Bonding Balsa and Carbon Fiber

Hi Niffy,

What adhesive to you use to bond your Carbon Fiber sheet to the balsa wood core? Epoxy?

Regards,

Hugh

Hi Carlo,

I've never seen end grain balsa sold in 3mm thickness. If I recall correctly I've only ever seen it in about 20mm thickness and then it was only sold as a full sheet, 2.4x1.2m.

Making your own is easy enough. You do what to start with wood with a reasonable cross section. Stick bits together with wood glue then cut with a saw to almost the right thickness then sand to the final dimension.

Niffy

Hi Niffy,

What adhesive to you use to bond your Carbon Fiber sheet to the balsa wood core? Epoxy?

Regards,

Hugh

Hi again warrjon,

I just received some 5mm Carbide rods from a US ebay seller called Castlebar. They seem pretty good when I roll them on a table. But now I'm wondering how you were able to check yours to be straight within 0.02mm. Did you use your Lathe for this? (I'm envious again).

Hugh

I have a 24'" granite surface plate. Place rods on Vee blocks and run a test indicator over them. Rotate the rod and check again, I used the Vee block clamps on top of the rod to hold it.

Also just rolling the rods on the surface plate you can hear the uneven roll if they are bent, even a small amount. The worst ones rocked back and forth.

Do it multiple times to ensure repeatability.

Hi all, since in winter it is too damp-cold to play with my hated 9"x20" in the garage, I tried to think how I would make a carriage without a lathe.

It's amazing how many things (except our V jewels) can be got from baymazon, of course spending much more on shipping than for buying a lathe.

The idea is to assemble, with just hand tools on the famous kitchen table, a very light, chattering free carriage (all weight is in the CW).

Will it work? just hoping there is some useful idea for someone (flexure? head shell?) .

carlo

sorry - the CW can be put asimmetrically, lowered with respect to the drawing

It's amazing how many things (except our V jewels) can be got from baymazon, of course spending much more on shipping than for buying a lathe.

The idea is to assemble, with just hand tools on the famous kitchen table, a very light, chattering free carriage (all weight is in the CW).

Will it work? just hoping there is some useful idea for someone (flexure? head shell?) .

carlo

sorry - the CW can be put asimmetrically, lowered with respect to the drawing

Attachments

Last edited:

No those wooden boards are temporary I have 12mm aluminium spacers made. I made the uprights for a different configuration of the rail, but this worked better so I raised the bases.

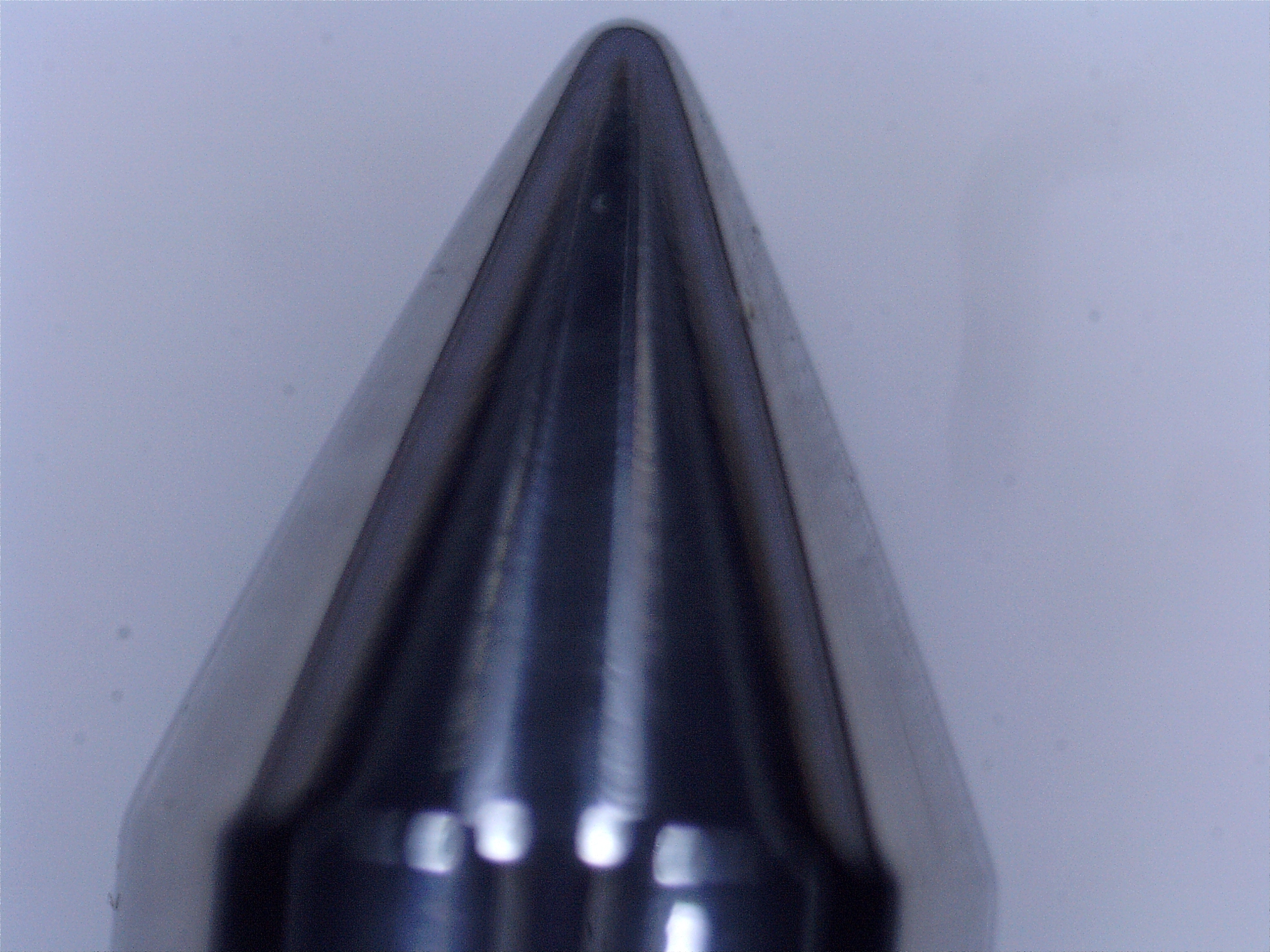

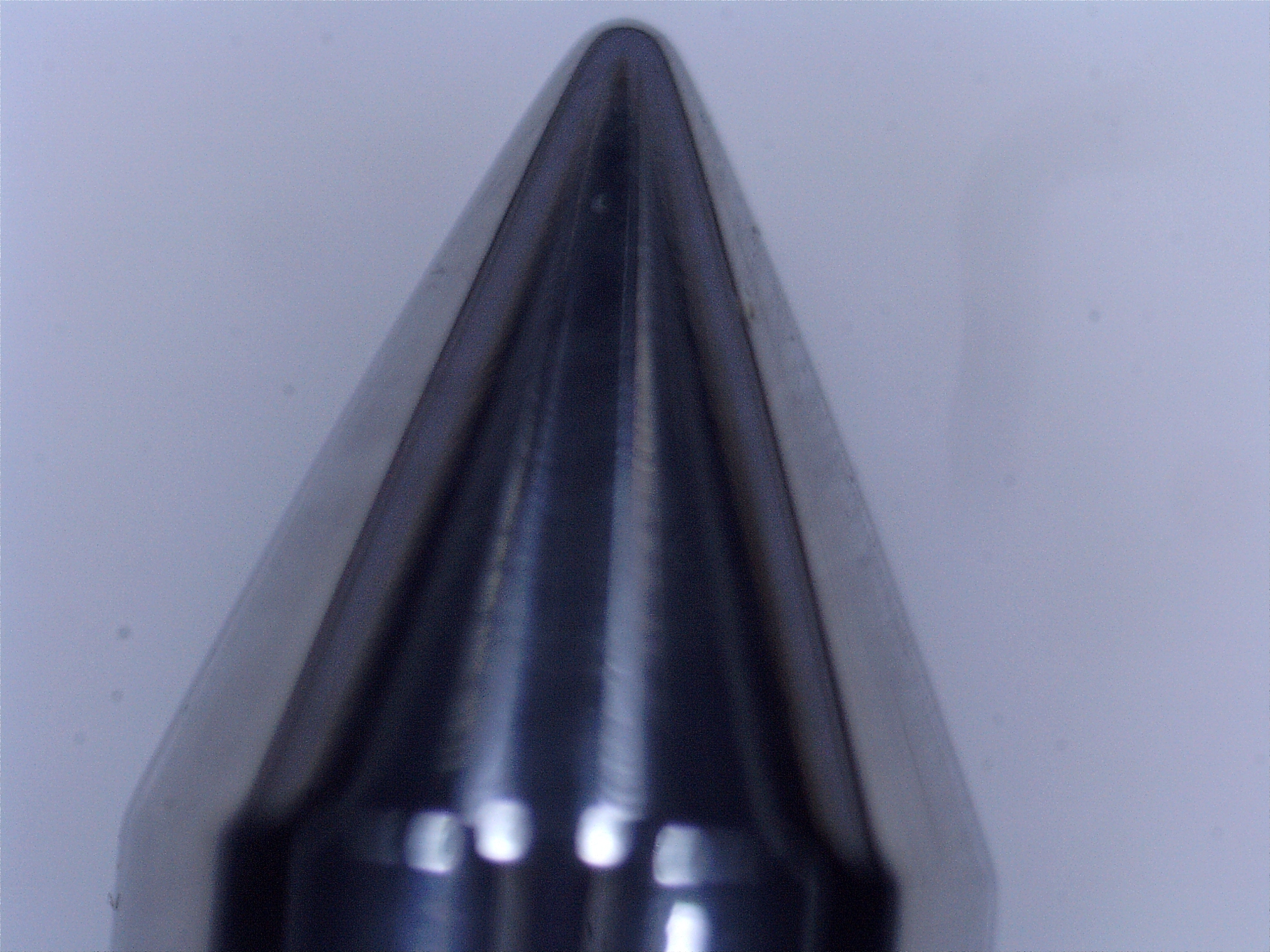

So finally I recived some stuff I ordered. This is a 2,5mm tungsten rod shaped into a 25mm long double sided pivot with a 0,16mm point radius. I have made two of them so the project is slowly going forward 🙂

http://www.dahlbergaudiodesign.se/images/linear_27.jpg

http://www.dahlbergaudiodesign.se/images/linear_27.jpg

Last edited:

I finally have it finished.......... Good new and Bad news

Good news it sounds great, micro detail has improved significantly.

Bad news is it miss tracks dreadfully I suspect the carriage is too heavy (50g including cartridge) for the ultra high compliance Stanton to pull.

The video is with the rail level. You can see the stylus is significantly pulled to the left. I tried tilting the rail slightly but then the carriage will not traverse backwards. Nothing I did would result in playing a full record side with at least 2-3 miss tracks.

YouTube

Next job to make a lighter carriage and re-test.

Good news it sounds great, micro detail has improved significantly.

Bad news is it miss tracks dreadfully I suspect the carriage is too heavy (50g including cartridge) for the ultra high compliance Stanton to pull.

The video is with the rail level. You can see the stylus is significantly pulled to the left. I tried tilting the rail slightly but then the carriage will not traverse backwards. Nothing I did would result in playing a full record side with at least 2-3 miss tracks.

YouTube

Next job to make a lighter carriage and re-test.

Attachments

Hi Warrjon,

My cartridge is also high compliance at 22um/mN though not as high as yours at 30um/mN. My carriage, including cartridge, wheels and counterweight, weights 55g. Even on my torture test record with the huge eccentricity the cantilever defection is barely noticeable. When I was using ballrace bearings with this carriage and cartridge I never suffered skipping (except for when there was an obstruction in the groove). The ball race bearings had about 4 times the friction of the current bearings.

I think the problem is more likely to be something with the setup of the bearings. I did build a lightweight carriage as an experiment but it didn't sound anywhere near as good as the heavier version.

Good luck finding the problem.

Niffy

My cartridge is also high compliance at 22um/mN though not as high as yours at 30um/mN. My carriage, including cartridge, wheels and counterweight, weights 55g. Even on my torture test record with the huge eccentricity the cantilever defection is barely noticeable. When I was using ballrace bearings with this carriage and cartridge I never suffered skipping (except for when there was an obstruction in the groove). The ball race bearings had about 4 times the friction of the current bearings.

I think the problem is more likely to be something with the setup of the bearings. I did build a lightweight carriage as an experiment but it didn't sound anywhere near as good as the heavier version.

Good luck finding the problem.

Niffy

Hi Niffy,

I thought about the bearings, the pin bearings spin far longer and smoother than the ABEC9's on the old arm. I was going to pull ABEC9's off my other carriage and install them on this just to test. I have to work for the next 3 days which will give some thinking time before I get back to it on Saturday.

I thought about the bearings, the pin bearings spin far longer and smoother than the ABEC9's on the old arm. I was going to pull ABEC9's off my other carriage and install them on this just to test. I have to work for the next 3 days which will give some thinking time before I get back to it on Saturday.

Very strange, Warren - but are the cables ok? they act in the shadows, like butlers in detective stories

Mistracking - Seems a matter more complicated than what the common sense suggests. On the Lil Casey of his friends Walter had noticed that low compliance cartridges were more prone to skipping, and I had verified it even on mine; so we had ventured some hypotheses - see #3026 - 27 - 28.

Quote what Niffy says, at most it should happen on excessive eccentricities. Have you measured the friction-stiction? even the cat whisker method gives some useful indications

Carlo

however, it is beautiful - congratulations

Mistracking - Seems a matter more complicated than what the common sense suggests. On the Lil Casey of his friends Walter had noticed that low compliance cartridges were more prone to skipping, and I had verified it even on mine; so we had ventured some hypotheses - see #3026 - 27 - 28.

Quote what Niffy says, at most it should happen on excessive eccentricities. Have you measured the friction-stiction? even the cat whisker method gives some useful indications

Carlo

however, it is beautiful - congratulations

If you look at the video carefully, the brush bristles are moving in step with the stylus deflection. It would appear that the brush is trying to help the stylus move the carriage. Disengaging it would seem to only make the problem worse.

Ray K

Ray K

Although the bristles seem moving with the cantilever, the brush in fact adds damping to the arm. It is not desirable for a mechanical linear arm. External damping may cause deflection of the cantilever, especially for a high compliance cartridge.

It makes all the difference where the damping is applied. If applied at the carriage of a mechanical linear arm, or the pivot of a conventional arm, then the damping can add some cantilever deflection. If applied in the form of a brush, as described in Shure’s patent, it couples the cartridge to the record surface. This shunts warp induced forces around the cantilever suspension and mitigates cantilever deflection, not cause it or make it worse. In any case, we’re dealing with horizontal issues here, and the bristles track the groove and help the stylus pull the carriage, not cause cantilever deflection.

Ray K

Ray K

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm