it tracks very nice as well. I spent a lot of time to try to get ride of buzz when it plays classical music with high dynamics. I tried different combos of VTF, VTA and did 4 different versions of counter weights. Finally, I get the sound which I like the most. It is my favorite cartridge and diy arm combo now.

At this point, I think I am done with this Cantus style rail diy arm. Personally, I am not fond of so called "knife edge" theory. I really suspect the validity of such theory and plan to build my own version diy arm. Here is the plan. Please see attached drawing.

Here are two videos.

https://www.youtube.com/watch?v=-nEQz_6UB4o

https://www.youtube.com/watch?v=p8UcE6XzDe8

Both videos show Denon DL-S1 playing.

Attachments

Last edited:

Hi super.

Good to see you still experimenting and coming up with new angles. Your lead pellet counterweight is neat as you can adjust both tracking force and effective mass.

You said " A counter weight should be on the same level as the needle of cartridge in order to track nicely". I've heard this stated many times but think it is true only under a very specific set of circumstances. Circumstances that are not met in this design of arm.

Ideally the vertical pivot should be level with the record surface in order to minimize warp wow. Also the centre of mass of the whole arm (not just the counterweight) should be level with pivot in order to minimize tracking force variations when traversing warps. Therefore the centre of mass of the arm should only be level with the surface of the record if the pivot is also level with the surface of the record.

As our arms have their pivots above the record surface the centre of mass of the arm should also be raised.

Also worth mentioning is a very good observation made by Colin quite some time ago. Having the centre of mass below the pivot causes a slight increase in tracking force on warps and this can be advantageous as it seems to make the cartridge a little more sure footed. The slightly higher than centre of mass pivot will also make the arm dynamically stable.

As you have excellent record clamping warps will be much less of an issue for you.

Keep up the good nay excellent work.

Hopefully the project that has sidetracked me from working on my arm will be finished soon so I can get on with some experiments of my own, I've got a 90% finished lightweight carriage that's been gathering dust for over a month.

Niffy

Good to see you still experimenting and coming up with new angles. Your lead pellet counterweight is neat as you can adjust both tracking force and effective mass.

You said " A counter weight should be on the same level as the needle of cartridge in order to track nicely". I've heard this stated many times but think it is true only under a very specific set of circumstances. Circumstances that are not met in this design of arm.

Ideally the vertical pivot should be level with the record surface in order to minimize warp wow. Also the centre of mass of the whole arm (not just the counterweight) should be level with pivot in order to minimize tracking force variations when traversing warps. Therefore the centre of mass of the arm should only be level with the surface of the record if the pivot is also level with the surface of the record.

As our arms have their pivots above the record surface the centre of mass of the arm should also be raised.

Also worth mentioning is a very good observation made by Colin quite some time ago. Having the centre of mass below the pivot causes a slight increase in tracking force on warps and this can be advantageous as it seems to make the cartridge a little more sure footed. The slightly higher than centre of mass pivot will also make the arm dynamically stable.

As you have excellent record clamping warps will be much less of an issue for you.

Keep up the good nay excellent work.

Hopefully the project that has sidetracked me from working on my arm will be finished soon so I can get on with some experiments of my own, I've got a 90% finished lightweight carriage that's been gathering dust for over a month.

Niffy

Hi Niff!

Please see the photo. The weight of bearing carriage is mostly concentrated on the bottom. So, all the weights of three sections, head shell, bearing carriage and counter weight should be in line with arm wand. I learn this by studying Clear Audio arm.

Please see the photo. The weight of bearing carriage is mostly concentrated on the bottom. So, all the weights of three sections, head shell, bearing carriage and counter weight should be in line with arm wand. I learn this by studying Clear Audio arm.

Attachments

I made another small improvement by adding .5 mm carbon fiber washers on the cartridge screws. These washers are about .15 g. Accordingly, I added two lead pellets (.05 g each) into the counter weight bucket. It seems to me that background noise is reduced.

Attachments

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm