Hi Carlo,

I like the idea of the spring I will give the one with the push screw a try. It will be easy to implement. I tend to over engineer things and make them complex. I like your simplicity. I have some 30mm OD Delrin I can make the base bushes from. Although the bearings I bought have no movement as they are industrial not average eBay units.

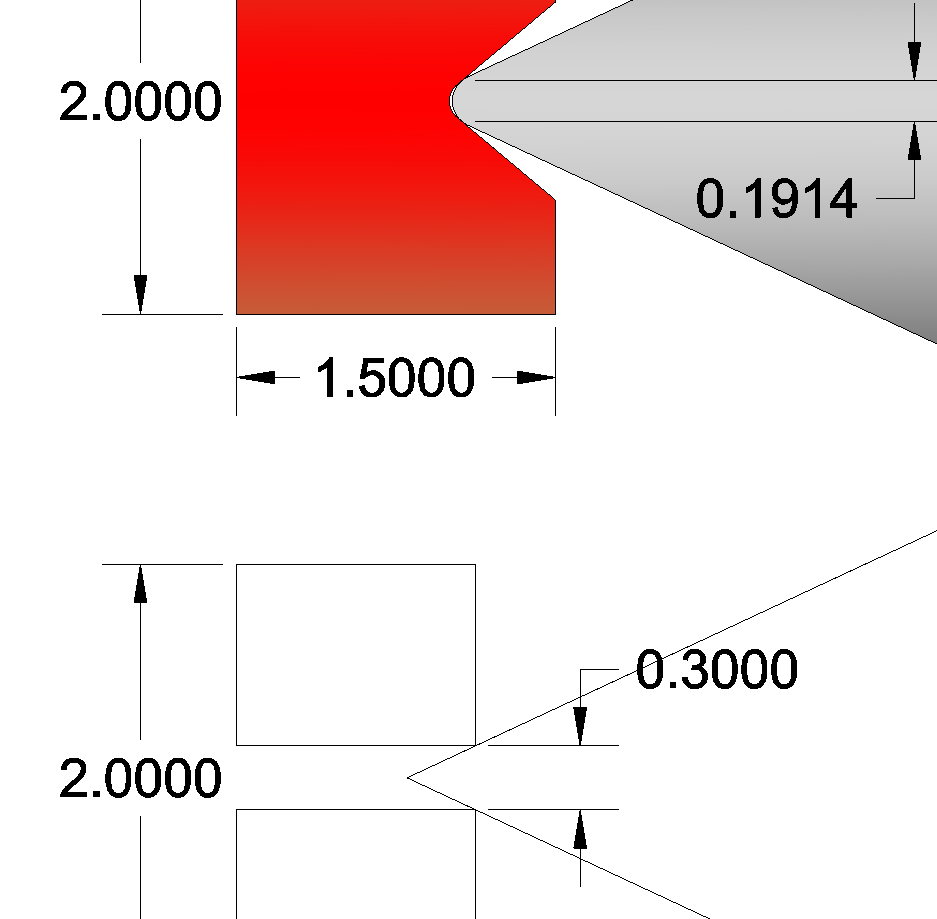

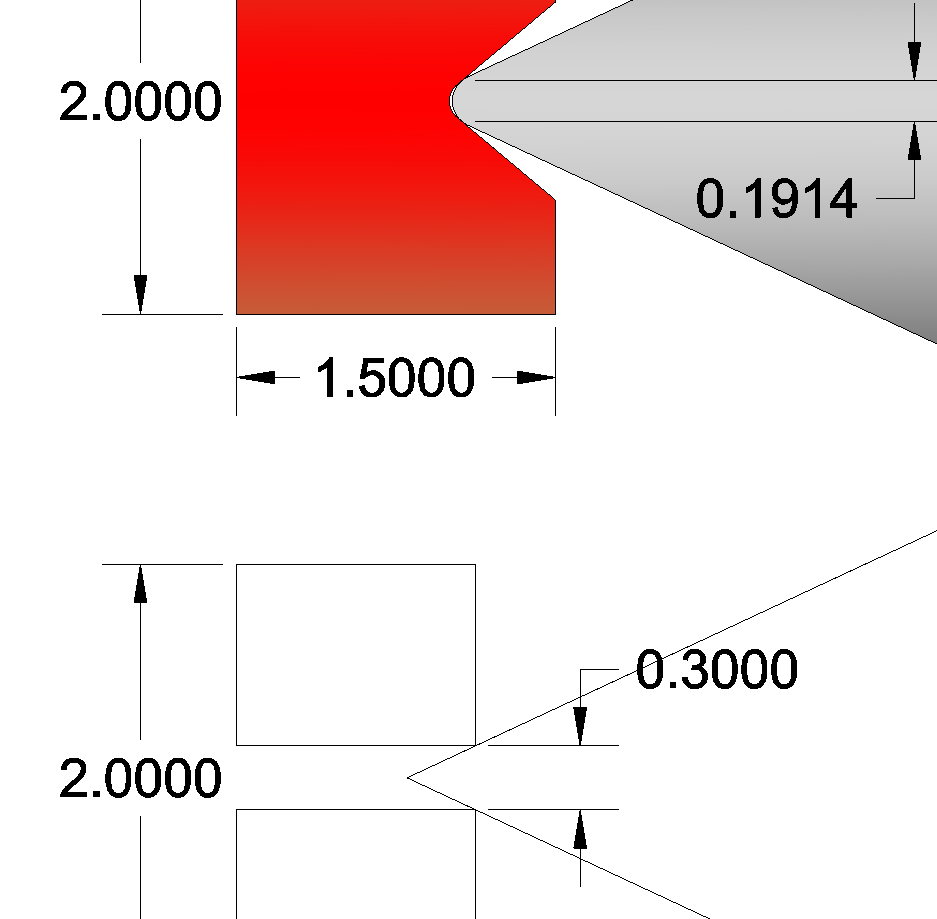

Here are the pillars with VTA blocks. I'll cut the VTA blocks shallower and implement Carlo's idea of the spring.

I like the idea of the spring I will give the one with the push screw a try. It will be easy to implement. I tend to over engineer things and make them complex. I like your simplicity. I have some 30mm OD Delrin I can make the base bushes from. Although the bearings I bought have no movement as they are industrial not average eBay units.

Here are the pillars with VTA blocks. I'll cut the VTA blocks shallower and implement Carlo's idea of the spring.

Attachments

the pulling screw + spring doesn't ask any change of the block. If I were you i'll try this first.

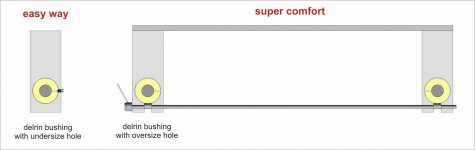

turn the delrin bar with an inner hole 2-3 tenths smaller, and cut them longitudinally for fine adjustment.

Indeed - it could be done a lever to position the arm with an eccentric that tightens both the delrin bearings, blocking everything - no play, but easy sliding once rotated back

carlo

beautifull milling - all my envy -(a no milling machine owner)

turn the delrin bar with an inner hole 2-3 tenths smaller, and cut them longitudinally for fine adjustment.

Indeed - it could be done a lever to position the arm with an eccentric that tightens both the delrin bearings, blocking everything - no play, but easy sliding once rotated back

carlo

beautifull milling - all my envy -(a no milling machine owner)

Last edited:

Hi Warrjon,

Very nice work. +1 on the machine shop envy.

Many tonearms have a large adjustment range to facilitate easy mounting on a wide range of decks. As you are building specifically for the SP10 you only really need a small range of adjustment. I have an adjustment range of about 6mm of which I use about 1. I think your pillars have plenty of range to be able to fit the spring. Possibly cast the spring in some low modulus silicone to damp it and prevent it from ringing.

Niffy

Very nice work. +1 on the machine shop envy.

Many tonearms have a large adjustment range to facilitate easy mounting on a wide range of decks. As you are building specifically for the SP10 you only really need a small range of adjustment. I have an adjustment range of about 6mm of which I use about 1. I think your pillars have plenty of range to be able to fit the spring. Possibly cast the spring in some low modulus silicone to damp it and prevent it from ringing.

Niffy

delrin: something like that-

spring + silicon - hi Niffy, long practice has landed both on the same beaches ..

c

spring + silicon - hi Niffy, long practice has landed both on the same beaches ..

c

Attachments

Last edited:

I originally made the VTA blocks big enough to hold a 8mm linear bearing but changed to the brass bush so I could lock the block in place, I have about 10mm of vertical adjustment.

I'm going to leave the bearing part of the block at 25mm deep to keep a longer bearing surface, I made the bushes a loose fit (0.04mm) so they don't bind with temperature changes and only machine the front to accept a spring. Good idea I will cast the spring in silicone.

The one with the undersized hole will become loose on the shaft when the collar is locked. The oversized hole might work,,,, as the cam will push the bush up and lock it to the shaft and pillar. I would need a separate locking cam for each pillar, Ill give it some thought and see what I can come up with.

I have sent a message to the company in the USA to see if they will ship jewel VEE's and pivots to Australia. If so I'll buy them.

Just want to say thanks for the input on the arm............

I'm going to leave the bearing part of the block at 25mm deep to keep a longer bearing surface, I made the bushes a loose fit (0.04mm) so they don't bind with temperature changes and only machine the front to accept a spring. Good idea I will cast the spring in silicone.

The one with the undersized hole will become loose on the shaft when the collar is locked. The oversized hole might work,,,, as the cam will push the bush up and lock it to the shaft and pillar. I would need a separate locking cam for each pillar, Ill give it some thought and see what I can come up with.

I have sent a message to the company in the USA to see if they will ship jewel VEE's and pivots to Australia. If so I'll buy them.

Just want to say thanks for the input on the arm............

undersized: the screw is just to adjust the delrin bushing with almost no play, the rest is up to your magnet

oversized: if you need two cams the solution becomes too uncomfortable: that mechanism should be moved instead by the arm lift itself.

Otherwise you could have an eccentric to disengage your magnets, like that on a dial gauge base...

sorry - just a blah blah without knowing well your design.

carlo

silicone: an heath shrink tube works too

oversized: if you need two cams the solution becomes too uncomfortable: that mechanism should be moved instead by the arm lift itself.

Otherwise you could have an eccentric to disengage your magnets, like that on a dial gauge base...

sorry - just a blah blah without knowing well your design.

carlo

silicone: an heath shrink tube works too

Last edited:

Hi Carlo,

I had a good look and think today about the delrin bush and could not work an easy way for it to operate, there is not enough meat under the bush to install the cam. So I decided to keep the linear bearings for the moment.

I have another challenge. The top bar needs to be extended 10mm as there is not enough room for the larger carriage, so I need to make a new top.

I had a good look and think today about the delrin bush and could not work an easy way for it to operate, there is not enough meat under the bush to install the cam. So I decided to keep the linear bearings for the moment.

I have another challenge. The top bar needs to be extended 10mm as there is not enough room for the larger carriage, so I need to make a new top.

I sent them an email to ask if they would ship to Australia but have not heard back yet........

I got an answer and it seems that they will ship to Sweden 🙂

65$ for express shipping.

I'm waiting for an invoice and payment arrangement. 😎

65$ for express shipping.

I'm waiting for an invoice and payment arrangement. 😎

Hi dahlberg,

Which components were you buying? Pivots and vees, and what tip/cup radius ? If you are buying pivots, what material are they made of? And finally do you have a price?

Niffy

Which components were you buying? Pivots and vees, and what tip/cup radius ? If you are buying pivots, what material are they made of? And finally do you have a price?

Niffy

Hi dahlberg,

Which components were you buying? Pivots and vees, and what tip/cup radius ? If you are buying pivots, what material are they made of? And finally do you have a price?

Niffy

I was ment to buy

8pc: VS-25 50$

8pc: ST-13S 30$

but since there was both 65$ shipping and a 25$ "bank transfer fee", and on top of that there will be 25 %VAT so I decided to drop it.

The payment method also seemed far from secure soo....Got a .pdf asking for the full card information, to be returned by mail.

I will make my own pivots from tungsten carbine 3mm drill shafts using my lathe and the dremel fixed to the tool holder with a diamond cutter/grinding tool.

I have also ordered this assortment 100x Top Cap Jewels For Watch Repair Tool Kit Watchmakers Parts Watches Random | eBay , to find 4 usefull ones in this lot seems possible and cost is almost none.

I should be possible to figure it out somehow, to be continued 😎

Drills, 1mm Tungsten Carbide CNC Engraving Print Circuit Board PCB Drill Bits 5 Pcs | eBay

Last edited:

Closeup of a broken drill. The shaft is some really hard material but it almost looks as if the actual drill is an insert.

I was ment to buy

8pc: VS-25 50$

8pc: ST-13S 30$

but since there was both 65$ shipping and a 25$ "bank transfer fee", and on top of that there will be 25 %VAT so I decided to drop it.

The payment method also seemed far from secure soo....Got a .pdf asking for the full card information, to be returned by mail.

I have also ordered this assortment 100x Top Cap Jewels For Watch Repair Tool Kit Watchmakers Parts Watches Random | eBay , to find 4 usefull ones in this lot seems possible and cost is almost none.

I should be possible to figure it out somehow, to be continued 😎

Drills, 1mm Tungsten Carbide CNC Engraving Print Circuit Board PCB Drill Bits 5 Pcs | eBay

Interesting I was going to make my own from brass for VEEs and HSS for the pivot If swissjewel is that hard to deal with I might go back to this method.

I think it's unlikely you will find VEE jewels in the watch repair kit. Watch movements use O'ring jewels with either flat or coned endcaps. VEE jewels are used in high quality instrument movements.

Hi, dahlberg

It may take some time and effort but look on Ebay under "watch jewel parts" in your part of the world or Ebay U.S.A.. You may be able to seat some of the jewels on some small brass set sctews. All depends on your skill and tools you have available.

https://www.ebay.com/sch/i.html?_nkw=watch+jewels+parts&_sop=12&_pgn=2

Good luck,

Joe

It may take some time and effort but look on Ebay under "watch jewel parts" in your part of the world or Ebay U.S.A.. You may be able to seat some of the jewels on some small brass set sctews. All depends on your skill and tools you have available.

https://www.ebay.com/sch/i.html?_nkw=watch+jewels+parts&_sop=12&_pgn=2

Good luck,

Joe

Watches do not use VEE jewels, they use cylindrical jewels with end caps.

VEE jewels are used in high quality mechanical meter movements.

.

VEE jewels are used in high quality mechanical meter movements.

.

Given the difficulty of obtaining the Vee jewels, what if we make them from aluminum? a thick, hard anodization (AL2O3) has Mohs 9, like sapphire: in fact it is sapphire.

Running just one turn or two every LP maybe the wear is non significant, and we can turn many spares easily. Such small parts can be anodized simply with a car battery.

From scrap, this is diying.

carlo

these are near me - but maybe don't sell to single costumers, as usual

Jewel bearings

Britaltec,products in sapphire,ruby,agate,ceramic,hard metal,diamond abrasives

Running just one turn or two every LP maybe the wear is non significant, and we can turn many spares easily. Such small parts can be anodized simply with a car battery.

From scrap, this is diying.

carlo

these are near me - but maybe don't sell to single costumers, as usual

Jewel bearings

Britaltec,products in sapphire,ruby,agate,ceramic,hard metal,diamond abrasives

How about replacing the wee bearing assembly with a teflon rod ? 😱

On the other hand true point has wee jewels.

From true point

To DIY the true point alternative (the colourful one) is quite a handful but the bottom one isn't that hard to manage.

On the other hand true point has wee jewels.

From true point

Notes: When used horizontally, the pivots should not bottom against the radius of the jewel. A degree of looseness is required which is called 'end shake'.

To DIY the true point alternative (the colourful one) is quite a handful but the bottom one isn't that hard to manage.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm