We could talk about feedback stability criterion. I do not expect a DC Servo system to have a gain above one even at DC. Of course DC is only a theoretical construct as I am not immortal!Sure, that's smart, and I assume that's one of the things Marcel implied.

But you need to be carefull with additional low pass filtering of the servo output.

Before you know it you have a 2nd order system and LF oscillations.

You should make sure that the integrator time constant and the additional filter TC are sufficiently apart.

Jan

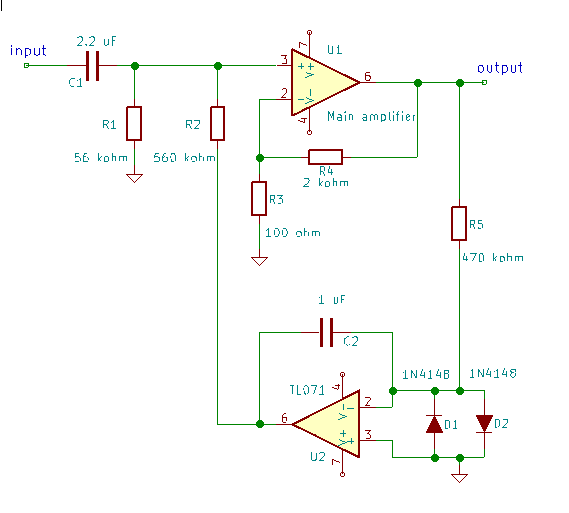

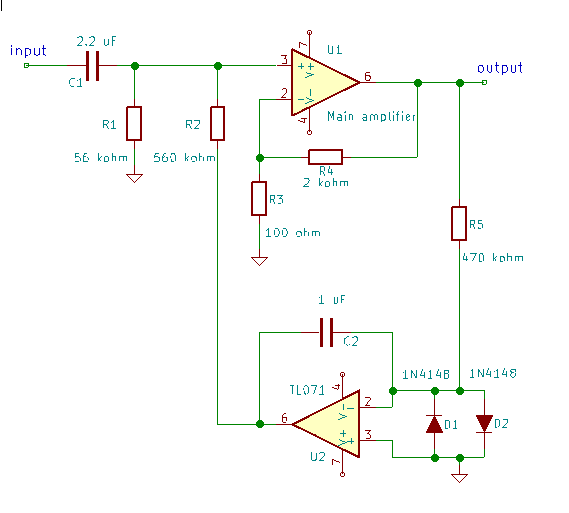

For what it's worth, my favourite type of DC feedback loop is as shown here. Nothing goes wrong if whatever drives the input has a large DC offset, it can handle reasonably large subsonic signals, the distortion of the op-amp (which hardly has to handle any signal current anyway) is filtered by the input capacitor and you can design it to have a second-order Butterworth response that gets more damped if the preamplifier has an output resistance or capacitance.

Main disadvantage: no-one likes it. People who dislike DC blocking capacitors don't like it because of the DC blocking capacitor, and people who don't like DC servos don't like it because of the DC servo. That is, no-one except QUAD likes it, as I later found out that QUAD uses the same principle in some of their amplifiers.

Main disadvantage: no-one likes it. People who dislike DC blocking capacitors don't like it because of the DC blocking capacitor, and people who don't like DC servos don't like it because of the DC servo. That is, no-one except QUAD likes it, as I later found out that QUAD uses the same principle in some of their amplifiers.

Aren't you Ed?? You seem to have been around here forever! ;-)as I am not immortal!

Jan

It’s similar to what I use. Mostly I just use a pot to dial out offsets, but if using a servo take the injection points to a low value R in series with R1. You can further decouple this with a suitable cap as well. Typically I use a 10 to 22 k bias resistor, 100 ohm in the lower leg and my R2 is 22k-47k. For C2 and R5 I use 2.2uF and 1Meg. I’ve never had a problem using a TL071/2 in this position.For what it's worth, my favourite type of DC feedback loop is as shown here. Nothing goes wrong if whatever drives the input has a large DC offset, it can handle reasonably large subsonic signals, the distortion of the op-amp (which hardly has to handle any signal current anyway) is filtered by the input capacitor and you can design it to have a second-order Butterworth response that gets more damped if the preamplifier has an output resistance or capacitance.

Main disadvantage: no-one likes it. People who dislike DC blocking capacitors don't like it because of the DC blocking capacitor, and people who don't like DC servos don't like it because of the DC servo. That is, no-one except QUAD likes it, as I later found out that QUAD uses the same principle in some of their amplifiers.

View attachment 1075671

Maybe many would if someone pointed out that low pass frequency of such inverting servo can easily be 0.002 Hz, with -100 dB impact at 20 Hz (-134 dB at 1 kHz). That’s how was my attempt with OPA1641 and inverting servo. I had to decrease C2 to 150 nF, as servo was too slow for changes at amplifier power up.Main disadvantage: no-one likes it.

Too slow can be quite destructive.

I didn't follow that entirely, but why?

Once had that with a power amplifier at a friends house and it was powered on in class AB when not used. The servo was slow. There was a mains blackout, mains was back again followed by a second short blackout and mains voltage was up again. Apart from the slow servos the amplifier did not have speaker protection.

No one was there to intervene so 2 burned woofers.

Saw it another time with a DC coupled preamp that had a slow servo connected to a DC coupled power amplifier that had no protection whatsoever. Again stuff was powered on 24/7 as that was then in fashion.

80ties/90ties HiFi …… cottage industry small brands. No muting, no protection, often damage when something went wrong.

That is why the habit came to have input caps in the power amplifier, not too slow servos, muting circuits and speaker DC protection. And most important: to not leave stuff powered on unattended.

No one was there to intervene so 2 burned woofers.

Saw it another time with a DC coupled preamp that had a slow servo connected to a DC coupled power amplifier that had no protection whatsoever. Again stuff was powered on 24/7 as that was then in fashion.

80ties/90ties HiFi …… cottage industry small brands. No muting, no protection, often damage when something went wrong.

That is why the habit came to have input caps in the power amplifier, not too slow servos, muting circuits and speaker DC protection. And most important: to not leave stuff powered on unattended.

Last edited:

A mains outage, else there was an odd voltage spike or so on the mains causing something unexpected, isn't any different than a human being powering on and off an appliance, to postulate that having something to do with the DC servo sounds a bit premature conclusion, more like an anecdote where nobody was on site when it burned the two woofers, as in the first case.

Perhaps the DC servo was implemented in wrong way, after all it appears this was an occurrence from long ago.

I wouldn't say a too slow DC servo based on this story to be a potential risk, one have to power on and off the equipment with different intervals to ensure it doesn't misbehave when the voltages builds up through the whole circuitry, nah.. very slow acting DC servos per se aren't culprits until proven so, though I would be curious to know what kind of design mistakes can cause it to misbehave under uncertain conditions, a matter for a new thread perhaps.

Perhaps the DC servo was implemented in wrong way, after all it appears this was an occurrence from long ago.

I wouldn't say a too slow DC servo based on this story to be a potential risk, one have to power on and off the equipment with different intervals to ensure it doesn't misbehave when the voltages builds up through the whole circuitry, nah.. very slow acting DC servos per se aren't culprits until proven so, though I would be curious to know what kind of design mistakes can cause it to misbehave under uncertain conditions, a matter for a new thread perhaps.

:)When the time constant of the DC loop exceeds the time a woofer needs to burn out, the loop doesn't provide any protection against DC applied at the amplifier input. Then again, maybe it doesn't need to if something else does.

If the amplifier's own offset is large enough to cause damage, you need a turn on delay of several times the DC loop time constant. For a first-order loop with 2 mHz cut-off frequency, that's many minutes (>> 80 s).

If the offset is small enough to neither cause damage nor cause substantial extra distortion, you might as well go for 0 Hz, no DC loop at all, instead of 2 mHz.

If the amplifier's own offset is large enough to cause damage, you need a turn on delay of several times the DC loop time constant. For a first-order loop with 2 mHz cut-off frequency, that's many minutes (>> 80 s).

If the offset is small enough to neither cause damage nor cause substantial extra distortion, you might as well go for 0 Hz, no DC loop at all, instead of 2 mHz.

For what it's worth, my favourite type of DC feedback loop is as shown here. Nothing goes wrong if whatever drives the input has a large DC offset, it can handle reasonably large subsonic signals, the distortion of the op-amp (which hardly has to handle any signal current anyway) is filtered by the input capacitor and you can design it to have a second-order Butterworth response that gets more damped if the preamplifier has an output resistance or capacitance.

Main disadvantage: no-one likes it. People who dislike DC blocking capacitors don't like it because of the DC blocking capacitor, and people who don't like DC servos don't like it because of the DC servo. That is, no-one except QUAD likes it, as I later found out that QUAD uses the same principle in some of their amplifiers.

View attachment 1075671

Thanks for that, this looks like a remarkly simple and well-dimensioned 2nd-order servo, doubling up as 2nd-order (Butterworth @1Hz) signal response. And is benign wrt to source impedance, open input is behaving well.

Did some loop gain spice'ing (@simon7000), the servo's open-loop gain has a robust 67deg of phase margin at the intersect with unity (as feedback factor is unity).

I could even introduce another pole after the integrator to get more attenuation in the passband with only minor impact on the alignment (58deg phase margin):

That will also result in a negative real zero in the response from amplifier input to output. I expect it will be almost but not exactly covered by a pole, and the pole-zero pair will affect the flatness of the response in the audio band to some extent. No idea if the impact is big enough to worry about.

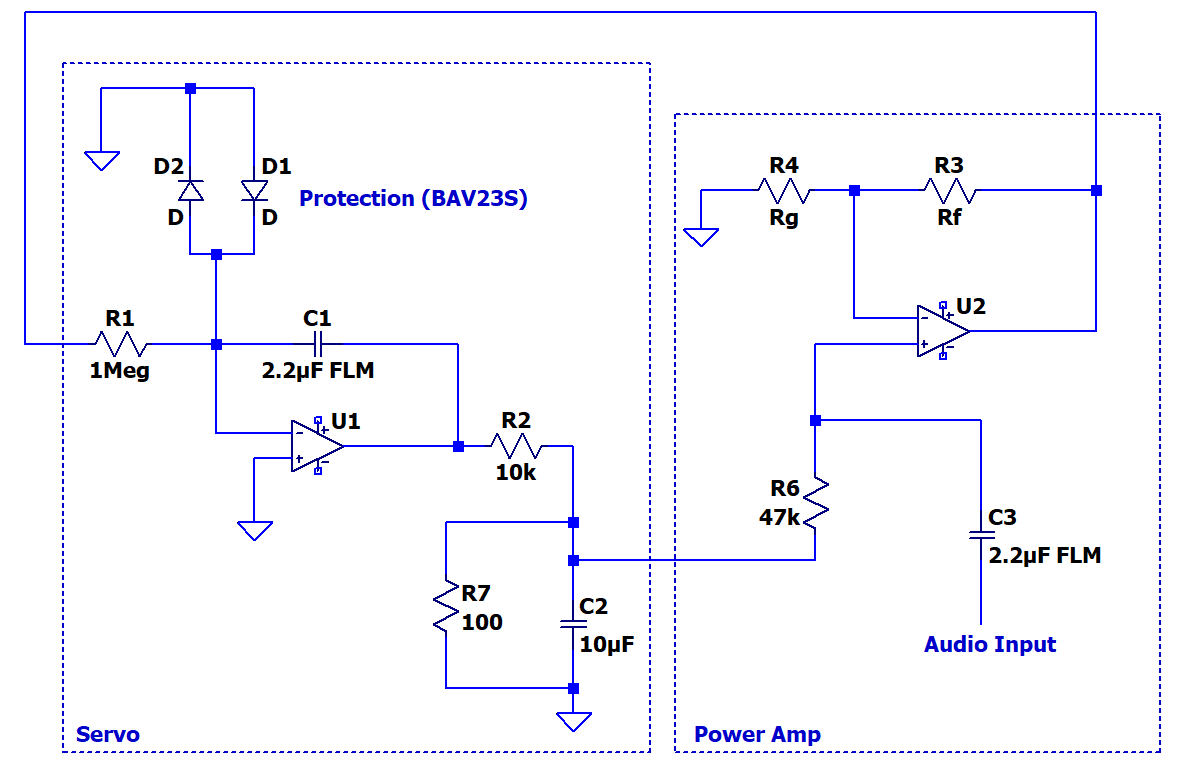

I'm doing it like this. On a CFA amp , the inverting input is low z in so its not a convenient place to inject a servo signal. This works well. U1 is a TL071.

I like Marcel's circuit plenty, well filtered and a belt'n'suspenders approach. I guess the biggest question is why the TLO7x? It's hardly what anyone would call a precision opamp for the location. Is it the PDIP factor? (blah, SO is easy) I can't imagine it's cost as jumping up even $1/channel is not changing anyone's BOM substantially.

Edit -- looks like the interest is around rail-to-rail input?

E.g. there's the OP07C in PDIP.

Edit -- looks like the interest is around rail-to-rail input?

E.g. there's the OP07C in PDIP.

Last edited:

I guess the biggest question is why the TLO7x? It's hardly what anyone would call a precision opamp for the location. Is it the PDIP factor? (blah, SO is easy) I can't imagine it's cost as jumping up even $1/channel is not changing anyone's BOM substantially.

I just chose a cheap FET op-amp with low enough offset (13 mV won't displace the cone much) that was available at the two part stores I had access to back in 1994, when I built the circuit. It had to be in a package suitable for mounting in dead bug style on a copper-clad board. You can use something else, of course.

The extra zero is set by the parallel combination of your R2, R6, R7 and C2. I haven't found a way to calculate or approximate the location of the third (closed-loop) pole yet.I'm doing it like this. On a CFA amp , the inverting input is low z in so its not a convenient place to inject a servo signal. This works well. U1 is a TL071.

View attachment 1076428

Do you see a small abberation in the frequency response around 160 Hz?

One thing I forgot to mention about this circuit

is that the input impedance of everything to the right of R1 is a resistance R2 in parallel with an inductance L = R5 C2 R2/(1 + R4/R3). Once you know it behaves as an LR parallel circuit, designing for a Butterworth response and figuring out what happens with a nonzero source impedance gets much easier.

is that the input impedance of everything to the right of R1 is a resistance R2 in parallel with an inductance L = R5 C2 R2/(1 + R4/R3). Once you know it behaves as an LR parallel circuit, designing for a Butterworth response and figuring out what happens with a nonzero source impedance gets much easier.

Hello MarcelThe extra zero is set by the parallel combination of your R2, R6, R7 and C2. I haven't found a way to calculate or approximate the location of the third (closed-loop) pole yet.

Do you see a small abberation in the frequency response around 160 Hz?

There is no frequency aberration.

- Home

- Amplifiers

- Solid State

- DC Servo using the OPA1656 CMOS Opamp