Well, having nothing to lose, performed silicone treatment on my both pairs of Stages. Used A + B component Ecoflex – 00-30 and silicon oil. Firstly, tried several different mixtures but already mentioned 2/3 of silicone mass and 1/3 silicon oil looked the best.

I had no luck with medical syringe, used 3-4 different sizes, but could not perform equal flow which was rather erratic making a big spill. So, I tried applying mixture with ordinary artist tiny brush which perform very nice. Silicone applied only on the front side.

I tried to remove the back perforated metal plate which is factory fixed to mdf frame with silicone, but that was very hard, the plate began to bend, so I decide to leave it.

Sonically, can’t say that I can hear any difference, but I am sure that the current foam condition will not deteriorate.

Just to point, it is important to mix both silicone components and oil thoroughly, at least about 5 min.

I had no luck with medical syringe, used 3-4 different sizes, but could not perform equal flow which was rather erratic making a big spill. So, I tried applying mixture with ordinary artist tiny brush which perform very nice. Silicone applied only on the front side.

I tried to remove the back perforated metal plate which is factory fixed to mdf frame with silicone, but that was very hard, the plate began to bend, so I decide to leave it.

Sonically, can’t say that I can hear any difference, but I am sure that the current foam condition will not deteriorate.

Just to point, it is important to mix both silicone components and oil thoroughly, at least about 5 min.

First of all we all have something very special to loose. Apogee is something special.

I studied a lot the design of these speakers (because i am a product designer).

There are a lot of subtle design issues here. It looks simple but it's not.

I did fix the prblem with the bass ribbon but it's not a professional fix. It works and this is important since i couldn't use and hear these magic speakers.

Everybody wrote about how great they and is the truth.

Making parts for these speakers is very very difficult. It takes experience.

At this moment there is no solution for Stages.

There is one solution. Graz to have enough orders to start the production of the ribbon. So, owners of the Stage, consider this: to open a list of the people who want bass ribbons for the Stage. That way we will convince Mr.Graz to do it.

He is very involved with Apogee and we have to support him with orders, otherwise it will come a day when we will speak about Apogee as a past.

Personally i will order two sets.

I studied a lot the design of these speakers (because i am a product designer).

There are a lot of subtle design issues here. It looks simple but it's not.

I did fix the prblem with the bass ribbon but it's not a professional fix. It works and this is important since i couldn't use and hear these magic speakers.

Everybody wrote about how great they and is the truth.

Making parts for these speakers is very very difficult. It takes experience.

At this moment there is no solution for Stages.

There is one solution. Graz to have enough orders to start the production of the ribbon. So, owners of the Stage, consider this: to open a list of the people who want bass ribbons for the Stage. That way we will convince Mr.Graz to do it.

He is very involved with Apogee and we have to support him with orders, otherwise it will come a day when we will speak about Apogee as a past.

Personally i will order two sets.

DAMIC I used what is called " flowable silicone". It was not two part, no mix just comes in a tube like regular silicone sealant but it is the viscosity of honey. At the time I bought it was marketed as a car windshield leak repair. The idea was that it would "flow" into the cracks. It goes on easily with a syringe and literaly flows into all the foam and voids. was very easy to use.

As far as the sound... I have spent the last year full time developing a small ribbon design that goes to 500 Hz. One of the biggest issues in the development was cracking near the terminations. Many many different termination designs / materials were tested to damp here. None of them had a significant effect on sonics but some were much more effective than others with absorbing energy and thus giving good reliability.

Good points LucianTH

IMO from years of development in this area and others I too now see there are many refined details in the App Bass panel that it took me years to uncover. Im a slow learner 😉

The double sided design of the Stage panel will be a bit tougher to build than the single sided ones. Not so much the corrugating but the laminating.

As far as the sound... I have spent the last year full time developing a small ribbon design that goes to 500 Hz. One of the biggest issues in the development was cracking near the terminations. Many many different termination designs / materials were tested to damp here. None of them had a significant effect on sonics but some were much more effective than others with absorbing energy and thus giving good reliability.

Good points LucianTH

IMO from years of development in this area and others I too now see there are many refined details in the App Bass panel that it took me years to uncover. Im a slow learner 😉

The double sided design of the Stage panel will be a bit tougher to build than the single sided ones. Not so much the corrugating but the laminating.

Last edited:

Who's not free to talk?

I was just encouraging "lowmass" to stay on topic for this thread.

His other ribbon efforts sound interesting, but start another thread and let's hear about them and see some photographs. He's yet to post any information on them at all.

I don't think we can expect Graeme to start producing Stage bass ribbons......unless he changes the mindset he's had for many years. Stage owners who develop bass transducer problems are out of luck unless a silicone repair is utilized.

Cheers,

Dave.

