Hi guys,

I have zero coding skills and can't seem to generate an .exe to operate the Tic 36v4 I just purchased, can someone help?

Or do you guys think I should get the module from m1ni.de?

thanks

I have zero coding skills and can't seem to generate an .exe to operate the Tic 36v4 I just purchased, can someone help?

Or do you guys think I should get the module from m1ni.de?

thanks

In case the pop-up windows that appear when ARTA sends a rotation command bother you, here is a version compiled to suppress them.

Attachments

Last edited:

Hi all,

may I bother with a different question?

I just finished the work on an Ardunio based Stepper Controller using standard GRBL software to operate the Turntable.

My remaining Task is now to "translate" between ARTA and the GRBL Controller.

I thought I could achieve this by simply modifying the Python Source, but my programming skills seem inadequate.

The GRBL Controller receives simple ASCII Commands on a serial port (115200 8N1)

At this point in Time I can't make contact to Wim (the Author of the original TurnTable Software) nor to Yvo (Author of ARTA).

So I have to solve this somehow myself.

BR Ralf

may I bother with a different question?

I just finished the work on an Ardunio based Stepper Controller using standard GRBL software to operate the Turntable.

My remaining Task is now to "translate" between ARTA and the GRBL Controller.

I thought I could achieve this by simply modifying the Python Source, but my programming skills seem inadequate.

The GRBL Controller receives simple ASCII Commands on a serial port (115200 8N1)

At this point in Time I can't make contact to Wim (the Author of the original TurnTable Software) nor to Yvo (Author of ARTA).

So I have to solve this somehow myself.

BR Ralf

The software that is the subject of this thread is targeted at Tic devices only. I did consider using GRBL and generic stepper controllers but I abandoned that idea due to the simplicity and ease of use of the Tic and it's available command software.

The python script here could be useful as a base to working out an alternative. There is a library called pyserial that allows serial commands to be sent via python. That could then be complied into an exe for ARTA. The basic idea would be that the script would take the angle input argument that ARTA put's out and the appropriate GRBL command is then sent via serial to the controller.

Simple idea but it does require some ability with python to realise. Sorry I can't help you further.

The python script here could be useful as a base to working out an alternative. There is a library called pyserial that allows serial commands to be sent via python. That could then be complied into an exe for ARTA. The basic idea would be that the script would take the angle input argument that ARTA put's out and the appropriate GRBL command is then sent via serial to the controller.

Simple idea but it does require some ability with python to realise. Sorry I can't help you further.

Ralf, try to get Ivo’s attention here:

https://www.diyaudio.com/community/threads/arta.76977/page-71

this was his last post on that thread - so not THAT long ago:

https://www.diyaudio.com/community/threads/arta.76977/page-70#post-7528412

https://www.diyaudio.com/community/threads/arta.76977/page-71

this was his last post on that thread - so not THAT long ago:

https://www.diyaudio.com/community/threads/arta.76977/page-70#post-7528412

Thanks for coming back to me gents!

It wasn't my intention to hijack this thread, but I agree that it would be best writing a ARTA_GRBL tool instead.

One question remains to me for getting further:

Which kind of data does ARTA send to the Remote Control Program?

From ARTA self I can see:

Go to Zero

Break / Reset

Degrees

Disable Driver

plus maybe some feedback ARTA waits for to see the command has been executed.

Unfortunately the copy of Wims software I have is lacking any documentation about available commands

It wasn't my intention to hijack this thread, but I agree that it would be best writing a ARTA_GRBL tool instead.

One question remains to me for getting further:

Which kind of data does ARTA send to the Remote Control Program?

From ARTA self I can see:

Go to Zero

Break / Reset

Degrees

Disable Driver

plus maybe some feedback ARTA waits for to see the command has been executed.

Unfortunately the copy of Wims software I have is lacking any documentation about available commands

There are only two commands -r which is a set as zero or an angle value e.g. 5,10 etc.Which kind of data does ARTA send to the Remote Control Program?

ARTA just sends the commands when you run the measurement sequence and have an exe selected.

There is no checking or feedback. In ARTA_TIC there is logging so you can see what is actually happening or being sent.

Most of anything else you might want to do can be straight GRBL commands.

You can get a good idea of the basic python script functions for GRBL in their sampl scripts

https://github.com/gnea/grbl/tree/master/doc/script

https://github.com/gnea/grbl/tree/master/doc/script

Thanks so much ... in that case I guess I'm already 90% done!

My wife borrowed me her ChatGPT4 account and with additional reading of some beginners guides for Python I was able getting it up and running.

PCBs are expected to arrive early next week. Not sure people are interested, but I might report about it on my web page (not to further spoil this thread).

My wife borrowed me her ChatGPT4 account and with additional reading of some beginners guides for Python I was able getting it up and running.

PCBs are expected to arrive early next week. Not sure people are interested, but I might report about it on my web page (not to further spoil this thread).

Last edited:

Here is the final (I hope) iteration of retrofitting my rotating table. I change the Nema 17 stepper motor + gearbox to a huge and heavy Nema 23 direct drive stepper motor.

I was wondering why I had to adjust the theoretical value for the gear_ratio in the config file to go to the correct position. Error was around 3-4%

The reason was simple, I forgot the fundamental of mechanical engineering : play in the gearbox ! And as it accumulates with number of steps, it's a dead end.

Bingo, with this direct drive stepper motor, everything works as it should, the value to be inserted for the gear_ration is the theoretical value (in my case (177/12 x200/360)

I did several tests from within Arta ( 0 to +/-180° in 5, 10, 30° steps and it always go back exactly to the 0° position by using the "go to zero" button in Arta

I'm happy, the only remaining task will be finish the reinforcement of the supporting gear for very heavy loads. The lazy seven bearing is able to support more than 150 Kg by itself...

I finally bought myself a tic 36v4 and a NEMO 23 motor. I also bought a 'lazy susan' just like yours. I'm planning to make a rotation device kinda like yours. Do you have any advice? Close up photographs how you mounted the stepper motor? A source for the gear/sprocket you use?

I have decided to do the same thing myself and bought the Hafele slewing ring locally.

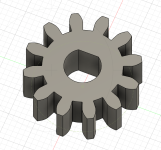

I have ordered this Spur Gear from Alixepress, it was the only one I could find that had the right number of teeth and bore size for the stepper.

https://www.aliexpress.com/item/100...o.order_list.order_list_main.5.22721802BqJrWo

I chose 14 teeth as it is the closest to producing a whole number of steps per degree from the stepper. The stepper I bought has a shaft that is 6.35mm 1/4". Most of the module 1.5 pinion gears I found had 6 or 8mm shafts. 8 would be OK as you could print a sleeve to fill the gap.

Madeler does one with 8mm

https://www.maedler.de/Article/21888114

This is the one or the 9 tooth version specified in the older ARTA turntable builds with a gearbox motor.

https://www.maedler.de/Article/21801100

I have ordered this Spur Gear from Alixepress, it was the only one I could find that had the right number of teeth and bore size for the stepper.

https://www.aliexpress.com/item/100...o.order_list.order_list_main.5.22721802BqJrWo

I chose 14 teeth as it is the closest to producing a whole number of steps per degree from the stepper. The stepper I bought has a shaft that is 6.35mm 1/4". Most of the module 1.5 pinion gears I found had 6 or 8mm shafts. 8 would be OK as you could print a sleeve to fill the gap.

Madeler does one with 8mm

https://www.maedler.de/Article/21888114

This is the one or the 9 tooth version specified in the older ARTA turntable builds with a gearbox motor.

https://www.maedler.de/Article/21801100

12 teeth gives you 8.148 steps per degree without microstepping.

14 teeth gives you 6.98 steps per degree. This error is less than 0.5 degree over 180 degrees.

14 teeth gives you 6.98 steps per degree. This error is less than 0.5 degree over 180 degrees.

Different sources quote different amounts of teeth, if you have counted and confirmed go with that number.

178 teeth changes the values slightly but 14 teeth is still the closest to a whole number of steps per degree

12 = 8.24

14 = 7.06

178 teeth changes the values slightly but 14 teeth is still the closest to a whole number of steps per degree

12 = 8.24

14 = 7.06

I was going to 3d print a large spur gear that fits over a lazy susan bearing I bought. Then belt drive from thr motor to minimise backlash. Direct gear to gear will have more backlash.

If you wanted to get fancy you could tryna 3d printed cycloidal drive like James Bruton designes for his robots.

If you wanted to get fancy you could tryna 3d printed cycloidal drive like James Bruton designes for his robots.

That was my original idea and I 3D printed a GT2 gear to use with a belt and pulley, both have pros and cons. Much easier to get an exact gear ratio with the belt.

Over time I changed my mind and decided to try the slewing ring and gear. If I make a rotating mic setup the original gear and pulley mechanism will likely be used.

Over time I changed my mind and decided to try the slewing ring and gear. If I make a rotating mic setup the original gear and pulley mechanism will likely be used.

Hi Tom,I finally bought myself a tic 36v4 and a NEMO 23 motor. I also bought a 'lazy susan' just like yours. I'm planning to make a rotation device kinda like yours. Do you have any advice? Close up photographs how you mounted the stepper motor? A source for the gear/sprocket you use?

This is the slewing ring I bought:

https://www.drehteller.com/slewing-...aluminium/61/slewing-ring-330-alu-sandblasted

It works well but there is an inherent little flaw in the design because the slewing ring teeth are just alu cast with only blast sanding and short depht. So with heavy unbalanced load the small, there is a small risc of tooth slip with the motor gear !

Don't get me wrong, overall, as it is now, it works 99% fine, only when making vertical polar with big and heavy loudspeaker (placed horizontally) I had this ocasionnal flaw...

I use a heavy 5 mm thick aluminium bracket to hold the stepper motor/gear on the bottom plate.

If I had to start from scratch again I would use a large belt (15 - 20 mm) instead like the original idea from Fluid. The tic controller/stepper motor / your little software work extremely well with ARTA

JC

This error is less than 0.5 degree over 180 degrees.

Much easier to get an exact gear ratio with the belt.

For full step I get 1.8 / 176 * 12 = 0.12 degree steps. The maximum that that can be off is half of that : 0.06 degrees.

I don't see why one would need an exact gear ratio. I think you calculated your accuracy like this:

180 degree x 7 steps_per_degree / 6.98 steps_per_degree = 0.5 degrees.

But you don't have to take 180x7=1260 steps, you can just take round(180x6.98)=1256 steps giving you 179.942 degrees resulting in a mismatch of only 0.057 degrees.

Of course everything above is theoretical and I'm sure other (mechanical) errors will be much larger.

- Home

- Loudspeakers

- Multi-Way

- Automatic Polar Measurements using ARTA, stepper motor and Tic Controller