Very nice! And well documented. Is the sound as expected?

Been searching for CNC shop nearby in the states. I'm a woodworker so have most tools, but not CNC.

Been searching for CNC shop nearby in the states. I'm a woodworker so have most tools, but not CNC.

Thanks gentlemen - they sound very nice for what they are, which is a small desktop speaker. I have read reviews on these that stated that they could be used as your main audiophile speakers for listening. Anyone who says that has either never heard good speakers or is simply lying. My honest assessment is that there are a good number of quality bookshelf speakers out there which sound better than these and are much easier to build. I built these for 2 reasons - I think they look stunning and they are very small, making them excellent desktop computer speakers.

Subsonic1050,

You nailed the visual aspect of the W5.

What amplification are you using to drive them?

You nailed the visual aspect of the W5.

What amplification are you using to drive them?

At my desk I'm just using a cheap chip amp from Amazon. I'm even using bluetooth! (the horror). However, I was curious about what they could really do so I took them down to my listening room and hooked them up to a PS audio BHK pre, BHK 250 amp fed by a Node 2i as a streamer into a Holo Audio Spring 3 KTE DAC to see what they could do with a nice system, a treated room, and some good cables.Subsonic1050,

You nailed the visual aspect of the W5.

What amplification are you using to drive them?

Hello guys

I think I'm starting the project.

I have some questions

1. OAK wood massive or MDF ? Is there some resonance if using OAK?

2. If Fountek FE85 is not a possible option, what do you think about : Tang Band W3-881SJF? I know you already like W3-1878!

Thanks,

I think I'm starting the project.

I have some questions

1. OAK wood massive or MDF ? Is there some resonance if using OAK?

2. If Fountek FE85 is not a possible option, what do you think about : Tang Band W3-881SJF? I know you already like W3-1878!

Thanks,

The fountek driver is still available, so why would you not use that? It's available from Madisound. If you use a different driver you'll have to tweak the crossover.

https://www.madisoundspeakerstore.c...Z1PLKIUUGJX8sK-C50R9-vdECGAkQaGEaAuiCEALw_wcB

Oak is totally fine and I'd definitely use it over MDF. In my opinion, basically the only reason you'd build these speakers is because they LOOK awesome while sounding pretty good as well. If you build them out of MDF you'll have to veneer them which is never going to look as good as building them out of solid wood - that's my opinion anyway.

https://www.madisoundspeakerstore.c...Z1PLKIUUGJX8sK-C50R9-vdECGAkQaGEaAuiCEALw_wcB

Oak is totally fine and I'd definitely use it over MDF. In my opinion, basically the only reason you'd build these speakers is because they LOOK awesome while sounding pretty good as well. If you build them out of MDF you'll have to veneer them which is never going to look as good as building them out of solid wood - that's my opinion anyway.

Yes. I saw it on this website.

more questions.

What is that red thing wire on woofer?

And what type of processing of the oak wood are you making /like varnish or so/ ??? What wood glue do you use?

more questions.

What is that red thing wire on woofer?

And what type of processing of the oak wood are you making /like varnish or so/ ??? What wood glue do you use?

And one more.

I see a lot of capacitors 1.0 uf - 250/400/600/1000V - What needed to be?

On one of the picture I see that Mundorfs is 250V ... Is it the voltage for all ?

I see a lot of capacitors 1.0 uf - 250/400/600/1000V - What needed to be?

On one of the picture I see that Mundorfs is 250V ... Is it the voltage for all ?

If anyone is interested, I’ve made 3D models of these in Fusion360. I can share the stl or fusion files. I’ve printed them in 8 parts and I’m just waiting for the crossover parts to arrive.

Hello,

I am interested in this build if you could share the files.

Thanks!

There is a ton of pictures on the internet. No problem making the gcode... It would not be nice towards boenicke to upload the files here. Either you can create them by yourself or you simply can't DIY this speaker. In this case just buy it.

Started the project... Hope to get it done It is pretty detailed and very time consuming. Now I know why they are so expensive ....

If someone can help me will appreciate it!

At this point will give you this info :

Found all the speakers - really happy about it!

1. Tang Band 13-1761S - Tweeters

2. Sven has been using 2 mid range speakers: Foundtek FE 85 / FE88EX

3. Sven is using 2 types of woofer Tang Band W5-1138SMF (for SE and SE+) / Peerless SLS ... 14 cm(for just W5)

Working on back plate now ... almost done. Need exact dimensions of backplate in mm. Need exact spaces in mm from both edges of the cabinet. If some can give me will be happy.

Connectors: WBT 0703 CU

Wood - 30 years dried walnut at 8 cm thick pieces

CNC - 3-4 hours at side x 4 for both speakers

Natural sheep Wool

And not on last place : Very brave woodman to do the job.

Job is continuing ... Keep you in touch

If someone can help me will appreciate it!

At this point will give you this info :

Found all the speakers - really happy about it!

1. Tang Band 13-1761S - Tweeters

2. Sven has been using 2 mid range speakers: Foundtek FE 85 / FE88EX

3. Sven is using 2 types of woofer Tang Band W5-1138SMF (for SE and SE+) / Peerless SLS ... 14 cm(for just W5)

Working on back plate now ... almost done. Need exact dimensions of backplate in mm. Need exact spaces in mm from both edges of the cabinet. If some can give me will be happy.

Connectors: WBT 0703 CU

For project used:Wood - 30 years dried walnut at 8 cm thick pieces

CNC - 3-4 hours at side x 4 for both speakers

Natural sheep Wool

And not on last place : Very brave woodman to do the job.

Job is continuing ... Keep you in touch

Attachments

-

0-02-05-04e1c5153eb8c75871eb137105b28a2aa862267aff93bfd290ff06d62792a775_d83f2a0213aed7ec.jpg461.4 KB · Views: 375

0-02-05-04e1c5153eb8c75871eb137105b28a2aa862267aff93bfd290ff06d62792a775_d83f2a0213aed7ec.jpg461.4 KB · Views: 375 -

0-02-05-7f6976c741fb702b552763138d5fa3fd1c836d0cf8a6fe085f4f3463e9cd3fb4_9a7501a917608fc2.jpg429.7 KB · Views: 371

0-02-05-7f6976c741fb702b552763138d5fa3fd1c836d0cf8a6fe085f4f3463e9cd3fb4_9a7501a917608fc2.jpg429.7 KB · Views: 371 -

0-02-05-2687037176d12979e63c4e15df07a1e822fa4a97ffb5acabc15d362bff7d547b_228aa50ed4e69f36.jpg443.7 KB · Views: 380

0-02-05-2687037176d12979e63c4e15df07a1e822fa4a97ffb5acabc15d362bff7d547b_228aa50ed4e69f36.jpg443.7 KB · Views: 380 -

0-02-05-c31358055c1e600471d758a5edd065a0b1fd72833b65fd79687d91b3c2dd46b7_d667f71a1ea2fb60.jpg445 KB · Views: 350

0-02-05-c31358055c1e600471d758a5edd065a0b1fd72833b65fd79687d91b3c2dd46b7_d667f71a1ea2fb60.jpg445 KB · Views: 350 -

0-02-05-dfcd4de9f0700564201aaa5d8d6020a9b9c6b17d776fdd1582a34fb201972163_b19e6ac398d0c6fe.jpg436 KB · Views: 372

0-02-05-dfcd4de9f0700564201aaa5d8d6020a9b9c6b17d776fdd1582a34fb201972163_b19e6ac398d0c6fe.jpg436 KB · Views: 372 -

1.jpg382.2 KB · Views: 338

1.jpg382.2 KB · Views: 338 -

2.jpg401.2 KB · Views: 362

2.jpg401.2 KB · Views: 362

Hello! Could you share your 600hz crossover option?My crossover is 600hz lowpass for the woofer, 600hz highpass for the fullrange, both 1st order. The backfiring tweeter is crossed around 6600hz highpass 3rd order.

After making several copies of the Boenicke w5se with different crossovers, I came to the conclusion that they all have compromises in sound.

Are you happy with the sound of your Boenicke clone? With such a low crossover point, many phonograms may have some peak 1-2kHz of Fe85 diaphragm. This unpleasant on S, Sh, Ks sounds.

Listen to a song at sufficient volume Youn Sun Nah - Isn't It A Pity, for example.

dont suppose anyone has the cnc files for enclosures for these please? found a place local to me but they insist on having everything ready on a usb stick

i cant seem to find anythong bar some pictures of the nternal side of the speakers

i cant seem to find anythong bar some pictures of the nternal side of the speakers

Hi all,

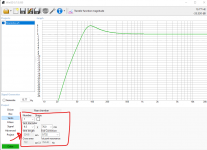

I would like to have your expert advice on the reflex port of the w5 clone. I have used the CAD model posted in this post and change some thicknesses just to make it more CNC friendly. Very minimal modification.

At the moment here is what I got:

· Internal volume 2.8L. If I remove the volume of the woofer it goes down to 2.5/2.6L. It depends also on the thickness of the walls. At the moment I keep at least 10mm. This volume is more or less confirmed by some articles I have read online about the w5. I am not so far off.

· Reflex port’s section is about 10mm x 76mm = 760mm2

· The length of the center line of the reflex port is about 210mm

Here is the problem.

I have simulated the driver W5-1138SMF in Winisd. At the moment I can make it work with a tuning Freq of 58Hz. The vent length is more or less correct. At the RMS power (40W) cone excursion works until 30 Hz and the air velocity is way too high.

It the port going to work ?

I would like to have your expert advice on the reflex port of the w5 clone. I have used the CAD model posted in this post and change some thicknesses just to make it more CNC friendly. Very minimal modification.

At the moment here is what I got:

· Internal volume 2.8L. If I remove the volume of the woofer it goes down to 2.5/2.6L. It depends also on the thickness of the walls. At the moment I keep at least 10mm. This volume is more or less confirmed by some articles I have read online about the w5. I am not so far off.

· Reflex port’s section is about 10mm x 76mm = 760mm2

· The length of the center line of the reflex port is about 210mm

Here is the problem.

I have simulated the driver W5-1138SMF in Winisd. At the moment I can make it work with a tuning Freq of 58Hz. The vent length is more or less correct. At the RMS power (40W) cone excursion works until 30 Hz and the air velocity is way too high.

It the port going to work ?

Attachments

hi do you have the stl files by any chance?It's a bit messy, but you can find all the parts there. The screw holes for the bass driver are for the peerless SLS-P830945 driver from the first generation of this speaker.

@ Gabriellobello: where do you have the measurements for the Reflex port from?

When I want to make a simple tube-style (round) reflex port: how can I convert the given data to a round common tube bass reflex port?

When I want to make a simple tube-style (round) reflex port: how can I convert the given data to a round common tube bass reflex port?

Last edited by a moderator:

I got them from the CAD model I have created. If you see the 3rd picture in my post you see that for WinISD I have used a squared port of 9.5mm x 76mm. This is how I modelled it. With these dimensions the resulting length of the reflex port is 224,8mm with a fb of 58Hz (picture 2). If you see in picture 1, the lenght of my reflex port at the moment is 205mm . So now I have 3 options:@ Gabriellobello: where do you have the measurements for the Reflex port from?

When I want to make a simple tube-style (round) reflex port: how can I convert the given data to a round common tube bass reflex port?

1. Reduce the section (maybe to 9mm x 76 as in the picture attached) to reduce the resulting port's length.

2. Increase the length of the port in my model to 224mm even if I don't think that 20mm will make a lot of difference.....

3. Increase tuning freq to match section & length.

These are all possible options. I am not worry, I am in the zone. The real problem is not the reflex port, but the air velocity. It's way too high and to bring it down the section should be much much larger and not compatible with the size of the speaker. I don't know how boenicke solved the problem. Unless you introduce a subwoofer filter under 40Hz.... or relative low volume.... or stay away from music going down to 30-40hz freq, but then what's the point of the reflex?

BTW you can use a round port as long as the resulting section area is the same. Apart from the losses between squared/round you should get the same results in term of port's lenght. The port calculation is based on the area of the section, not on the shape

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Boenicke W5 clone