I was just encouraging "lowmass" to stay on topic for this thread.

His other ribbon efforts sound interesting, but start another thread and let's hear about them and see some photographs. He's yet to post any information on them at all.

I don't think we can expect Graeme to start producing Stage bass ribbons......unless he changes the mindset he's had for many years. Stage owners who develop bass transducer problems are out of luck unless a silicone repair is utilized.

Cheers,

Dave.

Last edited:

Davey the info I add here is intended to help those making decisions. IMO it is on topic.

Its your wording that raises my red flag.

Btw all how do you post pics here?? I can post pics of some older stuff thats been shelved that pertains specifically to attempts to design a new kind of "panel" to replace but its not tensioned film type. It was attempt at a hybrid planer / dynamic driver.

As ar as the recent development I can give some potentialy helpful advice learned but cannot give pics as the product has a patent in process being filed soon. Company web site in about 2 weeks or so....

Its your wording that raises my red flag.

Btw all how do you post pics here?? I can post pics of some older stuff thats been shelved that pertains specifically to attempts to design a new kind of "panel" to replace but its not tensioned film type. It was attempt at a hybrid planer / dynamic driver.

As ar as the recent development I can give some potentialy helpful advice learned but cannot give pics as the product has a patent in process being filed soon. Company web site in about 2 weeks or so....

Last edited:

Cheers....heheh.....Dave sounds like a bully!...that likes being one...it lonely at the top!

Last edited:

Best to upload images. click on 'go advanced' tab when posting and you can upload pictures. That way they are correctly sized and there for all to see.

You can add attachments down below using the "attach files" section of the "Additional Options" block.

edit: Sorry, Bill beat me to it.

If your efforts are commercial, that puts you in the same boat as Graeme. The fellas here have a section for commercial efforts.

If you can translate any of your design/fabrication skills into help for DIY'ers, that would be great. But if everything is hiding behind a patent, it seems much less interesting to me and (possibly) the user base here.

tyu,

As usual your insight is mind-blowing. 🙂

Dave.

edit: Sorry, Bill beat me to it.

If your efforts are commercial, that puts you in the same boat as Graeme. The fellas here have a section for commercial efforts.

If you can translate any of your design/fabrication skills into help for DIY'ers, that would be great. But if everything is hiding behind a patent, it seems much less interesting to me and (possibly) the user base here.

tyu,

As usual your insight is mind-blowing. 🙂

Dave.

Last edited:

Dave ....thanks for the years ....helping people with all your great understanding of all things Apogee....an all other panel type speakers...an ways to get the best sound!

An yes ...your insights ...are mind-blowing..... in so minny ways

cheers

An yes ...your insights ...are mind-blowing..... in so minny ways

cheers

Last edited:

Yes I have a commercial product coming BUT I have always had a heart for DIY. Thats where it came from. I like to give what info I can to that end. Only mentioned it as it is reason cannot always post pics.

Cannot give the fundamental design and patent details BUT can give my advice at some level and enjoy doing so.

If thats outside the bounds I will of course stand down.

Cannot give the fundamental design and patent details BUT can give my advice at some level and enjoy doing so.

If thats outside the bounds I will of course stand down.

DIY is definitely INSIDE the bounds and what this forum is for. If you have a commercial product/interest, obviously you are free to divulge (or not divulge) any information you so choose. But I think it's important to be clear regarding this DIY/commercial separation. (The same issue I pointed out to Graeme a while back.)

Cheers,

Dave.

Cheers,

Dave.

Last edited:

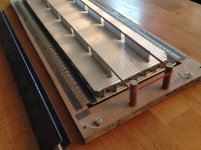

some old design work. Attemp at a linear array riggid across width/ flexy and damped along leignth. Honey comb core Al skins, a bit different in that the skins are corrugated to achieve flexy along length. Suspension is fiberglass half roll tuned in this pic by slits. Suspension Q also tuned by viscus material attached to suspension but not shown. Unit had almost 3/4 inch pk -pk travel in a panel approx 30 % smaller than Stage. Sensativity about the same but solid 5 ohms. Voice coil is litz wire and flexible. Magnet assembly at left. This would all bolt into a typical dipole frame work.

Midrange wasnt up to par BUT it worked well upto about 200 hz. Daughter wanted to mount to back of rear seat in car as a sub. Called it " Bass Plate" ha...

Midrange wasnt up to par BUT it worked well upto about 200 hz. Daughter wanted to mount to back of rear seat in car as a sub. Called it " Bass Plate" ha...

Attachments

Last edited:

Well Dave...what do you call your way.... tell people how you see things?....

Because most react negatively....to you being all knowing.....

like then posting the ..hate speech..... comment your self ....?

like I guess some one may have missed... me tell you that's what I see in your words............your just trolling around bullying...anyone from site to site....like it your way are know way.....

I think its to bad...you have so much to add...but the way you add it....I guess you don't care....

I come here to get others input-info....not to tell anyone not to add there findings

cheers....

Because most react negatively....to you being all knowing.....

like then posting the ..hate speech..... comment your self ....?

like I guess some one may have missed... me tell you that's what I see in your words............your just trolling around bullying...anyone from site to site....like it your way are know way.....

I think its to bad...you have so much to add...but the way you add it....I guess you don't care....

I come here to get others input-info....not to tell anyone not to add there findings

cheers....

Last edited:

I personally have no issues with Dave. He is consistent that he wants to seperate DIY and commercial. No problem there. He has some 'history' with Graz, but I can read around that.

Oh and he can string a complete sentence together 😛

Oh and he can string a complete sentence together 😛

Bill... all this comes from the guy that was the first to sine up on the great Diy Graz post .... that was all about commercial sales.......

cheers

cheers

Last edited:

Im a little surprised someone with totally trashed Stage panels hasnt simply tryed stripping them and installing a simple flat tensioned film diaphragm. Ther not teribly hard to make. A bit tedious cutting multiple traces but doable. Overall sonic will be just short of App panel in some ways but not bad.In fact if you use some nodal buttons like on Maggies it should be preety good.

Im not sure what method some here are using. I simply....

1- on a glass panel spray a very light coat of that cheap spray adhesiv like super 77, very thin light coat.

2- roll your foil out on this and use a cloth to rub the foil down flt and smooth

3- cut your traces using a roller cutter from fabric store

4- on a seprate frame made nice and stiff with big open area, roll the mylar film out and tension it with about a hundred pds of tape around edges. just keep going round and round retightening tapes till all it very tight.

5- spray a heavy coat of same spray on the foil

6- lay the tensioned film over the foil and rub it down smooth with cloth to adhear

7- starting from onecorner slowly lift tensioned film /frame up and foil will come with it.

9- may have to retension with a few new tapes at edges

10- lay bead of silicone adhesive around the frame you applying your fancy new diaphragm to and lay down the tensioned diaphragm

11- push down areas evenly where silicone adhesive is and waith 24 hrs for i to cure, cut diaphragm edges away

It will have some ugly resonances around 200 hz but for most part you will be suprised at the result.

i found 1/2 mil mylar and .7 mill foil to work about best. Thats the same foil thickness you get fron standard kitchen foil BTW not the "heavy duty" stuff. Its not tempered but if your not corrugating its fine. Havent done the math but I suspect 3 traces one side will get you in the ball park of 3 ohms

yes its slumin it but hey if your panels are trully ripped useless it doesnt cost much to try this. A few dollars of foil and plastic.

Im not sure what method some here are using. I simply....

1- on a glass panel spray a very light coat of that cheap spray adhesiv like super 77, very thin light coat.

2- roll your foil out on this and use a cloth to rub the foil down flt and smooth

3- cut your traces using a roller cutter from fabric store

4- on a seprate frame made nice and stiff with big open area, roll the mylar film out and tension it with about a hundred pds of tape around edges. just keep going round and round retightening tapes till all it very tight.

5- spray a heavy coat of same spray on the foil

6- lay the tensioned film over the foil and rub it down smooth with cloth to adhear

7- starting from onecorner slowly lift tensioned film /frame up and foil will come with it.

9- may have to retension with a few new tapes at edges

10- lay bead of silicone adhesive around the frame you applying your fancy new diaphragm to and lay down the tensioned diaphragm

11- push down areas evenly where silicone adhesive is and waith 24 hrs for i to cure, cut diaphragm edges away

It will have some ugly resonances around 200 hz but for most part you will be suprised at the result.

i found 1/2 mil mylar and .7 mill foil to work about best. Thats the same foil thickness you get fron standard kitchen foil BTW not the "heavy duty" stuff. Its not tempered but if your not corrugating its fine. Havent done the math but I suspect 3 traces one side will get you in the ball park of 3 ohms

yes its slumin it but hey if your panels are trully ripped useless it doesnt cost much to try this. A few dollars of foil and plastic.

Last edited:

lowmass... well you pull-move any of the magnets with your new foil traces?.....can you move them or well they brake?...you may not know...

I have seen others use foil strips on mylar....from top to bottem...for the bass driver....with what looks like some type of mylar to rubber...on all fore sides...

I like the look of your panels.....neet..thanks for your info... more pic...

I have seen others use foil strips on mylar....from top to bottem...for the bass driver....with what looks like some type of mylar to rubber...on all fore sides...

I like the look of your panels.....neet..thanks for your info... more pic...

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Apogee Stage – substitute for woofer panel, ideas/suggestions