No error on Korg Application note schematic. Simply follow the internal connections. In parallel, the filaments are each fed3.3 Vthrough a separate 150 ohm resistor to the "outer" end of each filament. The two inner ends are tied together internally within the tube, and the common point of that tie is to be connected to ground.

In series, one filament is fed 3.3V through a single 110 ohm resistor. The internal tie point between the two filaments is left floating (not connected). Then, the end of the second filament is shown to be connected to ground.

Have not read the Application note, but it appears that the extra internal structure which is connected to ground in both parallel and series, is an internal shield between the two tube sections. An analogous shield is present in many "regular" small signal tubes, and must be connected to ground via the designated external pin.

In series, one filament is fed 3.3V through a single 110 ohm resistor. The internal tie point between the two filaments is left floating (not connected). Then, the end of the second filament is shown to be connected to ground.

Have not read the Application note, but it appears that the extra internal structure which is connected to ground in both parallel and series, is an internal shield between the two tube sections. An analogous shield is present in many "regular" small signal tubes, and must be connected to ground via the designated external pin.

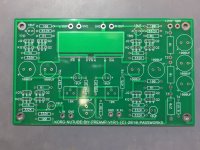

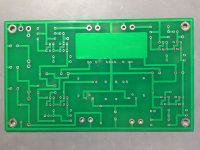

I would like to look at the possibility of powering the two Korg cathodes from a single 17mA constant current source and that means cutting and rerouting some traces. I can't find an image or a gerber of the diyaudiostore-provided pcb which I need in order to assign component numbers and follow trace connections. Does an image of the traces or a gerber exist anywhere?

Hi, I have hade the Nutube at 11,5v now for a long time. Want to try 9,5 volt, I have a Accuphase F-20 ( 2 way filter ) after the Nutube. It has phase shift on it ( 180’ ). Kan I switch there and that will work? Frank

I would like to look at the possibility of powering the two Korg cathodes from a single 17mA constant current source and that means cutting and rerouting some traces. I can't find an image or a gerber of the diyaudiostore-provided pcb which I need in order to assign component numbers and follow trace connections. Does an image of the traces or a gerber exist anywhere?

See attached

Attachments

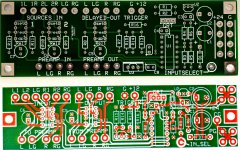

It took 10 days for the pcb order to get here from China and, of course, in those ten days I redid a lot of the board and rendered the received board not exactly obsolete because it should work fine, but maybe OBE because my new board is ¼ inch narrower which doesn’t sound like much until you realize the first board was only 1 ½ inches to start with and it needs to fit behind the Korg pcb in the diyaudiostore chassis. See image -- top is actual pcb, bottom is redesigned to be smaller and simpler.

I realized some things after ordering the first board:

1. When going from a 4-input board to a 2-input board I could reduce the input relays not to two, but to only one if I didn’t bother to terminate the unused input to ground through a resistor which is unnecessary because

2. I don’t have to worry about input switching noises because I can momentarily mute the output while the input switching occurs which means the termination resistors are not required. The relays switch in 3ms, it’ll be totally unnoticeable.

3. I found a trigger supply circuit which I hope will work, reduced the regulators from two to one by combining the current limiting and voltage regulation to a single LM317 – it’s a constant current battery charger configuration which I believe will do what I need it to do here. If excess current is drawn, the voltage drops to keep power at a constant value.

4. I added a chassis-ground pad to the ground aggregator area.

So, I’ll assemble the pcb I have on hand and verify it and if it all works as expected I’ll combine it with a constant-current circuit to the Korg cathodes (thank you, avdesignguru) and that should solve all noise issues both switching and power, provide a better signal path, and make it reasonable to switch the Korg on and off frequently while also extending the life of the Korg tube by eliminating the turn-on surge of excess current through a cold Korg.

I realized some things after ordering the first board:

1. When going from a 4-input board to a 2-input board I could reduce the input relays not to two, but to only one if I didn’t bother to terminate the unused input to ground through a resistor which is unnecessary because

2. I don’t have to worry about input switching noises because I can momentarily mute the output while the input switching occurs which means the termination resistors are not required. The relays switch in 3ms, it’ll be totally unnoticeable.

3. I found a trigger supply circuit which I hope will work, reduced the regulators from two to one by combining the current limiting and voltage regulation to a single LM317 – it’s a constant current battery charger configuration which I believe will do what I need it to do here. If excess current is drawn, the voltage drops to keep power at a constant value.

4. I added a chassis-ground pad to the ground aggregator area.

So, I’ll assemble the pcb I have on hand and verify it and if it all works as expected I’ll combine it with a constant-current circuit to the Korg cathodes (thank you, avdesignguru) and that should solve all noise issues both switching and power, provide a better signal path, and make it reasonable to switch the Korg on and off frequently while also extending the life of the Korg tube by eliminating the turn-on surge of excess current through a cold Korg.

Attachments

Is there any sort of plug for the Korg Triode? With all this talk of limited life could it just be a replaceable component and treat it like a tube?

So far I've read it has a limited life so turn it off when not in use and then read it's the in-rush voltage spike the kills it. I figure if I just keep a spare one around and change it every year or so, I'll not have to concern myself. I really do like this Pre and would like to keep it healthy.

So far I've read it has a limited life so turn it off when not in use and then read it's the in-rush voltage spike the kills it. I figure if I just keep a spare one around and change it every year or so, I'll not have to concern myself. I really do like this Pre and would like to keep it healthy.

IMO a socket is overkill - Nutube design life is 30,000 hours. 8760 hours per year gives 3.4 years between replacements, and replacing can't take more than 5 minutes clipping the leads, removing the old solder, and installing a new tube.

Now, I say this having looked at doing it on my current build 🙂 The pitch of the leads is small, so sockets with typical 0.1" spacing won't work. You could use individual lead sockets, but the Nutube leads are pretty soft and would be a PITA to insert without bending.

The solder sucker will do yeoman's work sometime in late 2024/early 2025...

Now, I say this having looked at doing it on my current build 🙂 The pitch of the leads is small, so sockets with typical 0.1" spacing won't work. You could use individual lead sockets, but the Nutube leads are pretty soft and would be a PITA to insert without bending.

The solder sucker will do yeoman's work sometime in late 2024/early 2025...

Point made and thanks. I assumed others were finding they were dying prematurely with all the smoke on this discussion. If not, then great. I won't worry.

Next question... is it better to leave it on or turn it off between sessions. I normally leave my equipment on all of the time except for extended travel.

Next question... is it better to leave it on or turn it off between sessions. I normally leave my equipment on all of the time except for extended travel.

Is there any sort of plug for the Korg Triode? With all this talk of limited life could it just be a replaceable component and treat it like a tube?

A socket sourced by Korg is available - you can see it on their webpage devoted to the tube. Unfortunately it is difficult to source. RS America had them at one time. You need to e-mail them directly.

Unlike others, I consider a socket or pins to be essential. Unsoldering and desoldering relatively small pins without lifting pads is difficult esp. for the relatively inexperienced. I socket all my ICs. I use Caig to clean the contacts and apply ProGold to reduce the possibility of corrosion. I am considering using Silclear (available form Mapleshade Audio) in the future. I use it on all my interconnects; I got tired of having to clean them thoroughly and re-treat with ProGold every two years or so. YMMV.

Considering how many of Papa's favorite parts are now unobtainium, how long will it be until the newTube joins the ranks. Buy 'em now while you can, the price can only go up.

I'm sure something new and interesting will come along before the Korg goes to NOS land. But that said, my next DIY order will likely contain another one for my NOS stash. I'm actually looking hard at Wayne's BA Linestage build already.

IMO a socket is overkill - Nutube design life is 30,000 hours. 8760 hours per year gives 3.4 years between replacements, and replacing can't take more than 5 minutes clipping the leads, removing the old solder, and installing a new tube.

The solder sucker will do yeoman's work sometime in late 2024/early 2025...

Five minutes, start to finish? YMMV, but here’s my mileage:

I disagree that replacing a Korg is a 5 minute job, or even that it's safe to perform for everyone who has built a Korg preamp. This is a tube that to replace requires cutting the pins and pulling it off the double-stick tape that has glued it to your pcb for the last four years and then sucking the old solder out of the pads before you can put the new tube in and solder it in place. And let’s not forget the need to clean the old sticky tape off the pcb and the possibility of damaging the pads or traces in the process of unsoldering, ungluing and cleaning and resoldering. Will this be straightforward for everyone of all skill levels? And, as skilled at soldering as I may or may not be, I don't want to do this every 3.4 years.

So, the Korg will last 30,000 hours = 3.4 years of continuous operation. If you left it on say six hours a day instead it would last 13+ years? Unfortunately, turning it off and on causes a current surge that reduces the life of the tube, so Catch-22 is in effect and it’s a wash.

But you can beat the Catch-22 and extend the life of your Korg by fixing the turn-on surge problem and then turning it off when not in use. There may be a down side but what would it be?

Maybe just me, but I would remove board from chassis to perform a job like removing/reinstalling tube. I like having the board in a jig so I can get at both sides.

Aside from the lead clipping, stub removal, solder sucking and resoldering, all the other complication remains the same with a socket.

I'll try to remember to post a walk through in '24 or '25.

I'll try to remember to post a walk through in '24 or '25.

Maybe just me, but I would remove board from chassis to perform a job like removing/reinstalling tube. I like having the board in a jig so I can get at both sides.

I agree. At a minimum you need to inspect and clean up the bottom of the board after desoldering. And the price of a surgical misstep is too high to be lazy about preparing for the surgery . . .

Is there a soft turn-on solution that is somewhat easily implemented and will address the surge damage problem?

Another point is... The Tube, Board, Parts cost a whole $75. Most of us have that invested in one output cable attached to it.

Another point is... The Tube, Board, Parts cost a whole $75. Most of us have that invested in one output cable attached to it.

Last edited:

Is there a soft turn-on solution that is somewhat easily implemented and will address the surge damage problem?

Another point is... The Tube, Board, Parts cost a whole $75. Most of us have that invested in one output cable attached to it.

I believe you missed a piece -- it costs $175 for pcb, parts, nutube.

No soft turn-on solution, but easy TO-92 LM317 solution to prevent startup surge to the cathode -- it's the high current delivery to the low resistance cold cathode that does the harm.

- Home

- Amplifiers

- Pass Labs

- B1 with Korg Triode