Absence of evidence is not evidence of absence , some evidence has to be search for one who's open to them ....

in this field like in others , tons have been made then forgot/hidden , this is partialy why we turn around and around ......

.

in this field like in others , tons have been made then forgot/hidden , this is partialy why we turn around and around ......

.

Last edited:

Yes, nicely put, show us the evidence! ... in the last 10-20 years or so half of this forum is focused on wet dreams regarding exotic materials 🙂 ... but I've seen no apt evidence! Show me an evidence!Absence of evidence is not evidence of absence , some evidence has to be search for one who's open to them ....

I'll make it simple; show me why amorphous or nanocrystalline is better than permalloy in specific cases, such as DAC apps, practical cases, comparative results... objective or subjective opinions, I'll take all 🙂

Last edited:

Yes, I did, but this is no evidence 🙂Read back carefully what I writted 😎

Saturation flux not so much, but permeability is very important for low level audio signals, along with core loss / eddy current.Saturation Flux / Relative Permeability is not a metric that is relevant in low signal level audio applications.

Modern......I use VAC Vitroperm 500F (nanocrystalline) toroidal cores since 1999; until then I used VAC permalloy EK cores 80%/0.1mm but when these became really expensive and VAC nanocrystalline toroidals entered the market I tried these, and finding out that these were at least on par (measurements; sonics) I went along with these toroidals and never looked back. Last year I bought 100 pieces for my inductive volume controls for 5 euro/piece. Pricewise try permalloy nowadays.....If you want Amorphous or Nanocrystaline Core transformers because it's modern and sexy sexy and super expensive, get them, clearly audio performance is not at issue.

As I apply these cores for MC SUT's as well, I will see if I can do HD measurements but based on the properties it will not be worse than for permalloy.If there is actual measured HD performance for a 1:10 Transformer at (say) 20Hz/30/50/100Hz and 1kHz with primary levels from -50 to 0dBu I will be happy to look at the results and if warranted change my view.

Quite likely it is (in German) vacoperm100 (80% nickel) or permenorm5000 (50% nickel), which are grades of permalloy. Nice stuf.

It seems to have a fixed airgap.

Check here; it seems to be an M-type lamination:

https://sekels.de/fileadmin/PDF/English/20_Info_Core_Packages.pdf

It seems to have a fixed airgap.

Check here; it seems to be an M-type lamination:

https://sekels.de/fileadmin/PDF/English/20_Info_Core_Packages.pdf

Last edited:

Very useful information, thanks. From a quick measurement of µr with LC resonance method I got 28500. That looks like Vacoperm 100B material.

permeability is very important for low level audio signals, along with core loss / eddy current.

Yup.

Modern......I use VAC Vitroperm 500F (nanocrystalline) toroidal cores since 1999; until then I used VAC permalloy EK cores 80%/0.1mm but when these became really expensive and VAC nanocrystalline toroidals entered the market I tried these, and finding out that these were at least on par (measurements; sonics) I went along with these toroidals and never looked back.

So as I noted, the Mothers of Invention at work.

IF VAC Vitroperm 500F really is competitive with 80% Nickel permalloy (and nothing in the Datasheet on VAC's would remotely ever make me suspect such a thing in a million years) that would be great.

As I apply these cores for MC SUT's as well, I will see if I can do HD measurements but based on the properties it will not be worse than for permalloy.

Looking forward to see something I can relate to this:

So test with Zsrc 150R and 20/30/50Hz at -40dBu to 0dBu.

Thor

Anybody has any idea what lamination material is this? Dimensions: M42, thickness: 0.1 mm, gap width: 0.2 mm. I am building a pair of 1:16 transformer from it. I will publish the measurements if ready.

Shiny, so definitly nickel. Others chipped in on the details.

One concern, permalloy looses performance when mechanically stressed (bent) and needs to be heat treated to "come back". Which is why normally it does come in EL so assembly of the core does not cause mechanical stresses.

Thor

Another one, the airgap is substantial. It will make it good for TDA1541 without offset compensation of course. And the airgap may moderate performance losses from mechanical stresses.

Thor

Thor

Wonder about this simultaneous design by @miro1360 but made with the 24 pins you advised. I'd like to see the I2S scope captures though : https://www.diyaudio.com/community/...st-tht-i2s-input-nos-r-2r.354078/post-7160128

I'll have a look on his cpld board as it has the good idea to have uf-l inputs, sma should not be hard to add as it is open design, I have to find the post of the pcb, though

I'll have a look on his cpld board as it has the good idea to have uf-l inputs, sma should not be hard to add as it is open design, I have to find the post of the pcb, though

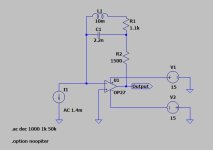

I will try this active filter as per your advice.I would suggest to not place anything between I/U conversion and DAC.

Add a peaking lowpass after the Op-Amp.

Say 10mH series inductor, 3.3nF +2k2 to ground after the coil.

Do a bit of curve fitting in the actual system to get a flat response at 10kHz.

Thor

Attachments

I will try this active filter as per your advice.

My advise was to place the LCR Filter between Op-Amp output and Line out, where it may also be used as normal 2nd order 40khz lowpass per TDA1541 design.

Thor

Wonder about this simultaneous design by @miro1360 but made with the 24 pins you advised. I

It does not divide down BCK, so it's stopped clock at the same BCK frequency as IIS.

You might remember my comments on the usefulness of doing that. I believe it read "might as well just use IIS directly".

The FPGA from raptor contains source and it works with continuous BCK at 1/4 of IIS BCK.

In terms of reducing noise in principle reduced frequency or higher frequency with periods of silence is the same.

Adding slew rate limiters reduces the problem to a much greater degree.

With 384kHz IIS input, we get 6.144MHz BCK. The FPGA even provides balanced FDEM feeds.

It's close to what I would have done discrete.

Thor

I agree and for me it is enough but for some reasons I don't controll people want simultaneous modes on coper as some women want Mini Cooper ! It is not electronic it is psychanalism, you know the plus cool fresh side of the red pill before the rabitt hole. They want the T Bone Steak,not the poridge milshake.

In the mean time I lauch the 5 pcb batch, one for me, and maybe it will be a good base for some measurements with your scopes guys (you, Zoran, Icsazsar... if wanting one). It will be my modest contribution.

In the mean time I lauch the 5 pcb batch, one for me, and maybe it will be a good base for some measurements with your scopes guys (you, Zoran, Icsazsar... if wanting one). It will be my modest contribution.

In terms of reducing noise in principle reduced frequency or higher frequency with periods of silence is the same.

Adding slew rate limiters reduces the problem to a much greater degree.

Thor

Wrong , until it is proven right , sound and measurements wise

it's like the magnetic material permeability for low level audio signals, , one day you state it's irelevant , and an other day you agree it is very important , are you sure you understand the matter ??

.

Last edited:

- Home

- Source & Line

- Digital Line Level

- Building the ultimate NOS DAC using TDA1541A