The power switch of the ACA mini really has to be the SPDT type. The connection to ground is needed to shut down the bias of the input stage. And that shuts down the bias of the output stage. The alternative: go the classic way and switch of the power supply on the mains side.

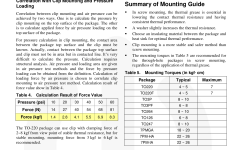

Why not just use Kep Nuts?...I always worry slightly, slightly that the high heat cyklings of the class A amps will loosen the screws and/or the pressure on the active devices...

Regular Nuts/bolts and split locking washers? Yea, of course, it works. Thats what i am using now and it works perfectly fine so far. 🙂

But it is not uncommon in a myriad of technical applications that those tings over time somtimes with heat/cold cykles works them self loose.

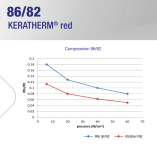

My thinking is that the spring steel fasteners better will flex and maintain pressure over time, far beyond my lifetime, spread the pressure better and will not overpressure the Keraterm.

Well, thats my theory anyway. 🙂🤚

But it is not uncommon in a myriad of technical applications that those tings over time somtimes with heat/cold cykles works them self loose.

My thinking is that the spring steel fasteners better will flex and maintain pressure over time, far beyond my lifetime, spread the pressure better and will not overpressure the Keraterm.

Well, thats my theory anyway. 🙂🤚

you'll find exactly those in all FW amps

split washers - I personally have no doubt in their longevity, under condition that they're of proper quality

I wrote several times - in my neck of wood, best way of obtaining controlled/trusted quality of M3 hardware is - using SS ones

everything above M3 I can buy "in quality" (local term of trade, meaning proper goods so you can trust marking), but M3, common things, that's made of ....... cheese

so, for me, buying locally SS is much simpler than buying non-SS-proper abroad

split washers - I personally have no doubt in their longevity, under condition that they're of proper quality

I wrote several times - in my neck of wood, best way of obtaining controlled/trusted quality of M3 hardware is - using SS ones

everything above M3 I can buy "in quality" (local term of trade, meaning proper goods so you can trust marking), but M3, common things, that's made of ....... cheese

so, for me, buying locally SS is much simpler than buying non-SS-proper abroad

Last edited:

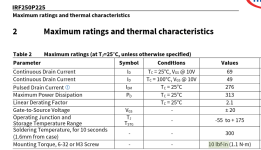

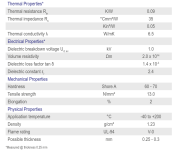

Post 2331 is an important one, particularly the excellent info/datasheet from Fairchild that MJ graciously shared. Page 8 has some recommendations, not specifically stating for Keratherm but they are at least a start.will have the right pressure for Keratherm ?

datasheet don't help

For me at least, I have used mounting clips before with great success. And particularly for Class A builds, I really like the idea.

In example with an older LM4780 (Class AB of course!):

ps

Attachments

I recently got the ACA Mini Essentials Kit. I didn’t order the Completion Kit as I already had a power supply on hand. My neighbor is currently building a Decware SE84 Z-kit SET amplifier and we plan to stage a shoot-out comparison of these two low-power amps in a few weeks.

The build process was effortless (thanks for the terrific instructions!). I regret not getting the completion kit as the Bill of Materials (wrong number of capacitors for C5, no mention of the necessity for jumpers, and potentially incorrect values from P1, P2 pots) led to some frustration. One surprise when the Essentials Kit arrived was the sticker calling for 1.5-2k mini pots for P1, P2, not the 1k pots specified in the BOM. I decided to proceed with the parts on hand. I used bent bits of snipped-off resistor leads as jumpers, an improvised fix but they seem to work fine.

The result is a lovely sounding amplifier, one I could listen to all day long. My one remaining issue is biasing the output transistors. The left channel Vb/Vo after a few days of warm up and tweaking is now perfect, but I could never get the right channel Vb to go above 272 mV even with a Vo of 11.8v. There’s plenty of travel left in both left channel pots but the right channel ones are pretty much maxed out.

I am wondering if replacing the pots will address this or whether some other fix is needed. I’m semi-inclined to leave well enough alone as the two channels sound identical playing back mono material to my admittedly subjective ears but I’m also a bit loath to bring my Mini to an amp shootout with one hand (or rather one channel) tied behind its back.

The build process was effortless (thanks for the terrific instructions!). I regret not getting the completion kit as the Bill of Materials (wrong number of capacitors for C5, no mention of the necessity for jumpers, and potentially incorrect values from P1, P2 pots) led to some frustration. One surprise when the Essentials Kit arrived was the sticker calling for 1.5-2k mini pots for P1, P2, not the 1k pots specified in the BOM. I decided to proceed with the parts on hand. I used bent bits of snipped-off resistor leads as jumpers, an improvised fix but they seem to work fine.

The result is a lovely sounding amplifier, one I could listen to all day long. My one remaining issue is biasing the output transistors. The left channel Vb/Vo after a few days of warm up and tweaking is now perfect, but I could never get the right channel Vb to go above 272 mV even with a Vo of 11.8v. There’s plenty of travel left in both left channel pots but the right channel ones are pretty much maxed out.

I am wondering if replacing the pots will address this or whether some other fix is needed. I’m semi-inclined to leave well enough alone as the two channels sound identical playing back mono material to my admittedly subjective ears but I’m also a bit loath to bring my Mini to an amp shootout with one hand (or rather one channel) tied behind its back.

I finally finished dressing out the ACA Mini I built a couple of months ago. It's simple, but it does the job. I was going to enclose it with acrylic panels and a fan, but I decided to go commando to save a little time . And yes, I realize I have the inputs backwards. 🙂

Holy crap that looks beautiful. You should push the DIY Audio store to include the side panels and the roof in a kit (if you are interested in providing them to Store, of course).... at least as an option.

Thank you for the kind words. I think I'll have to wait until they invent a 3D wood printer to offer that service. 🤓

Black Walnut. Amazon has quite a selection of hard-to-find wood in small sizes. My son build an enclosure for his B1 Korg out of Padauk he got from there. I had never heard of it before. It's bright orange and very dense. The sawdust looks like the powder at the bottom of a bag of Cheetos.

I’ve just finished soldering the ACA mini and have double checked all cap polarities, resistor values, solder joints and the correct position of all transistors. With the pots turned fully clockwise I am getting a reading or 23.85 volts at VB.

I am getting the same values regardless of the position of the pots. I am not sure what to look for? Can anyone help me out?

I am getting the same values regardless of the position of the pots. I am not sure what to look for? Can anyone help me out?

Attachments

- Home

- Amplifiers

- Pass Labs

- DIY ACA mini