Here is planar magnetic B&G Neo8-PDR nude without eq, 4ms 1/12 smoothing, in test baffle. I didn't find backside measuements, but it is just the same, but in my AINOGradients Neo8 and Neo3 are set on plywood frame, which makes diffractions around 6-8kHz to frontal sphere because drivers are attached on the backside of the frame.

Attachments

Last edited:

Thanks Mattes, very informative. How are the plans progressing for product release?

Hi James,

The flowers were never intended as a commercial product and would, if so, have been a total failure... there´s too much work, even too much material cost (and too much ugly black dust in my workshop... what a mess...), and the free-swinging installation would further minimize commercial success...

So, for now you´re on your own if you want flowers, sorry. Of course I could help with details, but I will not do this mess again... but still after some time, if I´m trying to imagine what could have been done better, I´m very happy with the flowers. Nude drivers would be an alternative, but you will have a hard time making an 8-inch fullrange go down to app. 300Hz and an 18-inch bass driver go down to 25Hz without DSP, which I don´t like and have passive filters instead.

But well, that´s just me, many other feasable approaches exist.

Best regards

Mattes

It's an interesting challenge to push acoustic solutions to their limits. Do you have measurements of your trapezoidal speaker Mattes? https://www.diyaudio.com/forums/multi-way/361993-baffle-mtm-questions-4.html#post6390392

Last edited:

That's a bit disappointing to hear but I'll do some playing about with the styrene and see if anything eventuates

We have Kyron Audio out here, who are really into the edgeless design. Pretty impressive sound, crazy prices.

We have Kyron Audio out here, who are really into the edgeless design. Pretty impressive sound, crazy prices.

Hi,

the EVA foam of my baffles is not the same as hard rubber, I think that the vibration absorbing properties of the material are better than hard rubber, but have no numbers on hand to proof it.

I´ve chosen the specific density of the EVA foam from several samples (and I have tried other materials before, including polystyrene, didn´t like it at all...), wanting

- some rigidity, to not have the petals flapping back and forth when Daniel Herskedal plays bass tuba

- low weight, in order to minimise all mass not being situated near mass centre, following Michael´s free-swinging approach

- a relatively soft surface after sanding, to minimise reflections from the material

- high inner damping, to suppress vibrations from the drivers as much as possible

As I don´t have equipment to measure surface or material vibration, I made several baffles, listened, and finally made the choice based on acoustic measurements, listening and feeling (the well-sanded EVA feels like a massive block of suede, quite a small tactile sensation...).

What I wanted to achieve was having a relatively small baffle providing a little bit better loading than a nude driver, but avoiding the negative effects of a baffle. A pretty good solution are certainly OllBolls wool/felt baffles, but I wanted something nicer... visually.

Of course an 8-inch fullrange driver in a small baffle will not represent a true dipole, but is maybe "close enough". I tried to "better" the rear radiation with an extra tweeter, but in the end returned to just the fullrange. Sounds better.

All the best

Mattes

Thanks @Mattes for providing that detail. The design intent is often as important as the details. It looks like you have a good solution. I like the odd #petals and the integrated roll back.

Are you able to provide a polar measurement / curves ?

.

Last edited:

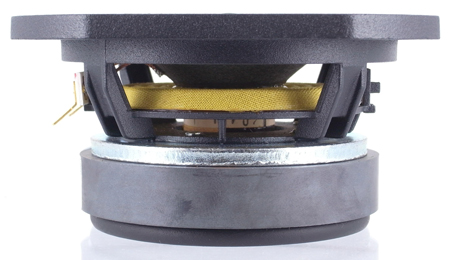

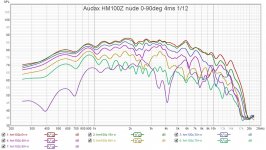

Here you are, measured by me in 2013 - a 4" midrange nude 0-90deg and 90-180deg.

Not so nice above 2kHz!

Audax HM100Z0

Thanks for sharing that data.

How important is the quality of the rear direction radiation. It must be an acceptable trade off in order to remove the box. I don't see many examples of people trying to correct it by making a phase plug over the magnet. The exception may be using planar drivers like you've shown so there is no magnet and more symmetric radiation.

Thanks for sharing that data.

How important is the quality of the rear direction radiation. It must be an acceptable trade off in order to remove the box. I don't see many examples of people trying to correct it by making a phase plug over the magnet. The exception may be using planar drivers like you've shown so there is no magnet and more symmetric radiation.

A very dificult question!

My first version of AINO's had two 3" cones and tweeter with wg. It sounded very nice but measured not-so-nice off-axis. The main problem was lack of treble in the room way off-axis. On-axis sound at spot was also a bit strange, too sharp in treble, because of this.

First I replaced cone-mids with Neo8, then added a rearside tweeter. I also changes xo from LR4 to LR2. Then finally purchased Neo3 tweeters. Every change made the speakers better in measurements and overall sound, but that last change muted treble transients remarkably. Overall sound signature was however better, more balanced throughout the spectrum.

Fortunately this was a diy project and I managed to get the measurements and sound that I like! Most hifi-friends have conventional or horn speakers and they prefer the sharp sound they have at home...

Last edited:

That's a bit disappointing to hear but I'll do some playing about with the styrene and see if anything eventuates

Are you planning to make one of Don's simulations? I think the thing to do would be to scale it up in proportion to your driver.

That's the plan for now Scott, 180mm centre hole for the driver, and outer diameter 540mm - not sure yet about driver mounting panel, surface treatment/finish, etc. Early days ...

Now playing with the curved baffle version (kerfed/grooved plywood) - simplified version of your 'kerdi-board V - the grooves at rear so curved in a parabola shape (to the back) and maybe also try grooves in the front surface to see if any reduction of baffle surface problems. Not as easy as I thought!

Now playing with the curved baffle version (kerfed/grooved plywood) - simplified version of your 'kerdi-board V - the grooves at rear so curved in a parabola shape (to the back) and maybe also try grooves in the front surface to see if any reduction of baffle surface problems. Not as easy as I thought!

Hi,

I´m waiting for a new microphone, then I´ll show some new and actual measurements. Spoiler: the trapezoidal baffle measurements are not any better than the flowers... but of course drivers are different.

All the best

Mattes

I´m waiting for a new microphone, then I´ll show some new and actual measurements. Spoiler: the trapezoidal baffle measurements are not any better than the flowers... but of course drivers are different.

All the best

Mattes

The trapezoid is elegant, something similar with a large round-over on the wings could work very well. Perhaps even a shallow waveguide too, all wrapped in a wool felt blanket. 🙂

Hi,

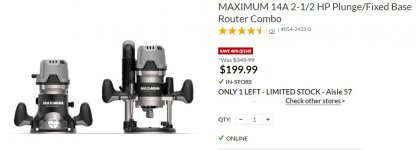

Sure, the largest roundover possible will be the best. The trapezoid baffle was intended to be more simple than the flowers, so the roundover radius is just 25mm, the largest possible (to my knowledge) for hand routers.

All the best

Mattes

Sure, the largest roundover possible will be the best. The trapezoid baffle was intended to be more simple than the flowers, so the roundover radius is just 25mm, the largest possible (to my knowledge) for hand routers.

All the best

Mattes

You can go a little bigger (see pic) R38 is the largest I've seen. Risky, unless you do a few passes to get the full radius.

I'm a fan of trapezoids as well. Simple and they work. These are a few sims:

Modular active 3 way - work in progress

Modular active 3 way - work in progress

.

I'm a fan of trapezoids as well. Simple and they work. These are a few sims:

Modular active 3 way - work in progress

Modular active 3 way - work in progress

.

Attachments

30 degree chamfers work well, it would be interesting to see a comparison between a large roundover and a succession of chamfers. 😉

I've tried with the ripple tank sim but it's too fiddly. One can get an idea by looking at how the wave responds to a discontinuity and infer the diffraction at that point.

I had that idea as well. Build with strips of wood (staves) then smooth down the chamfer edges to mimic a large radius fillet. Too many edges makes diffraction worse.

Last edited:

Hi Don,

Have you ever tried the 38mm bit? I know they are available, but at least in Europe I couldn´t find a suitable routing machine to accomodate bits that large, the 25mm bit was the largest overall diameter to fit into available machines. And a 1kW router with a 25mm radius bit is a serious machine, an even larger one would make me more than careful...

All the best

Mattes

Have you ever tried the 38mm bit? I know they are available, but at least in Europe I couldn´t find a suitable routing machine to accomodate bits that large, the 25mm bit was the largest overall diameter to fit into available machines. And a 1kW router with a 25mm radius bit is a serious machine, an even larger one would make me more than careful...

All the best

Mattes

Not yet, but I'm considering it. Agreed, care is required as it's a bit risky, so it would take several passes and maybe I'd use a router table.

The router I have (pic) has a 1/2inch collet. You have to remove the thin (5mm) plastic bottom layer then the opening is 4inch. If I used my router table

it would require a new insert to clear a 3inch bit, but easily done.

The router I have (pic) has a 1/2inch collet. You have to remove the thin (5mm) plastic bottom layer then the opening is 4inch. If I used my router table

it would require a new insert to clear a 3inch bit, but easily done.

Attachments

- Home

- Loudspeakers

- Full Range

- Did Siegfried Linkwitz miss a trick?