After chatting with you guys on here I've had the rails on Y axis upgraded to Hiwin EGR.

It's a vicious cycle (..financially). 😀

You got that right! The Y axis seems to be the one that will benefit from the hiwin rails the most, unfortunately I couldn't stretch to the X axis too but I'm assured there'd be less of an upgrade from swapping those out.

UK stock, 2.2kw watercooled spindle and the VFD. That doesn't seem bad at all for the money.

That looks very good. Maybe too good for the money.

Even factoring in the cheeky 100 quid for delivery, that's still incredibly cheap (£257). A top end router would cost more than that alone.

I've no experience with water cooling, so I've no idea if it needs an external pump, or just a passive tank (and it pumps the water itself). Very tempting to try one out for that price I must admit.

Though I love the comment "PASS ISO9001 quality certification which means this item is the top quality I item". Errr. No. That's not what ISO9001 means. At all.

After chatting with you guys on here I've had the rails on Y axis upgraded to Hiwin EGR.

Money pit! 😀

Its obviously a Chinese product at that price and the description reads along those lines too. Nothing wrong with that providing you accept the possibility of minimal support and problematic warranty issues.

I mailed the seller about the pump yesterday as nothing is shown in the image for auction.

He said it needs an external submersible pump(not supplied) and doesn't need a high flow rate. Virtually any pond fountain style pump can be used and these aren't much money from the quick search I've done.

I got the distinct impression I was chatting with a Chinese seller even though the item is listed as shipping from the UK. Perhaps they have an agent over here or something or maybe that explains the high postage. Dunno.

The auction is very vague so I asked for more detailed specs and here's what he gave:

I'm going to see how the Kress fares but if its not up to the job I'll likely order one of these. If you do get one in the meantime let me know how you get on with it and like wise if I do the same.

I mailed the seller about the pump yesterday as nothing is shown in the image for auction.

He said it needs an external submersible pump(not supplied) and doesn't need a high flow rate. Virtually any pond fountain style pump can be used and these aren't much money from the quick search I've done.

I got the distinct impression I was chatting with a Chinese seller even though the item is listed as shipping from the UK. Perhaps they have an agent over here or something or maybe that explains the high postage. Dunno.

The auction is very vague so I asked for more detailed specs and here's what he gave:

- PID control; advanced calculous PID closed-loop arithmetic, quick responding speed and high suitability

- Easy PLC function can realize 16 legs of speed and inverter control function

- RS485 communication port, adopting standard international MODBUS main circuit control

- With extremely strong anti-jamming capability

- Low output ratting torque 0.5HZ-150%, low speed running ability

- Carrier adjustable by 16KHZ, completely soundless working environment

- Auto voltage regulation (AVR) technique, for ensuring the inverter load capability

- Various control technique by both synchronization and non-synchronization, dynamically realize fast starting without changing brakes

- With perfect error protection and short circuit starting protection capability

I'm going to see how the Kress fares but if its not up to the job I'll likely order one of these. If you do get one in the meantime let me know how you get on with it and like wise if I do the same.

It seems to me that there should be some sort of cool-compressed air alternative for working with wood (..as opposed to water-cooling for metal).

It seems to me that there should be some sort of cool-compressed air alternative for working with wood (..as opposed to water for metal).

The cooling part refers to the keeping down the temperature of the router motor and moving parts. Kinda like an air cooled pc versus a water cooled one.

Water cooled spindles generally run quieter than air cooled ones as they are sealed with few to no openings and don't have a fan in there creating noise by air disturbance.

The cooling part refers to the keeping down the temperature of the router motor and moving parts. Kinda like an air cooled pc versus a water cooled one.

Water cooled spindles generally run quieter than air cooled ones as they don't have a fan in there creating noise by air disturbance.

Many makes of water-cooling, because it's pretty much essential for bit life with hard materials like most metal. (..edit, oh I see - talking about non-bit water cooling.. my bad.)

But (as far as the bit is concerned) are there any that are not simply compressed air (to cool the bit and keep the surface clean), but are also actively cooled air?

..it's not really something I've thought about until now. (..even though I've seen runs done on mdf that used bit's up pretty quickly.) Noise would go WAY up though..

Last edited:

I think we got our wires crossed, a water cooled spindle circulates water around the spindle motor and ignores the bit. Its a quieter alternative to air cooled spindles.

Your talking about keeping the bit cool when cutting which is valid too. My guess is that the rotation of the bit when cutting wood is the cooling. Pretty poor I know but I've not seen any compressed air bit cooling on my limited cnc travels.

Your talking about keeping the bit cool when cutting which is valid too. My guess is that the rotation of the bit when cutting wood is the cooling. Pretty poor I know but I've not seen any compressed air bit cooling on my limited cnc travels.

I think we got our wires crossed, a water cooled spindle circulates water around the spindle motor and ignores the bit. Its a quieter alternative to air cooled spindles.

Yeah, sorry about that.. 😱

> Its obviously a Chinese product at that price and the description reads along those lines too

I suspect the £100 postage is because eBay sellers pay a cut of the selling price, but not of the postage. So selling an item for £257 with free postage would cost the seller a higher fee than £157 for the item and £100 for shipping.

They appear to claim the kit's in the UK, so not coming direct to you from China.

Guess there's nothing fundamentally wrong with setting up a bath of water with a pump. Would be wary of water near PCs and control boxes, but I guess it could be done OK, as long as the piping didn't pop off the spindle!

> But are there any that are not simply compressed air (to cool the bit and keep the surface clean), but are also actively cooled air?

Not that much need for blowing air with wood cutting (plus it'd create quite a mess). I suspect it wouldn't have a massive effect on the cutter temperature, and with the correct feed & rpm rates you can cut without heat issues. Different story for hardcore metal cutting obviously.

I suspect the £100 postage is because eBay sellers pay a cut of the selling price, but not of the postage. So selling an item for £257 with free postage would cost the seller a higher fee than £157 for the item and £100 for shipping.

They appear to claim the kit's in the UK, so not coming direct to you from China.

Guess there's nothing fundamentally wrong with setting up a bath of water with a pump. Would be wary of water near PCs and control boxes, but I guess it could be done OK, as long as the piping didn't pop off the spindle!

> But are there any that are not simply compressed air (to cool the bit and keep the surface clean), but are also actively cooled air?

Not that much need for blowing air with wood cutting (plus it'd create quite a mess). I suspect it wouldn't have a massive effect on the cutter temperature, and with the correct feed & rpm rates you can cut without heat issues. Different story for hardcore metal cutting obviously.

Guess there's nothing fundamentally wrong with setting up a bath of water with a pump. Would be wary of water near PCs and control boxes, but I guess it could be done OK, as long as the piping didn't pop off the spindle!

Now that wouldn't bother me at all once I'd plumbed it all in and checked the connections are secure and leak free. I've had a couple of watercooled PC's in the last 4 years, the latest a Zalman LQ1000, and never had one mishap but I am a little OCD with the initial install so perhaps that helps.

BTW you can also get non conductive coolant too. I use this with the PC.

Thermochill EC6 Non Conductive Coolant - Deep Red [WA-EC6RD] from WCUK Online

I haven't tested the claims by throwing a load of it over a live PC motherboard for example but many watercooling enthusiast swear its saved their hardware on more than one occasion.

BTW you can also get non conductive coolant too. I use this with the PC...

Interesting.

BTW Some potentially useful links:

Cheap HuanYang VFD's

Mach3 Controlling Huanyang HY02D223B 2.2KW VFD

Huanyang VFD controller plugin

One more tip.

I use Dropbox to sync the program files. I generate them on the PC at work, and they just appear in the dropbox on the PC in the shed (which is wifi...).

This way I am running the latest version of the program (there are no copies floating around), but Mach3 is running from a local copy, in case of network issues.

Mach 3 loads the entire program into memory, so it's not so much of a problem, but many mill controllers drip feed, and you have to be 100% confident of the network if you are drip feeding over LAN.

Whatever you do, make sure you don't have different versions of the same program file kicking around on different pcs....or you will run the wrong one sooner or later.

I use Dropbox to sync the program files. I generate them on the PC at work, and they just appear in the dropbox on the PC in the shed (which is wifi...).

This way I am running the latest version of the program (there are no copies floating around), but Mach3 is running from a local copy, in case of network issues.

Mach 3 loads the entire program into memory, so it's not so much of a problem, but many mill controllers drip feed, and you have to be 100% confident of the network if you are drip feeding over LAN.

Whatever you do, make sure you don't have different versions of the same program file kicking around on different pcs....or you will run the wrong one sooner or later.

I requested a demo copy of SolidCAM Xpress when I rang the dealer the other day and sure enough it arrived this morning. Its fully featured but doesn't output g-code so you can't produce anything with it.

After installing and playing around for about 3 hours I can honestly say I haven't got a clue 😀 I don't know whether the program itself is complicated or if I'm just too much of a noob to understand it all. There's some kickstart tutorials on the DVD and I have gone through the first few parts of lesson 1 but its hard to relate the functions used in the demo example to my work. Initial impressions of SolidCAM are that's its very feature rich but complicated for a beginner. I'm probably in over my head with this particular one but I'll keep chipping away at it.

Out of curiosity what's the most friendly CAM program out there or are they all pretty much on a par?

After installing and playing around for about 3 hours I can honestly say I haven't got a clue 😀 I don't know whether the program itself is complicated or if I'm just too much of a noob to understand it all. There's some kickstart tutorials on the DVD and I have gone through the first few parts of lesson 1 but its hard to relate the functions used in the demo example to my work. Initial impressions of SolidCAM are that's its very feature rich but complicated for a beginner. I'm probably in over my head with this particular one but I'll keep chipping away at it.

Out of curiosity what's the most friendly CAM program out there or are they all pretty much on a par?

None of the cam packages are going to be as easy as you'd assume they would be (or should be) 🙄

The BEST way to choose a package is to get the reseller to show you how to create a toolpath for some of YOUR parts. Best to get them to do it on the spot, without giving them the models beforehand. That way you get to see how easy the software is to use AND how good the reseller is.

Your parts are relatively simple, and once you've done a couple of toolpaths you'll be fine.

Sent from my LT18a using Tapatalk

The BEST way to choose a package is to get the reseller to show you how to create a toolpath for some of YOUR parts. Best to get them to do it on the spot, without giving them the models beforehand. That way you get to see how easy the software is to use AND how good the reseller is.

Your parts are relatively simple, and once you've done a couple of toolpaths you'll be fine.

Sent from my LT18a using Tapatalk

Whatever you do, make sure you don't have different versions of the same program file kicking around on different pcs....or you will run the wrong one sooner or later.

Good points. My controller PC is a machine running XP, that's had a number of bits stripped out to reduce potential resource hogs (I have a file somewhere that explains the details, could dig it out if people want). The machine isn't networked, and I take gcode to it on a USB stick. There's nothing else on the PC apart from Mach 3.

Out of curiosity what's the most friendly CAM program out there or are they all pretty much on a par?

Would still suggest SheetCAM. It won't integrate with your toolset (you have to export an old text format of DXF and load into the package) but it will reload a drawing and update any cutting paths you've already added so you don't have to start from scratch for a minor drawing tweak.

It'll do drilling, cutting paths and pockets. No 2.5D work.

You can download a trial that'll output some tiny files: Downloads

To simulate, I use CNCSimulator (Download). It's free, simple and gives decent results. Not the best program in the world, but it does the job, shows if I've got problems with lead-in/lead-out arcs hitting parts, gives me an idea of whether tabs are in sensible places etc. Did I mention it's free 🙂.

I have one of those water cooled spindles but haven't hooked it up yet. I had mine shipped straight from China. I have a pc water cooling pump and radiator with pc fans on it. I'll also have a little tank plumbed in. Some people just use an open bucket, but that seems like a bad idea to me in an environment where there's tons of airborne dust. On the vfd, those have been where I've seen the majority of problems reported. The common solution is to get a Hitachi VFD. You can get these for not a lot more money, and they have models that will even run on 120VAC for some of the lower output levels (I'm not sure about 2.2kW specifically). You could also use many other makes of vfd as long as they go up to 400Hz (max frequency the high speed spindles typically run at). For example I have some Mitsubishi vfd's that I use. I bought them at an auction very cheaply.

Here's a thread with 1200 replies starting 3 years ago on the Chinese spindles - tons of information in there although a lot of it is 'me too' replies.

Cheap 1500W Chinese spindle, experiences? - CNCzone.com-The Largest Machinist Community on the net!

Here's a thread with 1200 replies starting 3 years ago on the Chinese spindles - tons of information in there although a lot of it is 'me too' replies.

Cheap 1500W Chinese spindle, experiences? - CNCzone.com-The Largest Machinist Community on the net!

Ha! Progress...

It was a lazy Sunday with nothing doing so I've spent the best part of the day looking at tutorials around the web and playing within SolidCAM.

Slowly but surely I'm getting the basics down and so far I've managed to:

Not a particularly long list but it'll cover around ~70% of the parts made by the machine. The other 30% require some 3D trickery and other operations.

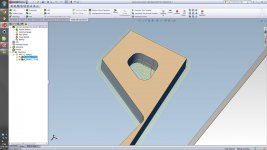

Some shots of SolidCAM in action:

Stock material and part

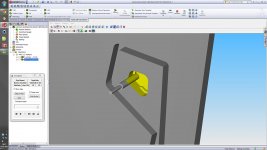

Tool paths

And simulation to verify

It was a lazy Sunday with nothing doing so I've spent the best part of the day looking at tutorials around the web and playing within SolidCAM.

Slowly but surely I'm getting the basics down and so far I've managed to:

- Defined a coordinate system and machine start point

- Defined and created cutters

- Create stock material and define the model to be cut within this.

- Use profile and pocket cuts with roughing and finish cuts. I found out how to leave 0.5mm material on the depth too so as not to hit the spoil board.

Not a particularly long list but it'll cover around ~70% of the parts made by the machine. The other 30% require some 3D trickery and other operations.

Some shots of SolidCAM in action:

Stock material and part

Tool paths

And simulation to verify

Attachments

I'm pretty impressed with SolidCAM but I would like to try out more packages so I've downloaded the demo version of Vectric VCarvePro. This one is more within my budget at £395.

VCarve Pro

VCarve Pro

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Apollo Construction Diary