Hi all,

2wice wrote. "This gives a generally lopsided smile profile to the skate force if graphed."

It actually gives more of a lopsided frown. The skating force, assuming constant stylus drag, increases as the arm tracks across the record to a maximum then more rapidly decreases towards the inner grooves. With a baerwald alignment the point of maximum skating force occurs at 83.9mm from the centre of the record. Just for a bit of fun I designed a falling weight over a variable pitch cam that tracked the variation in skating force. (I didn't actually build it as I have a linear arm that of course has no skating.) With this set up the only variable would be the variation in stylus drag due to groove modulation. Unfortunately I don't think anyone has devised a way of compensating for this passively.

Most pivoted tangential arms have a skating force that just decreases as the arm tracks across the record. The actual shape of the plotted force will be dependent upon the geometry of the arm. Building an anti-skate mechanism using a falling weight and variable cam should be simpler than for the conventional pivoted arm as the force only decreases not increases then decreases.

When calculating for the skating force mechanism it is much simpler to work as a torque about the main bearing rather than as a force at the stylus. Calculate the torque using just the offset angle as measured between the cantilever and the main bearing and the straight line distance between the stylus and bearing. (The rabbit was a bit different as the side force was applied at the rear of the arm by the string)

Hope this helps

Niffy

Ps

Do NOT set anti-skate using a blank record. This will set skating roughly correct for an unmodulated groove. As soon as there is modulation the stylus drag will increase increasing skating force. Using this method you are guaranteed to set your skating force too low.

2wice wrote. "This gives a generally lopsided smile profile to the skate force if graphed."

It actually gives more of a lopsided frown. The skating force, assuming constant stylus drag, increases as the arm tracks across the record to a maximum then more rapidly decreases towards the inner grooves. With a baerwald alignment the point of maximum skating force occurs at 83.9mm from the centre of the record. Just for a bit of fun I designed a falling weight over a variable pitch cam that tracked the variation in skating force. (I didn't actually build it as I have a linear arm that of course has no skating.) With this set up the only variable would be the variation in stylus drag due to groove modulation. Unfortunately I don't think anyone has devised a way of compensating for this passively.

Most pivoted tangential arms have a skating force that just decreases as the arm tracks across the record. The actual shape of the plotted force will be dependent upon the geometry of the arm. Building an anti-skate mechanism using a falling weight and variable cam should be simpler than for the conventional pivoted arm as the force only decreases not increases then decreases.

When calculating for the skating force mechanism it is much simpler to work as a torque about the main bearing rather than as a force at the stylus. Calculate the torque using just the offset angle as measured between the cantilever and the main bearing and the straight line distance between the stylus and bearing. (The rabbit was a bit different as the side force was applied at the rear of the arm by the string)

Hope this helps

Niffy

Ps

Do NOT set anti-skate using a blank record. This will set skating roughly correct for an unmodulated groove. As soon as there is modulation the stylus drag will increase increasing skating force. Using this method you are guaranteed to set your skating force too low.

It actually gives more of a lopsided frown.

Apologies niffy, you are correct.

for such complex tonearms the bearings and pivots being more in number compared to typical 9 inch tonearm, why doesn't friction counteracts any skating force ?

Thanks.

Thanks.

for such complex tonearms the bearings and pivots being more in number compared to typical 9 inch tonearm, why doesn't friction counteracts any skating force ?

Thanks.

Hi Hiten,

One of the problems with this type of arm is indeed excessive bearing friction. Bearing friction and skating force both have a similar effect. They both cause a side force acting on the stylus that translates directly as lateral tracking error. The amount of error is dependent upon the magnitude of the force and the compliance of the cartridge. If the tangential arm has high bearing friction it can easily end up with greater lateral tracking error than a conventional arm.

Unless the record is completely concentric the arm will spend a large percentage of the time moving to the right where bearing friction and skating will be additive.

The best (and only) approach is to try and minimize both friction and skating.

Even if bearing friction is high you still want to keep skating force to a minimum. A good analogy would be, just because your speakers might have 1% distortion doesn't mean that you don't want your amplifier to have only 0.001% distortion.

Niffy

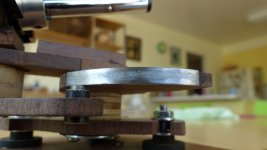

You have to pick your bearings correctly, then hope your arm building skills are good enough to utilize them. This has taken me a while, I finally have a mechanism that I am happy with how it performs. Just have to test geometry again, then it is a matter of getting the gap and magnetic force correct, whew. Not easy! Worth it though, no pumps, I can use high compliance carts and this type of arm has built in damping.

I've been following this thread with great interest, and I have a question regarding bearings. As a former computer systems engineer I have a lot of 'retired' hard drives; the motors are usually not worth trying to extract, needing too much heat to remove the epoxy . What are of interest to me are the bearing assemblies used for the swinging arm the heads are mounted on. These are not free running, but are preloaded to remove all free play (you wouldn't want any free play in a head assembly).

Any thoughts?

Any thoughts?

Ralph, Those might work for some of the bearings, I'd get a mechanism built and then see how it performs. I can envision mine working ok, as is. I'm not sure It will until I actually get some records playing. If there is something wrong then I will revisit the bearings. As far as pre-load I don't believe mine have any. But the mechanism doesn't seem to have any play. I think if you found some good quality Abec 5 or higher Racing bearings, hybrid ceramics with cerbic balls, those are what I use for the lever. For the arm pivot/guide rail bearings I use Abec 7s that were designed for fishing reels. For the vertical pivot I use the ones designed for dental instruments, also Abec 7s. I use aluminum outer tube and inner shaft. It is complicated, easier to show pictures, but everyone probably needs to approach it from their own benchtop design, based around their tools-skills.

Whatever rotates need some play to do it, and high speed bearings an increased one to compensate for thermal expansions (for our goals - 1° x 1' rotation - better those for instruments, or cnc). Bearing tolerances are inevitably bigger than the amplitude of the oscillations induced by the stylus (up to 20K Hz + harmonics) that's why serious tonearms manufacturers try to avoid them, at least for the vertical pivot, the first to face the resonances.

The worst way to use a ball bearing is an offset load: that's why the Rabbit has two cranks at 45 mm of distance. That's why I'm now experimenting ball pen nibs (and jewels in the future).

imho - carlo

pre loading with a split washer, or even an o-ring will work

The worst way to use a ball bearing is an offset load: that's why the Rabbit has two cranks at 45 mm of distance. That's why I'm now experimenting ball pen nibs (and jewels in the future).

imho - carlo

pre loading with a split washer, or even an o-ring will work

Thanks niffy. Thats why I guess unipivots probably have slight advantage (No play and as good mechanical contact as possible).

At least for the horizontal bearings, it should be feasible to use two leaf bearings aligned vertically, and widely-spaced to resist off-axis twisting.

https://static.tildacdn.com/tild3636-3261-4231-a134-663035366434/Alternative-flexures.jpg

If such leaf bearings are not available locally, an alternative could be made from piano wire perhaps 0.1mm or 0.15mm in diameter, clamped on either end so that the section that remains flexible is narrow and well-defined.

Two of these aligned vertically and widely-spaced to resist off-axis twisting, should be capable of functioning as a noiseless low-friction leaf bearing.

https://static.tildacdn.com/tild3636-3261-4231-a134-663035366434/Alternative-flexures.jpg

If such leaf bearings are not available locally, an alternative could be made from piano wire perhaps 0.1mm or 0.15mm in diameter, clamped on either end so that the section that remains flexible is narrow and well-defined.

Two of these aligned vertically and widely-spaced to resist off-axis twisting, should be capable of functioning as a noiseless low-friction leaf bearing.

Lots to catch up on.

diyrayk: Thanks for the link to your excellent work on the Rabco SL8E. I've looked for it more than once and couldn't find it.

carlo: dampdau's control curve looks a bit like the one in your drawing 4 (#1881). In my first experiments, I expected to find something like that curve, but never did. Thanks for the drawings and animations. I think dampdau's geometry is probably non-birch.

2wice: I hope you've solved the building aspect of your ingenious design. Seeing that one realized would be a real pleasure.

mcspack: It sounds like you've put a lot of thought and careful into your Schroeder build. I hope its performance is good enough for photos soon. I'm pretty sure I'm not the only one who wants to see it.

niffy and carlo: Are either of you concerned about long-term needle/cup wear in bearings with constant side forces?

ralphcooke: Your post prompted me to tear a hard drive apart yesterday. The swing arm bearing turns very smoothly, but doesn't spin - there is quite a lot of friction.

dampdau: I've included a couple of photos of another way to make the guide bar.

Re skating: Both carlo and I have found an adjustable three-point base handles that nicely.

diyrayk: Thanks for the link to your excellent work on the Rabco SL8E. I've looked for it more than once and couldn't find it.

carlo: dampdau's control curve looks a bit like the one in your drawing 4 (#1881). In my first experiments, I expected to find something like that curve, but never did. Thanks for the drawings and animations. I think dampdau's geometry is probably non-birch.

2wice: I hope you've solved the building aspect of your ingenious design. Seeing that one realized would be a real pleasure.

mcspack: It sounds like you've put a lot of thought and careful into your Schroeder build. I hope its performance is good enough for photos soon. I'm pretty sure I'm not the only one who wants to see it.

niffy and carlo: Are either of you concerned about long-term needle/cup wear in bearings with constant side forces?

ralphcooke: Your post prompted me to tear a hard drive apart yesterday. The swing arm bearing turns very smoothly, but doesn't spin - there is quite a lot of friction.

dampdau: I've included a couple of photos of another way to make the guide bar.

Re skating: Both carlo and I have found an adjustable three-point base handles that nicely.

Attachments

Last edited:

Playing with Linkage is a real fun, and virtual tonearms are the best to listen to imaginary music, lacking completely all the nuisances of reality.

Here are two strange geometries that I have "discovered" (attachment): imagine a contest to make the most ridiculous arm, with the most unlikely geometry: but this too has been done before, sometime with great incomes.

Calculate the torque using just the offset angle between the cantilever and the main line. (The rabbit was a bit different as the side force was applied to the arm of the string)

Correct, Niffy, but a bit simplistic: maybe the situation in my graph # 1733 is less disastrous than it seems, because SD + SF are composed in a complementary way to produce the rotation-advance of the arm, and not too much skating, as in traditional arms. If I'll be able to do some calculations, we'll talk about it.

Thats why I guess unipivots probably have slight advantage ...

Slight, Hiten? the biggest possible: "If it isn't there, it can't resonate" (Henry Ford)

Concerned Doug? not too much - ball pens write for kilometers, and billions of students use them to beat the time of rap music of their headphones - those tips will surely survive me

Magnetic guide - a doubt, from the beginning: which is the shape of the magnetic field around a cilindrical magnet? How can be used to guide precisely, or even correct skating ?

carlo

Here are two strange geometries that I have "discovered" (attachment): imagine a contest to make the most ridiculous arm, with the most unlikely geometry: but this too has been done before, sometime with great incomes.

Calculate the torque using just the offset angle between the cantilever and the main line. (The rabbit was a bit different as the side force was applied to the arm of the string)

Correct, Niffy, but a bit simplistic: maybe the situation in my graph # 1733 is less disastrous than it seems, because SD + SF are composed in a complementary way to produce the rotation-advance of the arm, and not too much skating, as in traditional arms. If I'll be able to do some calculations, we'll talk about it.

Thats why I guess unipivots probably have slight advantage ...

Slight, Hiten? the biggest possible: "If it isn't there, it can't resonate" (Henry Ford)

Concerned Doug? not too much - ball pens write for kilometers, and billions of students use them to beat the time of rap music of their headphones - those tips will surely survive me

Magnetic guide - a doubt, from the beginning: which is the shape of the magnetic field around a cilindrical magnet? How can be used to guide precisely, or even correct skating ?

carlo

Attachments

great work dtut,

yes this is very similar to the LT. I had a ready made Tonearm with only 11.5 cm, so I reveresed the cage of the vertical bearing cage. the pivot arm has to be lengthend to reach the inner circles of the platter. The guiding bow had to follow to the upside.

The price now is that now i wonder still now how to build a tonearmlift. One idea is to ultizise two wire-profils to get into reach of the lift mechanism near by the tonarm base. But i fear rattle noise when those wires are not under load, what is quite normal at playing time. The second solution would be a simple nylon or aramid line to lift the arm like a crane, mutch more simple and non resonant.

yes this is very similar to the LT. I had a ready made Tonearm with only 11.5 cm, so I reveresed the cage of the vertical bearing cage. the pivot arm has to be lengthend to reach the inner circles of the platter. The guiding bow had to follow to the upside.

The price now is that now i wonder still now how to build a tonearmlift. One idea is to ultizise two wire-profils to get into reach of the lift mechanism near by the tonarm base. But i fear rattle noise when those wires are not under load, what is quite normal at playing time. The second solution would be a simple nylon or aramid line to lift the arm like a crane, mutch more simple and non resonant.

Oh bearings:

I used four casting-sport high speed bearings, pre load is adjustable by washers. The bearings are made fat-free without sealing but with very thin oil the horizontal bearings are watch-jewels of ruby 1,3mm diameter, conical style with a hole of 0.2 mm diameter. These were a pain in.. to mount them in a predrilled hole in a brass srew, but ist worked after loosing the jewels every third try, you could not know if they land on the honyside or not, so try and error. If you loose them they jump away- such tiny jewels dissaparte, no chance to see them again.

I used four casting-sport high speed bearings, pre load is adjustable by washers. The bearings are made fat-free without sealing but with very thin oil the horizontal bearings are watch-jewels of ruby 1,3mm diameter, conical style with a hole of 0.2 mm diameter. These were a pain in.. to mount them in a predrilled hole in a brass srew, but ist worked after loosing the jewels every third try, you could not know if they land on the honyside or not, so try and error. If you loose them they jump away- such tiny jewels dissaparte, no chance to see them again.

Hi Doug,

My arm is a linear tracker that runs on wheels on a rail so somewhat different in approach to the arms in this thread. My bearings are tungsten carbide pivots running in sapphire vees. The load, the mass of the carriage 55g, is at 90° to the axis of the bearing so as much off axis as it's possible to get. I've had these bearings fitted to my arm for about two years now and have no problems with them. Before I upgraded to the jewelled bearings I was using home made pivots made of sewing pins running in home made vees made from stainless steel grub screws. I used these over a period of about 6 months. These were repeatedly removed and refitted as I experimented with different wheels and rails and saw much harsher handling than normal usage. They showed absolutely no sign of wear over this period.

So no, I'm not concerned with long term wear due to side force.

Niffy

My arm is a linear tracker that runs on wheels on a rail so somewhat different in approach to the arms in this thread. My bearings are tungsten carbide pivots running in sapphire vees. The load, the mass of the carriage 55g, is at 90° to the axis of the bearing so as much off axis as it's possible to get. I've had these bearings fitted to my arm for about two years now and have no problems with them. Before I upgraded to the jewelled bearings I was using home made pivots made of sewing pins running in home made vees made from stainless steel grub screws. I used these over a period of about 6 months. These were repeatedly removed and refitted as I experimented with different wheels and rails and saw much harsher handling than normal usage. They showed absolutely no sign of wear over this period.

So no, I'm not concerned with long term wear due to side force.

