Hi ZenMod

what happens if the irf9140 fails in the SissySIT and the SIT continues to work (SK180 in my case)?

After 4 years of music I suddenly fried a woofer of my Adamantes when I turned on the device (very bad experience).

what happens if the irf9140 fails in the SissySIT and the SIT continues to work (SK180 in my case)?

After 4 years of music I suddenly fried a woofer of my Adamantes when I turned on the device (very bad experience).

well, dc on output, unfortunately

though, SIT is so robust that it certainly lives

logic of your mishap is that mosfet simply gave up, tired of heat

what was your thermal arrangement for mosfet?

though, SIT is so robust that it certainly lives

logic of your mishap is that mosfet simply gave up, tired of heat

what was your thermal arrangement for mosfet?

mobile modushop 5U / 400mm. the transistors are placed on 4 mm aluminum angles. Temperature around 50 ° C of the heatsinks

I see gray drek under mosfets, certain recipe for catastrophe

use either Keratherm 86/82 or Alumina pads with goop

use either Keratherm 86/82 or Alumina pads with goop

your thingie:

Thermal Performance vs. Pressure

TO-220 Thermal Performance, ºC/W

@ 10 psi 2.82

@ 25 psi 2.64

@ 50 psi 2.41

@ 100 psi 2.13

@ 200 psi 1.9

Keratherm, check K/W:

https://cdn.shopify.com/s/files/1/1006/5046/files/kerafol_keratherm_red.pdf

try to beat conversion (area etc.) but numbers are saying what I suspected ........

not saying that it not exist, but I still didn't stumble on any silpad safe to put under 40W heated mosfet

max what you can allow is, say, 10C of difference between heatsink ditto by mosfet and mosfet case

Thermal Performance vs. Pressure

TO-220 Thermal Performance, ºC/W

@ 10 psi 2.82

@ 25 psi 2.64

@ 50 psi 2.41

@ 100 psi 2.13

@ 200 psi 1.9

Keratherm, check K/W:

https://cdn.shopify.com/s/files/1/1006/5046/files/kerafol_keratherm_red.pdf

try to beat conversion (area etc.) but numbers are saying what I suspected ........

not saying that it not exist, but I still didn't stumble on any silpad safe to put under 40W heated mosfet

max what you can allow is, say, 10C of difference between heatsink ditto by mosfet and mosfet case

The angle seems a bit thin at 4mm. It also looks like the mosfet is not fully on the angle. There seems to be a bit of overhang. When temperature is at a critical level, every little bit makes a difference, including the thermal interface as ZM said.

Since the mosfet is mounted on the angle, the heat sink temperature is not a good indicator of mosfet temperature, especially when the angle is thin. The angle is offering some thermal resistance between the mosfet and the heat sink.

Since the mosfet is mounted on the angle, the heat sink temperature is not a good indicator of mosfet temperature, especially when the angle is thin. The angle is offering some thermal resistance between the mosfet and the heat sink.

I fully agree with the factors enunciated by both ZenMod and Ben Mah.

Maybe I should have used Keratherm and maybe I should have considered using the angle exclusively for the SIT.

I was too confident and paid with a lot of pain.

Unfortunately you learn about mistakes.

Maybe I should have used Keratherm and maybe I should have considered using the angle exclusively for the SIT.

I was too confident and paid with a lot of pain.

Unfortunately you learn about mistakes.

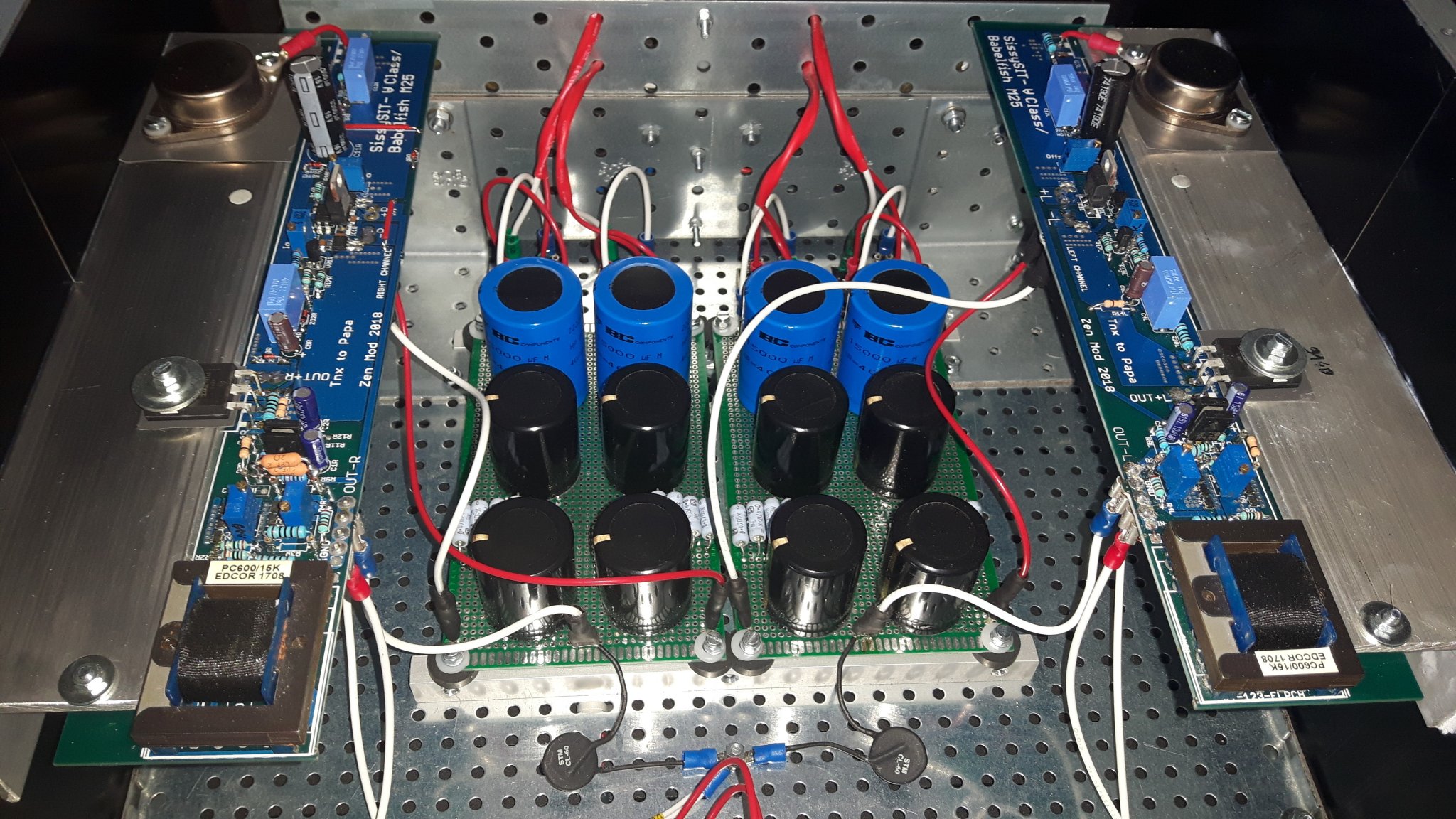

and I don't remember that you posted pictures of build, earlier .... or I would react about squishy silpads and maybe even thickness of L profiles

5mm is really minimum thickness (though, it still looks as 5mm on pictures)

if you did, sorry that I didn't spotted it

5mm is really minimum thickness (though, it still looks as 5mm on pictures)

if you did, sorry that I didn't spotted it

this gives me pause as I do not have any speaker protection on my sissy and i used similar angle bar but i did use keratherm. I have on occasion wondered if I was putting my speakers at risk but the amp has been solid since i built it, aside from minor dc drift on the output but never more than 100mV .

EDIT - based on ZM's comment, i did use 5mm angle. Still a wonderful amp

EDIT - based on ZM's comment, i did use 5mm angle. Still a wonderful amp

when you have TO247 mosfet heated close to 40W or even more, it's clever to use speaker protection

heck, one of the ways is to make it (protection) as separate unit; I'm not so anal about few connections more in speaker cables

heck, one of the ways is to make it (protection) as separate unit; I'm not so anal about few connections more in speaker cables

and I don't remember that you posted pictures of build, earlier .... or I would react about squishy silpads and maybe even thickness of L profiles

5mm is really minimum thickness (though, it still looks as 5mm on pictures)

if you did....................

I did not

I made choices, I was wrong, it's my fault.

... and maybe I should have equipped myself with a speaker protector

all my mistakes

in the construction I sent some posts:

https://www.diyaudio.com/community/...-building-tips-and-tricks.329316/post-5662572

I was about to ask for ZM's opinion on clever protection circuits in the Sissy. Looks like I got the answer already above. I think I may add a high quality board to mine.

Also, thoughts on NTC vs sophisticated soft start?

Also, thoughts on NTC vs sophisticated soft start?

Fuse question. There is a main fuse built into my switch, and because I did dual mono, and also for the easy ability to disconnect a channel, there are two more fuses after the main switch fuse.

What value should I use for the main fuse, and what value fuses for each channel?

What value should I use for the main fuse, and what value fuses for each channel?

common fuse - toss in whatever you can squeeze - concrete power pole, 1m rebar stick, 10cm nail , or 10A fuse

or - if you can wire it at back to omit fuse (some are made as that) , omit fuse

then choose wisely proper values of channel fuses and that's it

or - if you can wire it at back to omit fuse (some are made as that) , omit fuse

then choose wisely proper values of channel fuses and that's it

- Home

- Amplifiers

- Pass Labs

- Babelfish M25, SissySIT - general building tips and tricks