Thank's for the compliments.

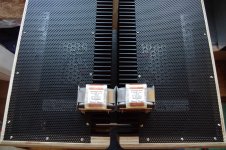

Heatsinks are from Conrad MF350-151.5,Overkill as they barely get warm but who knows what "EVIL" plan Michael has in store for MO-FO Mk2.

Maybe a couple of these critters pictured.

And a shot with the lids on.

Steve.

Heatsinks are from Conrad MF350-151.5,Overkill as they barely get warm but who knows what "EVIL" plan Michael has in store for MO-FO Mk2.

Maybe a couple of these critters pictured.

And a shot with the lids on.

Steve.

Attachments

Pass DIY Addict

Joined 2000

Paid Member

Very nice build! I was thinking you were constructing these in the "Classic DIY" style - that of over-engineering! I'm also a HUGE fan of wooden chassis - I like to make stuff look more like wooden furniture that can blend into the decor a bit. I see you've also used my favorite router bit - a 1/2 roundover. I use that bit on just about every project I make...

Thank's Eric,

Being that i'm a worn out carpenter i can't help but use timber.

As for over-engineering i'm not sure there is such a thing as too much heat sinking!!!

Steve.

Being that i'm a worn out carpenter i can't help but use timber.

As for over-engineering i'm not sure there is such a thing as too much heat sinking!!!

Steve.

Newb question since I’ve never built a SS amp from scratch. How does one determine the correct size of heatsink to use? I’d like to give this amp a go, but am unsure how to determine size heatsink to get for either the 19v or 24v. I know there is a minimum recommendation in the write up, but I don’t know how that is determined.

Last edited:

ZM,even if I use MoFo in bridge form ?

If it is still overkill and must use irf510 did I have to change passive components ?

Multo obligato

If it is still overkill and must use irf510 did I have to change passive components ?

Multo obligato

Bloozestringer -

In the article Mike says, "The device dissipation will be pretty close to your power supply voltage times the idle current. So, for the 19V, 1.7A example, we need a heatsink that can dissipate 32 watts with no more than a 25C rise above ambient temperature. That’s .78C/W, which I consider to be the minimum figure. I will award bonus points if you use oversized heatsinks. A lot of beginner projects run into trouble because of inadequate heatsinking, and using big heatsinks just makes life easier."

So... in english, that means a fairly big heatsink. Also of note, the smaller the number in the heatsink temp/watt coefficient the better.

Were I to build them I'd use a 4U 300mm heatsink from hifi2000, as it's more than big enough and I have them sitting on my shelf. 🙂

This would work beautifully as you'd need at least 4" height to keep the choke in the chassis - http://www.heatsinkusa.com/10-080-wide-extruded-aluminum-heatsink/

As would this - http://www.heatsinkusa.com/8-000-wide-serrated-fin-extruded-aluminum-heatsink/

(And yes, you are reading that correctly, the 8" has a better rating than the 10", mainly because the fins are deeper. At a height more than 3" they are both more than enough for the job.)

In the article Mike says, "The device dissipation will be pretty close to your power supply voltage times the idle current. So, for the 19V, 1.7A example, we need a heatsink that can dissipate 32 watts with no more than a 25C rise above ambient temperature. That’s .78C/W, which I consider to be the minimum figure. I will award bonus points if you use oversized heatsinks. A lot of beginner projects run into trouble because of inadequate heatsinking, and using big heatsinks just makes life easier."

So... in english, that means a fairly big heatsink. Also of note, the smaller the number in the heatsink temp/watt coefficient the better.

Were I to build them I'd use a 4U 300mm heatsink from hifi2000, as it's more than big enough and I have them sitting on my shelf. 🙂

This would work beautifully as you'd need at least 4" height to keep the choke in the chassis - http://www.heatsinkusa.com/10-080-wide-extruded-aluminum-heatsink/

As would this - http://www.heatsinkusa.com/8-000-wide-serrated-fin-extruded-aluminum-heatsink/

(And yes, you are reading that correctly, the 8" has a better rating than the 10", mainly because the fins are deeper. At a height more than 3" they are both more than enough for the job.)

That puts you in the vicinity of the heat pain threshold and keeps your transistors happy as well. 🙂

Last edited:

You want a Max rise of 25C above ambient.

To give you an idea have a look at the attached file, you will see a list of available heatsink from the DIYaudio store along with the heatsink size and c/w coefficients. For a regular MoFo look for 0.6 c/w or below, ex 0.5 c/w

BR

Eric

To give you an idea have a look at the attached file, you will see a list of available heatsink from the DIYaudio store along with the heatsink size and c/w coefficients. For a regular MoFo look for 0.6 c/w or below, ex 0.5 c/w

BR

Eric

Attachments

Thanks everyone. I’ve learned something useful here today, which is more than I can say about my job.

Hi

I bought a 13 inch long heatsink (Wakefield 392) and a friend of mine cut it in 2 parts and then sand blasted them with micro glass. They look stunning IMHO and now I’d like to protect them with a thin coat of clear spray.

What brand and type would you recommend knowing that the heatsink will be at about 45C ? Pls recommend something you have tried and trust.

Attach is a pic.

Thanks

Eric

I bought a 13 inch long heatsink (Wakefield 392) and a friend of mine cut it in 2 parts and then sand blasted them with micro glass. They look stunning IMHO and now I’d like to protect them with a thin coat of clear spray.

What brand and type would you recommend knowing that the heatsink will be at about 45C ? Pls recommend something you have tried and trust.

Attach is a pic.

Thanks

Eric

Attachments

Last edited:

Hi

I bought a 13 inch long heatsink (Wakefield 392) and a friend of mine cut it in 2 parts and then sand blasted them with micro glass. They look stunning IMHO and now I’d like to protect them with a thin coat of clear spray.

What brand and type would you recommend knowing that the heatsink will be at about 45C ? Pls recommend something you have tried and trust.

Attach is a pic.

Thanks

Eric

How will you apply the paint? I fear the shape will make very difficult to properly reach every area.

Have you thought about anodizing? It can be made natural color if you want to preserve it. Otherwise black will give you a marginally better heat transfer

These heatsinks were previously anodized but were gold.

Not sure what I’ll do, just wanted to know if someone knows a good clear that will resist heat and won’t turn yellow after a few years since from what I read this amp is a keeper!

BR

Eric

Not sure what I’ll do, just wanted to know if someone knows a good clear that will resist heat and won’t turn yellow after a few years since from what I read this amp is a keeper!

BR

Eric

Maybe black oxidizing? Problem with paint is it can seal in heat and not let the heat sink dissipate as effectively.

Not sure this will work. Maybe one of the chemists here can comment.

Blackening Processes for Aluminum – Black Oxide – EPi

Not sure this will work. Maybe one of the chemists here can comment.

Blackening Processes for Aluminum – Black Oxide – EPi

Last edited:

Pass DIY Addict

Joined 2000

Paid Member

I, too, have always heard that painting sinks is a bad idea as it greatly reduces the emissivity factor compared to black anodize. There is a nice table of emissivity factors that includes raw and anodized aluminum. I'm not quite sure what to make of the "aluminum paint" (highly variable at 0.27-0.67) and "paint" (0.96) entries in the table, though...

Last edited:

- Home

- Amplifiers

- Pass Labs

- Build This MoFo!