I have been in the process of researching and preparing to build an automatic measurement table for a while as making a large number of measurements manually is no fun and very time consuming.

I came across a great website I thought had everything I needed laid out and documented.

http://nicholasmart.in/measurement_platform/

I started getting together all the things I would need and came across a stumbling block. The software exe to have ARTA communicate with the Tic controller is not on the website and the author did not respond to my message or another request posted on another forum that seems to be discussing the same thing.

https://www.audiosciencereview.com/...ar-measurements-using-arta.14282/#post-438440

I started looking at coding it myself and quickly realised it would take me a long and frustrating time if I tried. Fortunately @Tom Kamphuys agreed to help me out with his coding skills, the reason this software works and is available here is due to almost solely to Tom's work.

He has created a github page where the source code is available. At this time the exe is not there but is attached to this post in a zip archive with a basic readme file to explain it.

https://github.com/TomKamphuys/Arta_Tic

This software was created to control a Tic stepper motor controller from Pololu via the ticcmd command line utility. ARTA sends commands to the turntable driver exe which interprets and passes the correct commands to ticcmd.

I have chosen to use the Tic 36v4 as it has the maximum current capacity (4.0A without extra cooling) and a NEMA 23 stepper with a 2.8A maximum current rating. These are probably overkill in most circumstances but I wanted to have the option to move heavier loads. In theory if the friction can be kept low enough these components can move more than 100Kg in the configuration I am building.

My setup will use two 600mm pre cut red oak circular table tops with ball castors in between. The red oak was chosen as it was stiff, solid and on special for on $10 AUD each.

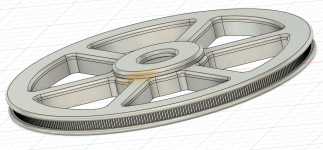

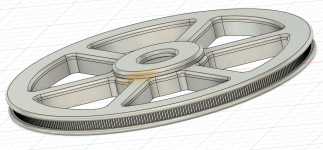

The gearing will be a 360 tooth GT2 main pulley mounted to the table top underside with a 20 tooth pulley on the stepper with a closed loop GT2 belt. Very similar to that in the above measurement platform article. Underneath there will be a pine base frame to aid in stability with levelling feet.

The pulley I have designed contains a 1" bearing that fits a 1" OD Aluminium tube piece used as a centre pin. I wanted to make this solid and low friction so the large bearing and tube seemed to fit the bill. I will make the pulley STL available once I have printed and tested it to make sure it works.

I have made a prototype without gears that functions as intended. I was able to make a 0 to 180 (10 degree increments) set of test measurements with ARTA on my laptop that took only a few minutes to complete.

@jcga was keen to update his existing ARTA turntable with a different motor and driver. He has also been able to use the software to move his table successfully, so I thought it worth making a thread to post the code in case this is useful to others.

Here is some information that might be helpful for set up to explain more of how the code functions

https://www.diyaudio.com/community/...-motor-and-tic-controller.387325/post-7769495

I went through a couple of different mechanisms before going back to belt drive. The final outcome can be seen here https://www.diyaudio.com/community/...-motor-and-tic-controller.387325/post-7776912

I came across a great website I thought had everything I needed laid out and documented.

http://nicholasmart.in/measurement_platform/

I started getting together all the things I would need and came across a stumbling block. The software exe to have ARTA communicate with the Tic controller is not on the website and the author did not respond to my message or another request posted on another forum that seems to be discussing the same thing.

https://www.audiosciencereview.com/...ar-measurements-using-arta.14282/#post-438440

I started looking at coding it myself and quickly realised it would take me a long and frustrating time if I tried. Fortunately @Tom Kamphuys agreed to help me out with his coding skills, the reason this software works and is available here is due to almost solely to Tom's work.

He has created a github page where the source code is available. At this time the exe is not there but is attached to this post in a zip archive with a basic readme file to explain it.

https://github.com/TomKamphuys/Arta_Tic

This software was created to control a Tic stepper motor controller from Pololu via the ticcmd command line utility. ARTA sends commands to the turntable driver exe which interprets and passes the correct commands to ticcmd.

I have chosen to use the Tic 36v4 as it has the maximum current capacity (4.0A without extra cooling) and a NEMA 23 stepper with a 2.8A maximum current rating. These are probably overkill in most circumstances but I wanted to have the option to move heavier loads. In theory if the friction can be kept low enough these components can move more than 100Kg in the configuration I am building.

My setup will use two 600mm pre cut red oak circular table tops with ball castors in between. The red oak was chosen as it was stiff, solid and on special for on $10 AUD each.

The gearing will be a 360 tooth GT2 main pulley mounted to the table top underside with a 20 tooth pulley on the stepper with a closed loop GT2 belt. Very similar to that in the above measurement platform article. Underneath there will be a pine base frame to aid in stability with levelling feet.

The pulley I have designed contains a 1" bearing that fits a 1" OD Aluminium tube piece used as a centre pin. I wanted to make this solid and low friction so the large bearing and tube seemed to fit the bill. I will make the pulley STL available once I have printed and tested it to make sure it works.

I have made a prototype without gears that functions as intended. I was able to make a 0 to 180 (10 degree increments) set of test measurements with ARTA on my laptop that took only a few minutes to complete.

@jcga was keen to update his existing ARTA turntable with a different motor and driver. He has also been able to use the software to move his table successfully, so I thought it worth making a thread to post the code in case this is useful to others.

Here is some information that might be helpful for set up to explain more of how the code functions

https://www.diyaudio.com/community/...-motor-and-tic-controller.387325/post-7769495

I went through a couple of different mechanisms before going back to belt drive. The final outcome can be seen here https://www.diyaudio.com/community/...-motor-and-tic-controller.387325/post-7776912

Attachments

Last edited:

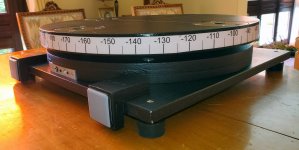

This is what the prototype looks like. I have used the motor mount plate from Nicholas Smart, custom 3D printed power supply bracket and Hall Sensor mount. I made an arm model that contains a heat set insert. A bolt goes through the insert with a rare earth magnet on the end this allows some adjustability of the sensor position. The Hall sensor is a digital trigger that sends a signal when the magnet is sensed. The homing routine moves forwards until the sensor triggers then moves away until it resets.

The down side to the switch I have is that it is Active low and can't easily be switched out of circuit for measurements. The Tic treats the switch as a limit and will not rotate beyond it. For now I run a manual routine of activating the limit switch in Tic Control Center, running the Homing Routine in Tic Control then disabling the limit switch.

It is debateable if the limit switch is even necessary as the table can be manually rotated to the 0 position and held there while the Tic is powered up. That setting then becomes 0 and seems to be returned to accurately by issuing a zero angle command through any of the command options.

The down side to the switch I have is that it is Active low and can't easily be switched out of circuit for measurements. The Tic treats the switch as a limit and will not rotate beyond it. For now I run a manual routine of activating the limit switch in Tic Control Center, running the Homing Routine in Tic Control then disabling the limit switch.

It is debateable if the limit switch is even necessary as the table can be manually rotated to the 0 position and held there while the Tic is powered up. That setting then becomes 0 and seems to be returned to accurately by issuing a zero angle command through any of the command options.

Attachments

-

19DD1CF5-35D4-486D-A562-6462B406AC0A.jpeg464.4 KB · Views: 232

19DD1CF5-35D4-486D-A562-6462B406AC0A.jpeg464.4 KB · Views: 232 -

ECFDA1DC-76C0-44A1-AE89-938882ADC923.jpeg416.9 KB · Views: 266

ECFDA1DC-76C0-44A1-AE89-938882ADC923.jpeg416.9 KB · Views: 266 -

916E2AFD-8CB6-48F1-9500-4E9722838464.jpeg370.6 KB · Views: 226

916E2AFD-8CB6-48F1-9500-4E9722838464.jpeg370.6 KB · Views: 226 -

ABF50805-1AD8-4D0A-88F5-D28AA4BB2E65.jpeg612.8 KB · Views: 217

ABF50805-1AD8-4D0A-88F5-D28AA4BB2E65.jpeg612.8 KB · Views: 217 -

B81AE1C4-0BA6-428B-A1BF-E0827D3C2F19.jpeg312.2 KB · Views: 224

B81AE1C4-0BA6-428B-A1BF-E0827D3C2F19.jpeg312.2 KB · Views: 224 -

B33CC5A1-AFC3-4F61-8151-59E1B60486AF.jpeg448.1 KB · Views: 230

B33CC5A1-AFC3-4F61-8151-59E1B60486AF.jpeg448.1 KB · Views: 230 -

3F8C70C3-D5E8-4677-9C07-DC70AB42EA66.jpeg182.7 KB · Views: 231

3F8C70C3-D5E8-4677-9C07-DC70AB42EA66.jpeg182.7 KB · Views: 231

Wow, that is really nice work all around! I still do lots of manual measurements manually, but luckily not frequently enough to need such a setup. Keep us posted.

Thanks for the kind words Charlie will do.Keep us posted.

I forgot to mention one thing about the software that it writes all the command line prints to a log file which can be viewed with a program like Baretail in real time. When the exe is used with ARTA and not called directly through a command prompt everything is hidden and hard to work out what is going on if nothing is happening.

Well @fluid you continue to be a damn excellent contributor! Thanks to you and Tom for the software, and documenting another relatively simple turntable design.

I was personally about to embark on my own build, using the design at m1n1.de. It uses a directly driven toothed platform rather than a belt, and I know some folk who have built it and had good results measuring very heavy cabinets without issue. The stepped gear element is purchasable and there’s good info on calibration along with some software and pre-made PCB boards, but it’s somewhat buried in a German YouTube video and old links within their site.

Just in case it’s useful as a hybrid or for others, I've attached a PDF export of the dumping ground for this project in my notes app - it has links to places to buy the bits you can't easily DIY, screenshots of the calibration info from the aforementioned video, and exports of the older ARTA application note document with more info.

On another note, I have actually encountered some odd data errors when making polar measurements in ARTA using the Outline ET turntable and a hemi-anechoic chamber. I never figured out exactly why, but there were significant amounts of incorrect data below 80Hz on several measurement steps. I can be certain it wasn't the room or nearby traffic, given the setup, but it persisted on repeat runs.

With Tom’s external app for motor control, it should be relatively easy to use other software and a timer countdown for the sweep trigger and processing, if you choose - even using REW (with max measurements bumped up in preferences) via external scripting tools like AutoHotkey or AutoIt.

@Tom Kamphuys is the control app’s Python script potentially usable in a *nix environment to do that?

I was personally about to embark on my own build, using the design at m1n1.de. It uses a directly driven toothed platform rather than a belt, and I know some folk who have built it and had good results measuring very heavy cabinets without issue. The stepped gear element is purchasable and there’s good info on calibration along with some software and pre-made PCB boards, but it’s somewhat buried in a German YouTube video and old links within their site.

Just in case it’s useful as a hybrid or for others, I've attached a PDF export of the dumping ground for this project in my notes app - it has links to places to buy the bits you can't easily DIY, screenshots of the calibration info from the aforementioned video, and exports of the older ARTA application note document with more info.

On another note, I have actually encountered some odd data errors when making polar measurements in ARTA using the Outline ET turntable and a hemi-anechoic chamber. I never figured out exactly why, but there were significant amounts of incorrect data below 80Hz on several measurement steps. I can be certain it wasn't the room or nearby traffic, given the setup, but it persisted on repeat runs.

With Tom’s external app for motor control, it should be relatively easy to use other software and a timer countdown for the sweep trigger and processing, if you choose - even using REW (with max measurements bumped up in preferences) via external scripting tools like AutoHotkey or AutoIt.

@Tom Kamphuys is the control app’s Python script potentially usable in a *nix environment to do that?

Attachments

Hi Kyleneuron,

I built that one you are referring to and unfortunately the original DC motor is no longer available, the two alternative that was suggested gave some erratic errors that I have never been able to eradicate. It still usable though.

I did test the new software/hardware from Tom and Fluid and it works well. I will come back here later with more details

I built that one you are referring to and unfortunately the original DC motor is no longer available, the two alternative that was suggested gave some erratic errors that I have never been able to eradicate. It still usable though.

I did test the new software/hardware from Tom and Fluid and it works well. I will come back here later with more details

Arta_tic is specifically written to translate ARTA calls (only -r and 'angle') to ticcmd commands. When you use AutoIt to automate all kinds of stuff I think it will be easy to have it call ticcmd directly.@Tom Kamphuys is the control app’s Python script potentially usable in a *nix environment to do that?

You're welcome I enjoy reading your contributions too 🙂Well fluid you continue to be a damn excellent contributor! Thanks to you and Tom for the software, and documenting another relatively simple turntable design.

I settled on belt drive being a good option after seeing MTG90 use it to drive the turntable platform directly without a toothed pulley.

This is strange and I suppose tricky to easily diagnose the cause. I did notice quite a lot of physical and electrical noise from my stepper because I was sitting right on top of it. The PWM current chopping used by the motor controller can be noisy. Changing the "Fixed off time" parameter in Tic Control alters the PWM frequency and I could change the audibility of the noise significantly by altering this value. I suspect rubber mounting the stepper might also be useful.I have actually encountered some odd data errors when making polar measurements in ARTA using the Outline ET turntable and a hemi-anechoic chamber. I never figured out exactly why, but there were significant amounts of incorrect data below 80Hz on several measurement steps. I can be certain it wasn't the room or nearby traffic, given the setup, but it persisted on repeat runs.

Tom and I discussed various options and settled to start with simplest option a basic program to connect ARTA and ticcmd. As Tom was helping me and not building something for himself to use I didn't want to ask too much.With Tom’s external app for motor control, it should be relatively easy to use other software and a timer countdown for the sweep trigger and processing, if you choose - even using REW (with max measurements bumped up in preferences) via external scripting tools like AutoHotkey or AutoIt.

There is an ARTA Autoit script that could be used as a base to adapt to REW, another thing that was too much for my brain at the current time.

Application note attached. It might be worth asking John Mulcahy if he has any interest in adding a turntable control option in REW, the multiple measurements and naming is already there the existing exe could be used with REW directly.

I also have an idea to try grbl on an arduino like Audiomatica did with their Open Source Turntable, then I could do it all via Bluetooth serial and do away with the USB cable

https://www.audiomatica.com/wp/?page_id=3024

Attachments

Here are some pictures from my rotating table based from Arta application note modified with a stepper motor, Tic controller and Arta_Tic from Tom

Attachments

Really nice design work. This should save a lot of time when making measurements. I manually rotate my unit-under-test, and walking back and forth 36 times does get tedious...

j.

j.

Yes, once I did my first iteration of the table in 2020 during the first major Covid peak and guess what, it's simply impossible to go back manually as before.This should save a lot of time when making measurements. I manually rotate my unit-under-test, and walking back and forth 36 times does get tedious...

Now, automatic 5° steps recording in full space is a snap. I even do that from other room (office) by taking my measurement gear remotely. Big big thank to Tom et Fluid. And I'm sure Fluid will come up with improvements like auto homing and more...

Jean-Claude

Outstanding Fluid, you're building one robust turntable !! Can't believe the weight you are planning for.

and you too Jean-Claude, very cool.....thanks for showing.. You're alignment techniques look awesome.

I admire and am jealous of, both the automation and the precision you guys build. 🙂

My setup is (and will always ,be I'm afraid) very manual.... and lacking real precision.

Lazy susan's of various sizes sit on a fabric wrapped compressed fiberglass steampipe tube, pointing out over a deck.

Also have a 3-mic rotatable boom off the deck as shown in photo...

My red neck, poor man's spinorama !!!

It's not so bad doing manual because with the speaker pointing out into space i can be behind it, and make a quick manual rotations and measurement grabs.

Worst part for me is the damn file naming....

and you too Jean-Claude, very cool.....thanks for showing.. You're alignment techniques look awesome.

I admire and am jealous of, both the automation and the precision you guys build. 🙂

My setup is (and will always ,be I'm afraid) very manual.... and lacking real precision.

Lazy susan's of various sizes sit on a fabric wrapped compressed fiberglass steampipe tube, pointing out over a deck.

Also have a 3-mic rotatable boom off the deck as shown in photo...

My red neck, poor man's spinorama !!!

It's not so bad doing manual because with the speaker pointing out into space i can be behind it, and make a quick manual rotations and measurement grabs.

Worst part for me is the damn file naming....

Nice,

increase somewhat the tube length and you can even go fishing from your balcony with the same gear 😉😉😉, I'm jealous

Jean-Claude

increase somewhat the tube length and you can even go fishing from your balcony with the same gear 😉😉😉, I'm jealous

Jean-Claude

I see your inventive genius extends past audio !!!! Good thinkin 😀Nice,

increase somewhat the tube length and you can even go fishing from your balcony with the same gear 😉😉😉, I'm jealous

Jean-Claude

Pack your turntable up and come on over. I'll take you fishing, and we can exchange jealousies !😎

best, mark

Seems like your lazy Susan is the perfect bed for an automated upgrade 😉My setup is (and will always ,be I'm afraid) very manual.... and lacking real precision.

Lazy susan's of various sizes sit on a fabric wrapped compressed fiberglass steampipe

Both Arta and rew have multiple measurement modes where the file naming follows the pattern you choose, have you not tried them?Worst part for me is the damn file naming....

- Home

- Loudspeakers

- Multi-Way

- Automatic Polar Measurements using ARTA, stepper motor and Tic Controller