Bill, Moray, Colin,

I just tried a quick one. Suspended the glass tube from a string and flicked it with my finger. Rings for a couple of seconds. Then I shoved one end into the maple block and flicked it again. Can't hear any sustained ringing. The block snuffs it out nicely. So, I'm thinking Duct seal or putty may be overkill like the oil.

Also tried various papers rolled up in the tube. One with wax on one side (for laying hardwood) seemed promising. None of this was while spinning LPs - later for that.

I will definitely get around to "both sides to the plinth" too.

Thanks

Hugh

Hi Hugh,

Suggest you try once more. This time place your stylus on a non-rotating record and turn the volume up somewhere just above listening level and then tap your tube. I too can't hear any sustained ringing with my naked ears. If you get a good bite on the assembly with it hanging in free air and tap it, you will clearly hear it ringing in your head/ears. Bone conduction through your teeth. What we have to do is keep the vibration from getting back into the stylus if we can't kill it. Thanks for trying.

BillG

And voila, two tube, two bearing working and non falling off arm with a dust cover, only arm lift left to go, PDR, thanks for the inspiration, this is what its all about 🙂. Seems all in all I needed to do some more work with the two tube design I tried out a couple moons back, thanks for proving it can work and needed further investigation.

Colin

Colin & PDR,

I second those remarks. Only for me it took a couple of years not moons. Well I learned a lot in the process. Still am. Tonight during a listening session I decided to find out how light the vertical tracking could go. Cartridge is the ADC XLM. The 2 tube design will track a record with some heavy passages and some light ones mostly average at 0.5 grams. No skipping or distortion. On some real loud music, Horowitz in Moscow concert, his grand finale playing all 88 at once and at full volume it was a little better at 0.9 grams. This is one amazing arm now.

BillG

A revelation!

Bill,

Yes it tracks phenomenal!, but!, I've utterly solved any ringing tone with my last iteration inspired by PDR!. My knock up with the aluminum angle and polycarbonate dust cover does not ring at all, even at low frequencies!. I've tapped it with a still record, no ring just a dull thud. There is no damping added to the arm at all!. This is great, this is getting refined.

Colin

Bill,

Yes it tracks phenomenal!, but!, I've utterly solved any ringing tone with my last iteration inspired by PDR!. My knock up with the aluminum angle and polycarbonate dust cover does not ring at all, even at low frequencies!. I've tapped it with a still record, no ring just a dull thud. There is no damping added to the arm at all!. This is great, this is getting refined.

Colin

dedication

How many iterations of these arms have you built? It must be dozens. I'm getting frustrated as I can't make time to work on my own project then every time I check this thread you seem to have built a whole new arm.

Does the two tube sound significantly better than the single tube model?

Niffy

How many iterations of these arms have you built? It must be dozens. I'm getting frustrated as I can't make time to work on my own project then every time I check this thread you seem to have built a whole new arm.

Does the two tube sound significantly better than the single tube model?

Niffy

How many iterations of these arms have you built? It must be dozens. I'm getting frustrated as I can't make time to work on my own project then every time I check this thread you seem to have built a whole new arm.

Does the two tube sound significantly better than the single tube model?

Niffy

Niffy,

I understand your frustration, believe me, both versions work equally well, but as I do not believe in just throwing a whole pile of damping at an arm the goal continues in the design as I feel a good design achieves what it should through trial and error and careful calculation. Decoupling sounds better than heavy damping, IMHO. The two tube version has better layering, I'm thinking so far, in the way I've done it it is quieter and better in the highs due to lower lateral friction but both will work well but the single tube is even more so dependant on bearing size, for the record I use the same bearings in the two tube as stock.

Colin

Last edited:

Bill,

Yes it tracks phenomenal!, but!, I've utterly solved any ringing tone with my last iteration inspired by PDR!. My knock up with the aluminum angle and polycarbonate dust cover does not ring at all, even at low frequencies!. I've tapped it with a still record, no ring just a dull thud. There is no damping added to the arm at all!. This is great, this is getting refined.

Colin

Colin,

Great! Is the free end of the tubes tied to the aluminum angle and dust cover. I'd be surprised if it isn't. This is what I was aiming at with the overhead aluminum beam linking the tube back to the mounting block. That was not doing anything significant. I will do additional work with this technique.

Thanks,

BillG

And voila, two tube, two bearing working and non falling off arm with a dust cover, only arm lift left to go, PDR, thanks for the inspiration, this is what its all about 🙂. Seems all in all I needed to do some more work with the two tube design I tried out a couple moons back, thanks for proving it can work and needed further investigation.

Colin

Colin

Can you post more pictures from different angle please?

Thank you very much

Greetings Gabor

Looks great , Colin !

So to speak , it looks like there's a new kid in town 😉 fantastic !

I have a single question regarding this 2 rodded , 2 bearing LT arm :

How does it compare soundwise in respect to the lower vertical friction ( smoother movement ) of

the carriage / armtube / cantilever ? as I recall some time ago some mentioned that it could be

beneficial to have the somewhat stiffer ( compliance ) vert. movement , up/down , back/forth ..

One would expect a major difference here .. or is it not so much important

as we might thought it was ??

Great works !! keep going .

THX

Paul

So to speak , it looks like there's a new kid in town 😉 fantastic !

I have a single question regarding this 2 rodded , 2 bearing LT arm :

How does it compare soundwise in respect to the lower vertical friction ( smoother movement ) of

the carriage / armtube / cantilever ? as I recall some time ago some mentioned that it could be

beneficial to have the somewhat stiffer ( compliance ) vert. movement , up/down , back/forth ..

One would expect a major difference here .. or is it not so much important

as we might thought it was ??

Great works !! keep going .

THX

Paul

Last edited:

That looks great Colin.

Just so I get it.....the tubes sit directly on top of the alum. angle?

Are they epoxied or glued? Do they sit on a membrane? Would a

membrane be beneficial for isolation?

This is cool as the angle becomes the connection point to the

rest of the arm and the tube assembly can easily be swung out of the way

to place an album, or detached quickly if needed.

Now just need some sort of caliper type adjustment to easily raise

or lower the arm to accommodate vinyl thickness.

I'm going to have to get back to my glass blower and pick up some

different size tubes....like the 6mm ones and give this version a go.

Going to pick up a bunch of different size bearings as well. The hobby shop

here sells bearings for $3 a piece and has a ton of different sizes.

Just so I get it.....the tubes sit directly on top of the alum. angle?

Are they epoxied or glued? Do they sit on a membrane? Would a

membrane be beneficial for isolation?

This is cool as the angle becomes the connection point to the

rest of the arm and the tube assembly can easily be swung out of the way

to place an album, or detached quickly if needed.

Now just need some sort of caliper type adjustment to easily raise

or lower the arm to accommodate vinyl thickness.

I'm going to have to get back to my glass blower and pick up some

different size tubes....like the 6mm ones and give this version a go.

Going to pick up a bunch of different size bearings as well. The hobby shop

here sells bearings for $3 a piece and has a ton of different sizes.

Paul,

I haven't spent enough time with it yet to really assess differences, at first though it seems a tad lighter in the Bass. Laterally it tracks better, as in feels smoother laterally and any ringing from tapping the track is non existent.

pdr,

The glass tubes are glued to the aluminum, works just fine this way with no added noise

. .

Thank you for the kind words, I spent a good day dreaming up the simplest most effective way to do this, this version makes my single tube look busy but the dust cover has two benefits, dirt protection and along the back out of sight underneath ithas a small strip of split carbon fiber tube which prevents the carriage from falling off during mishaps and cueing 🙂

Colin

I haven't spent enough time with it yet to really assess differences, at first though it seems a tad lighter in the Bass. Laterally it tracks better, as in feels smoother laterally and any ringing from tapping the track is non existent.

pdr,

The glass tubes are glued to the aluminum, works just fine this way with no added noise

. .

Thank you for the kind words, I spent a good day dreaming up the simplest most effective way to do this, this version makes my single tube look busy but the dust cover has two benefits, dirt protection and along the back out of sight underneath ithas a small strip of split carbon fiber tube which prevents the carriage from falling off during mishaps and cueing 🙂

Colin

VTA Adjustment

Hope these pictures show up. First attempt at adding photos.

Colin,

Nice workmanship on your double tube version. It's in stark contrast to the "Prototype" photos I'm attempting to attach.

PDR and others,

You hinted at VTA adjustment. I think that's even more important with this shorter arm because a change in LP thickness makes a bigger change in the rake angle.

On mine, the 3 bolts labelled A,B,C are used to set the nominal height of the dark brown base and set the glass tube parallel to the platter. I loosen the T nuts D and E, then use bolt F to lower or raise the maple block. Afterwards, the T nuts are made thumb tight.

In the second photo you can (maybe) see the hinge at the back that allows the maple block to swivel.

This is very quick. Works like a charm on the single tube version. I'm not sure if it will do so well on a double tube version. Tossing it into the ring anyway. Hope this sparks some better ideas.

I also want to mention the cartridge is attached to a piece of material that should be familiar to all the Canadians on this site. Any guesses?

Hugh

Hope these pictures show up. First attempt at adding photos.

Colin,

Nice workmanship on your double tube version. It's in stark contrast to the "Prototype" photos I'm attempting to attach.

PDR and others,

You hinted at VTA adjustment. I think that's even more important with this shorter arm because a change in LP thickness makes a bigger change in the rake angle.

On mine, the 3 bolts labelled A,B,C are used to set the nominal height of the dark brown base and set the glass tube parallel to the platter. I loosen the T nuts D and E, then use bolt F to lower or raise the maple block. Afterwards, the T nuts are made thumb tight.

In the second photo you can (maybe) see the hinge at the back that allows the maple block to swivel.

This is very quick. Works like a charm on the single tube version. I'm not sure if it will do so well on a double tube version. Tossing it into the ring anyway. Hope this sparks some better ideas.

I also want to mention the cartridge is attached to a piece of material that should be familiar to all the Canadians on this site. Any guesses?

Hugh

Attachments

Another pic, glass tube sizes are 6mm side by side at the back of the 1x1x1/8" alu L. Polycarbonate top is bolted with circuit board standoffs.

Colin,

You got my curiosity way up on how the resonance is eliminated in the new model. Needless to say I'm building something along those lines. A question though. How is the horizontal L angle mounted to the vertical member? Is there any lossy material between the two? Also, is the glue joint between the tubes and the "L" continuous along the tube length or just in places, like the middle and 2 ends?

Rgds,

BillG

Last edited:

Hello hjam

Having resided in Canada for five years, I'll make a guess.

It looks like one of those sheet metal "squeeze to release" spring clips. But I don't know what it is called.

If that's what it is, it actually is a very clever idea. It would allow instant adjustment for effective length and azimuth.

Sincerely,

Ralf

I also want to mention the cartridge is attached to a piece of material that should be familiar to all the Canadians on this site. Any guesses?

Having resided in Canada for five years, I'll make a guess.

It looks like one of those sheet metal "squeeze to release" spring clips. But I don't know what it is called.

If that's what it is, it actually is a very clever idea. It would allow instant adjustment for effective length and azimuth.

Sincerely,

Ralf

Bill,

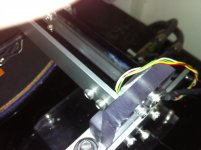

The two tubes are tacked in 5 points along the aluminum L. The L pieces is attached to the 10mm polycarbonate on the arm base via an aluminum L piece bolted to the inside on the track. Here is a photo of the connection.

The two tubes are tacked in 5 points along the aluminum L. The L pieces is attached to the 10mm polycarbonate on the arm base via an aluminum L piece bolted to the inside on the track. Here is a photo of the connection.

Attachments

Last edited:

Bill,

The two tubes are tacked in 5 points along the aluminum L. The L pieces is attached to the 10mm polycarbonate on the arm base via an aluminum L piece bolted to the inside on the track. Here is a photo of the connection.

Thanks. I have pieces of glass coming in a few days and some scrap aluminum for the L. It won't be long before there is a test piece made up. looks like we are evolving back to the Cantus albeit an inside out one. I have long felt that the bearing free play available with the 2 bearing design was a highly/most effective way of dealing with typical small warps. I nhave a couple of records with smallish warps and was clearly hearing a touch of warp wow with the single tube design. Was listening critically last night to those 2 records and not hearing even the faintest trace of warp at all. Will have to keep listening.

Rgds,

Billg

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm