Nice.

I do love reading a thread where I learn stuff and a bunch of people contribute, get their hands dirty and make something.

I have the parts handy for this too 🙂

I do love reading a thread where I learn stuff and a bunch of people contribute, get their hands dirty and make something.

I have the parts handy for this too 🙂

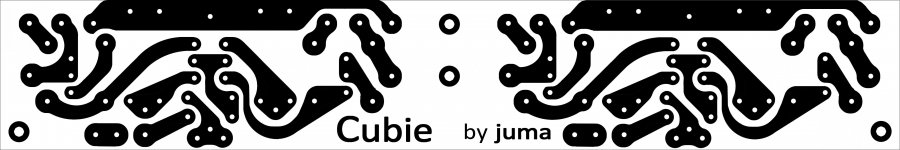

Nice layout, pls let me know if you have some extra PCB and if they are for sale.

Looks like 1 PCB is for 2 channel.

ps Hope you feel better.

BR,

Eric

Looks like 1 PCB is for 2 channel.

ps Hope you feel better.

BR,

Eric

It is one board for two channels. I will be doing one board with some form of resist, I will try laser toner transfer first, followed by a hand cut stencil and some spray on resist when the toner transfer fails.😀 I have a high resolution .tif that I'm sure no board house would touch, and no silk. I have only done an etched pc board once. I have enough board to screw up three times.😀 Thanks for the well wish, this flu is mild. I can send you the high res file, but I'm not equipt to offer any sort of tech support.

The tone transfer actually works. Use glossy paper like the ones from publicity flyer and make sure to use a laser printer. A deskjet won't work, it must be laser. I just finished one a few months ago (another Juma's design), PCB came out pretty good considering it's toner transfer.

BR,

Eric

BR,

Eric

It is one board for two channels. I will be doing one board with some form of resist, I will try laser toner transfer first, followed by a hand cut stencil and some spray on resist when the toner transfer fails.😀 I have a high resolution .tif that I'm sure no board house would touch, and no silk. I have only done an etched pc board once. I have enough board to screw up three times.😀 Thanks for the well wish, this flu is mild. I can send you the high res file, but I'm not equipt to offer any sort of tech support.

If you are patient enough just draw the circuit by hand (reversed dwg) with a Sharpie. The permanent ink of these Sharpie is not going to be attacked by the etching solution. For fun tonight I wrote Hiraga by hand on a small PCB then I etched it. What you see is actually in copper. Using a black PCB would give it a nice look as a nameplate for exemple.

BR,

Eric

Attachments

Last edited:

What price vanity? I like the precision of the tweaked graphic file, and I know I couldn't pull off the typography with a sharpie. I have read that a sharpie works, and it's nice to see proof. If it were something that I was tossing off, that would be fine. Unfortunately, I was schooled as a graphic designer. Originally thinking about using a sharpie, but some posts back I freaked out when I realized how tiny the board actually is. I was working on it greater than full screen, then I printed it out.😱 Thanks again!!!!

I ain't a graphic designer, I took the idea here so I won't take the credit 🙂

Wrong section of the forum to talk about Hiraga...LOL

Eric

Wrong section of the forum to talk about Hiraga...LOL

Eric

Attachments

Last edited:

fantastic

Thanks Fortier.🙂

If you are patient enough just draw the circuit by hand (reversed dwg) with a Sharpie. The permanent ink of these Sharpie is not going to be attacked by the etching solution. For fun tonight I wrote Hiraga by hand on a small PCB then I etched it. What you see is actually in copper. Using a black PCB would give it a nice look as a nameplate for exemple.

BR,

Eric

Thanks Fortier.🙂

Yes, Sharpie works great and that is how i make my prototype audio PCBs for the last 30 years.

But best results are achieved with oil-based permanent marker pen (google OHP marker pen) - I use Edding and Pilot. With them i routinely get good PCB tracks thinner than 10 mils (about 0.2mm).

The key to a good pcb made this way is to make the copper perfectly clean before drawing the lines and avoid touching the copper with fingers.

But best results are achieved with oil-based permanent marker pen (google OHP marker pen) - I use Edding and Pilot. With them i routinely get good PCB tracks thinner than 10 mils (about 0.2mm).

The key to a good pcb made this way is to make the copper perfectly clean before drawing the lines and avoid touching the copper with fingers.

Boards etched. Took me 9 tries to get the laser transfer correct

, but finally figured out that I needed to heat it with the iron until the glossy laser paper significantly yellowed, and then press it with a weighted platen, (a piece of picture frame glass and a weight, while the toner cooled. I don't know if the glass was necessary, but it worked. I retained all of the detail, down to itty bitty dots. Holes are drilled, some resistors are soldered. We are on the way!

, but finally figured out that I needed to heat it with the iron until the glossy laser paper significantly yellowed, and then press it with a weighted platen, (a piece of picture frame glass and a weight, while the toner cooled. I don't know if the glass was necessary, but it worked. I retained all of the detail, down to itty bitty dots. Holes are drilled, some resistors are soldered. We are on the way!

I'll post pics when I get everything soldered in. Now to jfet matching, lats measuring, and resistor value calculating. There was a post in tube amps where they asked the dude how long it took him to build his amp. 2 hours finding the amp schematic to build, three hours reading...total of like 18 hours. Mine are measured in months...sometimes years. Hopefully, this one will be less, but that 18 hour mark is long past.😀

Still haven't finished the 'lectronics, been working on the "case". Word of advise, take every precaution against breaking a tap off in your heatsink. Major pain in you know where. Coming along, two steps foreword, one back, or vice versa.

There are 'things' called transistor clips that use threaded holes beside the treansistor to avoid having to accurately align the smaller dia threads and insulating washers thru the transistor bodies and ensure there's not 'swarf' etc - I often use the simple bars between 2 transistors and these are especially handy holding down 2 diodes on the bridges, etc - saves an enormous amount of 'toil & trouble' and can much easier control the pressure applied to the transistors and insulating washers.

That's exactly how you should use your tapping tool in order not to break it. When drilling or tapping holes in aluminum use small quantity of ethyl alcohol (ethanol) as a lubricant and all will be well 🙂...two steps foreword, one back, ...

That's exactly how you should use your tapping tool in order not to break it. When drilling or tapping holes in aluminum use small quantity of ethyl alcohol (ethanol) as a lubricant and all will be well 🙂

🙂🙂🙂

I knew there was a step out of order. I applied the ethyl alcohol afterwards.😀 A bar with larger holes would have probably been a good idea. Next build. (I've got four amps in the works.) This one is the most fun. I can't wait to take pictures when it's finished. (I'll take them during the final rebuild.)

- Home

- Amplifiers

- Pass Labs

- Cubie - small F5 variant with GR grade JFETs and LatFETs

Got the stomach flu. Might as well mess with this.

Got the stomach flu. Might as well mess with this.