Niffy

I forgot to mention that I've been using the Bunny as my daily arm for a couple of months now and it continues to perform very well. I switched from a Shure M91 to a Stanton 681EEE and the difference between cartridges was more noticeable than with my conventional arms. I think that means the PLT has less influence over the sound. It seems to get out of the way and lets the cartridge do its job. On my project list is a heavier PLT for low compliance cartridges. I'd love to hear an M3D, SC35C, or 103R on a PLT.

carlo and niffy: Thanks for the reassurance about point/cup bearings. I've built uni-pivots, but the forces were axial. Radial forces seemed problematic to me.

carlo: Field for a single bar magnet I found that an attractor whose width is =/< than the width of the face of a cylindrical magnet is strongly centered by the forces at the edges of the magnet. The guide in the photos above is very positive. For skating, if the guide is slightly out of parallel to the magnet movement, the magnet and the arm it's attached to will move toward the closer end. I've never really been able to use this because I couldn't build the vertical axes precisely enough to eliminate all the weird forces.

dampdau: I understand your thinking and construction better now. We have all dropped tiny bearings on the shop floor and watched them disappear never to be found again. It's part of the brotherhood of tonearm builders.

carlo and niffy: Thanks for the reassurance about point/cup bearings. I've built uni-pivots, but the forces were axial. Radial forces seemed problematic to me.

carlo: Field for a single bar magnet I found that an attractor whose width is =/< than the width of the face of a cylindrical magnet is strongly centered by the forces at the edges of the magnet. The guide in the photos above is very positive. For skating, if the guide is slightly out of parallel to the magnet movement, the magnet and the arm it's attached to will move toward the closer end. I've never really been able to use this because I couldn't build the vertical axes precisely enough to eliminate all the weird forces.

dampdau: I understand your thinking and construction better now. We have all dropped tiny bearings on the shop floor and watched them disappear never to be found again. It's part of the brotherhood of tonearm builders.

I've read several things about magnets in the Schroeder's clone thread, and some physics on web. A cylindrical magnet is certainly self centering, if it is attracting a conical iron (or magnet): hence the difficulties of many diyers in reproducing the suspended arm. In a guide the problem seems more complex: first to be really self-centering the guide should be just a line (your blade seems to me better than the flat or cylindrical ones I saw), and the distance strictly uniform. But the problem of magnetization remains: even the purest iron over time assumes it, and will certainly not be uniform.

Tip bearings: non-axial load is certainly a problem (it is also for the ball bearings) this is the reason why I told Niffy that I preferred ballpen tips, that have a spherical seat, to jewels. The way to reduce the problem is the one you too used on the Bunny: conveniently space the bearings to reduce cantilever loads, or this Uwe's CW

carlo

Quote what you say about the Bunny: these PLT sounds very clean. The 3DTOY seems to me even more neutral than the sofisticated Rabbit: merit of the infamous plastic or of the scrap bearings?

Tiny bearings & small screws - what amazes me is their ability to hide away, better than beatles: they jump away silently and disappear where not even an Indian guide could find them. There are parts for two or three complete arms lurking around here ...

Tip bearings: non-axial load is certainly a problem (it is also for the ball bearings) this is the reason why I told Niffy that I preferred ballpen tips, that have a spherical seat, to jewels. The way to reduce the problem is the one you too used on the Bunny: conveniently space the bearings to reduce cantilever loads, or this Uwe's CW

carlo

Quote what you say about the Bunny: these PLT sounds very clean. The 3DTOY seems to me even more neutral than the sofisticated Rabbit: merit of the infamous plastic or of the scrap bearings?

Tiny bearings & small screws - what amazes me is their ability to hide away, better than beatles: they jump away silently and disappear where not even an Indian guide could find them. There are parts for two or three complete arms lurking around here ...

My tungsten carbide pivots HAVE spherical tips and the jewels have spherical cups. The radius of these spherical forms are just a lot smaller than a ball point pen nib, about 0.125mm for the pivots if I remember correctly. The smaller size will result in less play, lower friction and better mechanical grounding, especially when combined this with the fact that they are made of vastly harder materials. The one area that pen nibs win every time is cost, I could probably have bought a thousand pens for the price of my bearings.

Niffy

Niffy

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms