I'm going to put together a plan and parts list, so that will be coming up. All parts are available between Home Depot, scientific supply store,and most hobby stores that cater to rc car builders.

Colin

😀😀😀

I was here first, Thomas.

Ummmmm - actually I'm fairly sure that Colin wuz here before any of us.... and he's sharing.... 😀😀😀

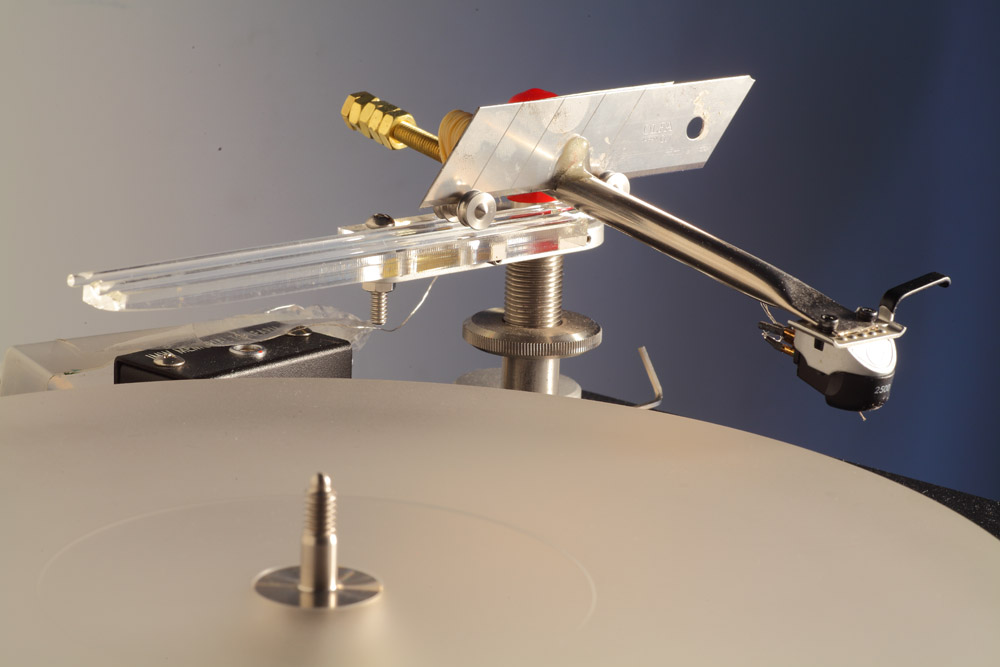

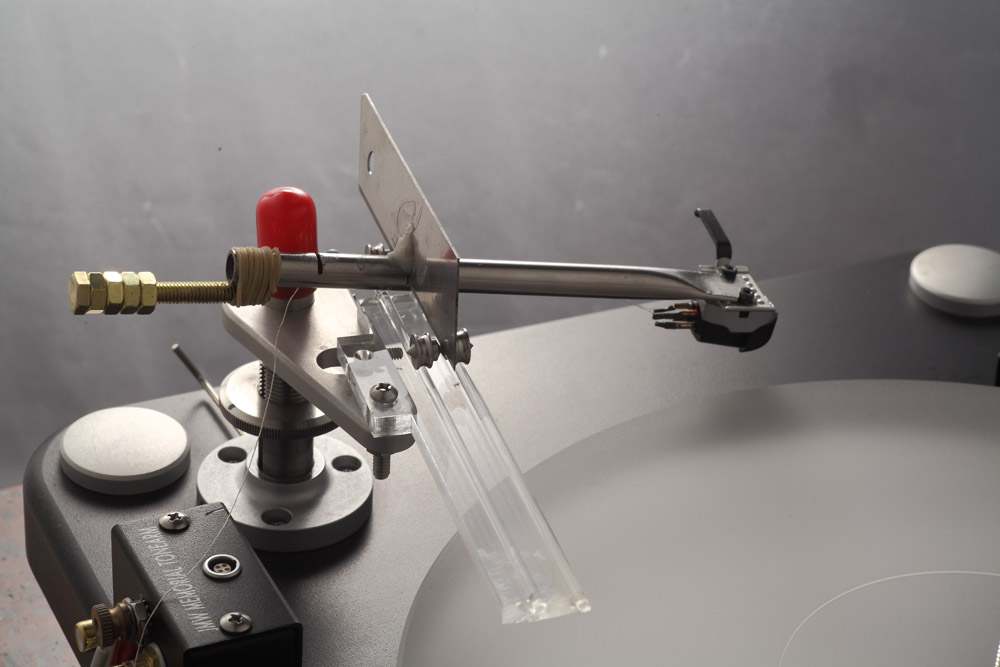

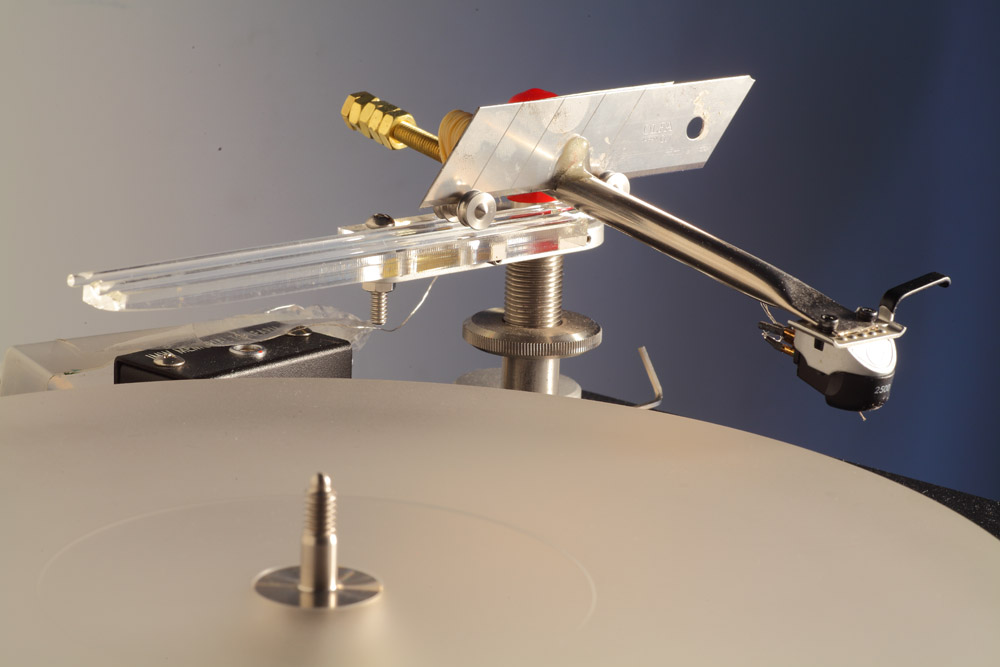

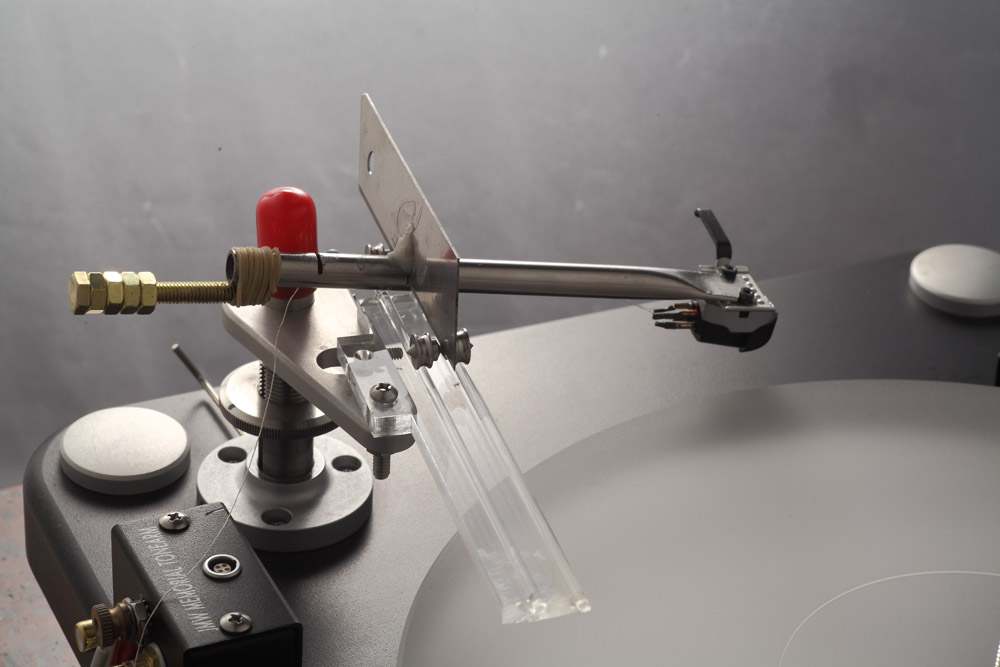

After looking at this diy arm closer, I discovered the builder reuse the arm base from a VPI JMW 9" pivot arm on a VPI Scout turntable! Clever. I always like projects that don't require reinventing the wheel. Be ecologically correct and recycle! 😀 And I would find a way to reuse that Lemo connector so I can swap out arm assemblies on the fly.

This is less inspired by the Cantus than the Souther or even the Ladegaard.

This is less inspired by the Cantus than the Souther or even the Ladegaard.

Cancelled the second one, mass is getting too high!. I've gone back to building a second copy of the first arm 🙂. This will be for a turntable project build!. Thank you for all the interest in this project and I'd urge anyone to give it a go 🙂, its worth it and easy to build.

Colin

Colin: way back somewhere in the Opus3 thread one of the members was playing with dual glass tubes in which he ran two horizontally mounted bearings on a simple carriage and then he experimented with a vee grove made up from glass window stock. Half the bearing weight/cost. Just a suggestion. Best regards Moray James.

Hi Moray,

That's part of the fun of this , builders are free to experiment with whatever setup they desire, the v groove is another good idea but I've found the 4 bearing works very well without much added cost. Just a different way of getting to point b.

Colin

That's part of the fun of this , builders are free to experiment with whatever setup they desire, the v groove is another good idea but I've found the 4 bearing works very well without much added cost. Just a different way of getting to point b.

Colin

Hi Moray,

I've looked into ceramic bearing assembly's, there may be a small gain in this case, but from what I've been told by some local bearing companies any gain may be small for the expense vs steel bearings, but the way I've used the bearings also keeps friction low since they roll free on a brass shim.

Colin

Hi Colin,

I've been following this discussion with great interest. Very good work on your part. I don't fully understand what you have done with the bearings and the brass shim. I can see that a brass sleeve provides a spacer between the back and front bearings of each pair. But do you have a portion of the spacer reduced in diameter so that the inner race of the bearing is free to rotate on the brass in the manner of a sleeve bearing? For this to provide any reduced friction over the already very low friction of the ball bearings would require precision machining and surface finish such that the sleeve bearing would have to be free enough that it would take over from the ball bearing if that bearing had tight spots in its rotation. Sorry, but I just don't get what you are up to here. Please explain?

Another question please. Do you or any other users of linear tracker arms, especially users of real Cantus 3 arms, experience high sensitivity to defects in record surface with clicks and pops? I have some records that have spots where the arm just sits there repeating that groove endlessly. Sometimes it will jump out and continue playing the record. With some of my older disks (favorites) this can be real annoying having to jump up and move the needle to the next groove. The most annoying part of this situation is that the Schroeder clone ignores these defects completely. At worst I hear a soft click as the needle goes through the defect. I would like to hear of any other folks experiencing this and what if anything you have done to eliminate it.

Thanks,

BillG

Bill I have both a Cantus arm and a Continuo table. Due to health issues they have been packed away for more than a year now. I did not get enough use on them prior to that to be able to provide you with any useful information expect to say I did not notice the problem that you have. I can say that the arm is sensitive to set up but is stable once adjusted. Sorry that I cannot be of more assistance. Best regards Moray James.

I look forward to reading that.Some really interesting reading what with this thread and the Opus Cantus one.Making one of these will certainly make a change from amps.

Bgruhn,

The bearing arrangement is only kept apart by the round of the tube. The shim/sleeve is just slightly smaller than the 5mm bearing center and is made from brass tubing from a hobby shop and also acts as a spacer. I have used a to220 nylon insulating washer to center this sleeve and space the bearing from the polycarbonate piece. It all works together in this arrangement and helps reduce friction, it's also not machined as my goal was to see if I could do this from basic materials 🙂.

Colin

The bearing arrangement is only kept apart by the round of the tube. The shim/sleeve is just slightly smaller than the 5mm bearing center and is made from brass tubing from a hobby shop and also acts as a spacer. I have used a to220 nylon insulating washer to center this sleeve and space the bearing from the polycarbonate piece. It all works together in this arrangement and helps reduce friction, it's also not machined as my goal was to see if I could do this from basic materials 🙂.

Colin

Also I realized, to further answer your question about skips. It tracks flawlessly unless something is embedded in the groove which shouldn't be an issue for clean vinyl, even well worn vinyl will track well as long as nothing is jammed in the grooves 🙂. I can play a record and shake the turntable while its playing and it won't skip, try that with a pivoted arm!!.

Colin

Colin

Also I realized, to further answer your question about skips. It tracks flawlessly unless something is embedded in the groove which shouldn't be an issue for clean vinyl, even well worn vinyl will track well as long as nothing is jammed in the grooves 🙂. I can play a record and shake the turntable while its playing and it won't skip, try that with a pivoted arm!!.

Colin

Hi,

Thanks for the additional information. I can echo this post in spades and I love the transparency of the music but still rich and full, not thin. It is just more realistic.

Maybe I'm looking at this from the wrong angle. Perhaps I should be asking "what's wrong with my pivoted arm that it is not responding to groove damage by skipping?". I've had the suspicion that whatever skating force exists with the pivoted arm is actually pulling the stylus through the flaw. With my magnetic anti-skate setup it is easy to change

the bias direction. If I can duplicate the problem it will be a pretty good indication of what is going on.

BillG

Bgruhn,

I've never heard such transparency with vinyl as I have with this arm, all with a 100 dollar mm too !. I'm thinking it must be mass related, a pivoted arms mass is much higher and will trudge through anything but sensitive to any tt movement. Might be a good thing that a something wedged in the groove Will make it jump to the next groove?, which a quick brush before playing a record should resolve 🙂.

Colin

I've never heard such transparency with vinyl as I have with this arm, all with a 100 dollar mm too !. I'm thinking it must be mass related, a pivoted arms mass is much higher and will trudge through anything but sensitive to any tt movement. Might be a good thing that a something wedged in the groove Will make it jump to the next groove?, which a quick brush before playing a record should resolve 🙂.

Colin

Colin,Bgruhn,

I've never heard such transparency with vinyl as I have with this arm, all with a 100 dollar mm too !. I'm thinking it must be mass related, a pivoted arms mass is much higher and will trudge through anything but sensitive to any tt movement. Might be a good thing that a something wedged in the groove Will make it jump to the next groove?, which a quick brush before playing a record should resolve 🙂.

Colin

Minor correction please. The problem is that the LT arm doesn't jump to the next groove. It sits there playing the same groove over and over.

The pivoted arm plays right through the whatever, junk in the groove, damaged groove etc..

I hung a couple pieces of solder, about 6 grams total, right below the bearings. This cleaned up virtually all the minor clicks and pops. The major ones that cause repeating the groove are still causing trouble. I haven't heard any degradation of the sound though. Mind you, I re-balance the arm for the same stylus pressure for each modification.

rgds,

BillG

could this be a case of compensating for the compliance of the cartridge? Best regards Moray James.

Bill,

That must be why my arm is pretty quiet, the last counterweight lowers the center of gravity below the bearings to the center of the arm tube. Previously this was balanced with nuts. The new cw is thick polycarbonate.

Colin

That must be why my arm is pretty quiet, the last counterweight lowers the center of gravity below the bearings to the center of the arm tube. Previously this was balanced with nuts. The new cw is thick polycarbonate.

Colin

I know that with TT platters you want the centre of gravity to be just below the pivot point by about a mm. Best regards Moray James.

Pictures of the earliest version of the Cantus tonearm. Notice the bearings are flanged, therefore only TWO contact points so the arm pivots up and down like conventional pivot arms.

Instructions:

Instructions:

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm