In the choice of a 4-Way system vs. 2- or 3-way system you have already sacrificed band-width for efficiency force majeure .

Exactly my point.

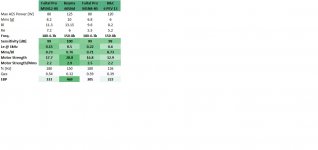

Please see the attached image. EBP correlates with motor strength (defined as Bl^2/Re) and motor strength/Mms.The more beef, the better.

Higher up, gossamer is good

The four drivers display significant motor strength. More beef, checked.

The four drivers have light cones (Mms). Gossamer, checked.

The Beyma has the heaviest cone of the 4, but a very strong motor, leading to the highest motor strength/Mms. But I have no references as to its actual performance in a horn...

Is this also valid if the range starts at 500Hz? Or were you referring to drivers reaching lower?A good bottom end performance is the key to the kingdom. A strong driver motor and sufficient volume displacement are most important here.

Attachments

N.B., EBP for this driver is 416 Hz. The more 'beef' the better.

I have fond memories of my visit to your country when I did some work for Acindar in Villa Constitucion.

Speaking of beef, hard to beat the flavor of a good Argentine steak.

Reference [1]

Ha! You know which buttons to push around here 🙂 You know we like our beef, and indeed we do!!

I started my career in steel milling 20+ years ago. I visited Acindar back then.

Anyway, thanks for the link. The SN8 looks good too. Below is my comparo to other top 8-inchers in my list. Looks very good indeed.

It's rated for up to 3kHz. Is it too close to my intended xo at 2.5kHz?

I confess I wonder if these 250W (AES) rated drivers would come alive if fed 0.25W. I'll look into it.

Regards

I prefer not to cross cone drivers in a horn above 5-600Hz. Something to consider when choosing midrange. But I gave up on the idea of midbass horns because I want to fit drivers in a straight vertical line from 70Hz-20kHz. Also, don't bother with Beyma 8" drivers. I hate the sound of them. So plastic and dull.

It's rated for up to 3kHz. Is it too close to my intended xo at 2.5kHz?

I confess I wonder if these 250W (AES) rated drivers would come alive if fed 0.25W. I'll look into it.

Regards

There is significant mass roll off in HF in a horn. I doubt those would be up to the task

I prefer not to cross cone drivers in a horn above 5-600Hz.

Why is this?

FWIW, my xo is going to be somewhere between 350 and 500Hz, but to be determined upon listening. Digital crossovers and active system give me a lot of freedom there.

Thanks for posting!

Why is this?

FWIW, my xo is going to be somewhere between 350 and 500Hz, but to be determined upon listening. Digital crossovers and active system give me a lot of freedom there.

Thanks for posting!

I think that's what he means already: "not above 500, or 600Hz" but, rather below that. btw 380Hz is a very nice crossover pointe, provided you can get

your horn to respond that low, and do it in a linear fashion.

additional pointe: In my humble, and yet to-be Validated opinion,

A large throat, short throw horn does not suffer from the mass roll-off equation as much as a horn done the opposite way "small throat/ long throw".

Sorry for the confusion, I meant lowpass at 5-600 Hz.

okay, so you mean like for a mid-bass horn ? If so I would agree; meaning perhaps a 10 inch used 90ish up to 600 Hz

Also, does that mean you are strictly against using a very light weight cone/ huge magnet driver for mid range proper, say as an example, 380-3.8k Hz >?

Next, Large Signal Issues

I have been pushing 8" drivers because I though you wanted to c/o at no more than 300-400 Hz., which requires good driver performance to say 150-200 Hz. If the horn used is on the small side as well (which is typical), a driver that is capable of moving some air ([Vd] = [Sd]*[Xmax]) is needed with tight electrical/mechanical control (big motor). If you are going to c/o in the region of 500-600 Hz. with a full-sized horn, then there are several good speech range compression drivers that can fill that mission. You need to explore your lower frequency options using David's program.

Note the 6-1/2" Beyma with a [Vd] = 14 cm³ is roughly equivalent to that of a typical 4" speech-range compression driver. So why mess designing your own. You do not have the prerequisite experience to guarantee a successful outcome. Existing designs on the market represent man-years work in an acoustics lab and include a history of numerous design modifications to improve performance.

The last driver I found for you should fill your lower frequency mission. In the US it can be purchased for $160 USD. It has a displacement [Vd] = 91 cm³ and smooth frequency response well beyond 3000 Hz.

Frank Massa of RCA published a very useful equation in the mid-1930s to recognize and quantify the compression driver large signal design problem as follows:

1) Diaphragm excursion [d] is the main limiting factor in using compression drivers at lower frequencies.

2) With a constant piston area [Ap] and power output [P], excursion [d] quadruples when the frequency [f] is halved.

3) It is very important that the horn loads the driver well at the low frequency limit to avoid over- excursion.

Here is his formula:

[P] = (0.0034 * [f]² *[d]² * [Ap]²)/[Ah]

Where:

[Ap] = diaphragm projected area in in² (Sd)

[Ah] = throat area in in² (St)

[f] = frequency in Hz.

[d] = peak diaphragm amplitude in in. (Xmax)

[P] = power output in acoustical watts

In this equation, he assumes that the driver is loaded by an exponential horn of low enough flare constant and large enough overall dimensions to load the driver to the lowest frequency of interest. The throat area [Ah] of a traditional compression driver would be the combined area of the exit paths on the surface of the phasing plug. For a woofer, sans phase plug, the throat area of the horn constitutes [Ah].

As can be seen in the equation, [Ah] exerts a great influence, as everything else is divided by it. [Ap]/[Ah] the driver's compression ratio typically has a value in the neighborhood of 10:1, which is how high output at low excursion is obtained. If this value is increased further, eventually the motor would not be able to push the larger load. This is one reason why compression drivers tend to have very strong motors.

Furthermore, a compression ratio of 10:1 has been determined through experience to be a practical limit, due to the viscosity and nonlinear elasticity exhibited by air entrained in narrow passages when it is exposed to high acoustic pressures. To avoid excessive distortion that would otherwise occur at lower frequencies (say below 1,000 Hz.), where more particle-flow is required, lower compression ratios are used.

Regards,

WHG

Exactly my point.

Please see the attached image. EBP correlates with motor strength (defined as Bl^2/Re) and motor strength/Mms.

The four drivers display significant motor strength. More beef, checked.

The four drivers have light cones (Mms). Gossamer, checked.

The Beyma has the heaviest cone of the 4, but a very strong motor, leading to the highest motor strength/Mms. But I have no references as to its actual performance in a horn...

Is this also valid if the range starts at 500Hz? Or were you referring to drivers reaching lower?

I have been pushing 8" drivers because I though you wanted to c/o at no more than 300-400 Hz., which requires good driver performance to say 150-200 Hz. If the horn used is on the small side as well (which is typical), a driver that is capable of moving some air ([Vd] = [Sd]*[Xmax]) is needed with tight electrical/mechanical control (big motor). If you are going to c/o in the region of 500-600 Hz. with a full-sized horn, then there are several good speech range compression drivers that can fill that mission. You need to explore your lower frequency options using David's program.

Note the 6-1/2" Beyma with a [Vd] = 14 cm³ is roughly equivalent to that of a typical 4" speech-range compression driver. So why mess designing your own. You do not have the prerequisite experience to guarantee a successful outcome. Existing designs on the market represent man-years work in an acoustics lab and include a history of numerous design modifications to improve performance.

The last driver I found for you should fill your lower frequency mission. In the US it can be purchased for $160 USD. It has a displacement [Vd] = 91 cm³ and smooth frequency response well beyond 3000 Hz.

Frank Massa of RCA published a very useful equation in the mid-1930s to recognize and quantify the compression driver large signal design problem as follows:

1) Diaphragm excursion [d] is the main limiting factor in using compression drivers at lower frequencies.

2) With a constant piston area [Ap] and power output [P], excursion [d] quadruples when the frequency [f] is halved.

3) It is very important that the horn loads the driver well at the low frequency limit to avoid over- excursion.

Here is his formula:

[P] = (0.0034 * [f]² *[d]² * [Ap]²)/[Ah]

Where:

[Ap] = diaphragm projected area in in² (Sd)

[Ah] = throat area in in² (St)

[f] = frequency in Hz.

[d] = peak diaphragm amplitude in in. (Xmax)

[P] = power output in acoustical watts

In this equation, he assumes that the driver is loaded by an exponential horn of low enough flare constant and large enough overall dimensions to load the driver to the lowest frequency of interest. The throat area [Ah] of a traditional compression driver would be the combined area of the exit paths on the surface of the phasing plug. For a woofer, sans phase plug, the throat area of the horn constitutes [Ah].

As can be seen in the equation, [Ah] exerts a great influence, as everything else is divided by it. [Ap]/[Ah] the driver's compression ratio typically has a value in the neighborhood of 10:1, which is how high output at low excursion is obtained. If this value is increased further, eventually the motor would not be able to push the larger load. This is one reason why compression drivers tend to have very strong motors.

Furthermore, a compression ratio of 10:1 has been determined through experience to be a practical limit, due to the viscosity and nonlinear elasticity exhibited by air entrained in narrow passages when it is exposed to high acoustic pressures. To avoid excessive distortion that would otherwise occur at lower frequencies (say below 1,000 Hz.), where more particle-flow is required, lower compression ratios are used.

Regards,

WHG

Notes

Ha! You know which buttons to push around here 🙂 You know we like our beef, and indeed we do!! [/QOUTE]

Ate my first Palmetto while there.

Since my return to the U.S., seldom do I eat dinner before 9:30 pm

and you can find cans of palmettos in my pantry.

Miss the good wine as well.

I started my career in steel milling 20+ years ago. I visited Acindar back then.

Anyway, thanks for the link. The SN8 looks good too. Below is my comparo to other top 8-inchers in my list. Looks very good indeed.

It's rated for up to 3kHz. Is it too close to my intended xo at 2.5kHz?

This driver has a smooth response well beyond 3,000 Hz.

Voicing it should not be a problem for your application.

I confess I wonder if these 250W (AES) rated drivers would come alive if fed 0.25W. I'll look into it.

Drive signal peaks will be much higher than RMS.

The crest factor for uncompressed music signal is very high.

The blooming phenomena that occurs when you crank the volume control has more to do with improved ear sensitivity to frequency extremes as their level is increased.

Regards,

WHG

Are you recommending this driver to be horn loaded ?

I believe so.

BTW, P.Audio Argentina seems to either be a ghost company, or some sort of funny business. Those phone numbers don't exist. I found 3 other (very different) phone numbers, and those didn't work either...

The SN8 indeed has a powerful motor, and has an Mms of 20.9g. Relatively speaking, the M5N12 MMs is 39% of that of the SN8, and motor strength is 33%. Motor strength/Mms is 2.2 for M5N12 and 2.6 for SN8.

I guess I need to pick my poison. Gossamer up high? Then the M5N12 would seem better. Higher motor strength to reach lower frequencies? Then SN8, or the B&C suggested earlier.

FWIW, before I started this thread I asked Pooh about the CMCD-81 vs CMCD-61 for my application and he thought the 61 might be better as the 81 was reaching its limit at 2-2.5kHz.

Good food for thought!

Faital 6PR122

Yes, you have some tough choices to make. In my opinion this driver---->

the sn8-250n2 has too low a ratio of flux to moving mass to be considered for horn use. But, again, that's ONLY my opinion. Whgeiger seems to posses a LOT more experience in this field, than I do. Maybe it's time to think in terms of a waveguide, instead of a horn (proper) since, basically, what you want is

some help in the directivity aspect ? btw, I found another driver that I really, really like (at least on paper) to be used in the mid range spectrum.

http://www.faitalpro.com/products/files/6PR122/8/6PR122_datasheet_8.pdf

I believe so.

BTW, P.Audio Argentina seems to either be a ghost company, or some sort of funny business. Those phone numbers don't exist. I found 3 other (very different) phone numbers, and those didn't work either...

The SN8 indeed has a powerful motor, and has an Mms of 20.9g. Relatively speaking, the M5N12 MMs is 39% of that of the SN8, and motor strength is 33%. Motor strength/Mms is 2.2 for M5N12 and 2.6 for SN8.

I guess I need to pick my poison. Gossamer up high? Then the M5N12 would seem better. Higher motor strength to reach lower frequencies? Then SN8, or the B&C suggested earlier.

FWIW, before I started this thread I asked Pooh about the CMCD-81 vs CMCD-61 for my application and he thought the 61 might be better as the 81 was reaching its limit at 2-2.5kHz.

Good food for thought!

Yes, you have some tough choices to make. In my opinion this driver---->

the sn8-250n2 has too low a ratio of flux to moving mass to be considered for horn use. But, again, that's ONLY my opinion. Whgeiger seems to posses a LOT more experience in this field, than I do. Maybe it's time to think in terms of a waveguide, instead of a horn (proper) since, basically, what you want is

some help in the directivity aspect ? btw, I found another driver that I really, really like (at least on paper) to be used in the mid range spectrum.

http://www.faitalpro.com/products/files/6PR122/8/6PR122_datasheet_8.pdf

I have the closed back chamber JBL 2169H (CMCD-82H) with the original JBL phase plug in a big Seos horn with 4" exit myself and it's the best midrange I have ever heard. Crossed over at 250Hz and 2200Hz.

I would not use a cone driver without closed rear chamber and phase plug in a horn. The FR would be very limited upwards, I would probably need to cross over closer to 1000Hz. There is not without reason JBL mounted both a back chamber and phase plug on the 165H driver in the CMCD-61H concept. http://www.jblproservice.com/pdf/AE Series/AM4200,95-WH.pdf

Thought I would like to try a 6.5" unit to extend the response to 3000Hz. The PHL Audio 1500Nd-SQ looks VERY interesting: PHL Audio: Products ?*6.5 inch in

Looks awesome!! I just got a pair of JBL 2250s. I'll start with a 60\40 conical with 3.6" by 3.6" throat I'm not sure the mouth or length yet.

How deep is that SEOS horn?

That P Audio 8" will choke in a horn, lol, let me see some measurements. Do you actually use these in a horn for upper midrange???

a good 8" for a horn is the B&C 8pe21 and it's good up to maybe 900 cycles

🙄

a good 8" for a horn is the B&C 8pe21 and it's good up to maybe 900 cycles

🙄

Mission Possible Revisited

Note that the CMCD-61[3] uses a 10" driver (JBL 2012H) [1] that has similar specs to that of 8" P-Audio SN8-250N [2]. Note that [Mms] for the two is 30g vs. 21g. Note also that more diaphragm mass for a given [Sd] should yield a stiffer moving structure that is required for operation as a compression driver. While your mission is a design challenge, you should be able to get the decade of spectrum that you want, particularly with the presence of DSP to voice each driver/baffle combination. In my view, the big problem remains M-R horn size and geometry. While keeping the speech-range intact makes for great system imaging and sound quality, the price for doing this is the presence of a pair of big horns in the listening space. Klipsch Jubilee (large M-R horn version) is about as good as it gets for domesticating an all-horn system. In this regard the 4-Way, EV PAT IV comes close as well, but here the M-R horn is too-small.

I will address P-Audio presence in Argentina later.

Regards,

WHG

I believe so.

BTW, P.Audio Argentina seems to either be a ghost company, or some sort of funny business. Those phone numbers don't exist. I found 3 other (very different) phone numbers, and those didn't work either...

The SN8 indeed has a powerful motor, and has an Mms of 20.9g. Relatively speaking, the M5N12 MMs is 39% of that of the SN8, and motor strength is 33%. Motor strength/Mms is 2.2 for M5N12 and 2.6 for SN8.

I guess I need to pick my poison. Gossamer up high? Then the M5N12 would seem better. Higher motor strength to reach lower frequencies? Then SN8, or the B&C suggested earlier.

FWIW, before I started this thread I asked Pooh about the CMCD-81 vs CMCD-61 for my application and he thought the 61 might be better as the 81 was reaching its limit at 2-2.5kHz.

Good food for thought!

Note that the CMCD-61[3] uses a 10" driver (JBL 2012H) [1] that has similar specs to that of 8" P-Audio SN8-250N [2]. Note that [Mms] for the two is 30g vs. 21g. Note also that more diaphragm mass for a given [Sd] should yield a stiffer moving structure that is required for operation as a compression driver. While your mission is a design challenge, you should be able to get the decade of spectrum that you want, particularly with the presence of DSP to voice each driver/baffle combination. In my view, the big problem remains M-R horn size and geometry. While keeping the speech-range intact makes for great system imaging and sound quality, the price for doing this is the presence of a pair of big horns in the listening space. Klipsch Jubilee (large M-R horn version) is about as good as it gets for domesticating an all-horn system. In this regard the 4-Way, EV PAT IV comes close as well, but here the M-R horn is too-small.

I will address P-Audio presence in Argentina later.

Regards,

WHG

Attachments

Last edited:

The CMCD61 uses a 6" and is a complete different animal than the P audio 8" - are you kidding or serious?

Hi Pooh, do you think that the cmcd 61 would be suitable in a 220hz tractrix horn crossing over around the 350-400hz mark? I would use this up to 2500-3000khz. Crossing over to a 1000khz tractrix horn.

I have emailed the Australian distributed , the drivers are available, he was chasing up about the phase plug and the back can for me.

Cheers Dave.

I have emailed the Australian distributed , the drivers are available, he was chasing up about the phase plug and the back can for me.

Cheers Dave.

- Home

- Loudspeakers

- Multi-Way

- Cone midrange horn 101